SMA 5000TL Operating Manual

Sunny tripower

Hide thumbs

Also See for 5000TL:

- Replacement manual (209 pages) ,

- Quick reference manual (122 pages) ,

- Service manual (38 pages)

Summary of Contents for SMA 5000TL

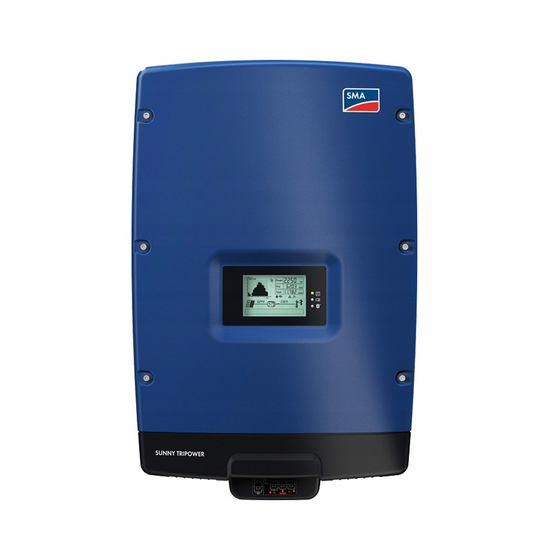

- Page 1 Operating Manual SUNNY TRIPOWER 5000TL/6000TL/7000TL/8000TL/9000TL/ 10000TL/12000TL ENGLISH STP5-12TL-20-BE-en-15 | Version 1.5...

- Page 2 The information contained in these documents is property of SMA Solar Technology AG. Any publication, whether in whole or in part, requires prior written approval by SMA Solar Technology AG. Internal reproduction used solely for the purpose of product evaluation or other proper use is allowed and does not require prior approval.

-

Page 3: Table Of Contents

SMA Solar Technology AG Table of Contents Table of Contents Information on this Document..........Validity ....................Target Group ..................Additional Information............... Symbols....................Nomenclature ..................Safety ..................Intended Use..................Safety Information ................Scope of Delivery ..............12 Product Description ..............14 Sunny Tripower.................. - Page 4 10 Disconnecting the Inverter from Voltage Sources ....57 11 Technical Data ................59 11.1 DC/AC....................59 11.1.1 Sunny Tripower 5000TL / 6000TL / 7000TL......59 11.1.2 Sunny Tripower 8000TL / 9000TL / 10000TL ......61 11.1.3 Sunny Tripower 12000TL ............. 63 11.2 General Data..................

- Page 5 SMA Solar Technology AG Table of Contents 11.4 Climatic Conditions................66 11.5 Equipment ..................67 11.6 Torques....................67 11.7 Multifunction Relay ................67 11.8 Electronic Solar Switch..............68 11.9 Data Storage Capacity ..............68 12 Accessories ................69 13 Contact ..................70 14 EU Declaration of Conformity ..........

-

Page 6: Information On This Document

• Knowledge of the applicable standards and directives • Knowledge of and compliance with this document and all safety information Additional Information Links to additional information can be found at www.SMA-Solar.com: Document title and content Document type Troubleshooting, Cleaning, Replacement of Varistors and De-... -

Page 7: Symbols

"SMA Bluetooth® Wireless Technology in Practice" Technical Information SMA BLUETOOTH range and safety "SMA Bluetooth® Wireless Technology" Technical Description Basics for planning a PV system with SMA BLUETOOTH "SMA Modbus® Interface" Technical Information Information on the commissioning and configuration of the SMA Modbus interface "SMA Modbus® Interface"... -

Page 8: Nomenclature

1 Information on this Document SMA Solar Technology AG Symbol Explanation Indicates a hazardous situation which, if not avoided, can result in death or serious injury Indicates a hazardous situation which, if not avoided, can result in minor or moderate injury... -

Page 9: Safety

Information "Leading Leakage Currents" at www.SMA-Solar.com). All components must remain within their permitted operating ranges at all times. The product must only be used in countries for which it is approved or released by SMA Solar Technology AG and the grid operator. - Page 10 2 Safety SMA Solar Technology AG Danger to life due to high voltages of the PV array When exposed to sunlight, the PV array generates dangerous DC voltage, which is present in the DC conductors and the live components of the inverter. Touching the DC conductors or the live components can lead to lethal electric shocks.

- Page 11 SMA Solar Technology AG 2 Safety Damage to the display or the type label due to the use of cleaning agents • If the inverter is dirty, clean the enclosure, the enclosure lid, the type label, the display and the LEDs with a damp cloth and clear water only.

-

Page 12: Scope Of Delivery

3 Scope of Delivery SMA Solar Technology AG Scope of Delivery Check the scope of delivery for completeness and any externally visible damage. Contact your distributor if the scope of delivery is incomplete or damaged. Figure 1: Components included in the scope of delivery... - Page 13 3 Scope of Delivery Position Quantity Designation Cylindrical screw M6 x 8 Operating manual, supplementary sheet with default set- tings, supplementary sheet with information on SMA Speedwire/Webconnect, installation manual of the DC connectors * One spare part for the enclosure lid included Operating Manual STP5-12TL-20-BE-en-15...

-

Page 14: Product Description

The type label uniquely identifies the inverter. You will require the information on the type label to use the product safely and when seeking customer sup- port from the SMA Service Line. You will find the following information on the type label: •... - Page 15 Observe the documentation Together with the red LED, this symbol indicates an error (for trou- bleshooting, see the service manual at www.SMA-Solar.com). BLUETOOTH Together with the blue LED, this symbol indicates active BLUETOOTH communication (only in inverters equipped as standard with BLUE- TOOTH).

- Page 16 4 Product Description SMA Solar Technology AG Symbol Explanation Operating principle of the ESS: • If the ESS is plugged in, the DC electric circuit is closed. • To interrupt the DC electric circuit, you must perform the following steps in the given order: –...

-

Page 17: Interfaces And Functions

SMA products, see www.SMA-Solar.com). SMA Speedwire/Webconnect The inverter is equipped with SMA Speedwire/Webconnect as standard. SMA Speedwire/ Webconnect is a type of communication based on the Ethernet standard. This enables inverter- optimized 10/100 Mbit data transmission between Speedwire devices in PV systems and the software Sunny Explorer. - Page 18 The inverter is equipped with a Modbus interface. The Modbus interface is deactivated by default and must be configured as needed. The Modbus interface of the supported SMA devices is designed for industrial use and has the following tasks: • Remote query of measured values •...

- Page 19 Sunny Portal. SMA OptiTrac Global Peak SMA OptiTrac Global Peak is an advancement of SMA OptiTrac and allows the operating point of the inverter to follow the optimal operating point of the PV array (MPP) precisely at all times. In addition, with the aid of SMA OptiTrac Global Peak, the inverter detects several maximum power points in the available operating range, such as may occur particularly with partially shaded strings.

-

Page 20: Mounting

5 Mounting SMA Solar Technology AG Mounting Requirements for Mounting Requirements for the mounting location: Danger to life due to fire or explosion Despite careful construction, electrical devices can cause fires. • Do not mount the product in areas containing highly flammable materials or gases. - Page 21 SMA Solar Technology AG 5 Mounting Figure 3: Permitted and prohibited mounting positions Operating Manual STP5-12TL-20-BE-en-15...

- Page 22 5 Mounting SMA Solar Technology AG Dimensions for mounting: 11 x 20 (5x) Ø 11 Ø 9 (4x) Figure 4: Position of the anchoring points (dimensions in mm (in)) STP5-12TL-20-BE-en-15 Operating Manual...

-

Page 23: Mounting The Inverter

SMA Solar Technology AG 5 Mounting Recommended clearances: If you maintain the recommended clearances, adequate heat dissipation will be ensured. Thus, you will prevent power reduction due to excessive temperature. ☐ Maintain the recommended clearances to walls as well as to other inverters or objects. - Page 24 5 Mounting SMA Solar Technology AG Risk of injury when lifting the inverter, or if it is dropped The inverter weighs 38 kg. There is risk of injury if the inverter is lifted incorrectly or dropped while being transported or when attaching it to or removing it from the wall mounting bracket.

- Page 25 SMA Solar Technology AG 5 Mounting • Mark the drill hole on the left-hand or right- hand side. If you want to secure the inverter with two safety screws, mark one drill hole on the left-hand side and one on the right- hand side.

-

Page 26: Electrical Connection

6 Electrical Connection SMA Solar Technology AG Electrical Connection Safety during Electrical Connection Danger to life due to high voltages of the PV array When exposed to sunlight, the PV array generates dangerous DC voltage, which is present in the DC conductors and the live components of the inverter. Touching the DC conductors or the live components can lead to lethal electric shocks. -

Page 27: Overview Of The Connection Area

SMA Solar Technology AG 6 Electrical Connection Overview of the Connection Area 6.2.1 View from Below Figure 6: Connection areas and enclosure openings at the bottom of the inverter Position Designation Positive DC connectors, input A Positive DC connectors, input B... -

Page 28: Interior View

6 Electrical Connection SMA Solar Technology AG 6.2.2 Interior View Figure 7: Connection areas in the interior of the inverter Position Designation Connecting terminal plate for the AC cable Multifunction relay with protective cover Slot for 485 Data Module Type B or SMA Power Control Module STP5-12TL-20-BE-en-15 Operating Manual... -

Page 29: Ac Connection

☐ If an external residual-current device is required, install a residual-current device which trips at a residual current of 100 mA or higher (for details on selecting a residual-current device, see the Technical Information ""Criteria for Selecting a Residual-Current Device"" at www.SMA- Solar.com). -

Page 30: Connecting The Inverter To The Utility Grid

In case of installations with long outdoor cabling routes, additional measures to reduce overvoltage category IV to overvoltage category III are required (see the Technical Information "Overvoltage Protection" at www.SMA-Solar.com). 6.3.2 Connecting the Inverter to the Utility Grid Requirements: ☐... -

Page 31: Connecting Additional Grounding

SMA Solar Technology AG 6 Electrical Connection Danger of crushing fingers when locking levers snap shut The locking levers close by snapping down fast and hard. • Press the locking levers of the connecting terminal plate for the AC cable down with your thumb only. -

Page 32: Connecting The Multifunction Relay

6 Electrical Connection SMA Solar Technology AG Connecting the Multifunction Relay 6.4.1 Procedure for connecting the multifunction relay Procedure Select for which operating mode you would like to use the Section 6.4.2, page 32 multifunction relay. Connect to the multifunction relay according to the operat- Section 6.4.3, page 32... - Page 33 SMA Solar Technology AG 6 Electrical Connection Operating mode Connection option Controlling loads via the multifunction relay or charging batteries de- Control via communica- pending on the power production of the PV system tion (ComCtl) Controlling loads via the multifunction relay or charging batteries de-...

- Page 34 6 Electrical Connection SMA Solar Technology AG Using the Multifunction Relay as a Fault Indicator Contact You can use the multifunction relay as a fault indicator contact and have an error or smooth operation of the inverter displayed or signaled via a suitable display device. You can connect multiple inverters to one fault indicator or operation indicator, as needed.

- Page 35 SMA Solar Technology AG 6 Electrical Connection Controlling loads via the multifunction relay or charging batteries depending on the power production of the PV system The multifunction relay can control loads or charge batteries power-dependently. To enable this function, you must connect a contactor (K1) to the multifunction relay. The contactor (K1) switches the operating current for the load on or off.

- Page 36 6 Electrical Connection SMA Solar Technology AG Reporting the switching status of the grid relay The multifunction relay can trip a signal to the grid operator as soon as the inverter connects to the utility grid. To enable this function, the multifunction relays of all inverters must be connected in parallel.

-

Page 37: Connection To The Multifunction Relay

Operating the multifunction relay and 485 Data Module Type B or SMA Power Control Module in parallel If you want to operate the multifunction relay and the 485 Data Module Type B or the SMA Power Control Module in parallel, a voltage of no more than 30 V DC or 25 V AC may be connected to the multifunction relay. Operating Manual... -

Page 38: Dc Connection

6 Electrical Connection SMA Solar Technology AG Procedure: 1. When connecting to the utility grid, fuse the multifunction relay with a separate circuit breaker. Danger to life due to high voltages • Ensure that the inverter is disconnected from all voltage sources (see Section 10, page 57). -

Page 39: Connecting The Pv Array

SMA Solar Technology AG 6 Electrical Connection ☐ The same number of series-connected PV modules must be connected to each string. ☐ The maximum input current per string must be maintained and must not exceed the through- fault current of the DC connectors (see Section 11 "Technical Data", page 59). - Page 40 6 Electrical Connection SMA Solar Technology AG 4. Ensure that there is no ground fault in the PV array (see service manual at www.SMA- Solar.com). 5. Check whether the DC connectors have the correct polarity. If the DC connector is equipped with a DC cable of the wrong polarity, the DC connector must be assembled again.

- Page 41 SMA Solar Technology AG 6 Electrical Connection Damage to the inverter due to moisture ingress The inverter is only properly sealed when all unused DC inputs are closed with DC connectors and sealing plugs. • Do not insert the sealing plugs directly into the DC inputs on the inverter.

-

Page 42: Commissioning

Procedure: 1. Determine the rotary switch position for your country and purpose. Call up the Technical Information "Overview of the Rotary Switch Settings" at www.SMA-Solar.com. Danger to life due to high voltages • Ensure that the inverter is disconnected from all voltage sources and that the enclosure lid is removed (see Section 10, page 57). -

Page 43: Setting The Netid

If the inverter is equipped with BLUETOOTH, you can set the NetID of the inverter. By default, the NetID is set to 1 for all SMA inverters and SMA communication products with BLUETOOTH. If your PV system consists of an inverter and a maximum of one further BLUETOOTH device (e.g. computer with BLUETOOTH interface or SMA communication product), you can leave the NetID set to 1. - Page 44 7 Commissioning SMA Solar Technology AG All BLUETOOTH devices in a PV system must have the same NetID. You can set a new NetID in the inverter by means of the rotary switch C. Figure 12: Positions of rotary switch C...

-

Page 45: Commissioning The Inverter

SMA Solar Technology AG 7 Commissioning 3. To deactivate communication via BLUETOOTH, set the rotary switch C to position 0 using a flat- blade screwdriver (blade width: 2.5 mm). This will protect your PV system from unauthorized access. ☑ The inverter will adopt the setting after commissioning. This can take up to five minutes. - Page 46 • Once the DC input voltage is sufficiently high and the grid-connection conditions are met, the inverter will start operation. ✖ The red LED is glowing and an error message and event number appear in the display? • Rectify the error (see the service manual at www.SMA-Solar.com). STP5-12TL-20-BE-en-15 Operating Manual...

-

Page 47: Configuration

SMA Solar Technology AG 8 Configuration Configuration Configuration Procedure Once you have commissioned the inverter, you may have to adjust various settings via the rotary switches in the inverter or via a communication product. This section describes the procedure for configuration and gives an overview of the steps you must perform in the prescribed order. -

Page 48: Connecting The Inverter To The Network

Additionally required material (not included in the scope of delivery): ☐ One mating plug for RJ45 pin connector in accordance with IEC 61076-3-106, model 4 with push-pull lock SMA Solar Technology AG recommends the plug sets "STX V4 RJ45" from "Telegärtner" or "IE-PS-V04P-RJ45-FH" from "Weidmüller". ☐ 1 network cable Cable requirements: The cable length and quality affect the quality of the signal. -

Page 49: Integrating The Inverter Into The Network

You will not need to carry out network configuration. If the router does not support DHCP, automatic network configuration will not be possible and you will need to use the SMA Connection Assist to integrate the inverter into the network. Requirements: ☐... -

Page 50: Configuring The Modbus Function

☐ The inverter must be registered in the communication product. ☐ The changes to the grid-relevant parameters must be approved by the responsible grid operator. ☐ When changing grid-relevant parameters, the SMA Grid Guard code must be available (see "Application for SMA Grid Guard Code" at www.SMA-Solar.com). Procedure: 1. -

Page 51: Setting The Tripping Threshold Of The Residual-Current Device

If a residual-current device with a tripping threshold of 30 mA is specified and installed, you must set the parameter RCD adjustment to 30 mA (for further information, see the Technical Information ""Leading Leakage Currents"" at www.SMA-Solar.com). The basic procedure for changing operating parameters is explained in another section (see Section 8.5 "Changing Operating Parameters", page 49). -

Page 52: Setting Sma Optitrac Global Peak

Setting SMA OptiTrac Global Peak For partially shaded PV modules, you should set the interval at which the inverter is to optimize the MPP of the PV system. If you do not want to use SMA OptiTrac Global Peak feature, you can deactivate the feature. -

Page 53: Operation

If an error occurs, the error message and the correspond- ing event number will be shown in the display. The error must be rectified by a qualified person (for troubleshoot- ing, see the service manual at www.SMA-Solar.com). Blue LED glowing For inverters including BLUETOOTH as standard equip- ment: BLUETOOTH communication is activated. - Page 54 9 Operation SMA Solar Technology AG Figure 13: Layout of the display (example) Position Symbol Explanation Current power Energy on the current day Total amount of energy fed in In inverters with BLUETOOTH: active BLUETOOTH connection In inverters with BLUETOOTH: strength of BLUETOOTH signal Active connection to a Speedwire network Active connection to Sunny Portal...

-

Page 55: Activating And Operating The Display

You can operate the display by tapping on the enclosure lid (see Section 9.3, page 55). The displayed error must be rectified on-site by a qualified per- son (for troubleshooting, see service manual at www.SMA-So- lar.com). The displayed error cannot be rectified on-site. -

Page 56: Calling Up Display Messages Of The Start-Up Phase

9 Operation SMA Solar Technology AG 2. To move to the next line, tap on the enclosure lid once. 3. In order to switch between the power curve of the last 16 feed-in hours and the energy yields of the last 16 days in the diagram, tap on the enclosure lid once. -

Page 57: Disconnecting The Inverter From Voltage Sources

SMA Solar Technology AG 10 Disconnecting the Inverter from Voltage Sources 10 Disconnecting the Inverter from Voltage Sources Prior to performing any work on the inverter, always disconnect it from all voltage sources as described in this section. Always adhere to the prescribed sequence. - Page 58 10 Disconnecting the Inverter from Voltage Sources SMA Solar Technology AG 10. Use an appropriate measuring device to ensure that no voltage is present at the AC connecting terminal plate between L1 and PE, L2 and PE, and L3 and PE. Insert the test probe into each round opening of the terminal.

-

Page 59: Technical Data

SMA Solar Technology AG 11 Technical Data 11 Technical Data 11.1 DC/AC 11.1.1 Sunny Tripower 5000TL / 6000TL / 7000TL DC Input STP 5000TL-20 STP 6000TL-20 STP 7000TL-20 Maximum DC power at 5100 W 6125 W 7175 W cos φ = 1 Maximum input voltage 1000 V 1000 V 1000 V MPP voltage range 245 V to 800 V... - Page 60 11 Technical Data SMA Solar Technology AG AC Output STP 5000TL-20 STP 6000TL-20 STP 7000TL-20 Rated power at 230 V, 50 Hz 5000 W 6000 W 7000 W Maximum apparent AC power 5000 VA 6000 VA 7000 VA at cos phi = 1 Rated grid voltage ∼3/N/PE, 230 V / ∼3/N/PE, 230 V / ∼3/N/PE, 230 V /...

-

Page 61: Sunny Tripower 8000Tl / 9000Tl / 10000Tl

SMA Solar Technology AG 11 Technical Data Efficiency STP 5000TL-20 STP 6000TL-20 STP 7000TL-20 Maximum efficiency, η 98 % 98 % 98 % European weighted efficiency, 97.1 % 97.4 % 97.5 % η 11.1.2 Sunny Tripower 8000TL / 9000TL / 10000TL DC Input STP 8000TL-20 STP 9000TL-20 STP 10000TL-20 Maximum DC power at cos φ = 1 8200 W... - Page 62 11 Technical Data SMA Solar Technology AG AC Output STP 8000TL-20 STP 9000TL-20 STP 10000TL-20 Rated power at 230 V, 50 Hz 8000 W 9000 W 10000 W Maximum apparent AC power at 8000 VA 9000 VA 10000 VA cos φ = 1 Rated grid voltage ∼3/N/PE, ∼3/N/PE, ∼3/N/PE, 230 V / 400 V 230 V / 400 V 230 V / 400 V...

-

Page 63: Sunny Tripower 12000Tl

SMA Solar Technology AG 11 Technical Data Efficiency STP 8000TL-20 STP 9000TL-20 STP 10000TL-20 Maximum efficiency, η 98 % 98 % 98 % European weighted efficiency, η 97.6 % 97.6 % 97.6 % 11.1.3 Sunny Tripower 12000TL DC Input STP 12000TL-20 Maximum DC power at cos φ = 1 12275 W Maximum input voltage 1000 V... -

Page 64: General Data

European weighted efficiency, η 97.9 % 11.2 General Data Width x height x depth, with Electronic So- 470 mm x 730 mm x 240 mm lar Switch Weight of STP 5000TL-20 / 6000TL-20 / 37 kg 7000TL-20 / 8000TL-20 / 9000TL-20 / 10000TL-20 Weight of STP 12000TL-20 38 kg Length x width x height of the packaging 798 mm x 598 mm x 398 mm... - Page 65 SMA Solar Technology AG 11 Technical Data Climatic category in accordance with 4K4H IEC 60721-3-4 Environmental category Outdoors Pollution degree outside the enclosure Pollution degree inside the enclosure Operating temperature range -25°C to +60°C Maximum permissible value for relative humid- 100 %...

-

Page 66: Protective Devices

Electronic Solar Switch, SUNCLIX DC connector AC short-circuit current capability Current control Grid monitoring SMA Grid Guard 4 Maximum permissible fuse protection 32 A Ground-fault monitoring for STP 5000TL-20 / Insulation monitoring: R > 385 kΩ 6000TL-20 / 7000TL-20 / 8000TL-20 / 9000TL-20 Ground-fault monitoring for STP 10000TL-20 / Insulation monitoring: R > 200 kΩ... -

Page 67: Equipment

SMA Solar Technology AG 11 Technical Data Extended humidity range 0% to 100% Extended air pressure range 79.5 kPa to 106 kPa Transport in accordance with IEC 60721-3-2, Class 2K3 Temperature range -25°C to +70°C 11.5 Equipment DC connection SUNCLIX DC connector AC-Anschluss Spring-cage terminal Display LC graphic display... -

Page 68: Electronic Solar Switch

11 Technical Data SMA Solar Technology AG 11.8 Electronic Solar Switch Electrical endurance in the event of short circuit, At least 50 switching operations at nominal current of 30 A Maximum switching current 30 A Maximum switching voltage 1000 V Maximum power 12 kW Degree of protection when plugged in... -

Page 69: Accessories

SMA Solar Technology AG 12 Accessories 12 Accessories You will find the accessories for your product in the following overview. If required, these can be ordered from SMA Solar Technology AG or your distributor. Designation Brief description SMA order number SMA Power Control Module Multifunction interface for implementing... -

Page 70: Contact

13 Contact SMA Solar Technology AG 13 Contact If you have technical problems with our products, please contact the SMA Service Line. We require the following information in order to provide you with the necessary assistance: • Inverter device type • Inverter serial number •... - Page 71 SMA France S.A.S. Ελλάδα SMA Service Partner AKTOR FM. Lyon Κύπρος Αθήνα +33 472 22 97 00 +30 210 8184550 SMA Online Service Center : www.SMA-Service.com SMA Online Service Center: www.SMA-Service.com España SMA Ibérica Tecnología Solar, United SMA Solar UK Ltd. S.L.U.

- Page 72 +562 2820 2101 08600SUNNY (08600 78669) Perú International: +27 (0)21 826 0600 SMA Online Service Center: www.SMA-Service.com Australia SMA Australia Pty Ltd. Other countries International SMA Service Line Sydney Niestetal Toll free for Australia: 00800 SMA SERVICE 1800 SMA AUS (+800 762 7378423) (1800 762 287) International: +61 2 9491 4200...

-

Page 73: Eu Declaration Of Conformity

(EMC) • Low Voltage Directive 2014/35/EU (29.3.2014 L 96/357-374) (LVD) SMA Solar Technology AG confirms herewith that the inverters described in this document are in compliance with the fundamental requirements and other relevant provisions of the above- mentioned directives. The entire EU Declaration of Conformity can be found at www.SMA- Solar.com. - Page 74 www.SMA-Solar.com...

Need help?

Do you have a question about the 5000TL and is the answer not in the manual?

Questions and answers