Table of Contents

Advertisement

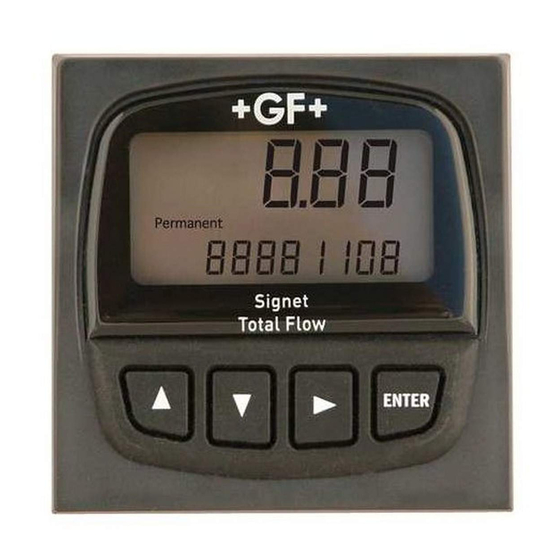

Signet 8150 Flow Totalizer

*3-8150.090-1*

3-8150.090-1

Rev. G 07/11

Topic:

1. Description

2. Speci¿ cations

3. Installation

4. Wiring

5. Battery Installation and Replacement

6. Operation

7. Security Code

8. Totalizer operation

9. Automatic Calibration

1. Description

The Signet 8150 Flow Totalizer is a battery-powered instrument capable of providing uninterrupted À ow and total volume information for

4 years and beyond. The unique features of the 8150 include:

• Easy setup and display selection with 4-button keypad.

• User selectable security access to prevent unwanted programming changes.

• Displays À ow rate from 0.001 to 9999 engineering units with an auto-ranging decimal point.

• Three totalizers, one permanent and two that are independently resettable.

• Displays elapsed time between operating periods.

• Integral mount and panel mount options.

• 3.6 V Lithium batteries last 4 years nominal in most applications.

• Non-volatile memory stores all programming and totalizer values even when batteries are removed.

Dimensions

41 mm

(1.6 in.)

97 mm

(3.8 in.)

SIDE VIEW

2. Specifi cations

General

Compatibility:

Input Frequency Range:

Accuracy:

Enclosure:

•

Rating:

•

Dimensions:

•

Case material:

•

Keypad material:

Display: LCD type

• 4-digit upper line: À ow rate

• 8-digit lower line: Three totalizer options:

Permanent Totalizer for life of instrument

Totalizer 1: resettable from keypad or remote 30 m (100 ft)

Totalizer 2: resettable with security code only

• Display Contrast: Automatic

English

Page

1

1

2

4

4

5

6

7

9

Optional

92 mm

Rear

(3.6 in.)

Cover

96 mm

(3.8 in.)

56 mm

(2.2 in.)

FRONT VIEW

Panel Mount

Signet 515, 525 Flow Sensors

1 to 400 Hz

±0.5% of reading

NEMA 4X/IP65 (front panel)

1/4 DIN (96 x 96 x 50 mm)

(3.8 x 3.8 x 2.0 in.)

PBT resin

Sealed 4-key silicon rubber

Topic:

10.

Flow K-Factor

11. Total K-Factor

12. Time Base

13. Decimal point placement

14. Speed

15. Sensitivity

16. Troubleshooting

17. Flow and Totalizer K-Factor selection

18. K-Factor Charts

19.

Ordering Information

96 mm

96 mm

(3.8 in.)

(3.8 in.)

42 mm

60 mm

(1.7 in.)

(2.3 in.)

102 mm

(4.0 in.)

Integral Mount

Electrical:

•

Battery:

•

Sensor power output:

•

Battery life:

•

Low Battery indication: Battery symbol on LCD display

Environmental:

•

Operating Temperature: –10 to 65 °C (14 to 149 °F)

•

Storage Temperature:

•

Relative Humidity:

Shipping Weight:

Quality Standards:

•

CE, CUL, UL

•

EN

•

Manufactured under ISO 9001 and 14001

China RoHS (Go to www.gfsignet.com for details)

English

82 mm

(3.2 in.)

106 mm

(4.2 in.)

Universal Mount

Two 3.6 V Lithium thionyl chloride,

AA-size

+3.6 VDC @ 20 —A

4 years nominal @ 50 °C (122 °F)

–40 to 100 °C (–40 to 212 °F)

0 to 95% Non-condensing

0.5 kg (1.1 lbs.)

Page

10

11

12

13

14

15

16

16

17

20

Advertisement

Table of Contents

Summary of Contents for Signet 8150

- Page 1 Ordering Information 1. Description The Signet 8150 Flow Totalizer is a battery-powered instrument capable of providing uninterrupted À ow and total volume information for 4 years and beyond. The unique features of the 8150 include: • Easy setup and display selection with 4-button keypad.

-

Page 2: Installation

Route the output wires through the conduit port in the conduit base. Use a liquid-tight connector or conduit connector to prevent moisture from entering the assembly. Conduit Base Place totalizer or cover onto conduit base and twist to lock in Conduit place. Ports Sensor wires 8150 Flow Totalizer... -

Page 3: Panel Cutout

3.7 Panel Mount Installation Detail • The 8150-1P Panel-mount Totalizer is a standard ¼ DIN package. Use a 92 x 92 mm punch tool to make the panel cutout. • Minimum spacing of 25 mm (1 in) between panel units is recommended. -

Page 4: Battery Installation And Replacement

5. Battery Installation and Replacement Two 3.6 V Lithium thionyl chloride batteries, AA-size (7400-0011) are included with the Totalizer. NOTE: THE 8150 WILL NOT OPERATE WITH STANDARD 1.5 V ALKALINE BATTERIES. USE 3.6 V LITHIUM BATTERIES ONLY! • Observe polarity! Note that both batteries should face the same direction. -

Page 5: Operation

6. Operation The 8150-1 display shows the À ow rate in large numerals and a totalizer value in smaller numerals. Any one of three different totalizers can be selected as the standard display (See section 8 for detailed information on the totalizers). -

Page 6: Changing The Security Code

7. Changing the Security Code The security code prevents unauthorized tampering with calibration and operational settings in the 8150. The factory standard code is 0-0-0-0. Change the code to any 4-digit number by following these steps: Example: Change the security code from the factory standard 0-0-0-0 to custom setting 1-0-0-1... - Page 7 8. Totalizer Setup and Operation During normal operation the 8150 displays the À ow rate and one selected totalizer value. Any one of the three totalizers can be set as the standard display: The other two totalizers can be viewed by pressing the keypad. The display will automatically return to the standard selection after ¿...

- Page 8 To prevent this loss, enter the security code, then enter any menu item and store the setting. Whenever the 8150 stores a setting, it also stores all current totalizer data: Enter the security code.

- Page 9 If the À ow rate display is erratic, set the SPEED (section 14) to 120 seconds during the AutoCAL procedure. • The timebase on the reference meter must be the same as the 8150 Totalizer. Example: The Totalizer fl ow rate shows 60 GPM, while an external reference indicates a true fl ow rate of 70 GPM.

- Page 10 As long as any element is À ashing, you can abort Press the UP and DOWN keys the change and return to the original value by simultaneously from the main menu to pressing UP and DOWN keys simultaneously. return to normal operation. 8150 Flow Totalizer...

- Page 11 Change the Flow K-Factor to 432 pulses per gallon. The result: The totalizer must count 10% fewer pulses from the À ow sensor to register one gallon, so both the totalizer and the À ow rate will increase by 10%. 8150 Flow Totalizer...

- Page 12 As long as any element is À ashing, you can abort Press the UP and DOWN keys the change and return to the original value by simultaneously from the main menu to pressing UP and DOWN keys simultaneously. return to normal operation. 8150 Flow Totalizer...

- Page 13 As long as any element is À ashing, you can abort Press the UP and DOWN keys the change and return to the original value by simultaneously from the main menu to pressing UP and DOWN keys simultaneously. return to normal operation. 8150 Flow Totalizer...

- Page 14 As long as any element is À ashing, you can abort Press the UP and DOWN keys the change and return to the original value by simultaneously from the main menu to pressing UP and DOWN keys simultaneously. return to normal operation. 8150 Flow Totalizer...

- Page 15 15. Sensitivity The SENSITIVITY setting determines how the 8150 responds to sudden surges in the À ow rate. It "overrides" the SPEED function just long enough to allow an actual change in À ow rate to be displayed, then resumes the averaging. The result is a smooth À ow display and a quick response to large shifts in the À...

-

Page 16: Troubleshooting

NOTE: If the Flow K-Factor is changed, be sure to make a corresponding change to the TOTAL K-Factor. 1. There is no À ow in the pipe. 8150 is not receiving a signal from 2. Flow sensor is not turning due to blockage or damage. the À ow sensor. - Page 17 18. K-Factor Charts 18.1 515 Paddlewheel Flow Sensor The following calibration data is reprinted from the instruction manual for the Signet 515 Flow sensor for your convenience. PIPE 515/8510-XX PIPE 515/8510-XX PIPE 515/8510-XX SIZE FITTING SIZE FITTING SIZE FITTING U.S. GAL LITERS U.S.

- Page 18 18.1 515 Paddlewheel Flow Sensor (continued) 18.2 525 Metalex Flow Sensor The following data is reprinted from the Signet 525 Metalex Flow sensor manual for your convenience. 515/8510-XX SCH 40S STAINLESS STEEL PIPE PIPE PER ANSI B36.19 FITTING U.S. LITERS...

- Page 19 À uid with possibly serious consequences, such as damage to equipment and serious personal injury. Retaining nuts that may have been in contact with such substances, e.g., due to leakage or spilling, must be replaced. 8150 Flow Totalizer...

-

Page 20: Ordering Information

Flow Sensor (3-8510-XX) Georg Fischer Signet LLC, 3401 Aerojet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057 For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090 For the most up-to-date information, please refer to our website at www.gfsignet.com...

Need help?

Do you have a question about the 8150 and is the answer not in the manual?

Questions and answers