ESAB Origo Mig 4002c Instruction Manual

Hide thumbs

Also See for Origo Mig 4002c:

- Instruction manual (34 pages) ,

- Service manual (64 pages) ,

- Instruction manual (32 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Service Manual

Advertisement

Table of Contents

Summary of Contents for ESAB Origo Mig 4002c

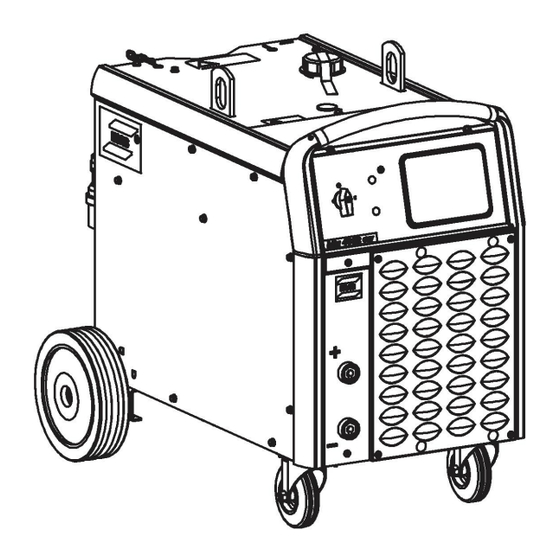

- Page 1 Origo™ Mig 4002c Mig 5002c Mig 6502c Instruction manual Valid for: serial no. 136-, 740-, 745-, 801-, 806-xxx-xxxx 0463 264 001 GB 20170310...

-

Page 3: Table Of Contents

6.1.2 Welding torch..................Topping up the coolant ................FAULT TRACING................... 20 ORDERING SPARE PARTS ................21 CLEANING......................DIAGRAM ......................CONNECTION INSTRUCTION................ORDER NUMBERS ....................ACCESSORIES ....................Rights reserved to alter specifications without notice. 0463 264 001 © ESAB AB 2017... -

Page 4: Safety

Data Sheets (SDSs). Safety precautions Users of ESAB equipment have the ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that apply to this type of equipment. The following recommendations should be observed in addition to the standard regulations that apply to the workplace. - Page 5 • Protect your eyes and body. Use the correct welding screen and filter lens and wear protective clothing. • Protect bystanders with suitable screens or curtains. NOISE - Excessive noise can damage hearing Protect your ears. Use earmuffs or other hearing protection. 0463 264 001 - 5 - © ESAB AB 2017...

- Page 6 For further information contact the nearest ESAB dealer. ESAB has an assortment of welding accessories and personal protection equipment for purchase. For ordering information contact your local ESAB dealer or visit us on our website. 0463 264 001 - 6 -...

-

Page 7: Introduction

The power sources are intended for use with the following wire feed units: • Feed 3004/4804 • MobileFeed 300 • YardFeed 2000 ESAB accessories for the product can be found in the "ACCESSORIES" chapter of this manual. Equipment The power source is supplied with: • Return cable 5m with return clamp •... -

Page 8: Technical Data

Valid for power sources without VRD specification on the rating plate. Valid for power sources with VRD specification on the rating plate. The VRD function is explained in the instruction manual for the control panel. 0463 264 001 - 8 - © ESAB AB 2017... - Page 9 Valid for power sources without VRD specification on the rating plate. Valid for power sources with VRD specification on the rating plate. The VRD function is explained in the instruction manual for the control panel. 0463 264 001 - 9 - © ESAB AB 2017...

- Page 10 Valid for power sources without VRD specification on the rating plate. Valid for power sources with VRD specification on the rating plate. The VRD function is explained in the instruction manual for the control panel. 0463 264 001 - 10 - © ESAB AB 2017...

- Page 11 3 TECHNICAL DATA Cooling unit Cooling power 1.0 kW at 25° C (77 °F) and flow 1.0 l/min (0.26 gpm) Coolant ESAB's ready mixed coolant Coolant quantity 5 l (1.45 gal) Maximum flow 2.1 l/min (0.55 gpm) Duty cycle The duty cycle refers to the time as a percentage of a ten-minute period that you can weld or cut at a certain load without overloading.

-

Page 12: Installation

Straps must be used when lifting the power source. The handle is only intended for pulling it. Location Position the welding power source so that its cooling air inlets and outlets are not obstructed. 0463 264 001 - 12 - © ESAB AB 2017... -

Page 13: Assembly Of Components

4 INSTALLATION Assembly of components WARNING! During transport, the rear wheels of the power source are in their forward position. Before use, place the wheels in their rear position. 0463 264 001 - 13 - © ESAB AB 2017... -

Page 14: Mains Power Supply

103A 62 A (68 A*) 59 A (65 A*) 53 A (69 A*) 47 A (52 A*) 100% duty cycle 80 A 48 A 46 A 42 A 37 A 0463 264 001 - 14 - © ESAB AB 2017... - Page 15 The mains cable areas and fuse sizes as shown above are in accordance with Swedish regulations. For other regions, supply cables must be suitable for the application and meet local and national regulations. 0463 264 001 - 15 - © ESAB AB 2017...

-

Page 16: Operation

General safety regulations for handling the equipment can be found in the "SAFETY" chapter of this manual. Read it through before you start using the equipment! WARNING! Secure the equipment - particularly if the ground is uneven or sloping. 0463 264 001 - 16 - © ESAB AB 2017... -

Page 17: Connections And Control Devices

Water connection The wire feed unit is equipped with a detection system ELP, (ESAB Logic Pump), which checks that the water hoses for the welding torch are connected. When a water cooled welding torch is connected, the water pump starts. -

Page 18: Water Flow Guard

"Live TIG-start" At a "Live TIG-start" the tungsten electrode must touch the workpiece. When the electrode is then lifted away from workpiece, the arc is struck with the set current value. 0463 264 001 - 18 - © ESAB AB 2017... -

Page 19: Maintenance

Wear parts should be cleaned and replaced at regular intervals in order to achieve trouble-free welding. Topping up the coolant Coolant Use ESAB approved coolant only. Non-approved coolants might damage the equipment and jeopardize product safety. For ordering information, see the "ACCESSORIES" chapter in the instruction manual. -

Page 20: Fault Tracing

• Check that the welding current supply and return cables are correctly connected. • Check that the correct current value is set. • Check that the correct welding wires are being used. • Check the main power supply fuses. 0463 264 001 - 20 - © ESAB AB 2017... -

Page 21: Ordering Spare Parts

Spare parts and wear parts can be ordered through your nearest ESAB dealer, see the back cover of this document. When ordering, please state product type, serial number, designation and spare part number in accordance with the spare parts list. -

Page 22: Cleaning

CLEANING CLEANING 0463 264 001 - 22 - © ESAB AB 2017... -

Page 23: Diagram

DIAGRAM DIAGRAM 0463 264 001 - 23 - © ESAB AB 2017... - Page 24 DIAGRAM Diagram (1) 0463 264 001 - 24 - © ESAB AB 2017...

- Page 25 DIAGRAM Diagram (2) 0463 264 001 - 25 - © ESAB AB 2017...

-

Page 26: Connection Instruction

CONNECTION INSTRUCTION CONNECTION INSTRUCTION 0463 264 001 - 26 - © ESAB AB 2017... - Page 27 CONNECTION INSTRUCTION 0463 264 001 - 27 - © ESAB AB 2017...

-

Page 28: Order Numbers

0349 311 380 Mig 6502c 230 V - 500 V , 50/60 Hz 0349 300 544 Spare parts list Mig 4002c - Mig 6502c Technical documentation is available on the Internet at: www.esab.com 0463 264 001 - 28 - © ESAB AB 2017... -

Page 29: Accessories

0459 906 887 YardFeed 2000 0459 906 897 YardFeed 2000 with water Wire feed unit with control panel U6 0459 906 886 YardFeed 2000 0459 906 896 YardFeed 2000 with water 0463 264 001 - 29 - © ESAB AB 2017... - Page 30 0349 302 250 Transformer for CO2 heater 0349 302 251 Water flow guard 0465 720 002 ESAB ready mixed coolant (10 l / 2.64 gal) Use of any other cooling liquid than the prescribed one might damage the equipment. In case of such damage, all warranty undertakings from ESAB cease to apply.

- Page 31 0459 528 572 10.0 m (32.8 ft) 0459 528 573 15.0 m (49.2 ft) 0459 528 574 25.0 m (82.0 ft) 0459 528 575 35.0 m (114.8 ft) 0459 528 576 50.0 m (164.0 ft) 0463 264 001 - 31 - © ESAB AB 2017...

- Page 32 0459 528 990 1.7 m (5.6 ft) 0459 528 991 5.0 m (16.4 ft) 0459 528 992 10.0 m (32.8 ft) 0459 528 993 15.0 m (49.2 ft) 0459 528 994 25.0 m (82.0 ft) 0463 264 001 - 32 - © ESAB AB 2017...

- Page 33 ACCESSORIES 0463 264 001 - 33 - © ESAB AB 2017...

- Page 34 ESAB subsidiaries and representative offices Europe THE NETHERLANDS North and South America SOUTH KOREA ESAB Nederland B.V. ESAB SeAH Corporation AUSTRIA Amersfoort ARGENTINA Kyungnam ESAB Ges.m.b.H Tel: +31 33 422 35 55 CONARCO Tel: +82 55 269 8170 Vienna-Liesing Fax: +31 33 422 35 44...

Need help?

Do you have a question about the Origo Mig 4002c and is the answer not in the manual?

Questions and answers