ESAB Mig 4002c Instruction Manual

Hide thumbs

Also See for Mig 4002c:

- Instruction manual (34 pages) ,

- Service manual (64 pages) ,

- Instruction manual (32 pages)

Summary of Contents for ESAB Mig 4002c

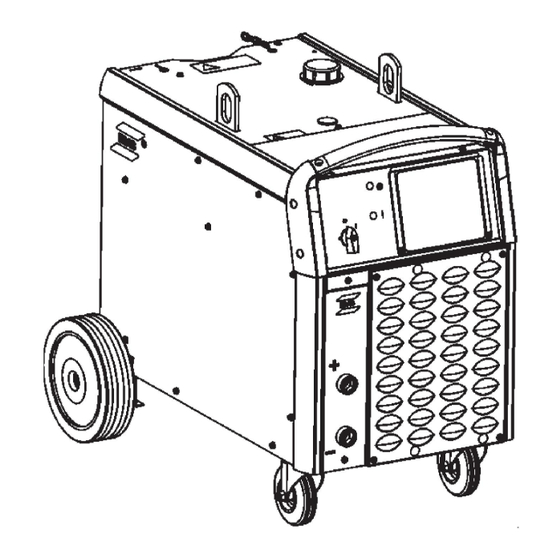

- Page 1 Origo™ Mig 4002c, Mig 5002c, Mig 6502c Instruction manual 0463 337 131 GB 20130924 Valid for: 850-xxx-xxxx, 851-xxx-xxxx...

-

Page 2: Table Of Contents

Topping up the coolant..................22 FAULT TRACING....................23 10 ORDERING OF SPARE PARTS ................. 24 CLEANING......................... 25 SCHEMATIC DIAGRAM ....................26 CONNECTION INSTRUCTION..................28 ORDERING NUMBER ....................29 ACCESSORIES ......................30 Rights reserved to alter specifications without notice. 0463 337 131 © ESAB AB 2013... -

Page 3: Users Resposibility

The user of this equipment shall have the sole responsibility for any malfunction which results from improper use, faulty maintenance, damage, improper repair or alteration by anyone other than the manufacturer or a service facility designated by the manufacturer. 0463 337 131 - 3 - © ESAB AB 2013... -

Page 4: Safety Precautions

4. Have fire extinguishing equipment handy for instant use, such as a garden hose, water pail, sand bucket, or portable fire extinguisher. Be sure you are trained in its use. 0463 337 131 - 4 - © ESAB AB 2013... - Page 5 Connect the work cable to the workpiece as close as possible to the area being welded. e) Keep welding power source and cables as far away from your body as possible. 0463 337 131 - 5 - © ESAB AB 2013...

- Page 6 5. For additional information, refer to CGA Standard P-1, “Precautions for Safe Handling of Compressed Gases in Cylinders”, which is available from Compressed Gas Association, 1235 Jefferson Davis Highway, Arlington, VA 22202. 0463 337 131 - 6 - © ESAB AB 2013...

- Page 7 8. ANSI/AWS F4.1 - “Recommended Safe Practices for Welding and Cutting of Containers That Have Held Hazardous Substances” MEANING OF SYMBOLS As used throughout this manual: Means Attention! Be Alert! 0463 337 131 - 7 - © ESAB AB 2013...

- Page 8 WARNING! Means potential hazards which could result in personal injury or loss of life. CAUTION! Means hazards which could result in minor personal injury. 0463 337 131 - 8 - © ESAB AB 2013...

-

Page 9: Safety

3 SAFETY SAFETY Users of ESAB equipment have the ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that apply to this type of equipment. The following recommendations should be observed in addition to the standard regulations that apply to the workplace. - Page 10 MALFUNCTION - Call for expert assistance in the event of malfunction. Read and understand the instruction manual before installing or operating. PROTECT YOURSELF AND OTHERS! ESAB can provide you with all necessary welding protection and accessories. WARNING! Do not use the power source for thawing frozen pipes.

- Page 11 3 SAFETY CAUTION! Read and understand the instruction manual before installing or operating. 0463 337 131 - 11 - © ESAB AB 2013...

-

Page 12: Introduction

4 INTRODUCTION INTRODUCTION The Mig 4002c, Mig 5002c and Mig 6502c are welding power sources intended for MIG/MAG welding, as well as for welding with powder filled cored wire (FCAW-S), Live TIG welding (only some of the control panels) and for welding with coated and cellulosic electrodes (MMA). -

Page 13: Technical Data

Valid for power sources without VRD specifications on the rating plate. Valid for power sources with VRD specifications on the rating plate. The VRD funtion is explained in the instruction manual for the control panel. 0463 337 131 - 13 - © ESAB AB 2013... - Page 14 Valid for power sources without VRD specifications on the rating plate. Valid for power sources with VRD specifications on the rating plate. The VRD funtion is explained in the instruction manual for the control panel. 0463 337 131 - 14 - © ESAB AB 2013...

- Page 15 Valid for power sources without VRD specifications on the rating plate. Valid for power sources with VRD specifications on the rating plate. The VRD funtion is explained in the instruction manual for the control panel. 0463 337 131 - 15 - © ESAB AB 2013...

- Page 16 Equipment marked IP23 is intended for indoor and outdoor use. Application class The symbol indicates that the power source is designed for use in areas with increased electrical hazard. 0463 337 131 - 16 - © ESAB AB 2013...

-

Page 17: Installation

It is the user's responsibility to take adequate precautions. Location Position the welding power source such way that its cooling air inlets and outlets are not obstructed. 0463 337 131 - 17 - © ESAB AB 2013... -

Page 18: Assembly Of Components

Check that the unit is connected to the correct mains power supply voltage, and that it is protected by the correct fuse size. A protective earth connection must be made, in accordance with regulations. 0463 337 131 - 18 - © ESAB AB 2013... - Page 19 * AAG (Arc Air Gouging) NOTE! The mains cable areas and fuse sizes as shown above are in accordance with Swedish regulations. Use the power source in accordance with the relevant national regulations. 0463 337 131 - 19 - © ESAB AB 2013...

-

Page 20: Operation

Connection BLUE for cooling water to the wire feed unit Connection for welding current cable (+) Connection RED for cooling water from the wire feed unit Connection for welding current cable (-) 0463 337 131 - 20 - © ESAB AB 2013... -

Page 21: Overheating Protection

Water connection The Feed has a sensor ELP, ESAB Logic Pump, that senses if the water hoses of the welding gun are connected. When a water cooled welding gun is connected, the water pump starts. -

Page 22: Maintenance

The air filter is an accessory, see "ACCESSORIES" chapter. Topping up the coolant ESAB ready mixed coolant is recommended for use, see "ACCESSORIES" chapter. 0463 337 131 - 22 - © ESAB AB 2013... -

Page 23: Fault Tracing

• Check that the correct current value is set. • Check that the correct welding wires are being used. • Check the main power supply fuses. 0463 337 131 - 23 - © ESAB AB 2013... -

Page 24: Ordering Of Spare Parts

10 ORDERING OF SPARE PARTS ORDERING OF SPARE PARTS Repair and electrical work should be performed by an authorized ESAB service personnel. Use only ESAB original replacement and wear parts. When ordering replacement parts, order by part number and part name, as illustrated on the figure. -

Page 25: Cleaning

CLEANING CLEANING 0463 337 131 - 25 - © ESAB AB 2013... -

Page 26: Schematic Diagram

SCHEMATIC DIAGRAM SCHEMATIC DIAGRAM 0463 337 131 - 26 - © ESAB AB 2013... - Page 27 SCHEMATIC DIAGRAM 0463 337 131 - 27 - © ESAB AB 2013...

-

Page 28: Connection Instruction

CONNECTION INSTRUCTION CONNECTION INSTRUCTION 0463 337 131 - 28 - © ESAB AB 2013... -

Page 29: Ordering Number

Mig 5002cw 0349 312 740 230 V - 575 V, 3~50Hz, 3~60Hz Origo Mig 6502c 0349 300 544 Spare parts list Technical documentation is available on the Internet at www.esab.com 0463 337 131 - 29 - © ESAB AB 2013... -

Page 30: Accessories

Feed 3004 W, with water 0460 526 981 Feed 4804 0460 526 991 Feed 4804 W, with water Control panel U8 0460 820 880 Control panel U8 0460 820 881 Control panel U8 Plus 0463 337 131 - 30 - © ESAB AB 2013... -

Page 31: Esab Ab

0459 906 896 YardFeed 2000 with water 0349 313 055 A24 Control panel kit 0349 302 251 Water flow guard 0349 483 296 Coolant ready mixed (5l) 0349 302 252 Filter 0463 337 131 - 31 - © ESAB AB 2013... - Page 32 0459 528 573 Connection set 15 m, water 0459 528 574 Connection set 25 m, water 0459 528 575 Connection set 35 m, water 0459 528 576 Connection set 50 m, water 0463 337 131 - 32 - © ESAB AB 2013...

- Page 33 0459 528 991 Connection set 5 m, water 0459 528 992 Connection set 10 m, water 0459 528 993 Connection set 15 m, water 0459 528 994 Connection set 25 m, water 0463 337 131 - 33 - © ESAB AB 2013...

- Page 34 ESAB Welding & Cutting Products, Florence, SC Welding Equipment COMMUNICATION GUIDE - CUSTOMER SERVICES CUSTOMER SERVICE QUESTIONS: Telephone: (800) 362-7080 / Fax: (800) 634-7548 Hours: 8.00 AM to 7:00 PM EST Order Entry Product Availability Pricing Order Information Returns ENGINEERING SERVICE: Telephone: (834) 664-4416 / Fax: (800) 446-5693 Hours: 7.30 AM to 5:00 PM EST...

Need help?

Do you have a question about the Mig 4002c and is the answer not in the manual?

Questions and answers