Table of Contents

Advertisement

Quick Links

Table of Contents

Engineering Data and Performance Curve............................................................ 1

Explanation of Pump Nomenclature ...................................................................... 2

Dimensions ............................................................................................................ 3

Principle of Operation ............................................................................................ 4

Installation and Start-Up ........................................................................................ 4

Air Supply .............................................................................................................. 4

Installation Guide ................................................................................................... 5

Air Inlet & Priming .................................................................................................. 6

Air Exhaust ............................................................................................................ 6

Between Uses ....................................................................................................... 6

Check Valve Servicing ........................................................................................... 6

Diaphragm Servicing ............................................................................................. 6

Air Valve Lubrication .............................................................................................. 7

: Externally Serviceable Air Distribution System ................................ 7

®

Pilot Valve .............................................................................................................. 8

Pilot Valve Actuator ................................................................................................ 8

Service Instructions: Troubleshooting ................................................................... 9

Warranty ................................................................................................................ 9

Recommended Accessories, Available Service Kits .............................................. 9

Temperature Limitations ...................................................................................... 10

Recycling ............................................................................................................. 10

Material Codes .................................................................................................... 11

Composite Repair Parts List ...........................................................................12-14

Composite Repair Drawing.................................................................................. 15

CE Declaration of Conformity - Machinery .......................................................... 16

CE Declaration fo Conformity - ATEX .................................................................. 17

Warren Rupp, Inc. • A Unit of IDEX Corporation • 800 N. Main St., Mansfield, Ohio 44902 USA

hdb2dl3sm-rev0217

SERVICE & OPERATING MANUAL

See pages 18

II 2GD T5

for ATEX ratings

Telephone (419) 524-8388 • Fax (419) 522-7867 • warrenrupp.com

©Copyright 2017 Warren Rupp, Inc. All rights reserved.

Type 3

Advertisement

Table of Contents

Summary of Contents for Sandpiper HDB2 Type 3

-

Page 1: Table Of Contents

SERVICE & OPERATING MANUAL Original Instructions See pages 18 Model HDB2 Type 3 II 2GD T5 for ATEX ratings Table of Contents Engineering Data and Performance Curve............1 Explanation of Pump Nomenclature ..............2 Dimensions ......................3 Principle of Operation .................... 4 Installation and Start-Up .................. - Page 2 Safety Information IMPORTANT WARNING When used for toxic or aggressive fluids, the pump should Read the safety warnings and instructions in this manual always be flushed clean prior to disassembly. before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty.

-

Page 3: Engineering Data And Performance Curve

5%. 30(51) 40(68) 50(85) 60(101.9) 70(118.9) 80(135.9) 90(152.9) 95(161.4) 100(169.9) U.S. Gallons per minute Liters per minute CAPACITY SANDPIPER pumps are designed to be powered only by compressed air. ® hdb2smdl3sm-rev0217 Model HDB2 Page 1... -

Page 4: Explanation Of Pump Nomenclature

Explanation of Pump Nomenclature, HDB2 Your Model #: _____ (fill in from pump nameplate) Pump Pump Pump Discharge Diaphragm/ Design Options Construction Series Design Size Porting Valve Level XXXX, Model #: Pump Series Diaphragm Check Valve Materials Design Level HD Heavy Duty Nitrile FKM with PTFE Pump Design... -

Page 5: Dimensions

Dimensions: HDB2 DISCHARGE PORT Dimensions are ± 1/8" 2” NPT(F) Figures in parenthesis = millimeters AIR INLET 3/4” NPT(F) DISCHARGE PORTING SUCTION PORT 2” NPT(F) * Indicates dimensions with suction and discharge ports rotated 180° to a vertical position. AIR EXHAUST 3/4”... -

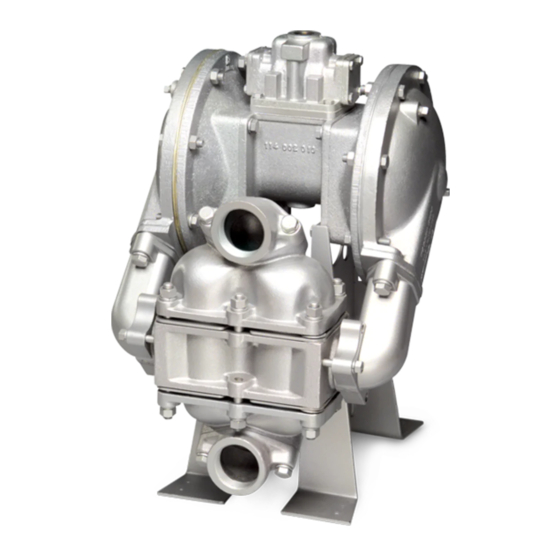

Page 6: Original Instructions Model Hdb2 Type

SERVICE & OPERATING MANUAL Original Instructions Model HDB2 Type 3 See pages 18 & 19 II 2GD T5 for ATEX ratings PLEASE NOTE! The photos shown in this manual are for general instruction only. YOUR SPECIFIC MODEL MAY NOT BE SHOWN. Always refer to the parts list and exploded view drawing for your specific model when installing, disasembling or servicing your pump. -

Page 7: Installation Guide

INSTALLATION GUIDE Top Discharge Ball or Flap Valve Unit CAUTION Available from The air exhaust should be Warren Rupp piped to an area for safe disposition of the product Tranquilizer /Surge Supressor being pumped, in the event ® of a diaphragm failure. Filter/Regulator Surge Suppressor... -

Page 8: Air Inlet & Priming

AIR INLET & PRIMING For start-up, open an air valve approximately 1/2" to 3/4" turn. After the unit primes, an air valve can be opened to increase flow as desired. If opening the valve increases cycling rate, but does not increase flow rate, cavitation has occurred, and the valve should be closed slightly. -

Page 9: Air Valve Lubrication

A Note about Air Valve Lubrication The SANDPIPER pump’s pilot valve and main air valve assemblies are designed to operate WITHOUT lubrication. This is the preferred mode of operation. There may be instances of personal preference, or poor quality air supplies when lubrica- tion of the compressed air supply is required. -

Page 10: Pilot Valve

This can cause the spool to stick in a position that prevents the pump from operating. If this is the case, the sleeve and spool set should be removed from the valve body for cleaning and further inspection. Remove the spool from the sleeve. Using an arbor press or bench vise (with an improvised mandrel), press the sleeve from the valve body. -

Page 11: Service Instructions: Troubleshooting

TROUBLESHOOTING PROBLEM: Pump cycles but will not pump. (Note: higher suction lifts require faster cycling speed for priming.) POSSIBLE CAUSES: A. Air leak in suction line. B. Excessive suction lift. C. Check valve not closing. D. Leakage at joint of suction manifold or elbow flange. E. -

Page 12: Temperature Limitations

ALLOY C CW-12MW equal to or exceeding ASTM A494 specification for nickel and nickel alloy castings. For specific applications, always consult “Chemical Resistance Chart" Technical Bulletin RECYCLING Many components of SANDPIPER AODD pumps are made ® of recyclable materials (see chart on page 11 for material specifications). -

Page 13: Material Codes

MATERIAL CODES THE LAST 3 DIGITS OF PART NUMBER Assembly, sub-assembly; Geolast; Color: BLACK Conductive Polypropylene; and some purchased items Injection Molded #203-40 Color: BLACK; Color Coded: SILVER Cast Iron Santoprene- Duro 40D +/-5; Color: RED Conductive HDPE; Color: BLACK Powered Metal Thermal Plastic Color Coded: SILVER... -

Page 14: Composite Repair Parts List

Composite Repair Parts List ITEM TOTAL PART NUMBER DESCRIPTION RQD. 114.002.010. Bracket Assembly, Intermediate 114.002.156. Bracket Assembly, Intermediate 070.006.170. Bearing, Sleeve 720.004.360. Seal, U-Cup 135.016.162. Bushing Assembly, Threaded 560.001.360. O-Ring 620.011.114. Plunger, Actuator 095.073.001. Pilot Valve Body Assy. 095.070.558. Pilot Valve Body 755.025.000. - Page 15 ITEM TOTAL PART NUMBER DESCRIPTION RQD. 560.047.360. O-Ring 560.060.611. O-Ring 685.032.080. Rod, Connector 722.035.110. Seat Assembly, Ball Check Valve (for use with PTFE balls only) 722.035.112. Seat Assembly, Ball Check Valve (for use with PTFE balls only) 722.097.110. Seat Assembly 722.097.112.

- Page 16 PART NUMBER DESCRIPTION RQD. 360.049.425. Gasket, Flange 360.049.603. Gasket, Flange 360.050.379. Gasket, Manifold 360.050.384. Gasket, Manifold 360.050.608. Gasket, Manifold 618.003.110. Pipe Plug 618.003.112. Plug, Pipe 618.003.330. Plug, Pipe (Cast Iron and Aluminum wetted end) 675.013.360. Ring, Sealing 675.013.365. Ring, Sealing 675.013.363.

-

Page 17: Composite Repair Drawing

For Types DGN, TGN Ribs on Virgin PTFE Diaphragm are ©2010 Warren Rupp, Inc. All rights reserved. to be toward the pumping material. ®SANDPIPER is a registered tradename of Warren Rupp, Inc. Printed in U.S.A. hdb2smdl3sm-rev0217 Model HDB2 Page 15... -

Page 18: Ce Declaration Of Conformity - Machinery

Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory. Warren Rupp brands include Warren Rupp ,SANDPIPER ® ® SANDPIPER Signature Series , MARATHON , Porta-Pump , SludgeMaster™ and Tranquilizer ®... -

Page 19: Ce Declaration Fo Conformity - Atex

EC / EU Declaration of Conformity The objective of the declaration described is in conformity with the relevant Union harmonisation legislation: Directive 94/9/EC (until April 19, 2016) and Directive 2014/34/EU (from April 20, 2016). Manufacturer: Applicable Standard: EN13463-1: 2001 Warren Rupp, Inc. A Unit of IDEX Corportion EN13463-5: 2003 800 North Main Street...

Need help?

Do you have a question about the HDB2 Type 3 and is the answer not in the manual?

Questions and answers