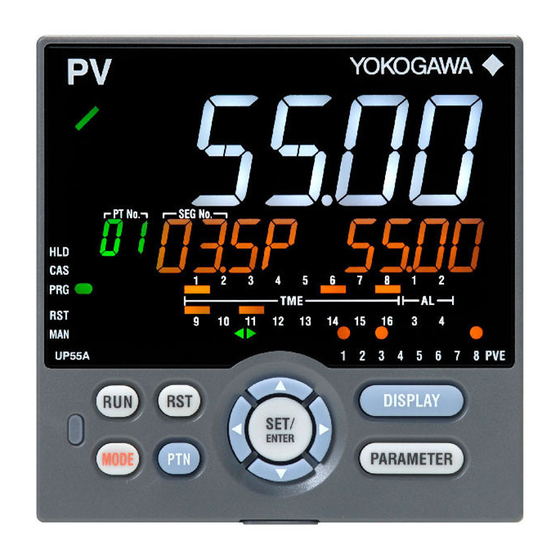

YOKOGAWA UTAdvanced UP55A Manuals

Manuals and User Guides for YOKOGAWA UTAdvanced UP55A. We have 3 YOKOGAWA UTAdvanced UP55A manuals available for free PDF download: User Manual, Technical Information, Operation Manual

YOKOGAWA UTAdvanced UP55A User Manual (516 pages)

Program

Brand: YOKOGAWA

|

Category: Controller

|

Size: 17 MB

Table of Contents

Advertisement

YOKOGAWA UTAdvanced UP55A Technical Information (25 pages)

Program Controller

Brand: YOKOGAWA

|

Category: Controller

|

Size: 0 MB

Table of Contents

YOKOGAWA UTAdvanced UP55A Operation Manual (14 pages)

Program Controller

Brand: YOKOGAWA

|

Category: Network Router

|

Size: 10 MB

Table of Contents

Advertisement