Stratasys Fortus 380mc Operation And Maintenance Manual

Hide thumbs

Also See for Fortus 380mc:

- Site preparation manual (20 pages) ,

- Site preparation manual (21 pages) ,

- User manual (273 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Stratasys Fortus 380mc

- Page 1 Fortus 380/450mc ® OPERATION AND MAINTENANCE GUIDE Part No. DOC-10000_REV_A...

-

Page 2: Declaration Of Conformity

COPYRIGHT STATEMENT © Copyright 2017 Stratasys Inc. All rights reserved.This document is protected by copyright. No part of this document may be photocopied, reproduced or translated into another language without the prior written consent of Stratasys, Inc. - Page 3 DISPOSAL OF WASTE EQUIPMENT BY USERS IN PRIVATE HOUSEHOLDS IN THE EUROPEAN UNION This symbol on the product or on its packaging indicates that this product must not be disposed of with your other household waste. Instead, it is your responsibility to dispose of your waste equipment by handing it over to a designated collection point for the recycling of waste electrical and electronic equipment.

-

Page 4: Table Of Contents

TABLE OF CONTENTS ABOUT THIS GUIDE ................1 FORTUS 380MC/450MC PRINTER............1 PRINTER COMPONENTS......................1 Access Doors and Panels..........................1 Oven Components............................. 2 Oven Lights................................ 2 Platen Components ............................3 Tip Wipe Components ............................4 Canister Bay Enclosure Components........................ 5 Rear Components.............................. - Page 5 SAFETY PRECAUTIONS ......................20 Oven ................................20 Gantry ................................20 Z Stage ................................20 DOOR LOCKS ......................... 21 STABILITY PADS........................21 GENERAL SAFETY PRACTICES.................... 21 BASIC USER OPERATIONS ..............22 POWERING ON THE PRINTER ....................22 POWERING OFF THE PRINTER .................... 23 USER INTERFACE ........................

- Page 6 USER MAINTENANCE ................76 DAILY MAINTENANCE......................77 Clean the Platen .............................. 77 Empty the Purge Bin............................77 WEEKLY MAINTENANCE ....................... 78 Vacuum the Build Envelope..........................78 Clean/Inspect Tip Wipe Assembly ........................78 Adjust the Tip Wipe Assembly ......................... 82 QUARTERLY MAINTENANCE ....................86 Clean the Tip Sensor Plunger..........................

-

Page 7: About This Guide

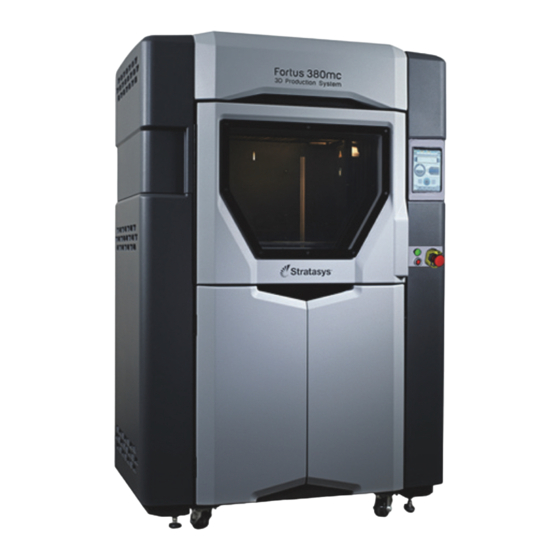

Stratasys representative. FORTUS 380MC/450MC PRINTER The Fortus 380mc/450mc™ 3D Production System incorporates the latest in innovative technologies to provide you with precise prototypes from a CAD design. Stratasys’ Fused Deposition Modeling (FDM) technology provides prototype parts, including internal features, that can be used to field-test form, fit, and function. -

Page 8: Oven Components

OVEN COMPONENTS The oven is comprised of the oven door and everything that you see through the oven door window, including the platen and the tip wipe assembly. The oven is where parts are built. Tip Wipe Assembly Oven Door Purge Chute Access Panel Platen... -

Page 9: Platen Components

PLATEN COMPONENTS The steel platen provides the level surface on which parts are built. A build sheet is securely affixed to the platen by the vacuum source. A checkerboard pattern is machined into the top surface of the platen which allows vacuum to be evenly distributed across the entire surface. -

Page 10: Tip Wipe Components

TIP WIPE COMPONENTS The tip wipe assembly is located on the front, right side of the oven. The assembly consists of two flicker/brush assemblies (one for each tip), two purge ledges (one for each tip), and a purge chute. The assembly is housed behind the purge chute access plate. -

Page 11: Canister Bay Enclosure Components

CANISTER BAY ENCLOSURE COMPONENTS The model and support material canister bays are accessed by opening the canister bay doors on the front of the printer. The canister bay doors do not contain electromagnetic locks and can therefore be opened while the printer is building. -

Page 12: Rear Components

The model tag lists the printer’s model number, part number, and power requirements. This tag also lists all patent numbers associated with the printer, some FCC compliance information, voltage warnings and the Stratasys web address. Use the information on these tags when identifying your printer with Customer Support. -

Page 13: Printer Highlights

PRINTER HIGHLIGHTS • Envelope Size: 380mc - 14 x 12 x 12 inch (355.6 x 304.8 x 304.8 mm) 450mc - 16 x 14 x 16 inch (406.4 x 355.6 x 406.4 mm) • Material Canister Bays: 380mc - 1 model, 1 support 450mc - 2 model, 2 support •... -

Page 14: Ac Power Disconnection

AC POWER DISCONNECTION LOCKOUT TAGOUT The printer’s AC disconnect switch is located on the right rear corner of the printer (as viewed from the rear). When the AC disconnect switch is in the OFF position, the printer’s electrical circuit is completely de-energised of AC power for service/maintenance purposes. -

Page 15: Emergency Stop

EMERGENCY STOP The emergency stop (E-stop) button is located on the front right surface of the printer, just below the touchscreen display. The E-stop is a safety mechanism used to shut off the printer in an emergency situation in which it cannot be powered down in the usual manner. Pressing the E-stop button inward immediately removes power to the printer. -

Page 16: Operating Environment

OPERATING ENVIRONMENT SAFE ENVIRONMENT • Connect equipment to a grounded facility power source. Do not defeat or bypass the ground lead. • Know the location of equipment branch circuit interrupters or circuit breakers and how to turn them on and off in case of emergency. Know the location of fire extinguishers and how to use them. -

Page 17: Tools

TOOLS WELCOME KIT CONTENTS The printer’s Welcome Kit contains the Welcome Insert document, software CD, the common tools you will need to maintain the printer, and a variety of replacement parts. Use the following figures and tables to identify the contents of the Welcome Kit. - Page 18 Figure 2: Welcome Kit Contents - Tools Key for Figure 2 Leather Printer components may be extremely hot. To prevent burns or other injuries, these gloves should Safety be worn any time you see the gloves safety sign. Gloves Magnetic Occasionally, you may need to use these picks to aid in the removal of breakaway supports or Handle clearing debris which have accumulated on the head and/or tips.

- Page 19 Figure 3: Welcome Kit Contents - Spare Parts Key for Figure 3 Oven Bulbs Periodically you may need to replace an oven bulb. Bulbs generally burn out in pairs. Replacement Kit The Welcome Kit contains oven bulb replacement kits, with 2 replacement Festoon bulbs per kit.

- Page 20 Figure 4: Welcome Kit Contents - Cleaning Supplies Key for Figure 4 Touchscreen From repeated use, the touchscreen may become dirty and occasionally need to be Cleaning Kit cleaned. Only use suitable LCD cleaning agents when cleaning the touchscreen. Oven Glass The oven door’s window may occasionally need to be cleaned.

-

Page 21: Safety Information

SAFETY INFORMATION The following basic safety tips are given to ensure safe installation, operation, and maintenance of Stratasys equipment and are not to be considered as comprehensive on matters of safety. The Fortus 450mc printer is designed to be a safe and reliable rapid prototyping printer. Access to areas of the printer are potentially dangerous. -

Page 22: Head Safety Label Locations

Gloves: The gloves sign indicates that if you enter the area specified by the symbol you must wear safety gloves (provided in the Welcome Kit) which have been approved for high temperatures. Crushed Hand: The crushed hand sign indicates that a hazard exists where you could get your hand crushed between two objects. -

Page 23: Oven Safety Label Locations

OVEN SAFETY LABEL LOCATIONS Z STAGE SAFETY LABEL LOCATIONS... -

Page 24: Air System Safety Label Locations

AIR SYSTEM SAFETY LABEL LOCATIONS Compressed Air System Vacuum System... -

Page 25: Rear Safety Label Locations

REAR SAFETY LABEL LOCATIONS AC DISCONNECT PANEL SAFETY LABEL LOCATIONS... -

Page 26: Safety Precautions

SAFETY PRECAUTIONS The following components and areas of the printer are potential safety hazards. Take adequate precautions when using and maintaining the printer. OVEN Warning: Always wear safety gloves and long sleeves when working inside the oven. Components are hot. The oven temperature is extremely hot. -

Page 27: Door Locks

DOOR LOCKS Sensors are used to communicate the status of the oven door and the top cover to the printer. For safety reasons, the oven door and top cover must be closed before the X, Y, and Z motors will operate. Electromagnetic locks ensure that the oven door and top cover remain securely closed when the printer is building. -

Page 28: Basic User Operations

ON (I) position. Press the green Power ON button on the front of the printer. The printer will begin to boot. The touchscreen will turn on and the Stratasys logo followed by start-up code will be displayed for a brief period. -

Page 29: Powering Off The Printer

Once the printer boots up "Initializing" will be displayed on the touchscreen, followed by "Starting". "Initializing" followed by "Starting" will also be displayed within the Information Bar. The icons within the Dashboard will be blank until this process is complete. After the initialization and start up process is complete, the printer will automatically perform an XY Home Calibration. -

Page 30: User Interface

USER INTERFACE The User Interface is broken up into six main pages providing access to the Build, Queue, Tips, Calibration, Settings, and Maintenance functions of the printer. A Navigation Bar provides one-touch access to each of the main pages, allowing you to perform tasks within that page. BUILD PAGE The Build page is comprised of the four main areas of functionality that are necessary for selecting and building parts on the printer. -

Page 31: Queue Page

QUEUE PAGE There are two, separate queues available on the 450mc: the Job Queue and the Sample Queue. From the Queue page you can view, edit, sort and select jobs from the Job Queue or Sample Queue. To access these queues, press the Queue button within the Navigation Bar;... -

Page 32: Tips Page

TIPS PAGE The Tips page displays a detailed representation of the printer’s current materials and tips configuration. Two Tip Status Icons and four Material Status Icons (similar to the icons within the Dashboard) represent the tips and model/support materials loaded/installed within the printer. These icons will take on a variety of colors and highlighted states depending on their status. -

Page 33: Calibration Page

CALIBRATION PAGE The Calibration page allows you to perform a variety of calibration procedures on the printer, including: • XYZ Tip Offset Calibration Touchscreen Calibration • Find XY Home • • Find Z Home To access the Calibration page, press the Calibration button within the Navigation Bar. Calibration Status Pane Calibration... -

Page 34: Settings Page

SETTINGS PAGE The options within the Settings page are organized into groupings of related functionality. Within each grouping, printer information can be viewed and individual printer settings and preferences can be configured. Within this page you can turn a variety of printer settings on/off (including UPnP, part placement, auto cooldown, etc.), select your printer’s address type (dynamic or static) and manually configure an IP address, network mask, and gateway address (if needed), and adjust the brightness of the touchscreen display. -

Page 35: Maintenance Page

MAINTENANCE PAGE The options within the Maintenance page are organized into groupings of related functionality. Within each grouping, maintenance related printer information can be viewed and individual maintenance settings and preferences can be configured. From this page you can upgrade your printer’s material license and/or software version, perform a variety of maintenance procedures on the printer, and view diagnostic/printer state information. -

Page 36: Loading/Unloading Material

LOADING/UNLOADING MATERIAL LOADING MATERIAL TO THE LIQUEFIER TIPS Caution: Any time the printer’s material type is changed, tips must also be changed. The information within this section will walk you through the process of loading material to the liquefier tips. As you complete the required steps, be sure to observe the status information displayed on the touchscreen. - Page 37 Observe the status information displayed below each of the model and support canister icons. The "Insert Canister" status indicates that a canister is not present in the material’s corresponding canister bay. Insert a material canister into its appropriate material bay and lower the canister drive. Feed filament into the cannister drive by pressing in and down on the canister’s thumbwheel.

-

Page 38: Unloading Material From The Liquefier Tips

UNLOADING MATERIAL FROM THE LIQUEFIER TIPS Perform the following steps to unload material from the liquefier tips: Ensure that the printer is stopped (idle) and is not building. Select the Tips button from the Navigation Bar. The information displayed represents the current configuration of your printer. -

Page 39: Changing Tips Or Material Type

CHANGING TIPS OR MATERIAL TYPE The information within this section is meant to guide you through the process of changing materials and tips. The Tips page includes a Tip Change Wizard designed to streamline the process of changing the printer’s model and/or support materials and tips. - Page 40 To access the Tip Change Wizard, press the Tip Change (Wizard) button within the Tips page. From the list of material options displayed, select the model material you'd like to switch to (ABS- M30 in this case). The newly selected model material will be indicated. Press the Next button to proceed with the wizard.

- Page 41 From the list of tip options displayed, select the model tip you'd like to switch to (T16 (new) in this case). The newly selected model tip will be indicated. Press the Next button to proceed with the wizard. Note: When selecting the tip you’d like to switch to you are given a "current" (i.e.

- Page 42 Based on the model material you selected in step 2, a list of support material options will be displayed. From the list of material options displayed, select the support material you'd like to switch to (SR-30 in this case). In this case, only one material option is displayed (and is selected by default) as only one support material is compatible with the model material selected previously.

- Page 43 Based on the support material you selected in the previous step, a list of compatible support tip options will be displayed. From the list of support tip options displayed select the support tip you'd like to switch to (T12 in this case). In this case, only one support tip option (T12) is displayed, and is selected by default, as only one support tip is compatible with the support material selected previously.

- Page 44 Verify that the material and tip selections displayed are correct. If you need to change your material and/or support tip selections, press the Previous button and make changes as needed. Ensure that a part is not on the platen and then press the Next button to proceed with the wizard. A screen will be displayed briefly informing you that the platen is moving to the oven cleaning location.

- Page 45 Once the platen moves to the oven cleaning location perform the steps displayed within the page. When finished, press the Next button to proceed with the wizard. Note: Please be aware of the warning(s) indicated within the page.

- Page 46 The model and support material currently loaded in the printer (Ultem and Ult_S in this case) will start to unload (model material will unload first followed by support material). A two-part radial progress graphic displays the amount of time remaining until this process is complete (12 minutes in this case).

- Page 47 As material unload progress is made, the radial progress graphic will be updated. A green checkmark will be displayed indicating that material has been completely unloaded from the printer.

- Page 48 Once the material unload process is complete, you will be prompted to remove unloaded canisters (as appropriate). Remove unloaded canisters and then press the Next button to proceed with the wizard.

- Page 49 Caution: Discard material pulled from printer. Do not attempt to rewind material in canister. If filament is forced into canister, cross winding will most likely occur, making the entire canister unusable. Once canisters have been removed, the printer will clear the filament remaining within the filament tubes.

- Page 50 Confirm that the material and tip selections displayed are correct and then press the Next button to proceed with the wizard. Note: Please be aware of the warnings associated with your selections. A tip and/or material type change will require calibration. If you proceed past this page of the wizard and exit the wizard without performing an XYZ Tip Offset Calibration, your printer will not be calibrated.

- Page 51 A screen will be displayed momentarily indicating that the printer is preparing to have its tip(s) replaced. Perform the necessary steps to replace model and/or support tips. If a tip is removed that may be re-installed at a later time, be sure to record the tip’s odometer reading (item 4 in the image below) and store this reading with the removed tip.

- Page 52 A default odometer value of 0.0 (in ) is automatically populated for the newly installed model and support tip; update tip odometer information as needed. If you are using brand new (unused) tips, no configuration is necessary. Simply accept the •...

- Page 53 Press the touchscreen anywhere within the Model field. When selected, the field will turn blue. Using the keypad, enter the odometer value corresponding to your model tip (150.6 in in this case). Use the delete key to erase a field’s default value. Repeat steps A and B as needed to update the support tip's odometer information.

- Page 54 Your materials and/or tip changes will be saved and the odometer values entered in the previous step will be displayed within the Tip Status Icons of the Dashboard.

- Page 55 Perform the necessary steps to prepare for tip calibration. Install a build sheet - make sure the build sheet is as centered as possible when placed onto the platen. Verify vacuum - within about 5 minutes the printer should attain sufficient vacuum to secure the build sheet to the platen.

- Page 56 Select the model and support canisters to be loaded during the calibration sequence (M2 and S2 in this case) by pressing the corresponding row on the touchscreen. When selected, the row will be blue. Selected canisters are indicated by a white outline encasing the canister's icon. Canisters with the lowest volume of material are selected by default.

- Page 57 A screen will be displayed allowing you to select the calibration part’s location on the build sheet prior to starting the build. The screen contains a graphic representing your printer’s platen as well as a blue bounding box graphic (the imaginary box surrounding the part). Select the calibration part’s build location by dragging and dropping the bounding box on the touchscreen;...

- Page 58 The printer will begin the process of building a calibration part. This process includes allowing oven temperature to stabilize, performing a Z tip-to-tip calibration, loading model material, loading support material, and then building the calibration part. The status of each task is indicated on the screen.

- Page 59 The screen will update as the printer: • Performs a Z tip-to-tip calibration.

- Page 60 • Loads model material, and then loads support material.

- Page 61 In addition to the screen updating, the Information Bar and the Build State button will update to indicate when the printer is building the calibration part.

- Page 62 Once the calibration part is complete you will be prompted to remove the part from the printer. Remove the completed part and then press the Next button to proceed with the wizard.

- Page 63 The Adjust XYZ Calibration page will open; this page will vary slightly depending on the type of units that the printer is configured for. The icons and buttons within this page will allow you to make XYZ tip offset adjustments based on an analysis of the calibration part. The Material Thickness field displays the slice height for the model tip installed in the printer.

- Page 64 Determine where on each axis the support toolpath is most centered between the X-Y alignment indicators (see Figure 5 Figure 6 for English units, and Figure 7 Figure 8 for Metric units). The numbers on the calibration part represent thousandths of an inch (e.g., 4 = 0.004 in.

- Page 65 Figure 7: Calibration Part - No Adjustment Needed (Metric units) Magnified single side of a calibration part with a reading of 0. Calibration Part Most centered at 0 Support toolpath Alignment indicators Figure 8: Calibration Part - Adjustment Needed (Metric units) Support toolpath is most centered between the alignment indicators at the 4, indicating an adjustment of +X = 0.1 Calibration Part...

- Page 66 Within the Adjust XYZ Calibration page, slide the scale icons on the screen to match where the support toolpath is most centered between the alignment indicators. The Delta X and Delta Y fields will reflect adjustments made. Note: Only one offset value can be selected for each axis, (i.e., an adjustment of +X = 2 (0.002 in.

- Page 67 • If the support toolpath is not centered at 2 (0.05 mm) or less (as in Figure 6 Figure 8) an offset adjustment is needed. The following figure shows a +X adjustment of 4 or 0.004 in. (0.1 mm). The +X scale icon has been moved downward to the 4 (0.1) and the Delta X value reflects this adjustment (0.0040 in./0.100 mm).

- Page 68 • Repeat the instructions in step 19. Continue to check and adjust for XY offset. Readjusting until the calibration toolpath is centered at 0 for the X and Y axis is preferable. However, readjusting until the calibration toolpath for X and Y is within tolerance, which is at or under 2 or 0.002 in. (0.05 mm) for an axis, is acceptable.

- Page 69 Refer to Table 1-1 and determine the slice height for the model tip installed in your printer. Table 1-1: Model Tip Slice Heights Model Tip Slice Height (in) Slice Height (mm) 0.005 0.127 0.007 0.178 0.010 0.254 0.010 0.254 0.013 0.330 T20B 0.013...

- Page 70 • Use the Up button to enter the value obtained in step C if this value is greater than the tip’s slice height. For example, if you measured an average of 0.012 in. (0.305 mm) for a tip with a slice height of 0.010 in. (0.254 mm), press the Up button until 0.0120 (0.305) is displayed within the Material Thickness field.

- Page 71 Once you’re finished adjusting for XYZ offsets, press the Next button to proceed with the wizard. A screen will be displayed momentarily and your calibration adjustment(s) will be saved. Once calibration is complete, a screen similar to the following is displayed. From this screen you have the option of: Exiting the wizard by pressing the X (Cancel) button.

-

Page 72: Changing Tips

CHANGING TIPS Any time the printer’s material type is changed, tips must also be changed. If you are following the steps outlined in the Tip Change Wizard, complete the steps below to change tips. Warning: Always use an approved ladder or step stool when working with components under the top cover. - Page 73 Using the 9/64 Hex Ball End Driver tip change tool (provided in the Welcome Kit), loosen the two (2) liquefier retaining screws which clamp the liquefier tip in place. Remove the desired tip from the head by gently grasping the tip’s tip shield and pulling the tip downward and out of the printer.

- Page 74 Repeat steps 3 - 5 if an additional tip needs to be changed. Remove the head from the head maintenance bracket and return head to its initial position. Secure the head to the head mounting plate using the two (2) recessed head mount fasteners. Close the top cover.

-

Page 75: Basic Job Build Tasks

Material residue on the sheet can adhere to the platen or interfere with the build sheet vacuum. Note: Using build sheets not provided by Stratasys may impact part quality and printer reliability. Note: ABS, ASA and PC parts use a clear build sheet. -

Page 76: Selecting A Job To Build

SELECTING A JOB TO BUILD Select the Queue button within the Navigation Bar. The Queue page will open, and the Job Queue tab will be selected by default. Within the Job Queue, select the job you wish to build by touching its entry in the list; the job’s row will turn blue. -

Page 77: Information Available During A Build

"Heating Oven and Tips" is displayed within the Information Bar. The oven will begin to heat to a set point temperature determined by the material types specified for the job. Please be patient. After the oven and liquefier tips reach temperature "Finding Z Zero" is displayed within the Information Bar, and the printer performs a Z Zero Calibration. -

Page 78: Build Warnings

BUILD WARNINGS If the printer detects an issue that may affect a build, it will be indicated within the Dashboard. The Build State button will turn yellow or red depending on the severity of the warning. Pressing the Build State button will open a dialog indicating the reason(s) for the warning/error. -

Page 79: Aborting A Build

ABORTING A BUILD When the printer is paused, you have the option of aborting the build. To do so: If it is not already, pause the printer by pressing the Pause button within the Build page. If the printer was paused automatically proceed to step 3. A pause command will be sent to the printer, and the User Interface will change to indicate the paused condition. -

Page 80: After A Build Is Complete

AFTER A BUILD IS COMPLETE After the completion of a build, the printer performs the following actions: • The Z stage is lowered and the head is parked. Depending on your printer’s auto cooldown configuration, the oven may or may not begin to •... -

Page 81: Removing A Part From The Printer

ABS, and Nylon 12 material. After building a part, you can remove supports using an Ultrasonic or Circulation Tank containing a solution of water and WaterWorks soluble solution. For more information on WaterWorks, refer to the WaterWorks User Guide located on Stratasys’ Customer Extranet. -

Page 82: User Maintenance

Welcome Kit. Once replacements are depleted, you will need to order additional replacement items from Stratasys or your regional Stratasys office. Use the part numbers listed in this table when ordering replacement parts... -

Page 83: Daily Maintenance

Note: Do not attempt to remove the vacuum port screen. It is not a customer replaceable item. Contact Stratasys Customer Support or your regional Stratasys office if an excessive amount of material debris has fallen into the vacuum port. EMPTY THE PURGE BIN The purge bin is located inside the canister bay. -

Page 84: Weekly Maintenance

WEEKLY MAINTENANCE VACUUM THE BUILD ENVELOPE The purge chute is designed to catch purged material debris and pass debris into the purge bin for disposal. However, some excess material debris may fall into the bottom of the build envelope. Do not allow excess material debris to accumulate in the build envelope as this could cause damage to the printer. - Page 85 Remove the model side purge ledge by lifting it upward until it clears it locating pin. Repeat step 5 to remove and the support side purge ledge.

- Page 86 Remove the model side flicker/brush assembly by lifting it upward until it clears it locating pins. Repeat step 7 to remove the support side flicker/brush assembly. Note: If the head is positioned above the purge area it may impede your ability to remove the flicker/brush assemblies.

- Page 87 Inspect the flicker portion of the flicker/brush assemblies. The top edge of the flicker should be straight and must not contain excessive notching/wear. A small amount of wear is acceptable. Inspect the brush portion of the flicker/brush assemblies. Brush bristles must not show evidence of wear (i.e.

-

Page 88: Adjust The Tip Wipe Assembly

Reinstall the support side flicker/brush assembly by placing the assembly onto its locating pins and sliding the assembly downward. Repeat step 14 to reinstall the model side flicker/brush assembly. Reinstall the support side purge ledge by placing the purge ledge onto its locating pin and sliding the purge ledge downward. - Page 89 Three buttons are displayed at the bottom of the Tips page (just above the Navigation Bar). These buttons are used to initiate a variety of tip related functions. Press the Tip Wipe Adjustment button. Tip Wipe Adjustment Button Press the Go to Purge Position button; the head will move to the purge position. Go to Purge Position Button Press the Wipe Tips button.

- Page 90 • Rolling a wheel down will move the corresponding flicker/brush assembly downward (away from tip/tip shield) and vice versa. Note: It is recommended that you first move the flicker/brush assembly upward, until extreme contact with the tip shield is made. Then, gradually move the flicker/brush assembly downward until proper placement is achieved.

- Page 91 If additional adjustments are needed readjust height using the Tip Wipe Height Adjustment Wheels. When finished, close the canister bay doors. • If working within the Tip Change Wizard, press the X (Cancel) button when finished to exit the wizard.

-

Page 92: Quarterly Maintenance

QUARTERLY MAINTENANCE CLEAN THE TIP SENSOR PLUNGER Hot Surface: Components can be hot; never touch the tip sensor plunger with your bare hands. It is recommended that you remove/replace the tip sensor plunger when the printer is powered OFF or has been allowed to cool thoroughly. Material debris can occasionally accumulate on the top of the tip sensor plunger. -

Page 93: As Needed Maintenance

AS NEEDED MAINTENANCE REPLACE AN OVEN BULB Hot Surface: Bulbs are hot; never touch bulbs with your bare hands. Always wear safety gloves (provided in the Welcome Kit) when changing bulbs. It is recommended that bulbs be removed/replaced when the printer is powered OFF. -

Page 94: Supplemental Information

SUPPLEMENTAL INFORMATION ELECTRICAL PANEL COMPONENTS Description Description Amplifier Cooling Fan Mini +24 VDC Power Supply MIO Board Line Filter (x3) +5/12 VDC Power Supply +120 VDC Power Supply (x3) Hard Disk Drive SSR Cooling Fan Single Board Computer AC Board SSC Board Z Motor Amplifier +24/48 VDC Power Supply... -

Page 95: Air/Vacuum System Components

AIR/VACUUM SYSTEM COMPONENTS The system integrates two individual air systems; vacuum and compressed dried air. The vacuum system is used in securing the part build sheet to the vacuum platen. The dried air system provides a positive air pressure environment to the filament feed path in order to minimize material moisture absorption. Both vacuum and compressed air configurations utilize a ¼... -

Page 96: Connection To Electrical Supply

CONNECTION TO ELECTRICAL SUPPLY Note: A licensed electrician must perform all AC electrical service connections to the printer. Consult a licensed electrician to comply with all applicable local and national electric codes. Do not apply power to the printer until the installation service representative has verified that AC service connections have been made correctly. - Page 97 2. AC Connection to the printer’s electrical disconnect switch: • N is neutral. • Line 1 connects to terminal L1. • Line 2 connects to terminal L2. • Line 3 connects to terminal L3. Ground wire connects to the ground lug (protective earth). •...

-

Page 98: Electrical Diagrams

ELECTRICAL DIAGRAMS BLOCK DIAGRAM... -

Page 99: Power Distribution Diagrams

POWER DISTRIBUTION DIAGRAMS Figure 9: Ladder Diagram 1 Figure 10: Ladder Diagram 2... - Page 100 Figure 11: Ladder Diagram 3...

-

Page 101: Safety Interlock Diagram

SAFETY INTERLOCK DIAGRAM • The oven door and top cover Interlock sensor switches utilize three contactor sets; one set is used to provide open/closed status to the MIO board CPLD. The other two sets of each sensor switch report this status to the safety control relay. •... - Page 102 Customers, resellers, and Stratasys employees are encouraged to send comments about our documentation and training to c-support@stratasys.com. We greatly value your comments, review all of them, and use them to improve subsequent releases of the documentation. In your email message please include the document title, part number (located on the front cover), and page number.

Need help?

Do you have a question about the Fortus 380mc and is the answer not in the manual?

Questions and answers