Subscribe to Our Youtube Channel

Summary of Contents for Blizzard B54

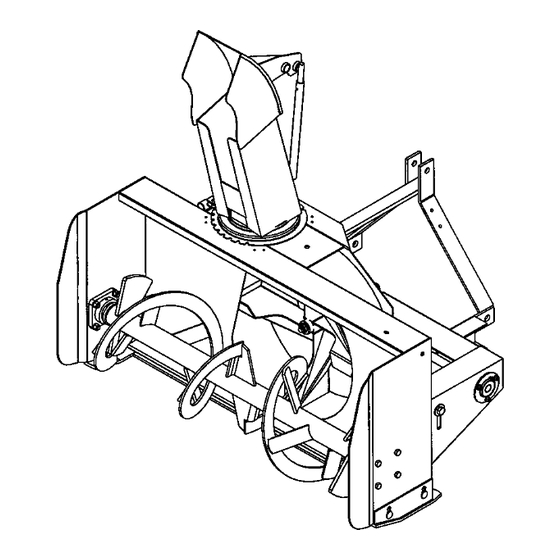

- Page 1 SNOWBLOWER BLIZZARD B54 & B64 MODELS SERIAL NO. 2024768 AND UP OM 0277-A 06/02 by RAD Technologies Inc.

-

Page 3: Table Of Contents

TABLE OF CONTENT INTRODUCTION – TO THE PURCHASER ....................3 SAFETY PRECAUTIONS.......................... 4 Before Operation ..........................4 Notice..............................5 The Snowblower ..........................5 Before Operation ....................... 5 Snowblower operation ....................... 6 The Tractor ............................7 General Information ......................7 Operating the Tractor......................7 During Operation ....................... - Page 4 Driveline.......................... 16 Lubrication........................16 PARTS ..............................17 Introduction ............................17 Frame and Related Parts - Blizzard B54 & B64 ................18 Gearbox (663485)..........................20 Manual Rotation – Kit 9377....................... 21 Hydraulic Rotation by Cylinder – Kit 8056..................22 Driveline (665341)..........................23 WARRANTY ............................

-

Page 5: Introduction - To The Purchaser

O THE URCHASER The illustrations may not necessarily reproduce All BER-VAC and BLIZZARD products are the full detail and the exact shape of the parts or designed to give safe, dependable service if they depict the actual models, but are intended for... -

Page 6: Safety Precautions

SAFETY PRECAUTIONS SAFETY FIRST This symbol, the industry's "Safety Alert Symbol", is used throughout this manual and on labels on the machine itself to warn of the possibility of personal injury. Read these instructions carefully. It is essential that you read the instructions and safety regulations before you attempt to assemble or use this unit. -

Page 7: Notice

SAFETY PRECAUTIONS- continued OTICE A safe operator is the best insurance against accidents. All operators, no matter how experienced they may be, should read this Operator's Manual and all other related manuals before attempting to operate an implement. Please read the following section and pay particular attention to all safety recommen- dations contained in this manual and those labeled on the implements and on the tractor. -

Page 8: Snowblower Operation

SAFETY PRECAUTIONS- continued 14. Never operate machine at high transport Snowblower Operation speeds on a slippery surface. 15. Use extra caution when backing up. 1. Before leaving the tractor unattended, take all possible precautions. Disengage the 16. Do not direct discharge at bystanders or PTO, stop the engine and remove the animals. -

Page 9: The Tractor

SAFETY PRECAUTIONS- continued RACTOR 13. Never allow anyone operate snowblower until they are thoroughly familiar General Information with basic tractor and snowblower operation. 14. Make sure the tractor is counterweighted as 1. Read the operator's manual carefully before recommended by your dealer. Weights using tractor. -

Page 10: Maintenance

SAFETY PRECAUTIONS- continued RANSPORTING AINTENANCE 1. If the tractor/snowblower is to be driven on Park the tractor/snowblower on level ground, set public roads, it must be equipped with an the parking brake, disengage the PTO, shut off SMV (Slow Moving Vehicle) sign. Check the engine, remove the key, and lower the local traffic codes that may apply to unit... -

Page 11: Decals

DECALS Replace immediately if damaged. 660988 660989 656779 664467 664459 655834 664458 Located on driveline Included with Option 8056 664548 656780 656781 OM 0279-A... -

Page 12: Assembly

ASSEMBLY Chute & Manual Rotation NOWBLOWER SSEMBLY 1. Place the anti-friction ring (fig.2, item 4) over The snowblower is assembled at the factory, the chute base, placing the raised part upside however, snowblower kit must be assembled. and toward the center of the frame. Use the present manual and lay out all parts for assembly. - Page 13 ASSEMBLY 5. Install the adjustment tube (fig. 2, item 3) in 9. Insert handle bracket (fig.4, item 14) inside the lower hole on the backside of the chute anchor tube (fig.4, item 15). Adjust the height and the adjustment rod (fig. 2, item 2) in the of the handle bracket according to your needs upper hole.

-

Page 14: Snowblower Installation

ASSEMBLY CAUTION: To avoid personal injury, CAUTION: Before connecting check the full lifting range of the snowblower, snowblower driveline to tractor drive shaft, to ensure that the chute rotation handle is make sure driveline is not too long in raised, clear of the operator’s area when the lowered and middle position. -

Page 15: Hydraulic Rotation With Cylinder - 8056 (Optional)

ASSEMBLY Hydraulic Rotation with Cylinder 8056 (Optional) Figure 6 1. Place the plastic anti-friction insert (fig.2, item 5. Install the bell crank (item 2) on the frame by 4) over the chute base, placing the raised part sliding a spacer (item 4) under the cylinder bracket, opposite the ∅11/16"hole. -

Page 16: Operation

OPERATION Reduction Chain Tension Adjustment ENERAL REPARATION The premature wear of the chain may be caused 1. Read the operator’s manual carefully before by tension being too tight. It is therefore important using the tractor and snowblower. Be not to tighten chain to its maximum. thoroughly familiar with the controls and •... -

Page 17: Snow Removal Methods

OPERATION EMOVAL ETHODS When removing snow, do not use the snowblower as a dozer blade to push snow. Let the snowblower work its way through deep drifts. If the speed of your tractor is too fast, the snowblower may become overloaded and clog. -

Page 18: Maintenance

MAINTENANCE Lubrication AINTENANCE 1. GEAR : Check the oil level in the worm gear drive every month. If necessary add SAE Storage 80W90 gear oil, AGMA 5EP or equivalent. 1. Check the shear bolts at frequent intervals for 2. REDUCTION CHAIN : Lubricate with chain proper tightness to be sure the blower is in saw lubricant every 4 hours of operation and safe working condition. -

Page 19: Parts

PARTS NTRODUCTION All parts are illustrated in "exploded views" which show the individual parts in their normal relationship to each other. Reference numbers are used in the illustrations. These numbers correspond to those in the "Reference Number" (REF) column, and are followed by the description and quantity required. O/L - "Obtain Locally"... -

Page 20: Frame And Related Parts - Blizzard B54 & B64

PARTS – B B54 & B64 RAME AND ELATED ARTS LIZZARD OM 0277-A... - Page 21 PARTS – B B54 & B64 RAME AND ELATED ARTS LIZZARD ESCRIPTION Housing Chute ass'y 664793 664793 Nylon ring 659151 659151 Bolt hex. 1/4" NC x 3/4" Retaining plate 659146 659146 Lockwasher 1/4" dia. hole Nut hex. 1/4" NC Cotter pin ∅1/4" x 2"...

-

Page 22: Gearbox (663485)

PARTS (663485) EARBOX ESCRIPTION Casing 659848 Gear 662236 Shim 656649 Bearing 656653 Parallel Key 659850 Input Shaft 664663 Oil Seal 659852 Output Shaft 659853 Shim 659854 Snap Ring 656652 Shim 659855 O-Ring 661144 Plug 659847 Bolt hex. M8 x 55mm – 8.8 Nut hex. -

Page 23: Manual Rotation - Kit 9377

PARTS – K 9377 ANUAL OTATION ESCRIPTION Handle 658252 Rotation tube 660188 Rotation yoke 659595 Universal block 658193 Rotation worm 659161 Worm rotation bracket 659145 Roll pin 1/4" x 1 1/4" Hairpin 5mm x 100mm 659073 Plastic handle 656797 Plastic bushing 1 5/16" 657335 Plastic bushing 1 11/16"... -

Page 24: Hydraulic Rotation By Cylinder - Kit 8056

PARTS – K 8056 YDRAULIC OTATION BY YLINDER ESCRIPTION UMBER Cylinder Bracket 664450 Bell Crank 664451 Push Arm 664452 Spacer 664429 Bushing 664428 Flatwasher (7/16") Hex. Nut (3/8" NC) Lockwasher (3/8") Stover Nut (5/16" NC) Flat washer (3/8") Shoulder Screw (3/8" x 1", 5/16" NC) 664583 Hex. -

Page 25: Driveline (665341)

PARTS (665341) RIVELINE ESCRIPTION UMBER Quick disconnect Yoke - Q.L. type 664543 Universal Joint Kit 658094 Outer Yoke 664544 Outer Tube 659107 Inner Tube 659105 Inner Yoke 664545 Yoke with Key 665350 Shield 664547 Bolt 8mm x 1.25mm x 45mm long gr.8.8 Nut 8mm x 1.0mm OM 0277-A... -

Page 26: Warranty

WARRANTY TECHNOLOGIES INC. RAD TECHNOLOGIES INC. warrants to the original buyer that the equipment is free from defects in material and workmanship. RAD TECHNOLOGIES INC.'s obligation, under this warranty, will be limited to the repair or replacement of any non-wear part or component, which RAD TECHNOLOGIES INC. -

Page 27: Torque Specification Table

TORQUE SPECIFICATION TABLE GENERAL SPECIFICATION TABLE Use the following torques when special torques are not given Note: These values apply to fasteners as received from supplier, when dry. These values do not apply if lubricants are used. BOLT SIZES (SAE) TORQUE INCHES Pounds-Foot... - Page 28 Manufactured by: RAD Technologies Inc. 2835, Chemin de l’Aéroport Thetford Mines, Québec, Canada, G6G 5R7 Tel.: (418) 338-4499 - Fax.: (418) 338-6090 E-mail : radtech@radinter.com Internet : www.radinter.com Printed in Canada...

Need help?

Do you have a question about the B54 and is the answer not in the manual?

Questions and answers