AUMA SG 12.1 Operation Instructions Manual

Control unit: electronic (mwg)

with actuator controls

aumatic ac 01.2 non-intrusive

Hide thumbs

Also See for SG 12.1:

- Operation instructions manual (80 pages) ,

- Operation instructions manual (17 pages) ,

- Operation instructions manual (80 pages)

Table of Contents

Summary of Contents for AUMA SG 12.1

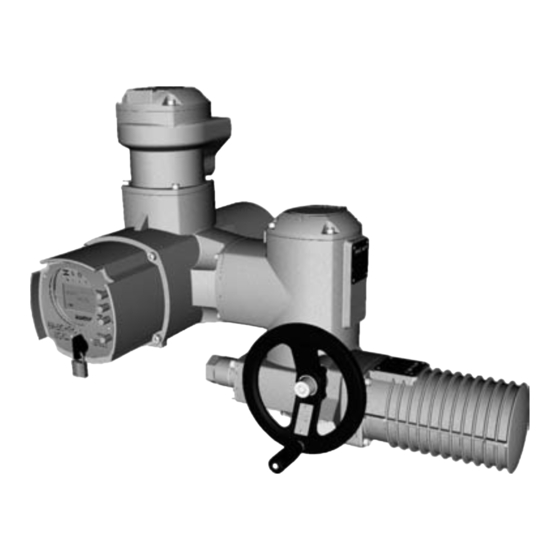

- Page 1 Part-turn actuators SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) with actuator controls AUMATIC AC 01.2 Non-Intrusive Control Parallel Profibus DP Modbus Operation instructions Assembly, operation, commissioning...

-

Page 2: Table Of Contents

Reference documents: Manual (Operation and setting) AUMATIC AC 01.2 Profibus DP Manual (Device integration Fieldbus) AUMATIC AC 01.2 Profibus DP Reference documents can be downloaded from the Internet (www.auma.com) or ordered directly from AUMA (refer to <Addresses>). Table of contents Page Safety instructions......................... - Page 3 Indications..........................7.1. Indications during commissioning 7.2. Indications in the display 7.2.1 Feedback indications from actuator and valve 7.2.2 Status indications according to AUMA classification 7.2.3 Status indications according to NAMUR recommendation 7.3. Mechanical position indicator/running indication 7.4. Indication lights Signals.............................

- Page 4 Accessories 12.6. Further information Spare parts..........................13.1. Part-turn actuators SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 13.2. Actuator controls AUMATIC AC 01.2 with AUMA plug/socket connector (SD bus) Certificates..........................14.1. Declaration of Incorporation and EC Declaration of Conformity Index............................Addresses..........................

-

Page 5: Safety Instructions

Any device modification requires prior consent of the manufacturer. Range of application AUMA part-turn actuators are designed for the operation of industrial valves, e.g. butterfly valves and ball valves. Other applications require explicit (written) confirmation by the manufacturer. -

Page 6: Applications In Ex Zone 22 (Option)

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Safety instructions AC 01.2 Non-Intrusive Profibus DP Passenger lifts according to DIN 15306 and 15309 Service lifts according to EN 81-1/A1 Escalators Continuous duty Buried service Permanent submersion (observe enclosure protection) -

Page 7: References And Symbols

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Safety instructions Indicates a potentially hazardous situation with a low level of risk. Failure to observe this warning may result in minor or moderate injury. May also be used with property damage. -

Page 8: Identification

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Identification AC 01.2 Non-Intrusive Profibus DP Identification Name plate Each device component (actuator, controls, motor) is equipped with a name plate. Figure 1: Arrangement of name plates Actuator name plate... -

Page 9: Short Description

(push buttons and display) and perform settings (contents of these instructions). read in or out data or modify and save settings via the AUMA ToolSuite software (option), using a computer (laptop or PC). The connection between computer and AUMATIC is wireless via Bluetooth interface (not included in these instruc- tions). -

Page 10: Transport, Storage And Packaging

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Transport, storage and packaging AC 01.2 Non-Intrusive Profibus DP Transport, storage and packaging Transport For transport to place of installation, use sturdy packaging. Hovering load! Risk of death or serious injury. -

Page 11: Assembly

AC 01.2 Non-Intrusive Profibus DP Assembly Assembly Mounting position AUMA actuators and actuator controls can be operated without restriction in any mounting position. Ball handle: fit to handwheel To avoid damage during transport, the ball handle is fitted at the rear of the handwheel. -

Page 12: Coupling

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Assembly AC 01.2 Non-Intrusive Profibus DP 4.3.1 Coupling Figure 6: Coupling fitting dimensions Coupling Valve shaft Grub screw Screw Table 1: Coupling fitting dimensions Type, size - mounting flange... -

Page 13: Mounting Positions Of Local Controls

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Assembly Fasten actuator with screws [4]. Information: We recommend glueing the screws using sealing material to avoid contact corrosion. Fasten screws [4] crosswise with a torque according to table:... - Page 14 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Assembly AC 01.2 Non-Intrusive Profibus DP Electrostatic discharge ESD! Risk of damage to electronic components. Earth both operators and devices. Loosen screws and remove the local controls. Check whether O-ring is in good condition, correctly insert O-ring.

-

Page 15: Electrical Connection

The pertaining wiring diagram/terminal plan (in German and English language) is plan attached to the device in a weather-proof bag, together with these operation instructions. It can also be obtained from AUMA (state commission no., refer to name plate) or downloaded directly from the Internet (www.auma.com). Permissible networks... - Page 16 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Electrical connection AC 01.2 Non-Intrusive Profibus DP The interference immunity of signal and bus cables increases if the cables are laid close to the earth potential. If possible, avoid laying long cables and make sure that they are installed in areas being subject to low interference.

-

Page 17: Connection With Auma Plug/Socket Connector

Terminal compartment: open Information The bus connection can be separately accessed from the mains connection (refer to <Bus terminal compartment: open>). Figure 10: Mains connection AUMA plug/socket connector SD bus Connection housing Screws for connection housing O-ring Screws for socket carrier... -

Page 18: Cable Connection

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Electrical connection AC 01.2 Non-Intrusive Profibus DP Insert cable glands [8] suitable for connecting cables. The enclosure protection IP... stated on the name plate is only ensured if suitable cable glands are used. -

Page 19: Terminal Compartment: Close

Fasten cable glands [8] applying the specified torque to ensure the required enclosure protection. 5.2.4 Bus terminal compartment: open The AUMA plug/socket connector (SD bus) is equipped with a connection board for connecting the bus cables. When removing the cover [1] the connection board is easily accessible. -

Page 20: Bus Cables: Connect

Bus cables: connect Information This description applies to the connection via RS-485 copper cables. Separate in- structions are available for connection via FO (fibre optic) cables. A label with the AUMA article number on the connection board identifies the installed Variants variant. - Page 21 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Electrical connection Variant Overvoltage AUMA art. no. protection up to 4 kV on label 1 channel (standard) Z071.720/02 1 channel Z071.720/04 2 channel for redundancy Z071.720/03...

-

Page 22: Bus Terminal Compartment: Close

SGR 12.1 Control unit: electronic (MWG) Electrical connection AC 01.2 Non-Intrusive Profibus DP 5.2.6 Bus terminal compartment: close Figure 17: AUMA plug/socket connector SD bus Cover Screws for cover O-ring Cable entries for bus cables Blanking plug Clean sealing faces of cover [1] and housing. -

Page 23: Parking Frame

Permissible length of connecting cables: max. 100 m. connection We recommend: AUMA cable set LSW20. If the AUMA cable set is not used: Use suitable flexible and screened connecting cables. Use separate, CAN bus data cable for MWG of 120 Ohm character impe- dance (e.g. -

Page 24: Protection Cover

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Electrical connection AC 01.2 Non-Intrusive Profibus DP Figure 19: Parking frame 5.3.3 Protection cover Protection cover for plug compartment when plug is removed. The open terminal compartment can be closed using a protective cover (not illustrated). -

Page 25: Operation

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Operation Operation Valve damage due to incorrect basic setting! Prior to electrical operation of the actuator, the basic settings i.e. type of seating, torque and limit switching have to be completed. -

Page 26: Actuator Operation From Remote

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Operation AC 01.2 Non-Intrusive Profibus DP Figure 22: Local controls Push button for operation command in direction OPEN Push button STOP Push button for operation command in direction CLOSE... -

Page 27: Menu Navigation Via Push Buttons (For Settings And Indications)

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Operation Menu navigation via push buttons (for settings and indications) Menu navigation for display and setting is made via the push buttons [1 4] of the local controls. -

Page 28: User Level, Password

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Operation AC 01.2 Non-Intrusive Profibus DP Figure 27: Groups Startup menu Status menu Main menu Status menu and main menu are marked with an ID. Figure 28: Marking with ID... -

Page 29: Password Entry

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Operation Figure 31: User level display (example) A password must be entered to allow parameter modification. The display indicates: Password Password 0*** A specific password is assigned to each user level and permits different actions. -

Page 30: Language In The Display

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Operation AC 01.2 Non-Intrusive Profibus DP Select parameter Change passwords either: Change passwords click via the menu to parameter, or via direct display: press and enter ID M0229 Display indicates: ▶ Change passwords The user level is indicated in the top row (1 6), e.g.:... - Page 31 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Operation Enter password (→ enter password). Display indicates: ▶ Language and Save (bottom row) Language selection 10. Select new language via Up ▲ Down ▼ resulting in the following significati- ons: black triangle: ▶...

-

Page 32: Indications

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Indications AC 01.2 Non-Intrusive Profibus DP Indications Indications during commissioning When switching on the power supply, all LEDs on the local controls illuminate for LED test approx. 1 second. This optical feedback indicates that the voltage supply is connected to the controls and all LEDs are operable. -

Page 33: Feedback Indications From Actuator And Valve

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Indications Figure 39: Information in the status bar (top) Operation mode Error symbol (only for faults and warnings) ID number: S = Status page... - Page 34 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Indications AC 01.2 Non-Intrusive Profibus DP Torque (S0002) The indication is only available if the actuator is equipped with an MWG (magnetic limit and torque transmitter). S0002 on the display indicates the torque applied at the actuator output.

- Page 35 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Indications If the positioner is enabled and activated, the bargraph indication for E1 (position Setpoint control setpoint) is displayed. The direction of the operation command is displayed by an arrow above the bargraph indication.

-

Page 36: Status Indications According To Auma Classification

(P1, P2, ...) selected position (1, 2, ...) ) no position selected Actual position value 7.2.2 Status indications according to AUMA classification These indications are available, if the parameter Diagnostic classific. M0539 is set to AUMA. Warnings (S0005) If a warning has occurred, the display shows S0005: the number of warnings occurred a blinking question mark after approx. -

Page 37: Status Indications According To Namur Recommendation

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Indications Figure 51: Fault For further information, please also refer to <Corrective action>. 7.2.3 Status indications according to NAMUR recommendation These indications are available, if the parameter Diagnostic classific. M0539 is set to NAMUR. -

Page 38: Mechanical Position Indicator/Running Indication

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Indications AC 01.2 Non-Intrusive Profibus DP Figure 54: Maintenance required For further information, please also refer to <Corrective action>. Failure (S0011) The S0011 indication shows the causes of the failure indication according to NAMUR recommendation NE 107. -

Page 39: Indication Lights

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Indications Indication lights Figure 57: Arrangement and signification of indication lights Marking with symbols (standard) Marking with figures 1 6 (option) End position CLOSED reached (blinking: for operation in direction CLOSE) -

Page 40: Signals

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Signals AC 01.2 Non-Intrusive Profibus DP Signals Signals via fieldbus Feedback signals via fieldbus can be configured. Configuration is possible for both data structure and data contents. Configuration is defined via the GSD file only. - Page 41 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Signals Analogue feedback signals are only available if a parallel interface is provided in addition to the fieldbus interface. Signal: E2 = 0/4 20 mA (galvanically isolated)

-

Page 42: Commissioning (Basic Settings)

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Commissioning (basic settings) AC 01.2 Non-Intrusive Profibus DP Commissioning (basic settings) Set selector switch to position 0 (OFF). Information: The selector switch is not a mains switch. When positioned to 0 (OFF), the actuator cannot be operated. -

Page 43: End Stop Open: Set

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Commissioning (basic settings) Move valve to end position CLOSED with handwheel. Check whether end stop nut [2] rotates simultaneously. Otherwise: Turn end stop nut [2] clockwise until end stop is reached. -

Page 44: Swing Angle: Modify

SG 05.1/ SGR 05.1 SG 07.1/ SGR 07.1 SG 10.1/ SGR 10.1 SG 12.1/ SGR 12.1 3.2 Move valve manually to the desired end position OPEN. 3.3 Turn end stop nut [2] clockwise until it is tight up to the travelling nut [4]. -

Page 45: Type Of Seating: Set

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Commissioning (basic settings) While holding end stop nut [2] in position with open end spanner fasten grub screw [1] at 85 Nm. Check O-ring [5] and replace if damaged. -

Page 46: Torque Switching: Set

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Commissioning (basic settings) AC 01.2 Non-Intrusive Profibus DP Enter password (→ enter password). The screen indicates the pre-set type of seating (▶ Limit or ▶ Torque) by means of a black triangle ▶. -

Page 47: Limit Switching: Set

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Commissioning (basic settings) Up ▲ Down ▼ to select user: Log on user Information: Required user level: Specialist (4) or higher The symbols have the following meanings: black triangle: ▶... - Page 48 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Commissioning (basic settings) AC 01.2 Non-Intrusive Profibus DP Select parameter either: Select parameter click via the menu to parameter, or via direct display: press and enter ID M0084. Display indicates: Set end pos.CLOSED? Up ▲...

-

Page 49: Bus Address (Slave Address): Set

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Commissioning (basic settings) 11. Make selection: Edit → back to step 9: Set end position CLOSED "once again" Esc → back to step 4; either set end position OPEN or exit the menu. -

Page 50: Test Run

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Commissioning (basic settings) AC 01.2 Non-Intrusive Profibus DP Select via Up ▲ Down ▼: ▶ DP1 slave address ▶ DP2 slave address The black triangle ▶ indicates the current selection. -

Page 51: Limit Switching: Check

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Commissioning (basic settings) 9.7.2 Limit switching: check Set selector switch to position Local control (LOCAL). Operate actuator using push buttons OPEN - STOP - CLOSE. -

Page 52: Switch Compartment: Close

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Commissioning (basic settings) AC 01.2 Non-Intrusive Profibus DP Hold lower indicator disc in position and turn upper disc with symbol (OPEN) until it is in alignment with the mark on the cover. - Page 53 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Commissioning (basic settings) Figure 75: Part-turn actuator with 1-ph AC motor Motor cover Potentiometer Hazardous voltage! Risk of electric shock. Disconnect device from the mains before opening.

-

Page 54: Corrective Action

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Corrective action AC 01.2 Non-Intrusive Profibus DP Corrective action 10.1 Faults during commissioning Table 10: Faults during commissioning Fault description Possible causes Remedy Fault in end position The overrun was not considered when setting... - Page 55 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Corrective action Table 12: Warnings and Out of specification Indication on display Description/cause Remedy Config. warning Collective signal 06: Details to display a list...

- Page 56 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Corrective action AC 01.2 Non-Intrusive Profibus DP Indication on display Description/cause Remedy Wrn FOC connection Warning FO cable connection is not available. Fit FO cable connection. Torque wrn OPEN...

-

Page 57: Fuses

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Corrective action Table 14: Not ready REMOTE and Function check (collective signal 04) Indication on display Description/cause Remedy Wrong oper. cmd Collective signal 13:... - Page 58 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Corrective action AC 01.2 Non-Intrusive Profibus DP Internal 24 V AC supply (115 V AC) for: Heater, switch compartment, reversing contactors control PTC tripping device for 115 V AC also control inputs OPEN - STOP - CLOSE G-fuse according to IEC 60127-2/III AUMA art.

-

Page 59: Motor Protection (Thermal Monitoring)

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Corrective action Fuses F3/F4: test/replace Loosen screws [1] and remove cover [2] on the rear of the actuator controls. The power supply unit has measurement points (solder pins) allowing to perform... -

Page 60: Servicing And Maintenance

Only perform servicing and maintenance tasks when the device is switched off. AUMA AUMA offer extensive service such as servicing and maintenance as well as customer Service & Support product training. For the relevant contact addresses, please refer to <Addresses>... -

Page 61: Technical Data

The following technical data includes standard and optional features. For detailed information on the customer-specific version, refer to the order-relevant data sheet. This data sheet can be downloaded from the Internet at http://www.auma.com in German and English (indication of commission number required). -

Page 62: Features And Functions Of Actuator Controls

Reversing contactors (mechanically and electrically interlocked) for motor power up to power class A1 Options: Thyristor unit for mains voltage up to 500 V AC (recommended for modulating actuators) for AUMA power class B1 Control Via Profibus DP interface Fieldbus interface with additio-... - Page 63 Topologies: Line, star and redundant loop (with single-channel Profibus DP interface) Baud rate: up to 1.5 Mbit/s Optical budget: Multi-mode: 13 dB Single-mode: 17 dB Wave length: 1,310 mm. FO coupler by EKS required at DCS, order addresses: AUMA or www.eks-engel.com...

- Page 64 Bluetooth class II chip, version 2.0 with a range up to 10 m in industrial environments. Supports Communication interface the SPP Bluetooth profile (Serial Port Profile). Programming software: AUMA ToolSuite, commissioning and diagnostic tool for windows based PCs, PDAs and smart phones Application functions Standard:...

-

Page 65: Profibus Dp Interface

Refer to name plate The reversing contactors are designed for a lifetime of 2 million starts. For the assignment of AUMA power classes, please refer to electrical data on actuator. All input signals must be supplied with the same potential. - Page 66 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Technical data AC 01.2 Non-Intrusive Profibus DP Commands and signals of the fieldbus interface Process representation output OPEN, STOP, CLOSE, position setpoint, RESET, EMERGENCY, Interlock OPEN/CLOSE, (command signals) Enable LOCAL...

-

Page 67: Service Conditions

IP 68 IP 68-DS IP 67-DS According to AUMA definition, enclosure protection IP 68 meets the following requirements: Water depth: Maximum 6 m head of water Duration of continuous immersion in water: maximum of 72 hours Up to 10 operations during flooding Modulating duty is not possible during continuous immersion. -

Page 68: Further Information

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Technical data AC 01.2 Non-Intrusive Profibus DP Cable distance between actuator and AUMATIC max. 100 m. Requires separate data cable for MWG. If actuator and AUMATIC are separated at a later date, the max. cable length is 10 m. -

Page 69: Spare Parts

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Spare parts Spare parts 13.1 Part-turn actuators SG 05.1 – SG 12.1/SGR 05.1 – SGR 12.1... - Page 70 Information: Please state type and commission no. of the device (see name plate) when ordering spare parts. Only original AUMA spare parts should be used. Failure to use original spare parts voids the warranty and exempts AUMA from any liability. Delivered spare parts may slightly vary from the representation.

-

Page 71: Actuator Controls Aumatic Ac 01.2 With Auma Plug/Socket Connector (Sd Bus)

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Spare parts 13.2 Actuator controls AUMATIC AC 01.2 with AUMA plug/socket connector (SD bus) - Page 72 Information: Please state type and commission no. of the device (see name plate) when ordering spare parts. Only original AUMA spare parts should be used. Failure to use original spare parts voids the warranty and exempts AUMA from any liability. Delivered spare parts may slightly vary from the representation.

-

Page 73: Certificates

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Certificates Certificates 14.1 Declaration of Incorporation and EC Declaration of Conformity... - Page 74 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP...

- Page 75 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP...

-

Page 76: Index

SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) Index AC 01.2 Non-Intrusive Profibus DP Index Handwheel Identification Accessories (electrical Indication lights connection) Indications Actual value - indication on Indications on display display Indicator disc 38 , 51... - Page 77 SG 05.1 SG 12.1/SGR 05.1 SGR 12.1 Control unit: electronic (MWG) AC 01.2 Non-Intrusive Profibus DP Index Packaging Wall bracket Parking frame Warnings - indication on dis- Password play Password change Wire cross section (bus cable) Password entry Wire diameter (bus cable)

-

Page 78: Addresses

Auma Endüstri Kontrol Sistemleri Limited UK Clevedon, North Somerset BS21 6TH irketi Tel +44 1275 871141 TR 06810 Ankara AUMA Riester GmbH & Co. KG Fax +44 1275 875492 Tel+90 312 217 32 88 mail@auma.co.uk Fax+90 312 217 33 88 Plant Müllheim... - Page 79 AUMA worldwide Ferrostaal de Colombia Ltda. AUMA Actuators Middle East W.L.L. CO Bogotá D.C. AE 15268 Salmabad 704 Tel +57 1 401 1300 Tel +973 17877377 Fax+57 1 416 5489 Fax +973 17877355 dorian.hernandez@ferrostaal.com Naveen.Shetty@auma.com www.ferrostaal.com PERFECT CONTROLS Ltd. PROCONTIC Procesos y Control HK Tsuen Wan, Kowloon Automático...

- Page 80 AUMA Riester GmbH & Co. KG P.O.Box 1362 D 79373 Muellheim Tel +49 7631 809 - 0 Fax +49 7631 809 - 1250 riester@auma.com www.auma.com Y004.845/003/en/4.12 For detailed information on AUMA products refer to the Internet: www.auma.com...

Need help?

Do you have a question about the SG 12.1 and is the answer not in the manual?

Questions and answers