Summary of Contents for Clarke CWS200

- Page 1 WHETSTONE SHARPENER MODEL NO: CWS200 PART NO: 6500530 OPERATION & MAINTENANCE INSTRUCTIONS GC0710...

- Page 2 INTRODUCTION Thank you for purchasing this CLARKE whetstone sharpener. Before attempting to use this product, please read this manual thoroughly and follow the instructions carefully. In doing so you will ensure the safety of yourself and that of others around you, and you can look forward to your purchase giving you long and satisfactory service.

-

Page 3: General Safety Rules

GENERAL SAFETY RULES 1) WORK AREA 1. Keep the work area clean and well lit. Cluttered and dark areas invite accidents. 2. Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes. -

Page 4: Grinder/Sharpener Safety Instructions

4) POWER TOOL USE AND CARE 1. Do not force the power tool. Use the correct accessories for your application. The correct power tool will do the job better and safer at the rate which it was designed. 2. Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired. - Page 5 7. Always use the tool attachments to steady the workpiece. If the tool attachments are not used, the torque of the spinning grinding/polishing wheel may pull the workpiece from your hands. 8. Never leave the grinder unattended when it is connected to an electrical power supply.

-

Page 6: Safety Symbols

SAFETY SYMBOLS Not suitable for hand-held cutting off Not suitable for face grinding Wear eye protection Wear protective gloves Read instruction manual before use ENVIRONMENTAL PROTECTION Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment Parts &... -

Page 7: Electrical Connections

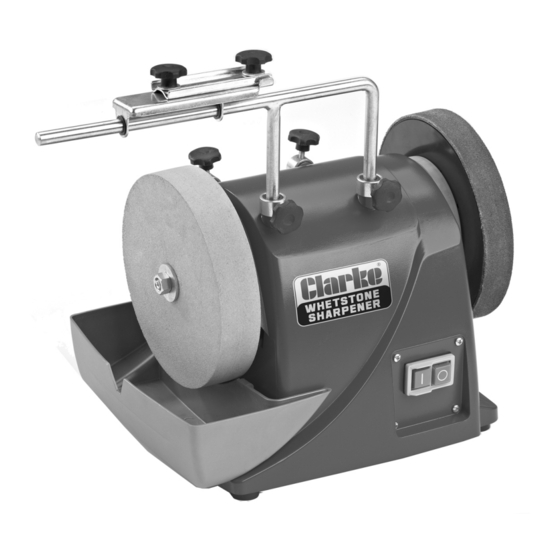

3. Should you wish to replace a detachable fuse carrier,ensure that the correct replacement is used (as indicated by marking or colour code). 4. Replacement fuse covers can be obtained from your local Clarke dealer or any electrical stockist. FUSE RATING The fuse in the plug must be replaced with one of the same rating and this replacement must be ASTA approved to BS1362. - Page 8 OVERVIEW DESCRIPTION NO DESCRIPTION ON/OFF Button Honing Wheel Tool Support Tool Support Plate Fixing Knob Grinding Wheel Water Tank Tool Holders (2) Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com...

-

Page 9: Before Use

BEFORE USE INVENTORY When unpacking, check to ensure that all the parts listed are present. If any are missing or damaged, contact your CLARKE dealer. • 1 x Grinder • 1 x Stone Grinding Wheel • 1 x Water Tank •... - Page 10 6. Install the water tank beneath the grinding stone. Fill the water tank with clean water up to the fill line indicated on the tank as in Fig 3. During operation,the grinding stone will become saturated with water. Ensure the water tank is re-filled when necessary and discard any excess particles of stone which have accumulated in the water tank.

-

Page 11: Using Your Grinder

USING YOUR GRINDER WARNING: FRAGMENTS FROM A BROKEN/DETACHED GRINDING WHEEL CAN CAUSE SERIOUS INJURY. WARNING: WHEN USING THE GRINDING WHEEL, DO NOT STAND DIRECTLY IN LINE WITH THE ROTATING WHEEL. WARNING: ENSURE THAT THE WORKING POSITION ADOPTED DOES NOT CAUSE OPERATOR FATIGUE WHICH MAY LEAD TO LOSS OF CONTROL OF THE TOOL BEING GROUND. -

Page 12: Grinding/Honing A Small Knife Blade

GRINDING/HONING A SMALL KNIFE BLADE 1. Loosen the two knurled screws on the holder. Centre the tension plate along the top edge of the knife blade then firmly tighten the two knurled screws to secure the knife blade in position as in Fig 7. 2. -

Page 13: Honing Tips

• Allow the grinding stone to do the cutting. Do not apply excessive downward pressure on the tool when grinding. • Make sure the level of water in the tank is adequate. Never attempt to dry grind. • When finished, turn the machine off and wait until it has completely stopped before unplugging from the power supply. -

Page 14: Maintenance

New grinding stones are frequently not true and in time can become grooved, glazed (built-up), out of round or otherwise mis-shapen. To correct these defects, a grinding stone dresser is required. This is available from your Clarke dealer. ET125 Grinding Wheel Dressser,- Part No: 1700225 Replacement Dresser Wheel,- Part No: 1700230 ET154 1/2 Carat Diamond Tip Wheel Dresser,- part No:1700329 1. -

Page 15: General Maintenance

SOLUTION Grinder will not No power supply. Check supply & rectify. operate. ON/OFF switch is faulty. Consult your CLARKE dealer. Fuse blown. Check & replace if necessary. Consult your dealer if condition persists. Motor faullty. Consult your CLARKE dealer. Motor runs but Retaining nut not tight. -

Page 16: Specifications

SPECIFICATIONS Product Dimensions (L x W x H) 330 x 280 x 275 mm Weight 9.7 kg Grinding StoneDimensions (D x T) 200 x 40 mm Honing Wheel Dimensions (D x T) 200 x 30 mm Stone type K220 Rated Voltage / Frequency 230 V / 50 Hz Motor Wattage 120 W... -

Page 17: Exploded Diagram And Parts List

EXPLODED DIAGRAM & PARTS LIST Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com... - Page 18 EXPLODED DIAGRAM & PARTS LIST No Description No Description Holder Assembly Main Housing Knurled Screw Self-tapping Screw Washer ON/OFF Pushbuttons Spring Cable and Plug Centre Tension Plate Junction Box Holder Arm Capacitor Guard Drive Motor Wing-nut Plastic Foot Handle Screw Tool Support Assy Water Tank Pivot bush...

-

Page 19: Declaration Of Conformity

DECLARATION OF CONFORMITY Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com...

Need help?

Do you have a question about the CWS200 and is the answer not in the manual?

Questions and answers