Summary of Contents for YOKOGAWA UP55A

- Page 1 User’s Manual UP55A Program Controller User’s Manual IM 05P02C41-01EN IM 05P02C41-01EN 5th Edition...

- Page 2 Product Registration Thank you for purchasing YOKOGAWA products. YOKOGAWA provides registered users with a variety of information and services. Please allow us to serve you best by completing the product registration form accessible from our homepage. http://www.yokogawa.com/ns/reg/...

-

Page 4: Introduction

Introduction Thank you for purchasing the UP55A program controller (hereinafter referred to as UP55A). This manual describes how to use UP55A functions other than UP55A’s communication function and ladder sequence function. Please read through this user’s manual carefully before using the product. -

Page 5: Target Readers

Yokogawa Electric’s sales office or sales representative. ● Under no circumstances may the contents of this manual, in part or in whole, be transcribed or copied without our permission. Trademarks ● Our product names or brand names mentioned in this manual are the trademarks or registered trademarks of Yokogawa Electric Corporation (hereinafter referred to as YOKOGAWA). ● Microsoft, MS-DOS, Windows, Windows XP, Windows Vista, and Windows 7 are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries. - Page 6 • Be sure to use the spare parts approved by YOKOGAWA when replacing parts or consumables. • This product is not designed or manufactured to be used in critical applications that directly affect or threaten human lives.

-

Page 7: Handling Precautions For The Main Unit

• YOKOGAWA makes no warranties regarding the product except those stated in the WARRANTY that is provided separately. • The product is provided on an “as is” basis. YOKOGAWA assumes no liability to any person or entity for any loss or damage, direct or indirect, arising from the use of the product or from any unpredictable defect of the product. -

Page 8: Checking The Contents Of The Package

The /HA option can be specified only when the Type 1 code is “-0.” When the /CT option is specified, the UP55A does not conform to the safety standards (UL and CSA) and CE marking. (Products with /CT option are not intended for EEA-market) - Page 9 The /L4 and /LC4 options for E4 terminal area can be specified only when the E3 terminal area option is not specified or specified any of /CH3, /X3, /Y3 or /W3. When the /CT option is specified, the UP55A does not conform to the safety standards (UL and CSA) and CE marking (Products with /CT option are not intended for EEA-market).

- Page 10 Check that none of them are missing or damaged. Product Name Quantity Remark Part number: L4502TP (For fixing the upper and Brackets lower parts) Terminal cover For UP55A: L4502XP Unit label Part number: L4502VZ Tag label Part number: L4502VE (Only when ordered.) Single-loop control (A3 size, x7) (Standard model Operation Guide only) How to use the unit label •...

- Page 11 See the General Specifications (*) Resistance Module *: Necessary to input the current signal to the voltage input terminal. • Terminal cover For model UP55A: UTAP001 For UP55A • Brackets Part number L4502TP (2 pieces for fixing the upper and lower parts) • User’s Manual (A4 size)

-

Page 12: Symbols Used In This Manual

Symbols Used in This Manual This symbol is used on the instrument. It indicates the possibility of injury to the user or damage to the instrument, and signifies that the user must refer to the user’s manual for special instructions. The same symbol is used in the user’s manual on pages that the user needs to refer to, together with the term “WARNING” or “CAUTION.” WARNING Calls attention to actions or conditions that could cause serious or fatal injury to the user, and indicates precautions that should be taken to prevent such occurrences. -

Page 13: How To Use This Manual

For the ladder sequence and communication functions, see the respective manuals. This user’s manual is organized into Chapters 1 to 18 as shown below. Chapter Title and Description Introduction to Functions Describes the main functions of the UP55A. UP55A Operating Procedures Describes the flow from unpacking to regular operations. Part Names Describes part names and functions on the front panel. -

Page 14: Table Of Contents

Checking the Contents of the Package ................v Model and Suffix Codes of UP55A (for Standard model) .............v Model and Suffix Codes of UP55A (for Detailed model) ............. vi Symbols Used in This Manual ..................... ix How to Use This Manual ......................x Chapter 1 Introduction to Functions Quick Setting Function ..................... - Page 15 Contents Performing and Canceling Auto-tuning ................6-26 6.3 Adjusting PID Manually ....................6-29 Setting Alarm Setpoint ....................6-34 Selecting Program Pattern Number (PTNO.) ..............6-35 Switching Operation Modes ................... 6-36 6.6.1 Operation Display Switching Diagram .............. 6-36 6.6.2 Switching to PROG Operation ................6-37 Selecting by RUN Key .......................6-37 Selecting by Operation Mode Parameter ................6-37 6.6.3...

- Page 16 Contents Chapter 7 Input (PV, Remote, and Auxiliary Analog) Functions Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input ......7-1 7.1.1 Setting Input Type, Unit, Range, Scale, and Decimal Point Position ....7-1 7.1.2 Setting Burnout Detection for Input ..............7-5 7.1.3 Setting Reference Junction Compensation (RJC) or External Reference Junction Compensation (ERJC) .................

- Page 17 Contents 8.4.1 Switching PID According to Target Setpoint Number (SPNO) ......8-54 8.4.2 Switching PID According to PV ................. 8-55 8.4.3 Switching PID According to SP ................. 8-56 8.4.4 Switching PID According to Target SP .............. 8-58 8.4.5 Switching PID According to Deviation (Reference Deviation) ......8-60 8.4.6 Setting Hysteresis at Time of PID Switch ............

- Page 18 Contents Setting Program Pattern-2 Retransmission ..................9-41 9.10 Setting Starting time of program operation ..................9-42 9.11 Setting the Program Pattern Number Clearance ............9-43 9.12 Program Pattern End Signal .......................9-44 9.13 Editing the Prgram Pattern ..................... 9-45 9.13.1 Checking the Number of Remaining Segments ..........9-45 9.13.2 Checking the Number of Segments in specified pattern ........

- Page 19 Contents 12.1.1 Setting Contact Input Function ................. 12-1 12.1.2 Changing Contact Type of Contact Input ............12-11 12.2 Setting Contact Output Function .................. 12-12 12.2.1 Setting Function of Contact Output ..............12-12 12.2.2 Changing Contact Type of Contact Output ............. 12-19 Chapter 13 Display, Key, and Security Functions 13.1 Setting Display Functions ....................

- Page 20 Contents 16.2.2 Packaging when Shipping the Product for Repair .......... 16-15 16.2.3 Replacing Parts ....................16-15 16.3 Periodic Maintenance ....................16-16 16.4 Disposal ........................16-17 Chapter 17 Installation and Wiring 17.1 Installation Location ......................17-1 17.2 Mounting Method ......................17-3 17.3 External Dimensions and Panel Cutout Dimensions ..............17-4 17.4 Wiring ..........................

- Page 21 Blank Page...

-

Page 22: Chapter 1 Introduction To Functions

Chapter 1 Introduction to Functions 1.1 Quick Setting Function The Quick setting function is a function to easily set the basic function of the controller. Check the contents. Buy and Unpacking Installation and Wiring: Chapter 17 Installation and Wiring Install and wire a controller, and then turn on the power. -

Page 23: Input/Output Function

1.2 Input/Output Function PV Input PV input is a universal input to arbitrarily set the type and range for the thermocouple (TC), resistance-temperature detector (RTD), and DC voltage/current. ► Chapter 7 Input (PV, Remote, and Auxiliary Analog) Functions Current Voltage pulse Relay contact / Triac 2-wire trans- Motor-operated valve mitter Control Output Control output (OUT) is a universal output to arbitrarily set the type for the current,... - Page 24 (OUT) and the like as an analog signal to, for example, the recorder. ► Chapter 10 Output (Control and Retransmission) Functions External device such as recorder etc. UP55A Current Contact Input Up to 23 contact inputs can be incorporated. The operation modes can be switched.

-

Page 25: Control Functions

1.3 Control Functions Control Mode The UP55A are controllers equipped with 5 control modes. Some control modes require a remote input (RSP) terminal. For the auxiliary functions of control modes, see the respective sections. Control mode schematic diagram Description “Single-loop control” provides the basic control function having one control computation unit. - Page 26 Heating/cooling Loop Control with PV Auto- selector, and Position Proportional Loop Control with PV Auto-selector PID Control PID control is a general control using the PID control-related parameters. ► 8.2.1 PID Control Recorder UP55A Alarms Retransmission output 4-20 mA DC Electric furnace...

- Page 27 1.3 Control Functions Position Proportional Control Position proportional control is available only for Position proportional type. It is used exclusively for the motor-operated valve. ► 10.16 Adjusting Motor-operated Valve Position (Position Proportional Output) UP55A H (direct) or L (reverse) contact signal Control motor Position signal Motor-operated valve Furnace Burner...

-

Page 28: Program Pattern Functions

1.4 Program Pattern Functions The program pattern function allows performing a program operation by changing the setpoint in conjunction with the time according to the preset program pattern. A program pattern consists of multiple segments. A program pattern can be created by setting the final target setpoint, segment time, PV event, time event, and the like. The use of the program pattern-2 retransmission function allows creating a program pattern for retransmission. -

Page 29: Display And Key Functions

To intended use of the operator, the display level of the parameter can be set. ► Chapter 18 Parameters User Function Keys The UP55A has user function keys (RUN, RST, MODE, and PTN). Assign a function to a user function key to use it as an exclusive key. ► 13.2 Assigning Function to User Function Key... -

Page 30: Ladder Sequence Function

1.6 Ladder Sequence Function To use the ladder sequence function, it is necessary to create a ladder program using LL50A Parameter Setting Software and download it to a controller. ► Ladder sequence function: LL50A Parameter Setting Software User’s Manual Ladder program IM 05P02C41-01EN... -

Page 31: Communication Functions

► UTAdvanced Series Communication Interface (RS-485, Ethernet) User’s Manual ► UTAdvanced Series Communication Interface (Open Network) User’s Manual RS-485 Communication (Modbus communication, PC link communication, and Ladder communication) The UP55A can communicate with PCs, PLCs, touch panels, and other devices. RS-232C/ Model: ML2 of YOKOGAWA is recommended. RS-485 converter... - Page 32 Modbus Slave Modbus Slave DeviceNet Communication The UP55A can be used as the slave devices for DeviceNet communication. Read-out of PV, operation or alarm status, and SP setting can be done by accessing the remote I/O on the master unit of DeviceNet.

- Page 33 1.7 Communication Functions CC-Link Communication The UP55A can be used as the slave devices for CC-Link communication. Read-out of PV, operation or alarm status, and SP setting can be done by accessing the remote I/O on the master unit of CC-Link. CC-Link Master...

- Page 34 Maintenance port is used to connect with the dedicated cable when using LL50A Parameter Setting Software (sold separately). The parameters can be set without supplying power to the UP55A. Likewise, the ladder program and the program pattern can also be downloaded.

-

Page 35: Definition Of Main Symbols And Terms

1.8 Definition of Main Symbols and Terms Main Symbol PV: Measured input value SP: Target setpoint OUT: Control output value RSP: Remote setpoint PRG, PROGRAM: Start of Program operation RST, RESET: Stop of Program operation LOC, LOCAL: Start of Local operation REM, REMOTE: Start of Remote operation HLD, HOLD: Pause of program operation ADV, ADVANCE: Advance of segment A/M: AUTO/MAN... -

Page 36: Chapter 2 Up55A Operating Procedures

Chapter 2 UP55A Operating Procedures 2.1 UP55A Operating Procedures Installation Install and wire a controller. and Wiring Installation and Wiring: Chapter 17 Power ON Control mode setup Section 8.1 Control type setup Section 8.2 Control mode: Single-loop control only Control type setup Quick setting function: Input/output setup... - Page 37 Blank Page...

-

Page 38: Chapter 3 Part Names

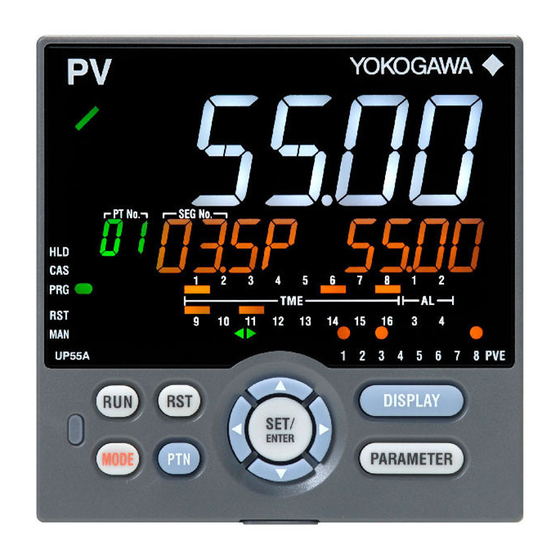

Chapter 3 Part Names 3.1 Names and Functions of Display Parts See the next page. IM 05P02C41-01EN... - Page 39 3.1 Names and Functions of Display Parts UP55A (9) Deviation indicator (1) PV display (2) Group display (4) Data display (Pattern number) (3) Symbol display (10) Status indicator (5) Bar-graph display (Event, alarm) (11) Security indicator (6) Event indicator (7) Key navigation indicator (12) Ladder operation indicator...

- Page 40 3.1 Names and Functions of Display Parts No. in figure Name Description Displays PV. Displays an error code if an error occurs. PV display Displays the scrolling guide in the Menu Display and (white or red) Parameter Setting Display when the guide display ON/ OFF is set to ON. 1 to 30 or 99 (99 when the option “/AP” is specified) Group display represent pattern numbers in the Operation Display.

-

Page 41: Names And Functions Of Keys

3.2 Names and Functions of Keys UP55A (1) DISPLAY key (4) Light-loader interface (2) PARAMETER key (3) SET/ENTER key (5) User function keys Up/Down/Left/Right arrow keys IM 05P02C41-01EN... - Page 42 3.2 Names and Functions of Keys No. in figure Name Description Used to switch the Operation Displays. Press the key in the Operation Display to switch the DISPLAY key provided Operation Displays. Press the key in the Menu Display or Parameter Setting Display to return to the Operation Display. Hold down the key for 3 seconds to move to the Operation Parameter Setting Display.

- Page 43 3.2 Names and Functions of Keys Maintenance Port (Power supply is not required for the UP55A). The maintenance port is used to connect with the dedicated cable when using LL50A Parameter Setting Software (sold separately). The parameters can be set without supplying power to the UP55A. Maintenance port Upper surface UP55A CAUTION When using the maintenance port, do not supply power to the controller. Otherwise, the controller does not work normally.

-

Page 44: List Of Display Symbols

3.3 List of Display Symbols The following shows the parameter symbols, menu symbols, alphanumeric of guide, and symbols which are displayed on the UP55A. Figure (common to all display area) PV display (14 segments): Alphabet Symbol display and Data display (11 segments): Alphabet (lower-case) IM 05P02C41-01EN... - Page 45 3.3 List of Display Symbols Group display (7 segments): Alphabet None PV display (14 segments): Symbol Space ‘ IM 05P02C41-01EN...

-

Page 46: Brief Description Of Setting Details (Parameters)

Brief Description of Setting Details (Parameters) This manual describes the Setting Details as follows in addition to the functional Description. Setting Details (Display Example) Parameter Display Name Setting range Menu symbol symbol level Set a display value of setpoint of PV alarm, SP alarm, deviation alarm, output alarm, or velocity Alarm-1 to -8 alarm. - Page 47 Blank Page...

-

Page 48: Chapter 4 Basic Operation

Chapter 4 Basic Operation 4.1 Overview of Display Switch and Operation Keys The following shows the transition of Operation Display, Operation Parameter Setting Display, and Setup Parameter Setting Display. The “Operation Parameter Setting Display” has the parameters for setting the functions necessary for the operation. The “Setup Parameter Setting Display” has the parameters for setting the basic functions of the controller. - Page 49 4.1 Overview of Display Switch and Operation Keys The display pattern of the UP55A is as follows; the Menu Display and Parameter Setting Display. For the Operation Display, see Chapter 6, “Monitoring and Control of Regular Operations.” Display Description The Menu Display is segmented by the function and optional terminal position.

- Page 50 4.1 Overview of Display Switch and Operation Keys Display Description The following is the Display for displaying and setting a parameter. The parameters have three types of display levels; Easy setting mode, Standard setting mode, and Professional setting mode. The parameters to be displayed can be limited according to the setting of the parameter display level. The scrolling guide for the parameter is displayed on PV display.

- Page 51 4.1 Overview of Display Switch and Operation Keys Basic Key Operation Sequence ● To move to the Setup Parameter Setting Display Hold down the PARAMETER key and the Left arrow key simultaneously for 3 seconds. Hold down the keys for 3 seconds. ● To move to the Operation Parameter Setting Display Hold down the PARAMETER key for 3 seconds. Hold down the key for 3 seconds. ● To move to the Operation Display Press the DISPLAY key once.

-

Page 52: How To Set Parameters

4.2 How to Set Parameters The following operating procedure describes an example of setting alarm setpoint (A1). Operation Hold down the PARAMETER key for 3 seconds in the Operation Display to call up the [MODE] Menu Display. Press the Right arrow key to display the [AL] Menu Display. Press the SET/ENTER key to display the [A1] Parameter Setting Display. - Page 53 4.2 How to Set Parameters Press the Up or Down arrow key to change the setpoint. (Change the setpoint using the Up/Down arrow keys to increase and decrease the value and the Left/Right arrow keys to move between digits.) Press the SET/ENTER key to register the setpoint (the setpoint stops blinking). Press the PARAMETER key once to return to the Menu Display.

- Page 54 4.2 How to Set Parameters How to Set Parameter Setpoint Numeric Value Setting . Display the Parameter Setting Display. . Press the SET/ENTER key to move to the setting mode (the setpoint blinks). . Press the Left arrow key to move one digit to the left.(Press the Right arrow key to move one digit to the right.) . Press the Up or Down arrow key to change the setpoint.

- Page 55 4.2 How to Set Parameters Time (minute.second) Setting Example of 17 minutes 59 seconds . Display the Parameter Setting Display. . Press the SET/ENTER key to move to the setting mode (the setpoint blinks). . Press the Left arrow key to move one digit to the left.(press the Right arrow key to move one digit to the right.) . Press the Up or Down arrow key to change the setpoint.

-

Page 56: Chapter 5 Quick Setting Function

Chapter 5 Quick Setting Function 5.1 Setting Using Quick Setting Function Description The Quick setting function is a function to easily set the basic function of the controller. The Quick setting function starts when the power is turned on after wiring. The Quick setting function can be used only when the control mode is Single-loop control. - Page 57 5.1 Setting Using Quick Setting Function Flowchart of Quick Setting Function Power ON Decide whether or not to use the Quick setting function. Press the UP arrow key to select YES. Press the SET/ENTER key to start the Quick setting function. Press the Down arrow key to select NO. Press the SET/ENTER key not to start the Quick setting function.

- Page 58 5.1 Setting Using Quick Setting Function Setting Example Set the following parameters to set to PID control, thermocouple Type K (range: 0.0 to 500.0ºC), and current control output. No need to change the parameters other than the following parameters. Set QSM = YES to enter the quick setting mode. (1) Set CNT = PID.

- Page 59 5.1 Setting Using Quick Setting Function Input Function Parameter Display Name Setting range Menu symbol symbol level OFF: Disable K1: -270.0 to 1370.0 ºC / -450.0 to 2500.0 ºF K2: -270.0 to 1000.0 ºC / -450.0 to 2300.0 ºF K3: -200.0 to 500.0 ºC / -200.0 to 1000.0 ºF J: -200.0 to 1200.0 ºC / -300.0 to 2300.0 ºF T1: -270.0 to 400.0 ºC / -450.0 to 750.0 ºF T2: 0.0 to 400.0 ºC / -200.0 to 750.0 ºF...

- Page 60 5.1 Setting Using Quick Setting Function Input Function (Continued) Parameter Display Name Setting range Menu symbol symbol level 0: No decimal place PV input scale 1: One decimal place decimal point EASY 2: Two decimal places position 3: Three decimal places 4: Four decimal places Maximum value of EASY PV input scale -19999 to 30000, (SL<SH),...

-

Page 61: Restarting Quick Setting Function

5.2 Restarting Quick Setting Function Once functions have been built using the Quick setting function, the Quick setting function does not start even when the power is turned on. The following methods can be used to restart the Quick setting function. ● Set the parameter QSM (Quick setting mode) to ON and turn on the power again. ● Set the parameter IN (PV input type) to OFF and turn on the power again. -

Page 62: Monitoring And Control Of Operation Displays

Chapter 6 Monitoring and Control of Regular Operations 6.1 Monitoring and Control of Operation Displays 6.1.1 Operation Display Transitions in Single-loop Control, Cascade Primary- loop Control, Loop Control with PV switching, and Loop Control with PV auto-selector ► Display/Non-display of Operation Display: 13.3.5 Setting Display/Non-display of Operation Display ► Registration of SELECT Display: 13.1.3 Registering SELECT Display (Up to 5 displays) See the next page. IM 05P02C41-01EN... -

Page 63: Standard Type

6.1 Monitoring and Control of Operation Displays Standard Type SP Display Displays "SSP" during reset-mode. Displays "L.SP" during local-mode operation. Displays "R.SP" during remote-mode operation. TSP Display Displays during program operation. SP Display (When the program pattern-2 retransmission is selected (PT2.G=ON).) Displays "SSP" during reset-mode. Displays "L.SP" during local-mode operation. Displays "L.SP"... - Page 64 Remaining Repetition Display Dispalys the number of remaining repetitions (R.CYC) on Setpoint display. This display is displayed only when the repeat function is set and the operation mode is PROG. 6.1 Monitoring and Control of Operation Displays Soak and ramp display Program Pattern Display program pattern (overview) When pattern number is 0, pattern is not displayed.

-

Page 65: Position Proportional Type

6.1 Monitoring and Control of Operation Displays Position Proportional Type SP Display Displays "SSP" during reset-mode. Displays "L.SP" during local-mode operation. Displays "R.SP" during remote-mode operation. TSP Display Displays during program operation. SP Display (When the program pattern-2 retransmission is selected (PT2.G=ON).) Displays "SSP" during reset-mode. Displays "L.SP" during local-mode operation. Displays "L.SP"... - Page 66 Segment Number Display When the pattern number is 0, 0/0 is displayed. 6.1 Monitoring and Control of Operation Displays Remaining Repetition Display Dispalys the number of remaining repetitions (R.CYC) on Setpoint display. This display is displayed only when the repeat function is set and the operation mode is PROG. Soak and ramp display Program Pattern Display program pattern (overview)

-

Page 67: Heating/Cooling Type

6.1 Monitoring and Control of Operation Displays Heating/cooling Type SP Display Displays "SSP" during reset-mode. Displays "L.SP" during local-mode operation. Displays "R.SP" during remote-mode operation. TSP Display Displays during program operation. SP Display (When the program pattern-2 retransmission is selected (PT2.G=ON).) Displays "SSP" during reset-mode. Displays "L.SP" during local-mode operation. Displays "L.SP"... - Page 68 Remaining Repetition Display Dispalys the number of remaining repetitions (R.CYC) on Setpoint display. This display is displayed only when the repeat function is set and the operation mode is PROG. 6.1 Monitoring and Control of Operation Displays Soak and ramp display Program Pattern Display program pattern (overview) When pattern number is 0, pattern is not displayed.

-

Page 69: Operation Display Transitions In Cascade Control

6.1 Monitoring and Control of Operation Displays 6.1.2 Operation Display Transitions in Cascade Control ► Display/non-display of Operation Display: 13.3.5 Setting Display/Non-Display of Operation Display ► Registration of SELECT Display: 13.1.3 Registering SELECT Display (Up to 5 Displays) Standard Type When the operation mode is Cascade (CAS): Loop-1 SP Display PV display: Loop-1 PV Displays "SSP"... - Page 70 Segment Number Display When the pattern number is 0, 0/0 is displayed. 6.1 Monitoring and Control of Operation Displays Remaining Repetition Display Dispalys the number of remaining repetitions (R.CYC) on Setpoint display. This display is displayed only when the repeat function is set and the operation mode is PROG. Soak and ramp display Program Pattern Display program pattern (overview)

- Page 71 6.1 Monitoring and Control of Operation Displays When the operation mode is LOC(LSP): Loop-1 SP Display Displays "SSP" during reset-mode. Displays "L.SP" during local-mode operation. Displays "R.SP" during remote-mode operation. TSP Display Displays during program operation. Remaining Segment-time Display Displays during program operation. Loop-2 SP Display PV display: Loop-2 PV LP2 lamp is lit.

- Page 72 Remaining Repetition Display Dispalys the number of remaining repetitions (R.CYC) on Setpoint display. This display is displayed only when the repeat function is set and the operation mode is PROG. 6.1 Monitoring and Control of Operation Displays Soak and ramp display Program Pattern Display program pattern (overview) When pattern number is 0, pattern is not displayed.

-

Page 73: Position Proportional Type

6.1 Monitoring and Control of Operation Displays Position Proportional Type When the operation mode is Cascade (CAS): Loop-1 SP Display PV display: Loop-1 PV Displays "SSP" during reset-mode. Displays "L.SP" during local-mode operation. Displays "R.SP" during remote-mode operation. TSP Display Displays during program operation. Remaining Segment-time Display Displays during program operation. Valve Position Display (display only) PV display: Loop-1 PV LP2 lamp is lit. - Page 74 Segment Number Display When the pattern number is 0, 0/0 is displayed. 6.1 Monitoring and Control of Operation Displays Remaining Repetition Display Dispalys the number of remaining repetitions (R.CYC) on Setpoint display. This display is displayed only when the repeat function is set and the operation mode is PROG. Soak and ramp display Program Pattern Display program pattern (overview)

- Page 75 6.1 Monitoring and Control of Operation Displays When the operation mode is LOC(LSP): Loop-1 SP Display Displays "SSP" during reset-mode. Displays "L.SP" during local-mode operation. Displays "R.SP" during remote-mode operation. TSP Display Displays during program operation. Remaining Segment-time Display Displays during program operation. Loop-2 SP Display PV display: Loop-2 PV LP2 lamp is lit.

- Page 76 Segment Number Display When the pattern number is 0, 0/0 is displayed. 6.1 Monitoring and Control of Operation Displays Remaining Repetition Display Dispalys the number of remaining repetitions (R.CYC) on Setpoint display. This display is displayed only when the repeat function is set and the operation mode is PROG. Soak and ramp display Program Pattern Display program pattern (overview)

-

Page 77: Heating/Cooling Type

6.1 Monitoring and Control of Operation Displays Heating/cooling Type When the operation mode is Cascade (CAS): Loop-1 SP Display PV display: Loop-1 PV Displays "SSP" during reset-mode. Displays "L.SP" during local-mode operation. Displays "R.SP" during remote-mode operation. TSP Display Displays during program operation. Remaining Segment-time Display Displays during program operation. Loop-2 Heating/cooling OUT Display (OUT can be changed.) PV display: Loop-1 PV... - Page 78 Segment Number Display When the pattern number is 0, 0/0 is displayed. 6.1 Monitoring and Control of Operation Displays Remaining Repetition Display Dispalys the number of remaining repetitions (R.CYC) on Setpoint display. This display is displayed only when the repeat function is set and the operation mode is PROG. Soak and ramp display Program Pattern Display program pattern (overview)

- Page 79 6.1 Monitoring and Control of Operation Displays When the operation mode is LOC(LSP): Loop-1 SP Display Displays "SSP" during reset-mode. Displays "L.SP" during local-mode operation. Displays "R.SP" during remote-mode operation. TSP Display Displays during program operation. Remaining Segment-time Display Displays during program operation. Loop-2 SP Display PV display: Loop-2 PV LP2 lamp is lit.

- Page 80 Segment Number Display When the pattern number is 0, 0/0 is displayed. 6.1 Monitoring and Control of Operation Displays Remaining Repetition Display Dispalys the number of remaining repetitions (R.CYC) on Setpoint display. This display is displayed only when the repeat function is set and the operation mode is PROG. Soak and ramp display Program Pattern Display program pattern (overview)

-

Page 81: Details Of The Operation Display

6.1 Monitoring and Control of Operation Displays 6.1.3 Details of the Operation Display The following is the Operation Display types and each display and operation description. PV display Setpoint display Operation Display Display and operation description PV display: Displays measured input value (PV). Setpoint display: Displays and changes target setpoint (SP). Program setpoint Symbol Program pattern number (PTNO.) The Display is switched to the SP Display if the operation mode is switched to AUTO, CAS, LOC, or REM when other Operation Display is... - Page 82 6.1 Monitoring and Control of Operation Displays (Continued) Operation Display Display and operation description PV display: Displays measured input value (PV). Setpoint display: Displays final target setpoint (TSP). TSP Display Symbol Final target setpoint Program pattern number (PTNO.) PV display: Displays measured input value (PV). Setpoint display: Displays remaining segment-time. Remaining Segment-time Display Symbol Remaining segment-time Program pattern number (PTNO.) PV display: Displays measured input value (PV).

- Page 83 6.1 Monitoring and Control of Operation Displays (Continued) Operation Display Display and operation description PV display: Displays measured input value (PV). Setpoint display: Displays heating-side and cooling-side control output value and changes control output value in MAN mode. Heating-side control output Symbol of heating side Cooling-side control output Symbol of cooling side Program pattern number (PTNO.) When the control output value is less than 100%, one digit is displayed to the right of the decimal point.

- Page 84 6.1 Monitoring and Control of Operation Displays (Continued) Operation Display Display and operation description PV display: Displays measured input value (PV). Setpoint display: Displays PID number currently being used. PID Number Display Symbol PID number Program pattern number (PTNO.) PV display: Displays measured input value (PV). Setpoint display: Displays the segment number for which operation is in progress / the number of segments included in the selected program pattern.

- Page 85 6.1 Monitoring and Control of Operation Displays (Continued) Operation Display Display and operation description PV display: Displays measured input value (PV). Setpoint display: Displays alarm-5 to -8 status. Alarm-5 to -8 Alarm-8 status Symbol Status Display Alarm-7 status Alarm-6 status Alarm-5 status Program pattern number (PTNO.) The following is the Display shown when the control mode is cascade. PV display: Displays Loop-1 PV input.

- Page 86 6.1 Monitoring and Control of Operation Displays (Continued) Operation Display Display and operation description PV display: Displays measured input value (PV). Setpoint display: Displays PV, RSP, AIN2, or AIN4 analog input value. AIN2 auxiliary analog input value Symbol AIN2 input Analog Input Program pattern number (PTNO.) Display AIN4 auxiliary analog input value Symbol AIN4 input Program pattern number (PTNO.)

-

Page 87: Performing And Canceling Auto-Tuning

6.2 Performing and Canceling Auto-tuning Setting Display Operation Display > PARAMETER key for 3 seconds (to Operation Mode Setting Display [MODE] Menu Display) > SET/ENTER key (The operation mode is displayed.) > Down arrow key (The operation mode is displayed.) The parameter AT is displayed when the operation mode is AUTO. - Page 88 6.2 Performing and Canceling Auto-tuning In Cascade control, perform Loop-2 auto-tuning in AUTO and RUN modes, then Loop-1 auto-tuning in Cascade and RUN modes. Lamp Status Status STOP lamp CAS lamp MAN lamp During auto-tuning of Loop-2 Unlit Unlit Blinking During auto-tuning of Loop-1 Unlit Blinking Description Auto-tuning is a function with which the controller automatically measures the process characteristics and sets PID constants, which are control-related parameters, to optimum values for the setpoint.

- Page 89 6.2 Performing and Canceling Auto-tuning Tuning Point and Storage Location of Tuning Results The tuning point when performing auto-tuning is the target setpoint that is currently used for control computation. PID constants after the tuning are stored in the PID group that is specified when performing auto-tuning. Operation AT setpoint Tuning point Storage location mode P, I, and D of the PID group specified in...

-

Page 90: Adjusting Pid Manually

6.3 Adjusting PID Manually Setting Display Operation Display > PARAMETER key for 3 seconds (to Parameter Setting Display [MODE] Menu Display) > Right arrow key (to [PID] Menu Display ) > SET/ENTER key (The setting parameter is displayed.) > Down arrow key (The setting parameter is displayed.) In the Setting Display for the PID parameters, Displays can be arbitrarily switched using the Up, Down, Left or Right arrow... - Page 91 6.3 Adjusting PID Manually Description Description and Tuning of Proportional Band The proportional band is defined as the amount of change in input (or deviation), as a percent of span, required to cause the control output to change from 0% to 100%. Because a narrower proportional band gives greater output change for any given deviation, it therefore also makes the control performance more susceptible to oscillation.

- Page 92 6.3 Adjusting PID Manually Description and Tuning of Integral Time The integral action (I action) is a function that will automatically diminish the offset (steady-state deviation) that is inherently unavoidable with proportional action alone. The integral action continuously increases or decreases the output in proportion to the time integral of the deviation (the product of the deviation and the time that the deviation continues.) The integral action is normally used together with proportional action as proportional- plus-integral action (PI action).

- Page 93 6.3 Adjusting PID Manually Description and Tuning of Derivative Time If the control object has a large time constant or dead time, the corrective action will be too slow with proportional action or proportional-plus-integral action alone, causing overshoot. However, even just sensing whether the deviation is on an increasing or a decreasing trend and adding some early corrective action can improve the controllability. Thus the derivative action (D action) is action that changes the output in proportion to the deviation derivative value (rate-of-change).

- Page 94 6.3 Adjusting PID Manually Manual PID Tuning Procedure (1) In principle, auto-tuning must be used. (2) Tune PID parameters in the order of P, I, and D. Adjust a numeric slowly by observing the result, and keep notes of what the progress is. (3) Gradually reduce P from a larger value. When the PV value begins to oscillate, stop tuning and increase the value somewhat.

-

Page 95: Setting Alarm Setpoint

6.4 Setting Alarm Setpoint Setting Display Operation Display > PARAMETER key for 3 seconds (to Parameter Setting Display [MODE] Menu Display) > Right arrow key (to [SP] Menu Display) > SET/ENTER key (The setting parameter is displayed.) > Down arrow key (The setting parameter is displayed.) Setting Details Parameter... -

Page 96: Selecting Program Pattern Number (Ptno.)

6.5 Selecting Program Pattern Number (PTNO.) Selecting by PTN Key Setting Display PRG lamp is unlit. When the PTN key is pressed, the program pattern number is blinking. Press the Up or Down arrow key to select the pattern number. Press the SET/ENTER key to register the pattern number. Selecting by Operation Mode Parameter Setting Display Parameter Setting Display... -

Page 97: Switching Operation Modes

6.6 Switching Operation Modes 6.6.1 Operation Display Switching Diagram Program Hold-mode operation operation (*1) Local-mode Remote-mode Reset operation operation (1) Press RUN key for 1 s. *1: For another operation, when select (2) Press RST key for 1 s. ADV=ON and starts program (3) Press MODE key, select HOLD=ON and press SET/ENT key. operation. -

Page 98: Switching To Prog Operation

6.6 Switching Operation Modes 6.6.2 Switching to PROG Operation Selecting by RUN Key Setting Display PRG lamp is lit in PROG mode. Press RUN key for 1 s. Selecting by Operation Mode Parameter Setting Display Parameter Setting Display Operation Display > PARAMETER key for 3 seconds (to [MODE] Menu Display) > SET/ENTER key (The setting parameter is displayed.) >... -

Page 99: Selecting By Operation Mode Parameter

6.6 Switching Operation Modes 6.6.3 Switching to RESET Operation Selecting by RST Key Setting Display RST lamp is lit in RESET mode. Press RST key for 1 s. Selecting by Operation Mode Parameter Setting Display Operation Display > PARAMETER key for 3 seconds (to Parameter Setting Display [MODE] Menu Display) > SET/ENTER key (The setting parameter is displayed.) >... - Page 100 6.6 Switching Operation Modes Switch Output action PROG→RESET The control output bumps. RESET→PROG RESET→LOCAL The control output does not bump (bumpless). RESET→REM Output Control output Preset output PROG → RESET RESET → PROG ► Preset output value: 10.12.1 Setting Output Value in STOP Mode (Preset Output) The PV event and time event are disabled in RESET mode (OFF).

-

Page 101: Selecting By Operation Mode Parameter

6.6 Switching Operation Modes 6.6.4 Enabling/Disabling Hold Mode of Program Operation Selecting by MODE Key Setting Display HLD lamp is lit in HOLD mode. Each time you press the key, Operation modes is switched. • Display HOLD ON (blinking), and press the SET/ENTER key. HLD lamp is lit. • Display HOLD OFF (blinking), and press the SET/ENTER key. HLD lamp is unlit. -

Page 102: Hold Operation In Soak Segment

6.6 Switching Operation Modes The hold operation function allows pausing the progress of the program pattern. The hold operation stops the segment time and the time of the time event. As a result, the segment time and the time of the time event are extended by the amount of the holding time. -

Page 103: Excuting Advance

6.6 Switching Operation Modes 6.6.5 Excuting Advance Selecting by MODE Key Setting Display Each time you press the key, Operation modes is switched. Display ADV ON (blinking), and press the SET/ENTER key. Selecting by Operation Mode Parameter Setting Display Operation Display > PARAMETER key for 3 seconds (to Parameter Setting Display [MODE] Menu Display) > SET/ENTER key (The setting parameter is displayed.) >... - Page 104 6.6 Switching Operation Modes Executing Advance advances the program to the next segment, irrespective of the junction code (JC). Advance is performed as follows depending on the segment to execute and the operating state. • When executing Advance in the last segment: The program switches to Reset operation (when JC=CONT), Local operation, or Remote operation depending on the junction code (JC).

-

Page 105: Switching Between Auto And Man

6.6 Switching Operation Modes 6.6.6 Switching between AUTO and MAN Selecting by MODE Key Setting Display From Auto to Man MAN lamp is lit in MAN mode. (The lamp is lit after the switching operation is completed.) Each time you press the key, Operation modes is switched. Display MODE MAN (blinking), and press the SET/ENTER key. From Man to Auto MAN lamp is unlit in MAN mode. - Page 106 6.6 Switching Operation Modes Description AUTO/MAN switching can be performed by any of the following: (1) MODE key (2) Operation mode parameter (3) Contact input (4) Communication When the above (1) or (2) is used to switch AUTO to MAN and MAN to AUTO, the display is switched to OUT Display and SP Display, respectively.

-

Page 107: Switching To Local Operation

6.6 Switching Operation Modes 6.6.7 Switching to Local Operation Selecting by MODE Key Setting Display HLD, CAS, PRG, or RST lamp is unlit in LOC mode. (The lamp is unlit after the switching operation is completed.) Each time you press the key, Operation modes is switched. Display MODE LOC (blinking), and press the SET/ENTER key. Selecting by Operation Mode Parameter Setting Display Parameter Setting Display... -

Page 108: Switching To Remote Operation

6.6 Switching Operation Modes 6.6.8 Switching to Remote Operation Selecting by MODE Key Setting Display HLD, CAS, PRG, or RST lamp is unlit in REM mode. (The lamp is unlit after the switching operation is completed.) Each time you press the key, Operation modes is switched. Display MODE REM (blinking), and press the SET/ENTER key. Selecting by Operation Mode Parameter Setting Display Operation Display >... -

Page 109: Selecting By Operation Mode Parameter

6.6 Switching Operation Modes 6.6.9 Switching between Local (LSP) and Cascade Selecting by MODE Key Setting Display CAS lamp is lit in CAS mode. (The lamp is lit after operation right.) Each time you press the key, Operation modes is switched. Display MODE CAS (blinking), and press the SET/ENTER key. Selecting by Operation Mode Parameter Setting Display Parameter Setting Display Operation Display >... -

Page 110: Selecting By Operation Mode Parameter

6.7 Selecting Start-of-program Pattern Number Selecting by MODE Key Setting Display Every time you press the MODE key, the operation mode is switched. Display SST (start-of-program segment number), and press the SET/ENTER key. Selecting by Operation Mode Parameter Setting Display Operation Display > PARAMETER key for 3 seconds (to Parameter Setting Display [MODE] Menu Display) >... - Page 111 6.7 Selecting Program Pattern Number Description Program operation starts from the set segment number. When the operation mode is switched to reset (RST), local (LOC), or remote (REM) operation, or when power is turned on, the segment number automatically returns to 1. Setpoint Seg.1 Seg.2 Seg.3 Seg.4...

-

Page 112: Fast-Forwarding Program Pattern

6.8 Fast-forwarding Program Pattern Performing by MODE Key Setting Display Every time you press the MODE key, the operation mode is switched. Display P.FWD (fast-forwarding), and press the SET/ENTER key. Performing by Operation Mode Parameter Setting Display Operation Display > PARAMETER key for 3 seconds (to Parameter Setting Display [MODE] Menu Display) > SET/ENTER key (The setting parameter is displayed.) >... -

Page 113: Changing Sp, Tsp, Or Remaining Segment-Time (R.tim) In Hold-Mode

6.9 Changing SP, TSP, or Remaining Segment-time (R.TIM) in HOLD-mode Changing SP in HOLD Operation Operation HLD lamp is lit . Display the SP Display, switch to HOLD mode. See “6.6.4 Enabling/Disabling Hold Mode of Program Operation.” . Press the SET/ENTER key to move to the setting mode (the setpoint blinks). . Press the Left arrow key to move one digit to the left. -

Page 114: Changing Tsp In Hold Operation

6.9 Changing SP, TSP, or Remaining Segment-time (R.TIM) in HOLD-mode Changing TSP in HOLD Operation Operation HLD lamp is lit . Display the TSP Display, switch to HOLD mode. See “6.6.4 Enabling/Disabling Hold Mode of Program Operation.” . Press the SET/ENTER key to move to the setting mode (the setpoint blinks). . Press the Left arrow key to move one digit to the left. - Page 115 6.9 Changing SP, TSP, or Remaining Segment-time (R.TIM) in HOLD-mode Description The current setpoint (hold SP), final target setpoint (TSP), and remaining segment time can be changed during the hold operation. The value changed during the hold operation is temporary. When the program is operated again, it is operated according to the original program pattern. To operate the program using the changed value, the original program pattern needs to be changed.

-

Page 116: Modifying Target Setpoint In Soak Segment

6.9 Changing SP, TSP, or Remaining Segment-time (R.TIM) in HOLD-mode Modifying Target Setpoint in Soak Segment When the hold SP is changed in the soak segment, the final target setpoint (TSP) is also changed. When the hold state is released, the program pattern operation restarts from the changed setpoint. Setpoint Before Seg.1 Seg.2 Seg.3 Seg.4 Seg.5 After... -

Page 117: Modifying Final Target Setpoint (Tsp) In Soak Segment

6.9 Changing SP, TSP, or Remaining Segment-time (R.TIM) in HOLD-mode Modifying Final Target Setpoint (TSP) in Soak Segment The final target setpoint (TSP) can be changed in the soak segment. When the hold state is released, the program pattern operation restarts towards the changed final target setpoint (TSP). Setpoint Seg.1 Seg.2 Seg.3 Seg.4 Seg.5 Before After Seg.2 Seg.3 Seg.4... -

Page 118: Decreasing Segment-Time In Soak Segment

6.9 Changing SP, TSP, or Remaining Segment-time (R.TIM) in HOLD-mode Decreasing Segment-time in Soak Segment The remaining segment time from the time when the hold state is released can be changed during the hold operation. When the remaining segment time is changed in the soak segment and the hold state is released, the program pattern operation restarts from the changed segment time. When the segment time is increased, the segment time and the time of the time event are extended by the increased amount of time. -

Page 119: Increasing Segment-Time In Soak Segment

6.9 Changing SP, TSP, or Remaining Segment-time (R.TIM) in HOLD-mode Increasing Segment-time in Soak Segment The remaining segment time from the time when the hold state is released can be changed during the hold operation. When the remaining segment time is changed in the soak segment and the hold state is released, the program pattern operation restarts from the changed segment time. When the segment time is decreased, the segment time and the time of the time event are shortened by the decreased amount of time. -

Page 120: Decreasing Segment-Time In Ramp Segment

6.9 Changing SP, TSP, or Remaining Segment-time (R.TIM) in HOLD-mode Decreasing Segment-time in Ramp Segment The remaining segment time from the time when the hold state is released can be changed during the hold operation. However, the ramp-rate for the changed program setpoint changes. When the remaining segment time is changed in the ramp segment and the hold state is released, the program pattern operation restarts from the changed segment time. -

Page 121: Changing Program Pattern During Program Operation

6.10 Changing Program Pattern during Program Operation Description The program pattern can be changed during the program operation in Program Parameter Setting Display. Unlike changing during the hold operation, changing the program pattern in Program Parameter Setting Display saves the changed setpoint. However, even if the parameter of the segment in process is changed, it is not reflected in operation. -

Page 122: Manipulating Control Output During Manual Operation

6.11 Manipulating Control Output during Manual Operation Operation Direct key method The value specified by the Up and Down arrow keys is output as is. Press the Up arrow key to increase the control output. Press the Down arrow key to decrease the control output. MAN lamp is lit. - Page 123 6.11 Manipulating Control Output during Manual Operation Setting Details Parameter Display Name Setting range Menu symbol symbol level In manual operation mode, you can use the direct key method or the SET/ENT key method to control the output value. (Note) Direct key method Manual output The value specified by the MAN.T operation type Up and Down arrow keys is output as is.

-

Page 124: Releasing On-State (Latch) Of Alarm Output

6.12 Releasing On-State (Latch) of Alarm Output Description Alarm latch can be released by any of the following. (1) User function key (RUN, RST, PTN, MODE) (2) Communication (3) Contact input For the switching operation by using the above, the last switching operation is performed. Releasing the alarm latch function releases all of the latched alarm outputs. - Page 125 Blank Page...

-

Page 126: Chapter 7 Input (Pv, Remote, And Auxiliary Analog) Functions

Chapter 7 Input (PV, Remote, and Auxiliary Analog) Functions 7.1 Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input 7.1.1 Setting Input Type, Unit, Range, Scale, and Decimal Point Position Description The figure below describes the case of PV input. The remote input and auxiliary analog input can be set in the same way. Example of Temperature Input The figure below is an example of setting Type K thermocouple and a measurement range of 0.0 to 800.0 ºC. - Page 127 7.1 Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input Setting Details Parameter Display Name Setting range Menu symbol symbol level OFF: Disable K1: -270.0 to 1370.0 ºC / -450.0 to 2500.0 ºF K2: -270.0 to 1000.0 ºC / -450.0 to 2300.0 ºF K3: -200.0 to 500.0 ºC / -200.0 to 1000.0 ºF J: -200.0 to 1200.0 ºC / -300.0 to 2300.0 ºF T1: -270.0 to 400.0 ºC / -450.0 to 750.0 ºF T2: 0.0 to 400.0 ºC / -200.0 to 750.0 ºF...

- Page 128 7.1 Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input (Continued) Parameter Display Name Setting range Menu symbol symbol level Depends on the input type. - For temperature input - Set the temperature range Maximum value of PV EASY that is actually controlled. input range (RL<RH) - For voltage / current input - Set the range of a voltage / current signal that is applied.

- Page 129 7.1 Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input Parameter Display Name Setting range Menu symbol symbol level Minimum value of PV EASY input scale Minimum value of RSP EASY remote input range -19999 to 30000, (SL<SH), (Scaling) | SH - SL | ≤ 30000 Minimum value of AIN2 EASY AIN2 aux. analog input scale Minimum value of AIN4 EASY AIN4 aux.

-

Page 130: Setting Burnout Detection For Input

7.1 Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input 7.1.2 Setting Burnout Detection for Input Description The input value when input burnout occurs can be determined. The input value is 105.0% of the input range when the upscale is set, and -5.0% of the input range when the downscale is set. Burnout detection is activated for TC, RTD, and standard signal (0.4–2 V or 1–5 V). For standard signal, burnout is determined to have occurred if it is 0.1 V or less for the range of 0.4–2 V and 1–5V, or if it is 0.4 mA or less for the range of 4–20 mA. -

Page 131: Setting Reference Junction Compensation (Rjc) Or External Reference

External Reference Junction Compensation (ERJC) For TC input, a temperature compensation value for external device can be set. The external RJC can be used only when RJC = OFF. UP55A Terminal block Compensating lead wire Furnace UP55A... -

Page 132: Correcting Input Value

7.1 Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input 7.1.4 Correcting Input Value (1) Setting Bias and Filter Description PV Input Bias The PV input bias allows bias to be summed with input to develop a measured value for display and control use inside the controller. This function can also be used for fine adjustment to compensate for small inter- instrument differences in measurement reading that can occur even if all are within the specified instrument accuracies. - Page 133 7.1 Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input Setting Details Parameter Display Name Setting range Menu symbol symbol level -100.0 to 100.0% of PV PV input bias EASY input range span (EUS) PV input filter EASY OFF, 1 to 120 s Parameter Display Name Setting range Menu symbol symbol level PV analog input bias RSP analog input bias -100.0 to 100.0% of each A.BS...

-

Page 134: Setting Square Root Extraction And Low Signal Cutoff Point

7.1 Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input (2) Setting Square Root Extraction and Low Signal Cutoff Point Description This calculation is used to convert, for example, a differential pressure signal from a throttling flow meter such as an orifice and nozzle into a flow-rate signal. There is no hysteresis for low signal cutoff point. Output Output Low signal cutoff Low signal cutoff point is variable. point is variable. Input Input Output = Input Output = Input The slope equals “1”... -

Page 135: Setting 10-Segment Linearizer

7.1 Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input (3) Setting 10-segment Linearizer Description A total of up to four 10-segment linearizers can be used for the input unit and output unit. For the position used by a ten-segment linearizer, see the function block diagram. ► Function block diagram: 8.1 Setting Control Mode (CTLM) ► Output Linearizer: 10.13 Setting 10-segment Linearizer for Output 10-segment Linearizer Bias This function is used to correct an input signal affected by sensor deterioration. The corrected values are obtained by adding the corresponding bias values to each of the 11 points of optionally set input values. When 10-segment linearizer input is A1 or less, B1 is to be added. When 10-segment linearizer input is A11 or more, B11 is to be added. - Page 136 7.1 Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input Setting Details Parameter Name Display level Setting range Menu symbol symbol OFF: Disable PV: PV analog input RSP: RSP analog input 10-segment AIN2: AIN2 analog input Group 1, 2: STD linearizer AIN4: AIN4 analog input Group 3, 4: PRO selection PVIN: PV input OUT: OUT analog output OUT2: OUT2 analog output RET: RET analog output...

-

Page 137: Setting Ratio Bias/Filter

7.1 Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input Initial value of eatch control mode Control mode Group-1 PYS Goup-2 PYS Group-3 and -4 PYS Single-loop control Cascade primary-loop control Cascade control Loop control with PV switching Loop control with PV auto-selector PVIN 7.1.5 Setting Ratio bias/filter Description Ratio bias computing performs ratio computation and bias addition for remote setpoints. SP = Remote input x Remote input ratio (RT) + Remote input bias (RBS) Setting Details Parameter... -

Page 138: Setting Input Sampling Period (Control Period)

7.2 Setting Input Sampling Period (Control Period) Setting Details Parameter Display Name Setting range Menu symbol symbol level Input sampling period 100: 100 ms (control period) 200: 200 ms 7-13 IM 05P02C41-01EN... -

Page 139: Using 4-Wire Rtd As Pv Input

7.3 Using 4-wire RTD as PV Input Description To use the 4-wire RTD, the optional suffix code /DR is required for remote input. Or the optional suffix code /U1 is reauired. Normally, PV terminal input is used as PV. When RSP terminal is used as PV, use the ladder program of LL50A Parameter Setting Software (sold separately) to switch the functions of the PV terminal and RSP terminal. -

Page 140: Using Larger, Smaller, Average, Or Difference Of Two To Four Inputs As Pv

7.4 Using Larger, Smaller, Average, or Difference of Two to Four Inputs as PV Description Loop control with PV auto-selector function automatically selects or calculates the larger, smaller, average, or difference of multiple (two to four) inputs and uses the result as PV. The larger, smaller, and average are automatically computed based on the specified number of inputs. -

Page 141: Setting Remote Input Method

7.5 Setting Remote Input Method Description There are two methods for remote input: analog input and communication. Decide which to use among two methods in advance. Analog input: Remote setting using external analog signal (RSP terminal) Communication: Remote setting via external communication. Analog input LOCAL RESET REMOTE... -

Page 142: Adjusting Pv Range For Loop Control With Pv Switching Or Loop Control With Pv Auto-Selector

Adjusting PV Range for Loop Control with PV Switching or Loop Control with PV Auto-selector Description Loop control with PV switching and Loop control with PV auto-selector need to determine the PV range for control if the measurement ranges of two input signals are different. The figure below is an example of setting PV input range of 0 to 200ºC, RSP terminal input of 100 to 800ºC, and control PV range of 0 to 800ºC. -

Page 143: Setting Pv Switching Methods Of Loop Control With Pv Switching

7.7 Setting PV Switching Methods of Loop Control with PV Switching Description PV switching method of Loop control with PV switching can be set when the control mode is Loop control with PV switching. ► Block diagram of Loop control with PV switching: 8.1.4 Loop Control with PV Switching, Heating/cooling Loop Control with PV Switching, and Position Proportional Loop Control with PV Switching Input 1: PV terminal input Input 2: RSP terminal input... - Page 144 7.7 Setting PV Switching Methods of Loop Control with PV Switching Switching within the Temperature Range (High-temperature side) (Parameter PV.2C=3) This method automatically switches PV within the range of input switching PV high limit and low limit. It should be selected in case where a sudden change in PV must be avoided. PV rising process Input 2 (High-temperature side) PV.HL PV.LL Input 1...

- Page 145 7.7 Setting PV Switching Methods of Loop Control with PV Switching Switching at the Input Switching PV High Limit (Parameter PV.2C=1) This method automatically switches two inputs at switching point (input switching PV high limit) It should be selected in case where a sudden change in PV is allowed. Control output will change smoothly (i.e., without any bumps) when PV switches. Hysteresis (0.5% of PV range span) is provided around the switching point.

- Page 146 7.7 Setting PV Switching Methods of Loop Control with PV Switching Switching by Contact Input (Parameter PV.2C=2) This method switches two inputs by contact input ON/OFF. When the contact input is OFF, PV = Input 1 (low-temperature side). When the contact input is ON, PV = Input 2 (high-temperature side). Input 2 (High-temperature side) Input 1 (Low-temperature side) Time Input 1 Input 2 Input 1 Input 2...

- Page 147 Blank Page...

-

Page 148: Chapter 8 Control Functions

Chapter 8 Control Functions 8.1 Setting Control Mode (CTLM) 8.1.1 Single-loop Control, Single-loop Heating/cooling Control, and Single- loop Position Proportional Control Setting Details Parameter Name Display level Setting range Menu symbol symbol SGL: Single-loop control CAS1: Cascade primary-loop control CAS: Cascade control CTLM Control mode PVSW: Loop control with PV switching PVSEL: Loop control with PV auto- selector CAUTION • Some parameters will be initialized if the control mode (CTLM) is changed. -

Page 149: Single-Loop Control Function Block Diagram

n Single-loop Control Function Block Diagram (for Detailed model) (for Detailed model) Remote input can be used when DI16 is equipped when optional suffix code /R1. optional suffix code /R1. DI41 to DI45 are equipped when optional suffix code /X4. (for Standard model) (for Standard model) Remote input can be used when Communication Equipped as standard... - Page 150 Output limiter OH, OL Input error preset output Normal When sensor burnout occurs Manual preset output MPON Manual operation Output limiter OH, OL OLMT AUTO Preset output RESET RESET/RUN switch DO11 to DO15 are assinged PV event 4 to 8, and DO31 to * After the control output terminal is specified by the parameter OT, DO35 are assinged Time event Output terminal assignment...

-

Page 151: Single-Loop Heating/Cooling Control Function Block Diagram

n Single-loop Heating/cooling Control Function Block Diagram (for Detailed model) (for Detailed model) Remote input can be used when DI16 is equipped when optional suffix code /R1. optional suffix code /R1. DI41 to DI45 are equipped when optional suffix code /X4. (for Standard model) (for Standard model) Remote input can be used when Communication Equipped as standard... - Page 152 MPON Manual preset output Manual operation AUTO Heating/cooling computation Manual output is prioritized even if sensor burnout occurs in MAN. Heating-side output limiter Cooling-side output limiter Input error preset output Input error preset output OH, OL OHc, OLc Normal Normal Heating-side preset output When sensor When sensor...

-

Page 153: Single-Loop Position Proportional Control Function Block Diagram

n Single-loop Position Proportional Control Function Block Diagram (for Detailed model) (for Detailed model) Remote input can be used when DI16 is equipped when optional suffix code /R1. optional suffix code /R1. DI41 to DI45 are equipped when optional suffix code /X4. (for Standard model) (for Standard model) Remote input can be used when Communication Equipped as standard... - Page 154 Output limiter OH, OL In Estimating-type position proportional control, the limiter function Input error preset output does not work on output operation. Normal The reverse-signal relay turns on when being limited by low limit. When sensor burnout occurs The direct-signal relay turns on when being limited by high limit. In Manual operation, the relay turns on while the key is pressed.

- Page 155 8.1 Setting Control Mode (CTLM) Intentionally blank IM 05P02C41-01EN...

-

Page 156: Cascade Primary-Loop Control

8.1 Setting Control Mode (CTLM) 8.1.2 Cascade Primary-loop Control Setting Details Parameter Display Name Setting range Menu symbol symbol level SGL: Single-loop control CAS1: Cascade primary-loop control CAS: Cascade control CTLM Control mode PVSW: Loop control with PV switching PVSEL: Loop control with PV auto-selector CAUTION • Some parameters will be initialized if the control mode (CTLM) is changed. • When using the ladder program, the control mode cannot be changed. Description Cascade primary-loop control sets up a controller as the primary-loop controller when two controllers are used for Cascade control. -

Page 157: Cascade Primary-Loop Control Function Block Diagram

n Cascade Primary-loop Control Function Block Diagram (for Detailed model) (for Detailed model) (for Detailed model) Remote input can be used when DI16 is equipped when Optional suffix code /R1 is necessary. optional suffix code /R1. optional suffix code /A2. (for Standard model) (for Standard model) (for Standard model) Equipped as standard Suffix code: Type 2 = 1 or 4 is necessary. - Page 158 Output limiter Input error preset output OH, OL Normal When sensor burnout occurs Manual preset output MPON Manual operation Output tracking input Output limiter OH, OL OLMT AUTO Output limiter OH, OL Preset output Output tracking switch (Tracking at ON) RESET RESET/RUN switch DO31 to DO35 are assinged Time...

- Page 159 8.1 Setting Control Mode (CTLM) Intentionally blank 8-12 IM 05P02C41-01EN...

-

Page 160: Cascade Control, Cascade Heating/Cooling Control, And Cascade Position Proportional Control

8.1 Setting Control Mode (CTLM) 8.1.3 Cascade Control, Cascade Heating/cooling Control, and Cascade Position Proportional Control Setting Details Parameter Display Name Setting range Menu symbol symbol level SGL: Single-loop control CAS1: Cascade primary-loop control CTLM Control mode CAS: Cascade control PVSW: Loop control with PV switching PVSEL: Loop control with PV auto- selector CAUTION • Some parameters will be initialized if the control mode (CTLM) is changed. -

Page 161: Cascade Control Function Block Diagram

n Cascade Control Function Block Diagram (for Detailed model) For the model with optional suffix code /U1: (for Detailed model) Remote input can be used when Remote input with direct input DI16 is equipped when optional suffix code /A2. (E1-terminal area) can be used (for Detailed model) optional suffix code /R1. - Page 162 Output limiter OH, OL Input error preset output Normal When Loop-2 sensor burnout occurs ** Loop-2 parameters. Manual preset output MPON Manual operation Output limiter OH, OL OLMT CAS, AUTO Preset output RESET RESET/RUN switch * After the control output terminal is specified by the parameter OT, Output terminal assignment other current output terminals can be used as retransmission output.

-

Page 163: Cascade Heating/Cooling Control Function Block Diagram

n Cascade Heating/cooling Control Function Block Diagram (for Detailed model) (for Detailed model) For the model with optional suffix code /U1: DI16 is equipped when Remote input can be used when Remote input with direct input optional suffix code /R1. optional suffix code /A2. - Page 164 Manual preset output MPON Manual operation CAS, AUTO Heating/cooling computation Manual output is prioritized even if sensor burnout occurs in MAN. ** Loop-2 parameters. Heating-side output limiter Cooling-side output limiter Input error preset output Input error preset output OH, OL OHc, OLc Normal Normal...

-

Page 165: Cascade Position Proportional Control Function Block Diagram

n Cascade Position Proportional Control Function Block Diagram (for Detailed model) For the model with optional suffix code /U1: (for Detailed model) Remote input can be used when DI16 is equipped when Remote input with direct input (for Detailed model) optional suffix code /A2. - Page 166 In Estimating-type position proportional control, the limiter function Output limiter OH, OL Input error preset output does not work on output operation. Normal The reverse-signal relay turns on when being limited by low limit. When Loop-2 sensor burnout occurs The direct-signal relay turns on when being limited by high limit. In Manual operation, the relay turns on while the key is pressed.

- Page 167 8.1 Setting Control Mode (CTLM) Intentionally blank 8-20 IM 05P02C41-01EN...

-

Page 168: Loop Control With Pv Switching, Heating/Cooling Loop Control With Pv Switching, And Position Proportional Loop Control With Pv Switching

8.1 Setting Control Mode (CTLM) 8.1.4 Loop Control with PV Switching, Heating/cooling Loop Control with PV Switching, and Position Proportional Loop Control with PV Switching Setting Details Parameter Display Name Setting range Menu symbol symbol level SGL: Single-loop control CAS1: Cascade primary-loop control CAS: Cascade control CTLM Control mode PVSW: Loop control with PV switching PVSEL: Loop control with PV auto-selector CAUTION • Some parameters will be initialized if the control mode (CTLM) is changed. •... -

Page 169: Loop Control With Pv Switching Function Block Diagram

n Loop Control with PV Switching Function Block Diagram (for Detailed model) (for Detailed model) (for Detailed model) Remote input can be used when DI16 is equipped when Optional suffix code /R1 is necessary. optional suffix code /A2. optional suffix code /R1. (for Standard model) (for Standard model) (for Standard model) Suffix code: Type 2 = 1 or 4 is necessary. - Page 170 Output limiter OH, OL Input error preset output Normal When sensor burnout occurs Sensor burnout occurs when PV or RSP input burnout occurs. However, burnout is not detected if input is not connected. Manual preset output MPON Manual operation Output limiter OH, OL OLMT AUTO...

-

Page 171: Heating/Cooling Loop Control With Pv Switching Function Block Diagram

n Heating/cooling Loop Control with PV Switching Function Block Diagram (for Detailed model) (for Detailed model) (for Detailed model) DI16 is equipped when Remote input can be used when Optional suffix code /R1 is necessary. optional suffix code /R1. optional suffix code /A2. (for Standard model) (for Standard model) (for Standard model) Suffix code: Type 2 = 1 or 4 is necessary. - Page 172 Manual preset output MPON Manual operation AUTO Heating/cooling computation Manual output is prioritized even if sensor burnout occurs in MAN. Heating-side output limiter Cooling-side output limiter Input error preset output Input error preset output OH, OL OHc, OLc Normal Normal When sensor Heating-side preset output When sensor...

-

Page 173: Position Proportional Loop Control With Pv Switching Function Block Diagram

n Position Proportional Loop Control with PV Switching Function Block Diagram (for Detailed model) (for Detailed model) (for Detailed model) Remote input can be used when DI16 is equipped when Optional suffix code /R1 is necessary. optional suffix code /A2. optional suffix code /R1. (for Standard model) (for Standard model) (for Standard model) Suffix code: Type 2 = 1 or 4 is necessary. - Page 174 In Estimating-type position proportional control, the limiter function Output limiter OH, OL does not work on output operation. The reverse-signal relay turns on when being limited by low limit. Input error preset output The direct-signal relay turns on when being limited by high limit. Normal When sensor burnout occurs In Manual operation, the relay turns on while the...

- Page 175 8.1 Setting Control Mode (CTLM) Intentionally blank 8-28 IM 05P02C41-01EN...

-

Page 176: Loop Control With Pv Auto-Selector, Heating/Cooling Loop Control With Pv Auto-Selector, And Position Proportional Loop Control With Pv Auto-Selector

8.1 Setting Control Mode (CTLM) 8.1.5 Loop Control with PV Auto-selector, Heating/cooling Loop Control with PV Auto-selector, and Position Proportional Loop Control with PV Auto- selector Setting Details Parameter Display Name Setting range Menu symbol symbol level SGL: Single-loop control CAS1: Cascade primary-loop control CAS: Cascade control CTLM Control mode PVSW: Loop control with PV switching PVSEL: Loop control with PV auto-selector CAUTION • Some parameters will be initialized if the control mode (CTLM) is changed. •... -

Page 177: Loop Control With Pv Auto-Selector (2 Inputs) Function Block Diagram

n Loop Control with PV Auto-selector (2 inputs) Function Block Diagram (for Detailed model) (for Detailed model) Optional suffix code /R1 is necessary. DI16 is equipped when optional suffix code /R1. DI41 to DI45 are equipped when optional suffix code /X4. (for Standard model) For the model with optional suffix code /DR: Suffix code: Type 2 = 1 or 4 is necessary. - Page 178 Output limiter OH, OL Input error preset output Normal When sensor Sensor burnout occurs when PV or RSP input burnout occurs. burnout occurs However, burnout is not detected if input is not conncted. Manual preset output MPON Manual operation Output limiter OH, OL OLMT AUTO...

-

Page 179: Heating/Cooling Loop Control With Pv Auto-Selector (2 Inputs) Function Block Diagram

n Heating/cooling Loop Control with PV Auto-selector (2 inputs) Function Block Diagram (for Detailed model) (for Detailed model) DI16 is equipped when optional suffix code /R1. Optional suffix code /R1 is necessary. DI41 to DI45 are equipped when optional suffix code /X4. (for Standard model) For the model with optional suffix code /DR: Suffix code: Type 2 = 1 or 4 is necessary. - Page 180 Manual preset output MPON Manual operation AUTO Sensor burnout occurs when PV or RSP input burnout occurs. However, burnout is not detected if input Heating/cooling computation Manual output is prioritized even if is not conncted. sensor burnout occurs in MAN. Heating-side output limiter Cooling-side output limiter Input error preset output...

-

Page 181: Position Proportional Loop Control With Pv Auto-Selector (2 Inputs) Function Block Diagram

n Position Proportional Loop Control with PV Auto-selector (2 inputs) Function Block Diagram (for Detailed model) (for Detailed model) Optional suffix code /R1 is necessary. DI16 is equipped when optional suffix code /R1. (for Standard model) DI41 to DI45 are equipped when optional suffix code /X4. Suffix code: Type 2 = 1 or 4 is necessary. For the model with optional suffix code /DR: (for Standard model) Equipped as standard... - Page 182 Output limiter OH, OL In Estimating-type position proportional control, the limiter function Input error preset output does not work on output operation. Normal The reverse-signal relay turns on when being limited by low limit. When sensor The direct-signal relay turns on when being limited by high limit. burnout occurs In Manual operation, the relay turns on while the key is pressed.

-

Page 183: Loop Control With Pv Auto-Selector (4 Inputs) Function Block Diagram

n Loop Control with PV Auto-selector (4 inputs) Function Block Diagram (for Detailed model) Optional suffix code /R1 is necessary. (for Detailed model) For the model with optional suffix code /U1: DI16 is equipped when Refer to the function block diagram of optional suffix code /R1. Loop control with PV auto-selector (2 inputs). DI26 and DI46 are equipped when Necessary for Loop control with PV auto-selector for 3 inputs or 4 inputs optional suffix code /A2 and /A4. - Page 184 Output limiter OH, OL Error preset output Normal When sensor Sensor burnout occurs when PV, RSP, AIN2, or AIN4 input burnout occurs. burnout occurs However, burnout is not detected if input is not conncted. Manual preset output MPON Manual operation Output limiter OH, OL OLMT...

-

Page 185: Heating/Cooling Loop Control With Pv Auto-Selector (4 Inputs) Function Block Diagram

n Heating/cooling Loop Control with PV Auto-selector (4 inputs) Function Block Diagram (for Detailed model) Optional suffix code /R1 is necessary. (for Detailed model) DI16 is equipped when For the model with optional suffix code /U1: optional suffix code /R1. Refer to the function block diagram of DI26 and DI46 are equipped when Loop control with PV auto-selector (2 inputs). - Page 186 Manual preset output MPON Manual operation AUTO Heating/cooling computation Manual output is prioritized even if Sensor burnout occurs when PV, RSP, AIN2, or AIN4 input burnout occurs. sensor burnout occurs in MAN. However, burnout is not detected if input is not conncted. Heating-side output limiter Cooling-side output limiter Input error preset output...

-

Page 187: Position Proportional Loop Control With Pv Auto-Selector (4 Inputs) Function Block Diagram

n Position Proportional Loop Control with PV Auto-selector (4 inputs) Function Block Diagram (for Detailed model) Optional suffix code /R1 is necessary. (for Detailed model) For the model with optional suffix code /U1: DI16 is equipped when Refer to the function block diagram of optional suffix code /R1. Loop control with PV auto-selector (2 inputs). Necessary for Loop control with PV auto-selector for 3 inputs or 4 inputs DI26 and DI46 are equipped when optional suffix code /A2 and /A4. - Page 188 In Estimating-type position proportional control, the limiter function does not Output limiter OH, OL work on output operation. Input error preset output The reverse-signal relay turns on when being limited by low limit. The direct-signal relay turns on when being limited by high limit. Normal When sensor burnout occurs...

-

Page 189: Setting Control Type (Cnt)

8.2 Setting Control Type (CNT) The following table shows combination of Standard type, Heating/cooling type, Position proportional type and control type (CNT). Suffix code: Type 1 Control type Heating/cooling Position Standard type type proportional type PID control √ √ √ ON/OFF control √ √ (1 point of hysteresis) ON/OFF control √... -

Page 190: Pid Control

8.2 Setting Control Type (CNT) 8.2.1 PID Control Description PID control is a general control using control-related parameters PID. PID should be obtained by adjusting manually or by auto-tunings at SP during program pattern operation, local target setpoint, or remote setpoint. Setting Details Parameter Display Name Setting range Menu symbol symbol level PID: PID control ONOF: ON/OFF control (1 point of hysteresis) Control type EASY... -

Page 191: On/Off Control (1 Point Of Hysteresis / 2 Points Of Hysteresis)

8.2 Setting Control Type (CNT) 8.2.2 ON/OFF Control (1 point of hysteresis / 2 points of hysteresis) Description ON/OFF control compares the SP and PV and outputs an on or off signal according to the positive or negative deviation (PV – SP). Hysteresis can be set in the vicinity of the on/off output operating point. If the SP and PV become close and the polarity of the deviation reverses frequently, the on/off output will cycle repeatedly. - Page 192 8.2 Setting Control Type (CNT) Setting Details Parameter Display Name Setting range Menu symbol symbol level PID: PID control ONOF: ON/OFF control (1 point of hysteresis) Control type EASY ONOF2: ON/OFF control (2 points of hysteresis) H/C: Heating/cooling control Hysteresis (in ON/OFF control, or Position In ON/OFF control: 0.0 to 100.0% proportional of PV input range span (EUS) control)

-

Page 193: Heating/Cooling Control

8.2 Setting Control Type (CNT) 8.2.3 Heating/cooling Control Description Heating/cooling control can be used only for Heating/cooling type. In Heating/cooling control, the controller outputs the result of computation after splitting it into heating-purpose and cooling-purpose signals. PID control or ON/OFF control can be selected for each of the heating side and the cooling side. Set the heating-side proportional band to “0”... - Page 194 8.2 Setting Control Type (CNT) Positive Dead Band Cooling-side control output (%) Heating-side control output (%) 100% 100% Heating-side control output Cooling-side high limit control output (OH) high limit (OHc) Dead Dead band band (DB) (DB) 100% 100% Control computation output (OUT) Negative Dead Band Cooling-side control output (%) Heating-side control output (%) 100% 100%...