Sandpiper Signature Series Service & Operating Manual

Heavy duty flap valve design level 6

Hide thumbs

Also See for Signature Series:

- Service & operating manual (18 pages) ,

- Service & operating manual (23 pages)

Table of Contents

Advertisement

SERVICE & OPERATING MANUAL

Original Instructions

Certified Quality

ISO 9001 Certified

ISO 14001 Certified

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone (419) 524.8388

Fax (419) 522.7867

SANDPIPERPUMP.COM

© Copyright 2017 Warren Rupp, Inc.

All rights reserved

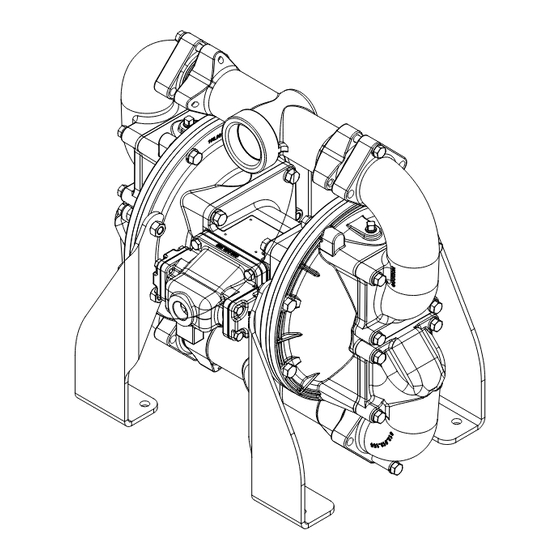

Model HDF2

& HDF50

Heavy Duty Flap Valve

Design Level 6

.

s a n d p i p e r p u m p

c o m

Advertisement

Table of Contents

Summary of Contents for Sandpiper Signature Series

- Page 1 SERVICE & OPERATING MANUAL Original Instructions Certified Quality Model HDF2 & HDF50 Heavy Duty Flap Valve Design Level 6 ISO 9001 Certified ISO 14001 Certified Warren Rupp, Inc. A Unit of IDEX Corporation 800 N. Main St., Mansfield, Ohio 44902 USA Telephone (419) 524.8388 Fax (419) 522.7867 SANDPIPERPUMP.COM...

- Page 2 Safety Information IMPORTANT WARNING When used for toxic or aggressive fluids, the pump should Read the safety warnings and instructions in this manual always be flushed clean prior to disassembly. before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty.

-

Page 3: Table Of Contents

Table of Contents SECTION 1: PUMP SPECIFICATIONS ....1 • Explanation of Nomenclature • Performance • Materials • Dimensional Drawings SECTION 2: INSTALLATION & OPERATION ..4 • Principle of Pump Operation • Recommended Installation Guide • Troubleshooting Guide SECTION 3: EXPLODED VIEW ......7 •... -

Page 4: Explanation Of Nomenclature

Explanation of Pump Nomenclature Your Model #: _____ (fill in from pump nameplate) Pump Pump Pump Discharge Diaphragm/ Design Options Construction Series Design Size Porting Valve Level XXXX, Model #: Pump Series Diaphragm Check Valve Materials Construction HD Heavy Duty Aluminum Wetted, Aluminum Air Neoprene - Urethane Nitrile... -

Page 5: Performance

Performance HDF2/HDF50 SUCTION/DISCHARGE PORT SIZE MODEL HDF2 Performance Curve Performance based on the following: elastomer fitted pump, flooded suction, water at ambient temperature. AIR CONSUMPTION • HDF2: 2" (50mm) NPT(F) The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. SCFM (M 3 /hr) •... -

Page 6: Dimensional Drawings

Dimensional Drawings HDF2 & HDF50 Heavy Duty Flap Valve Dimensions in inches (metric dimensions in brackets). Dimensional Tolerance .125" (3mm). 13.56 21.64 7.06 OPTIONAL VERTICAL SUCTION PORT 2.59 2"NPT [2" BSPT] SUCTION PORT 2.61 3/4" NPT AIR INLET 20.30 19.87 17.69 9.81 2.55... -

Page 7: Principle Of Pump Operation

UNIVERSAL ALL AODD Principle of Pump Operation Principle of Pump Operation Air-Operated Double Diaphragm (AODD) pumps are powered by compressed The pump primes as a result of the suction stroke. The suction stroke lowers (P3) air or nitrogen. the chamber pressure increasing the chamber volume. -

Page 8: Recommended Installation Guide

UNIVERSAL ALL AODD, EXCEPT FLAP Recommended Installation Guide Recommended Installation Guide Unregulated Air NOTE: Surge Suppressor and Supply to Surge Piping must be Supported After Suppressor the Flexible Connection Flexible Connector Pipe Connection Style Optional Vacuum Gauge Shut O Valve Surge Suppressor Suction Pressure Gauge... -

Page 9: Troubleshooting Guide

Troubleshooting Guide Symptom: Potential Cause(s): Recommendation(s): Pump Cycles Once Deadhead (system pressure meets or exceeds air Increase the inlet air pressure to the pump. Pump is designed for 1:1 pressure ratio at zero flow. supply pressure). (Does not apply to high pressure 2:1 units). Air valve or intermediate gaskets installed incorrectly. -

Page 10: Composite Repair Parts Drawing

Composite Repair Parts Drawing ITEM TORQUE: 360 IN-LBS (40 N-m) TORQUE: 480 IN-LBS (54 N-m) Service & Repair Kits 476.247.000 Air End Kit Sleeve and Spool Set, Pilot Valve Body Assembly, Bumpers, Bushings, Gaskets, O-rings, Seals, and Plungers 476.314.000 Air End Refurbishment Kit Bumpers, Bushings, Gaskets, O-rings, Seals, Plungers, and Retaining Rings 476.270.360... -

Page 11: Composite Repair Parts List

Composite Repair Parts List Item Part Number Description Item Part Number Description 360.041.379 Gasket, Pilot Valve 031.019.156 Air Valve Assy (Aluminum Center - 360.048.425 Gasket, Air Valve see pg #10 for details) 518.001.157 Manifold (w/ aluminum wetted) 031.019.010 Air Valve Assy (Cast Iron Center) 1 518.001.010 Manifold (w/ cast iron wetted) 031.019.001... -

Page 12: Material Codes

R E C YC L I N G (Some Applications) 644..Santoprene /PTFE ® (Compression Mold) 656 ..Santoprene Diaphragm and ® Many components of SANDPIPER AODD ® 359..Urethane Rubber Check Balls/EPDM Seats pumps are made of recyclable materials. 360..Nitrile Rubber Color coded: RED 661..EPDM/Santoprene ®... -

Page 13: Air Distribution Valve Assembly

Air Distribution Valve Assembly Air Distribution Valve Assembly Air Distribution Valve Servicing See repair parts drawing, remove screws. Step 1: Remove Hex Head Cap Screws (1-G). Step 2: Remove end cap (1-F), gasket (1-E) and bumper (1-C). Step 3: Remove spool part of (1-B) (caution: do not scratch). Step 4: Press sleeve (1-B) from body (1-A). -

Page 14: Pilot Valve Assembly

Pilot Valve Assembly Pilot Valve Assembly Pilot Valve Servicing PILOT VALVE ASSEMBLY PARTS LIST With Pilot Valve removed from pump. Item Part Number Description Step 1: Remove snap ring (3-F). 095.073.001 Pilot Valve Assembly Step 2: Remove sleeve (3-B), inspect O-Rings (3-C), 095.070.558 Valve Body 755.025.000... -

Page 15: Diaphragm Servicing

Turn the pump over of diaphragm plate assemblies utilized throughout the and thread the second diaphragm / inner plate onto Sandpiper product line: Outer plate with a threaded the diaphragm rod. Turn the diaphragm until the stud, diaphragm, and a threaded inner plate. - Page 16 Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory. Warren Rupp brands include Warren Rupp ,SANDPIPER ® ® SANDPIPER Signature Series , MARATHON , Porta-Pump , SludgeMaster™ and Tranquilizer ®...

- Page 17 EC / EU Declaration of Conformity The objective of the declaration described is in conformity with the relevant Union harmonisation legislation: Directive 94/9/EC (until April 19, 2016) and Directive 2014/34/EU (from April 20, 2016). Manufacturer: Applicable Standard: Warren Rupp, Inc. EN13463-1: 2001 A Unit of IDEX Corportion EN13463-5: 2003...

Need help?

Do you have a question about the Signature Series and is the answer not in the manual?

Questions and answers