Summary of Contents for ESAB ESABMig C240

- Page 1 ESABMig C240 ESABMig C240s Instruction manual 0349 301 064 060324 Valid for serial no. 310...

-

Page 2: Table Of Contents

............6.3 ESABMig C240 . -

Page 3: Directive

ESAB Welding Equipment AB, S−695 81 Laxå, Sweden, gives its unreserved guarantee that welding power source ESABMig C240 / ESABMig C240s from serial number 310 complies with standard IEC/ EN 60974−1, in accordance with the requirements of directive (73/23/EEC) and addendum (93/68/EEC) and with standard EN 60974−10 in accordance with the requirements of directive... - Page 4 WARNING ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAU- TIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE BASED ON MANUFACTURERS’ HAZARD DATA. ELECTRIC SHOCK − Can kill Install and earth the welding unit in accordance with applicable standards. Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

-

Page 5: Introduction

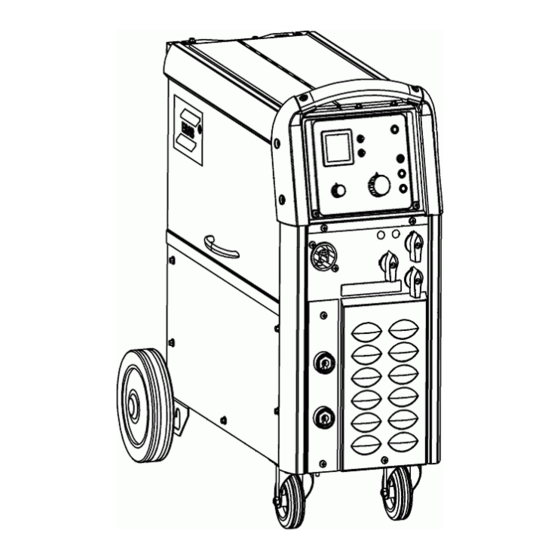

INTRODUCTION ESABMig C240 & ESABMig C240s are step controlled power sources in a compact design, intended for welding with solid steel, stainless steel or aluminium wire as well as tubular wire with or without shielding gas. The possibility of welding with homogeneous wire/shielding gas and welding with gasless tubular wire is obtained by switching the + and −... -

Page 6: Installation

Duty cycle The duty cycle refers to the time as a percentage of a ten−minute period that you can weld at a cer- tain load without overloading. Enclosure class The IP code indicates the enclosure class, i. e. the degree of protection against penetration by solid objects or water. -

Page 7: Electrical Installation

WARNING! During transport, the rear wheels of the power source are in their forward position. Before use, place the wheels in their rear position. Electrical installation − 7 − C240e... -

Page 8: Mains Power Supply

Check that the unit is connected to the correct mains power supply voltage, and that it is protected by the correct fuse size. A protective earth connection must be made, in accordance with regulations. Rating plate with supply connection data ESABMig C240/C240s 3∼ 50/60 Hz 3∼ 50/60 Hz Voltage V... -

Page 9: Connection And Control Devices

Connection and control devices ESABMig C240 Mains supply switch Connection for return cable (−), high induc- tance Switch, coarse control Connection for return cable (−), low induc- tance Switch, precise control Knob for wire speed setting Indicating lamp, power supply ON Knob for spot welding −... -

Page 10: Functions Explanation

Higher inductance produces a more flowing weld and fewer spatters. Lower inductance produces a harsher sound and a stable, concentrated arc. ESABMig C240 The ESABMig C240 is equipped with standard control unit. Welder can manually select and adjust all welding parameters. Wire speed (1,9 − 19m/min). -

Page 11: Esabmig C240S

ESABMig C240s the standard control (welder can manually select and adjust all welding parameters) − switch “SYNERGY” [16] set to OFF the synergy control (partly preprogrammed welding parameters) − switch “SYNERGY” [16] set to any material/gas group The stroke control (2/4 stroke) or motor inching (only wire feed motor is activated) is selected with switch [19]. -

Page 12: Maintenance

Digital display [11] shows values depending on display selectors [12, 13] and machine status. Before welding start: the upper display shows expected values of welding current [A] or voltage [V] (both only in SYNERGY mode); the lower display shows wire speed reference [m/min] or recommended maximum thickness [mm] of workpiece. -

Page 13: Fault Tracing

Spare parts may be ordered through your nearest ESAB dealer, see the last page of this publication. -

Page 14: Diagram

Diagram ESABMig C240, 230/400−415V − 14 − dC240... - Page 15 ESABMig C240s, 230V − 15 − dC240...

- Page 16 ESABMig C240s, 400−415V − 16 − dC240...

-

Page 17: Ordering Numbers

ESABMig C240, ESABMig C240s Valid for serial no. 310−XXX−XXXX Ordering numbers 0349 304 657 ESABMig C240 400−415V 3~50/60Hz (welding gun PSF 250, 3m) 0349 304 658 ESABMig C240 230V 3~50/60Hz (welding gun PSF 250, 3m) 0349 304 659 ESABMig C240s 400−415V 3~50/60Hz (welding gun PSF 250, 3m) - Page 18 ESABMig C240, ESABMig C240s W. F. Mechanism 0455 890 882 Item Denomination Ordering no. Notes Pressure roller 0455 907 001 0367 556 001 Ø 0.6−0.8mm Fe, Ss, cored wire. 0367 556 002 Ø 0.8−1.0mm Fe, Ss, cored wire. Feed roller 0367 556 006 Ø...

-

Page 19: Accessories

ESABMig C240, ESABMig C240s Accessories Digital meter ......0349 302 598 Transformer kit for CO heater . - Page 20 ESAB subsidiaries and representative offices Europe NORWAY Asia/Pacific Representative offices AS ESAB AUSTRIA BULGARIA CHINA Larvik ESAB Ges.m.b.H ESAB Representative Office Shanghai ESAB A/P Tel: +47 33 12 10 00 Vienna−Liesing Sofia Shanghai Fax: +47 33 11 52 03 Tel: +43 1 888 25 11...

Need help?

Do you have a question about the ESABMig C240 and is the answer not in the manual?

Questions and answers