Summary of Contents for Taski swingobot 1650 CE

- Page 1 TASKI SWINGOBOT 1650 CE TASKI SWINGOBOT 1650 CE UV USER MANUAL Rev. B: www.intellibotrobotics.com 01/09/17...

-

Page 2: Table Of Contents

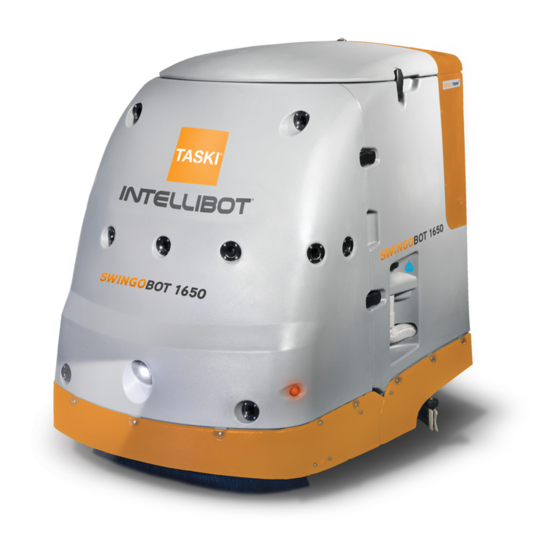

6. General Safety Awareness ......3 1. System Overview 7. System Safety Awareness ....... 4 The TASKI Intellibot SWINGOBOT 1650 and TASKI Intellibot 8. Risk ..............6 SWINGOBOT 1650 UV are robotic floor scrubbing machines 9. Preventing Unsafe Situations ......7 intended for commercial use. -

Page 3: Customer Assistance

Frame Powder-coated 5052 aluminum and should be used. To maintain performance, and safety of the stainless steel machine, personnel, and property, only TASKI Intellibot parts Exterior High-density, molded, seamless and accessories should be used to maintain this robotic floor scrubber system. -

Page 4: General Safety Awareness

Do not use this machine to vacuum the customer or mandated by TASKI Intellibot. Service flammable, toxic, caustic, or irritating technicians are equipped with proper tools and parts for the installation, maintenance, and service of this robotic floor substances. -

Page 5: System Safety Awareness

7.1. Ratings Label Regularly inspect the battery charger, Example machine ratings label: mains cord, and machine charging cable for damage and replace the cord or charger immediately if any damage is found. Frayed September or damaged charging components could lead to shock or fire. SWINGOBot 1650-UV Robotic Floor Scrubber System Caution:... - Page 6 7.2. System Warning Labels The following labels are used to warn and remind the operator, maintenance, and service personnel of specific hazards when using the machine: Maximum 8% Grade September Warning Label SWINGOBot 1650-UV Robotic Floor Scrubber System 11608-1105-0001 24V , 53.2A, 1280W Input: IPX4 208kg without battery pack...

-

Page 7: Risk

Unfit Components: Only components battery. authorized by TASKI Intellibot may be fitted Cover was designed to meet the standards to this machine. Use of unfit components for a level 4 protection against liquid ingress may result in serious damage and injury. -

Page 8: Preventing Unsafe Situations

Operating on an Incline: The machine Machine Impact Hazard: When in can tip over causing damage and injury if autonomous mode, the robotic floor operated on an incline. scrubber system uses sonar for locating objects in its path. The sonar system cannot Parking on Incline: Always apply the parking be relied on for safety. -

Page 9: Healthcare/Uv User And Service Personnel Warnings

9.6. Battery Acid Consult the battery manufacturer’s recommendations for cleanup. For help with batteries supplied by TASKI Intellibot, please contact Customer Assistance. 10. Healthcare/UV User and Service Personnel Warnings Personnel should be made aware of the following hazards: 10.1. UV Hazard... - Page 10 Figure: 9 10 Emergency Stop Button 11 User Interface Figure: 7 12 Standby Button Front Access Door 13 Touch Control Handlebar Electronics Box 14 Warning Lamp Figure: 10 15 Scrubber Head Figure: 8 Filters Figure: 11 Filter Wrench 16 Squeegee Assembly Battery Pack Parking Brake...

-

Page 11: Theory Of Operation

TASKI Intellibot SWINGOBOT 1650 CE UV systems include an additional UV sterilizer in the water recycling system. 12. Theory of Operation: The TASKI Intellibot SWINGOBOT 1650 CE and CE UV machines are commercial wet floor scrubbing systems capable of manual and autonomous robotic operation. - Page 12 12.1. TASKI Intellibot SWINGOBOT 1650 CE Flow Diagram (Parallel) TANK BYPASS VALVE FILTRATION FLOW WATER SENSOR VALVE CIRCULATION VACUUM SQUEEGEE PUMP CYLINDER SCRUB Figure: 18 The robotic floor scrubber system utilizes 53-liter tank for storing and recycling cleaning solution. The standard system uses a parallel canister filtration system with two 10 micron filters. Optional filters are also available.

- Page 13 12.2. TASKI Intellibot SWINGOBOT 1650 CE UV Flow Diagram (In Series Healthcare Only) TANK BYPASS VALVE SERIES FILTRATION FLOW WATER SENSOR VALVE STERALIZER CIRCULATION VACUUM SQUEEGEE PUMP REACTOR SCRUBBER DC-TO-AC UV POWER SUPPLY INVERTER BALLAST Figure: 19 The robotic floor scrubber system utilizes 53-liter tank for storing and recycling cleaning solution.

-

Page 14: Safety Devices

12.3. Robotic Operation: 13. Safety Devices The machine uses a number of advanced systems enabling The robotic floor scrubber system is equipped with the it to clean robotically. following safety devices: 13.1. Emergency Stop Button The Emergency Stop Button is the red switch located on the top right of the handlebar assembly. - Page 15 13.6. Floor Sensors The robotic floor scrubber system includes four infrared floor sensors located underneath the machine. The sensors measure the distance to the floor at each of the four corners and are used to detect drops in the floor, such as a stairwell. Figure: 23 Moving the handle to the right unlocks the brake.

-

Page 16: Safety Circuit Wiring

14. Safety Circuit Wiring SAFETY EMERGENCY RELAY STOP BUTTON FRONT COVER MAGNETIC INTERLOCK MAIN CONTROLLER MIRROR CONTACTS SAFETY CONTACTOR Safety Relay 12 22 32 BATTERY FUSE - 24V BATTERY BOX CONTACTOR STATE 2300129 R50955 1300573 1300589 1300633 1300614 1300614 Circuit Breaker - Fuse - Blade - Fuse - Blade - Fuse - Blade -... -

Page 17: Batteries

15.2. Accessory Battery Cart Figure: 31 TASKI Intellibot offers an accessory battery cart that allows Before Removing Batteries, hold ~ Standby button, for battery pack removal and charging in one station. If a... -

Page 18: Charging

It is typical of a gel cell charger set at 20 Always lock the wheels on the battery Amps to initially overshoot to as much as cart to prevent the cart from moving while 30 Amps and then settle back to around removing the battery from the machine. -

Page 19: Language Setup

Caution: 17. Language Setup The robotic floor scrubber system interface supports If the standby button remains illuminated three languages, English, German, and Spanish. for more than 120 seconds, press the Perform the following to select the system interface Emergency Stop button before charging the language: system. - Page 20 operator. To edit operator information press the information key to access the user setting screen. To inactivate an operator, press the inactivate operator key. This prevents an operator from accessing the machine. To edit or delete an existing operator, press the operator name.

-

Page 21: System Preferences

19. System Preferences Press the OK button to exit the system Perform the following to set the WiFi, beeper, language, preference menu. measurement system, and water flow rate system preferences. 20. Commissioning After Storage Turn on the system by pressing the standby If the machine has been in storage, the following items must button. - Page 22 Squeeze the handlebar for one second, If the system passes the operational then release. Verify that the parking brake check, twist the Emergency Stop button is holding and the machine does not drive counterclockwise to reset and press the OK forward.

- Page 23 Zone contact indicator Zone indicator (yellow text) Total number of contact detections since machine installation (white text) Total number of contact detections since machines last startup or diagnostics where performed (orange text) Resets total number of contact detections to 0 since machine last startup Return to diagnostics main screen Record the orange numbers (4) if needed.

-

Page 24: Daily Startup Procedure

30 days. operating the robotic floor scrubbing system. 22.1. Set the Parking Brake The TASKI Intellibot SWINGOBOT 1650 CE Ensure the parking brake is in the locked position by moving UV utilizes a series filtration system. The the red lever to the left. -

Page 25: Review Of Work Area

Only use cleaning products recommended 23. Review of Work Area by TASKI Intellibot. Use of products Before beginning cleaning, the operator is responsible for containing chlorine, acids, or unsuitable reviewing and preparing the work area. solvents may damage the machine and may be hazardous to the operator. -

Page 26: Manual Drive

25. Manual Cleaning Block all stairways and doorways when Use the following functions to operate the machine in manual using robotic mode. Failure to block a clean mode: stairway could result in the machine tumbling down the stairs, resulting in serious From the home screen, press the manual property damage, machine damage and clean button. - Page 27 26.2. Area Clean Area clean uses any of twelve different cleaning patterns with the option of having the machine return to the starting location when the cleaning is complete. For example the following is a Side T Right cleaning pattern: Figure: 51 The machine starting location is shown as (3).

- Page 28 The following cleaning patterns are available: Single Area Single Area Return Side T Right Side T Right Return L Left L Left Return Side T Left Side T Left Return L Right L Right Return Cross Left Cross Left Return T Left T Left Return Cross Right...

-

Page 29: Daily Shutdown Procedure

27. Daily Shutdown Procedure Using the Manual Drive mode, position the machine at the cleaning start location. The machine must be located within After completing cleaning, the following steps should be 2 ft (61 cm) of start location shown on cleaning pattern. performed daily: To enable Area Clean, perform the following from the home Use of protective glasses, gloves, and... - Page 30 Flush the tank with clean water and lose the drain valve. 27.3. Clean the Squeegee: Clean the squeegee by removing any debris between the squeegee blades. Check the pickup tube for obstructions. 27.4. Clean Caster Wheels Inspect and clean the rear caster wheels Figure: 55 27.5.

-

Page 31: Maintenance

28. Maintenance The following maintenance schedule should be followed for proper machine operation: MAINTENANCE ITEM DAILY WEEKLY □ Drain and clean tank □ Clean tank basket filter □ Remove and clean canister filters □ Clean squeegee and pick up area □... -

Page 32: Replacement Components

29. Replacement Components TASKI NO. INTELLIBOT SKU ITEM 7523968 049870 Filter - Cotton 10 Micron 7523969 1300165 Filter - Pleated 1 Micron 7523970 1300755 Filter - Cotton 20 Micron 10" 4132145 3300051 Front Blade - Squeegee - Linatex - SS... -

Page 33: Diagnostics

32. Diagnostics 33. Sonar Diagnostic The following diagnostics may be performed by operators The sonar diagnostic shows the distance with diagnostic privileges. measured in millimeters, by each of the 17 Perform the following steps with the system turned on and sonar transceivers (numbered 0-16). -

Page 34: Floor Sensor Diagnostic

It is possible to receive a false “no ground” warning on some surfaces. If the floor is causing false readings, move the machine to a different location to perform the diagnostic. 36. Gyro Diagnostic The gyro diagnostic requires machine rotation it should only be performed in an open area where the machine can be rotated 360 degrees with room for the operator. -

Page 35: Network Diagnostic

Caution: Do not change any of the gyro calibration parameters unless instructed to do so by a trained service technician. Gyro parameters affect machine performance and stability. Unauthorized changes could result in unexpected machine behavior, resulting in damage or injury. 38. -

Page 36: Outputs Diagnostic

41. Outputs Diagnostic Once priming is complete, the measured flow rate should be within 0.03 gpm (0.11 lpm) of the expected flow rate. The outputs diagnostic is used to aid in system troubleshoot by allowing privileged 43. Drive Motor Diagnostic operators to turn on specific machine devices and verify their operation. -

Page 37: Technical Data

44. Technical Data MACHINE AMOUNT UNIT AMOUNT UNIT Working width 29.13 Suction nozzle width 35.04 48.42 123 x Dimensions (L x W x H) x 32.28 82 x x 43.31 Maximum weight of operational machine 1133.18 Rated voltage Rated power, nominal 1248 1248 Fresh water tank, nominal +/ 5%... -

Page 38: Revisions

45. Revisions Date Section Content Description "10. Healthcare/UV User and Service 01-06-17 Text/copy UV/Healthcare Warnings Section Added Personnel Warnings" on page 8 01-06-17 Cover Image Large "Taski" Decal removed from Front Cover of Machine...

Need help?

Do you have a question about the swingobot 1650 CE and is the answer not in the manual?

Questions and answers