Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Instruction Manual

Advertisement

Table of Contents

Summary of Contents for Rosemount 951c

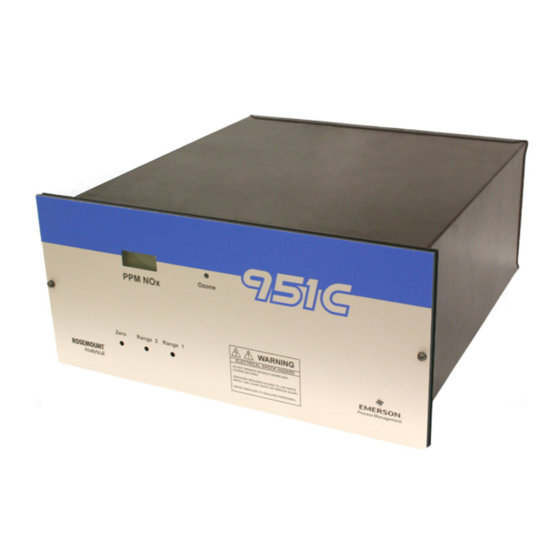

- Page 1 Instruction Manual 748214-T September 2002 Model 951C Analyzer http://www.processanalytic.com...

- Page 2 • Read all instructions prior to installing, operating, and servicing the product. • If you do not understand any of the instructions, contact your Rosemount Analytical representative for clarification.

-

Page 3: Table Of Contents

Instruction Manual 748214-T Model 951C September 2002 TABLE OF CONTENTS PREFACE............................P-1 Definitions ............................P-1 Safety Summary ..........................P-2 General Precautions For Handling And Storing High Pressure Gas Cylinders .........P-5 Documentation............................P-6 Compliances ............................P-6 Condensed Startup And Calibration Procedure .................P-7 DESCRIPTION AND SPECIFICATIONS................1-1 Overview..........................1-1 Typical Applications.......................1-1... - Page 4 Instruction Manual 748214-T Model 951C September 2002 THEORY..........................4-1 Nitric Oxide Determination by Chemiluminescence Method ..........4-1 Analyzer Flow System ......................4-1 a. Flow of Sample, Standard Gas or Zero Gas to Reaction Chamber .......4-1 b. Ozone Generation......................4-1 Signal Conditioning And Display ...................4-2 a.

- Page 5 Figure 2-2. Temperature Control Board ................... 2-2 Figure 2-3. Cable Gland ......................2-3 Figure 2-4. Rear View of Model 951C (cover removed) ............2-4 Figure 2-5. Rear Panel Wiring Connections................2-4 Figure 3-1. Model 951C Controls, Indicators and Adjustments ..........3-1 Figure 3-2.

- Page 6 Instruction Manual 748214-T Model 951C September 2002 Contents Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 7: Preface

September 2002 PREFACE The purpose of this manual is to provide information concerning the components, functions, installation and maintenance of the 951C NO Analyzer. Some sections may describe equipment not used in your configuration. The user should become thoroughly familiar with the operation of this module before operating it. Read this instruction manual completely. -

Page 8: Safety Summary

Instruction Manual 748214-T Model 951C September 2002 SAFETY SUMMARY If this equipment is used in a manner not specified in these instructions, protective systems may be impaired. AUTHORIZED PERSONNEL To avoid explosion, loss of life, personal injury and damage to this equipment and on-site property, all personnel authorized to install, operate and service the this equipment should be thoroughly familiar with and strictly follow the instructions in this manual. - Page 9 Instruction Manual 748214-T Model 951C September 2002 WARNING TOXIC CHEMICAL HAZARD This instrument generates ozone which is toxic by inhalation and is a strong irritant to throat and lungs. Ozone is also a strong oxidizing agent. Its presence is detected by a characteristic pungent odor.

- Page 10 Instruction Manual 748214-T Model 951C September 2002 WARNING. TOXIC AND OXIDIZING GAS HAZARD The ozone generator lamp contains mercury. Lamp breakage could result in mercury exposure. Mercury is highly toxic if absorbed through skin or ingested, or if vapors are inhaled.

-

Page 11: General Precautions For Handling And Storing High Pressure Gas Cylinders

Instruction Manual 748214-T Model 951C September 2002 GENERAL PRECAUTIONS FOR HANDLING AND STORING HIGH PRESSURE GAS CYLINDERS Edited from selected paragraphs of the Compressed Gas Association's "Handbook of Compressed Gases" published in 1981 Compressed Gas Association 1235 Jefferson Davis Highway... -

Page 12: Documentation

Instruction Manual 748214-T Model 951C September 2002 DOCUMENTATION The following 951C instruction materials are available. Contact Customer Service Center or the local representative to order. 748214 Instruction Manual (this document) COMPLIANCES This product satisfies all obligations of all relevant standards of the EMC framework in Australia and New Zealand. -

Page 13: Condensed Startup And Calibration Procedure

Instruction Manual 748214-T Model 951C September 2002 CONDENSED STARTUP AND CALIBRATION PROCEDURE The following summarized instructions on regulator on the zero gas cylinder as startup and calibration are intended for required. operators already familiar with the analyzer. 7. Establish correct pressure of upscale... - Page 14 Instruction Manual 748214-T Model 951C September 2002 NOTE appropriate to the application, normally once a month. It is the responsibility of the user to measure efficiency of the NO -to-NO converter during initial startup, and thereafter at intervals Preface Rosemount Analytical Inc.

-

Page 15: Description And Specifications

Model 951C September 2002 SECTION 1 DESCRIPTION AND SPECIFICATIONS 1-1 OVERVIEW The case heater assembly of the Model 951C maintains the internal temperature at approximately 50 C (122 The Model 951C NO Analyzer is designed to measure NO using one of two sets of ranges designated as Hi or Lo. -

Page 16: Specifications

Instruction Manual 748214-T Model 951C September 2002 1-3 SPECIFICATIONS Ranges ........... 0 to 10, 0 to 25, 0 to 100, 0 to 250 ppm NO ........... 0 to 100, 0 to 250, 0 to 1000, 0 to 2500 ppm NO Repeatability........ -

Page 17: Installation

Instruction Manual 748214-T Model 951C September 2002 SECTION 2 INSTALLATION 2-1 UNPACKING This instrument was shipped from the factory set up to operate on 115 VAC, 50/60 Hz electric power. For operation on 230 VAC, 50/60 Hz, on Carefully examine the shipping carton and the Power Supply Board (Figure 3-9, page 3-5) contents for signs of damage. -

Page 18: Figure 2-1. Power Supply Board Voltage Select Switches

Instruction Manual 748214-T Model 951C September 2002 not slide out with the chassis, no excess Power Cord/Enclosure Support Kit • power cable slack is necessary. 654008 North American power cord set (10 foot) • The following power cord and/or support Enclosure support feet (4) •... -

Page 19: Potentiometric Recorder Connections

20 PSI (138 kPa) NOMINAL (70 kPa - 120 kPa) See Figure 2-5 for connections L1/HOT FUSE L2/NEUT VOLT OUTPUT OUTPUT Figure 2-4. Rear View of Model 951C (cover removed) Rosemount Analytical Inc. A Division of Emerson Process Management Installation... -

Page 20: Figure 2-5. Rear Panel Wiring Connections

Instruction Manual 748214-T Model 951C September 2002 RECORDER POWER OUTPUT Remote Range Change Connections L1/HOT FUSE AC Power Connections L2/NEUT VOLT OUTPUT OUTPUT Current Output Connections Recorder Connections Figure 2-5. Rear Panel Wiring Connections Installation Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 21: Gas Requirements

(nitrogen Proper supply pressure for sample, zero can also be used). Gas for each purpose and span gases for the Model 951C is must be supplied from a separate cylinder 20 psig (138 kPa). due to different pressure requirements at ozonator and zero inlets. -

Page 22: Leak Test

Instruction Manual 748214-T Model 951C September 2002 1. Remove plugs and caps from all inlet and 2-8 LEAK TEST outlet fittings. (See Figure 2-4, page 2-3.) The following test is designed for sample 2. Connect EXHAUST outlet to external vent pressure up to 5 psig (35 kPa). -

Page 23: Operation

(Signal Board DS1) Zero Control (Signal Board R100) Range2 Control (Signal Board R102) Range1 Control Ozone Indicator Lamp (Signal Board R101) (Signal Board DS2) Figure 3-1. Model 951C Controls, Indicators and Adjustments Rosemount Analytical Inc. A Division of Emerson Process Management Operation... -

Page 24: Zero And Span Potentiometers

Instruction Manual 748214-T Model 951C September 2002 Zero and Span Potentiometers Ozone Interlock See Figure 3-1 (page 3-1) and Figure 3-2 The ozone-producing UV lamp will not below. Screwdriver access holes through ignite or stay lit unless adequate air the front panel allow adjustments of the... -

Page 25: Startup Procedure

Instruction Manual 748214-T Model 951C September 2002 3-2 STARTUP PROCEDURE c. Set DP SELECT jumpers to desired position as shown in Figure 3-7 The following are detailed instructions on below. startup and calibration. 1. Supply electrical power to the analyzer. - Page 26 Instruction Manual 748214-T Model 951C September 2002 SAMPLE pressure gauge. This should indicates insufficient sample supply remain constant when the analyzer input pressure at the SAMPLE inlet. Use a SAMPLE is switched from calibration gas 2400 cc flowmeter (i.e., Brooks P/N standard to a zero gas standard.

-

Page 27: Figure 3-9. Power Supply Board

Instruction Manual 748214-T Model 951C September 2002 Figure 3-9. Power Supply Board Rosemount Analytical Inc. A Division of Emerson Process Management Operation... -

Page 28: Calibration

3-2) set Upscale Calibration the named calibration gas value is indicated PPM RANGE Switch (Figure 3-6, by the Model 951C, the instrument is ready for page 3-3) to the position appropriate adjustment of the converter temperature. to the particular span gas. -

Page 29: Table 3-1. Resistance Of Converter Temperature Sensor Vs. Temperature

Instruction Manual 748214-T Model 951C September 2002 temperature to a lower value to improve the potentiometer, waiting for thermal stability converter efficiency. and determination of the calibration gas value until either a 95% value is obtained It is important that the converter temperature... -

Page 30: Measurement Of Converter Efficiency

Instruction Manual 748214-T Model 951C September 2002 3-6 MEASUREMENT OF CONVERTER consume nitrogen dioxide as it delivers EFFICIENCY sample to the analyzer. Losses of nitrogen dioxide in the pump will be It is the responsibility of the user to measure reported as converter inefficiency. -

Page 31: Theory

Instruction Manual 748214-T Model 951C September 2002 SECTION 4 THEORY 4-1 NITRIC OXIDE DETERMINATION BY The flow rate of the selected gas into CHEMILUMINESCENCE METHOD the reaction chamber is controlled by a back pressure regulator inside the The chemiluminescence method for detection of analyzer. -

Page 32: Signal Conditioning And Display

• Signal conditioning circuit consisting of Intermediate gain ranges as required by AR4, AR5 and AR6 the 951C 10, 25, 100, 250 ppm NOx or 100, 250, 1000, 2500 ppm NOx are • An analog to digital converter U1, U2 and... -

Page 33: Analyzer Thermal System

Note that this adjustment does not affect or connector panel at the rear of the 951C. change the instrument display, A ten terminal barrier strip provides connection for remote range selection. -

Page 34: Figure 4-1. Analyzer Signal Conditioning Circuit

Instruction Manual 748214-T Model 951C September 2002 the temperature of the PMT. This load is The electronics which support the Analyzer produced by a case heater and exhaust fan Thermal System and the NO -to-NO which control the temperature inside the case Converter are contained on the Power Supply Board. -

Page 35: Figure 4-2. Analyzer Thermal System

Instruction Manual 748214-T Model 951C September 2002 INLET VENT HOLES Top View of Analyzer EXHAUST FAN SOLID-STATE COOLER Cooling Fins CASE HEATER Cooler Fan Heater FRONT PANEL Figure 4-2. Analyzer Thermal System Rosemount Analytical Inc. A Division of Emerson Process Management... - Page 36 Instruction Manual 748214-T Model 951C September 2002 Theory Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 37: Routine Servicing

Instruction Manual 748214-T Model 951C September 2002 SECTION 5 ROUTINE SERVICING display reading. If not, obtain agreement WARNING by adjustment of R20 on the Signal Board ELECTRICAL SHOCK HAZARD (see Figure 3-1 (page 3-1) and Figure 3-2 (page 3-2). If agreement cannot be Servicing requires access to live parts reached, check the recorder. -

Page 38: Ozone Output

To facilitate servicing and testing, the Model some degradation in analyzer response 951C has front drawer access. time characteristics may occur. Drawing 654090 shows flow system details, including fittings, thread specifications and connecting tubing. -

Page 39: Cleaning Sample Capillary

Instruction Manual 748214-T Model 951C September 2002 Cleaning Sample Capillary 8. With the photomultiplier still covered, slowly insert the free end of the capillary into the corresponding fitting If clogging of sample capillary is suspected, measure flow rate as on the reaction chamber. Push the capillary in until it touches bottom described below. -

Page 40: Removal

Instruction Manual 748214-T Model 951C September 2002 The assembly must be removed from the and duration of the previous exposure. analyzer in order to clean the reaction Noise level on the most sensitive chamber or to replace the photomultiplier range usually drops to normal within tube. -

Page 41: Photomultiplier Tube And Housing

(P/N 634929). Alconox replace and reconnect it in reversed detergent is included in the shipping kit removal sequence. Orient as noted in provided with the Model 951C NO step 2. Analyzer, and is available from Sargent-Welch Scientific Company under Photomultiplier Tube and Housing its catalog number S-195650-A. -

Page 42: Ozone Generation System

Instruction Manual 748214-T Model 951C September 2002 metal shield and the black plastic Do not place in trash, incinerate or flush insulating cover. down sewer. Cover any fine droplets of mercury in non-accessible crevices with 3. Carefully unplug the photomultiplier calcium polysulfide and sulfur dust. -

Page 43: Power Supply Removal

Instruction Manual 748214-T Model 951C September 2002 4. Insert replacement lamp assembly 1. Carefully disconnect the blue silicon using care not to hit or touch lamp connectors from the ends of the inlet and housing. outlet tubes. 5. Insert new O-ring into new end cap. - Page 44 Instruction Manual 748214-T Model 951C September 2002 Routine Servicing Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 45: Replacement Parts

To identify the configuration of an analyzer, locate the analyzer name-rating plate. The Each analyzer is configured per the customer sales matrix identifier number appears on the sales order. Below is the 951C sales matrix analyzer name-rating plate. which lists the various configurations available. -

Page 46: Circuit Board Replacement Policy

623936 Sample Flow Restrictor troubleshooting procedures do not resolve the 644055 Sample Pressure Gauge problem, contact your local Rosemount 815187 Sample Regulator Analytical service office. A list of Rosemount 622917 Sensor, Temperature Analytical Service Centers is located in 661250 Signal/Control Board Section 7. -

Page 47: Figure 6-1. Major Assemblies Of The Model 951C

Air Restrictor Pressure Switch 655519 (on Ozone Generator inlet) 654085 Ozone Generator Power Supply 655129 Sample Regulator 815187 Sample Pressure Gauge 644055 Figure 6-1. Major Assemblies of the Model 951C Rosemount Analytical Inc. A Division of Emerson Process Management Replacement Parts... -

Page 48: Figure 6-2. Photomultiplier Housing Assembly

Instruction Manual 748214-T Model 951C September 2002 Photomultiplier Assembly 654062 001522 O-Ring 008423 O-Ring, Photomultiplier 655168 Photomultiplier Tube Refer to Figure 6-2. 654381 Reaction Chamber 654086 Socket Assembly 654943 Housing 639722 Thermal Shield 649541 Insulating Washer 636318 Magnetic Shield 630916... -

Page 49: Converter Assembly 654070

Instruction Manual 748214-T Model 951C September 2002 Converter Assembly 654070 Refer to Figure 6-3. 632784 Connector, Blue Silicone 657127 Heater 632782 Temperature Sensor 632795 Tube Temperature Sensor 632782 Connectors, Glass Tube 632784 Converter Tube - Packed 632795 Heater 657127 Figure 6-3. Converter Assembly Rosemount Analytical Inc. -

Page 50: Temperature Control Assembly 654068

Instruction Manual 748214-T Model 951C September 2002 Temperature Control Assembly 654068 Refer to Figure 6-4. 622733 622732 Heater 655335 Temperature Control Board 900492 Thermal Fuse Temperature Control Board 655335 Thermal Fuse 900492 Heater Cable Orientation 622733 Heater 633732 Figure 6-4. Case Heater Temperature Control Assembly Replacement Parts Rosemount Analytical Inc. -

Page 51: Return Of Material

Rosemount instructions or it will not For equipment no longer under warranty, the be accepted. equipment will be repaired at the factory and... - Page 52 Instruction Manual 748214-T Model 951C September 2002 Return of Material Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 53: Index

Instruction Manual 748214-T Model 951C September 2002 SECTION 8 INDEX establish correct pressure of zero gas, 3-3 Excessive Photomultiplier Dark Current, 5-2 230 VAC conversion, 2-1 flow rate, measuring, 5-3 flow rate, subnormal, 5-3 Air (U.S.P. Breathing Grade), 2-5 AIR inlet... - Page 54 Instruction Manual 748214-T Model 951C September 2002 Range2 Select jumpers, 3-3 Upscale Calibration, 7 reaction chamber, 4-1, 5-1, 5-2, 5-3, 5-4, 5-5, 5-6 PPM RANGE switch, 3-6 reaction chamber, alternate cleaning procedure, 5-5 RANGE1 control, 3-6 reaction chamber, standard cleaning procedure, 5-4...

- Page 55 WARRANTY Goods and part(s) (excluding consumables) manufactured by Seller are warranted to be free from defects in workmanship and material under normal use and service for a period of twelve (12) months from the date of shipment by Seller. Consumables, glass electrodes, membranes, liquid junctions, electrolyte, o-rings, etc., are warranted to be free from defects in workmanship and material under normal use and service for a period of ninety (90) days from date of shipment by Seller.

- Page 56 1 Pandan Crescent Bognor Regis 3333 sala 1004 Singapore 128461 West Sussex PO22 9SH Rio de Janeiro, RJ Republic of Singapore England Brazil 22631-003 T 65-777-8211 T 44-1243-863121 T 55-21-2431-1882 F 65-777-0947 F 44-1243-845354 http://www.processanalytic.com © Rosemount Analytical Inc. 2002...

Need help?

Do you have a question about the 951c and is the answer not in the manual?

Questions and answers