Table of Contents

Advertisement

Quick Links

Iwaki

Photoresist Dispensing Pump

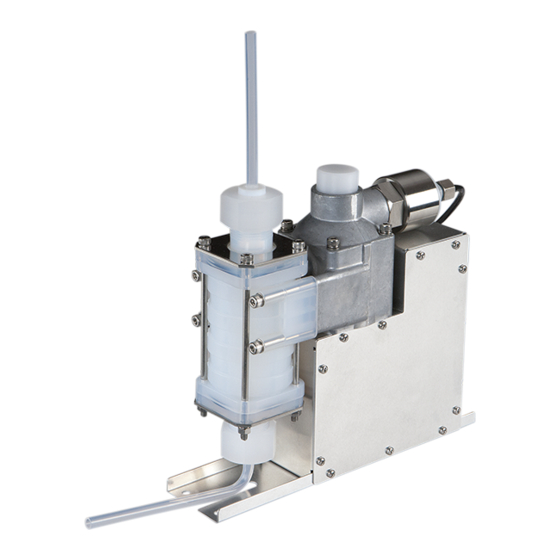

PDS-105 RA/RB

Instruction manual

Thank you for choosing our product.

Please read through this instruction manual before use.

This instruction manual describes important precautions and instruc-

tions for the product. Always keep it on hand for quick reference.

©2011 IWAKI CO., LTD.

Advertisement

Table of Contents

Summary of Contents for IWAKI PUMPS PDS-105 RA

- Page 1 Iwaki Photoresist Dispensing Pump PDS-105 RA/RB Instruction manual Thank you for choosing our product. Please read through this instruction manual before use. This instruction manual describes important precautions and instruc- tions for the product. Always keep it on hand for quick reference.

-

Page 2: Order Confirmation

Order confirmation Open the package and check that the product conforms to your order. If any problem or inconsistency is found, immediately contact your distributor. a. Check if the delivery is correct. Check the nameplate to see if the information such as model codes and production number are as or- dered. -

Page 3: Table Of Contents

Contents Order confirmation ............................2 Safety instructions ..............5 Warnings ................................ 6 Cautions ................................. 7 Precautions for use ............................8 Overview ..................9 Introduction ..............................9 Pump structure & Operating principle ......................9 Discharge process ..........................9 Suction process ..........................10 Part names .............................. - Page 4 Maintenance ................22 Troubleshooting ............................22 Inspection ..............................23 Daily inspection ............................23 Specification/Outer dimension ........................24 Specification ............................. 24 Pump ..............................24 Stepping motor ............................ 25 Encoder (RB type) ..........................25 Home sensor ............................25 Pressure sensor ..........................25 Outer dimension ............................26 PDS-105R A/B ............................

-

Page 5: Safety Instructions

Safety instructions Read through this section before use. This section describes important information for you to prevent personal injury or property damage. ■ Symbols In this instruction manual, the degree of risk caused by incorrect use is noted with the follow- ing symbols. -

Page 6: Warnings

WARNING Turn off power before work Risk of electrical shock. Be sure to turn off power to stop the pump and related devices before service is performed. Let other people know about the situation by displaying a notice such as "POWER OFF (Maintenance)" Requirement near the power switch. -

Page 7: Cautions

CAUTION Qualified personnel only The pump should be handled or operated by qualified personnel with a full understanding of the pump. Any person not familiar with the product Requirement should not take part in the operation or maintenance of the pump. Use specified power only Do not apply any power other than that specified on the nameplate. -

Page 8: Precautions For Use

Precautions for use • Electrical work should be performed by a qualified electrician. Otherwise, personal injury or property damage could result. Caution • Do not install the pump: –In a flammable atmosphere. –In a dusty/humid place. Caution – In a corrosive atmosphere. •... -

Page 9: Overview

Overview Pump working principle, part names and identification codes are de- scribed in this section. Introduction Pump structure & Operating principle The rotational motion of the stepping motor is changed to linear motion by the direct drive unit. Liquid is loaded into the pump head and then delivered to a discharge line as the bellows reciprocates. -

Page 10: Suction Process

■ Suction process Introduction... -

Page 11: Part Names

Part names Pressure sensor Monitors hydraulic pressure. Outlet Base Always anchor it with bolts. Inlet Speed controller joint Used for air purge. Motor-Driver wiring terminal Used for connecting a motor driver. Nameplate Shows a model code and MFG number. Signal line terminal Used for connection with user's PLC. -

Page 12: Identification Codes

Identification codes Each code represents the following information. PDS - 1 05 RA - K T W2 - 01 a. Series name b. Product classification 1: Pump c. Flow rate 05: 5.0ml/shot (max discharge capacity) d. Drive unit RA: Compact type (with no encoder) RB: Compact type (with an encoder) e. -

Page 13: Installation

Installation This section describes the installation of the pump, piping and wiring. Read through this section before work. Points to be observed Observe the following points when installing the pump: • Be sure to turn off power to stop the pump and related devices before service is per- formed. -

Page 14: Installation/Piping/Wiring

Installation/Piping/Wiring NOTE Do not hold the pump head to lift the pump unit up, or the pump head may deform and a leak may result. Installation Observe the following points during installation. ● Installation location Mount the pump indoors. Allow sufficient space around the pump for easy access and maintenance. ●... -

Page 15: Wiring

Wiring Observe the following diagram. Installation/Piping/Wiring... -

Page 16: Applicable Motor Drivers

Applicable motor drivers See the table below for applicable ORIENTAL MOTOR's motor drivers. Rated power Pulse input Product name Driver type Driver type Cable Attached connector voltage type • Cable set • MOREX 51103-0200 LCS04SD5 (0.6m) Pulse-train 1 pulse/ • MOREX 51103-1200 CRD5107PB 24VDC •... -

Page 17: Operation

Operation This section describes pump operation. Observe instructions in this manu- al. See manufacturer's instruction manual for the motor driver. Pump setting First, program operation of the pump. Pulse input & Motor rotation The pump lets out liquid at the input of the CCW direction command pulse and takes in liquid at the input of the CW direction command pulse. -

Page 18: Return To Origin

Return to origin Program the origin return behaviour to ensure the motor-driven cylinder to come back to origin before opera- tion every day. The behaviour should be different depending on whether the home sensor output is ON or OFF at an input of an origin return signal. See the programming chart below for detail. ■... -

Page 19: Time Based Control (When Using An Oriental Motor Sg9200-2 Pulse Controller)

■ Time based control (when using an Oriental Motor SG9200-2 pulse controller) An ORIENTAL MOTOR SG9200-2 pulse controller is needed for discharge-time control and an OMROM H3RN-1 Off-delay timer for suction-time control. A discharge process is made for a discharge time; a time period when the pump is receiving the discharge signal from the pulse controller, and a suction process starts as re- ceiving a suction signal from the Off-delay timer. -

Page 20: Flow Based Control (When Using A Pulse Signal As A Start Signal)

■ Flow based control (when using a pulse signal as a start signal) Use the pulse controller or user's PLC to program a discharge and a suction flow rate as well as a pause time [T1] of 0.5 sec or more between the end of a discharge process and the start of a suction process and a wait- ing time (at least 1/2 of the time taken to finish suction process per set flow rate) [T2] between the end of the suction process and the start of the next discharge process as well. -

Page 21: Pump Operation

Pump operation Filter flushing Check that filter has been flushed in user's system. NOTE See manufacturer's manual for filter flushing. Degassing Eliminate air from the filter cartridge before operation. Air in a filter or a pipeline reduces a flow rate. NOTE See manufacturer's manual for degassing. -

Page 22: Maintenance

Maintenance This section describes troubleshooting, inspection, specification and dimensions. Points to be observed Observe the following points during maintenance work: • Follow instructions in this manual for replacement of wear parts. Do not disassemble the pump. Contact us when repairs are needed. •... -

Page 23: Inspection

States Possible causes Check items Solutions No home sen- Faulty wiring If the signal and power lines are • Correct wiring and resume opera- sor signal connected in place? See page 15. tion. Home sensor failure Use a tester to check the voltage •... -

Page 24: Specification/Outer Dimension

Specification/Outer dimension Specification Information in this section is subject to change without notice. ■ Pump Item Spec Max discharge capacity 5.0 [ml/shot] Max discharge pressure* 150 [kPa] 4&6 Pressure resistance 300 [kPa] Discharge flow rate 0.1-4.0 [ml/sec] Suction flow rate* 0.1-3.0 [ml/sec] Resolution 0.01 [ml]... -

Page 25: Stepping Motor

■ Stepping motor Items Spec Manufacturer ORIENTAL MOTOR Co, Ltd. Model PK545-NB or equivalent Maximum holding torque 0.23 N·m Rated current 0.75 A/Phase Step angle 0.72° Insulation resistance B class (130ºC) The above date is based on use of an ORIENTAL MOTOR CSD5807N2-P driver. ■... -

Page 26: Outer Dimension

Outer dimension ■ PDS-105R A/B (2000) (189) (100) 213.5 Tube size 1/4" PFA tube ø6×ø4 PFA tube Specification/Outer dimension... - Page 28 IWAKI Norge AS TEL : (47)23 38 49 00 FAX : 23 38 49 01 China IWAKI Pumps (Guandong) Co., Ltd. TEL : (86)750 3866228 FAX : 750 3866278 Singapore IWAKI Singapore Pte. Ltd. TEL : (65)6316 2028 FAX : 6316 3221 China GFTZ IWAKI Engineering &...

Need help?

Do you have a question about the PDS-105 RA and is the answer not in the manual?

Questions and answers