Table of Contents

Advertisement

Quick Links

Ride-on Brushcutter

CMX 224/ CM225/ CM184

Operator's Manual

Read this manual completely before operating or maintaining this machine.

Failure to follow safety precautions could result in serious injury or death.

Keep this manual for future reference by you and by all those who operate

and maintain this machine.

Original Instructions

(in English)

5321 5311 003

CHIKUSUI CANYCOM, INC.

90-1 Fukumasu, Yoshii-machi,

Ukiha-shi, Fukuoka, Japan 839-1396

Tel.+81-(0)943-75-2195 Fax.+81-(0)943-75-4396

5332 5351 000 02

Advertisement

Table of Contents

Summary of Contents for CanyCom CMX 224

- Page 1 Ride-on Brushcutter CMX 224/ CM225/ CM184 Operator's Manual 5321 5311 003 Read this manual completely before operating or maintaining this machine. Failure to follow safety precautions could result in serious injury or death. Keep this manual for future reference by you and by all those who operate and maintain this machine.

- Page 2 CHIKUSUI CANYCOM, INC. http://www.canycom.co.jp/ Sales Headquarters TEL +81-(0)943-75-2195 FAX +81-(0)943-75-4396 ■ (International) Authorized Dealer All rights reserved. Unauthorized use or reproduction of this material is prohibited.

- Page 3 Notice to Users and Maintenance Personnel Thank you for purchasing this machine. This manual provides information needed for safe and effective use of this machine to those who operate or maintain machine. Make sure to read and understand the manual thoroughly before operating this product.

- Page 4 Notice to Owner • Be sure that everyone who uses this machine, including those who rent or lease this machine, receives a copy of this Operator's Manual and understands the importance of reading and following the information in this manual. Warning Terms Used in this Manual In this manual, the following four warning terms are used to signal the four levels of hazard (or seriousness of possible accidents).

- Page 5 Warranty and After-Sales Service Warranty CHIKUSUI CANYCOM, INC. guarantees this product, based on the terms of warranty. After-Sales Service Consult your local CANYCOM dealer or our company’s sales department regarding service orders or any questions or problems that may arise when using this machine. Please make sure to have the product name, serial number, and the make and type of engine handy at the time of contact.

-

Page 6: Table Of Contents

Contents 1. Safety Safety Labels ........1 Safety Mechanisms . - Page 7 Driving ........22 Starting .

- Page 8 Removing and Installing Body Panels ....49 Front Cover ........... 49 Head Lamp.

- Page 9 Storage ........76 6.

-

Page 10: Safety

• Replace these labels immediately if they have been removed, have fallen off or become illegible. Use the part number, on the label or shown in this manual, to order a replacement label from your CANYCOM representative. (CMX224 Only) 5332M-0101-010E... - Page 11 Safety 5332 5122 000 (CMX224 Only) 5332 5109 000 5332 5121 000 5332 5114 000 5332 5128 000 5321 5116 000 5332 5125 000 3667 5063 000 5305 5326 000 5332 5127 000 5332 5127 000 5332M-0101-020...

-

Page 12: Safety Mechanisms

Safety Safety Mechanisms This product is equipped with the following safety mechanisms. Start Interlock Mechanism Engine can be started only when parking brake is in [ (engaged)] position and cutting rotary clutch in [OFF] position. This is to prevent unintended movement of machine or cutting blade when starting engine. -

Page 13: Safety Precautions

Safety Safety Precautions This section contains safety precautions to follow when operating and maintaining the machine. Read and understand the precautions in this section as well as throughout this manual and follow them when operating or maintaining the machine. Failure to follow safety precautions could result in property damage, serious injury or death to the operator or bystanders. -

Page 14: Preparation

Safety Preparation • Fuel is highly flammable. See Checking and Filling Fuel, page 17, for important safety information on handling fuel. • Always wear protective footwear, long trousers, hardhat, safety glasses and ear protection when operating or servicing the machine. Proper clothing will minimize the chance of injury. -

Page 15: Operation

Safety Operation This machine is intended for cutting grass and bushes. Any other use may pose hazard or cause damage to the machine. The stability of the machine is affected by the speed, rate of steering, terrain and the operator's weight. Always pay close attention to these factors or a loss of control or tip over could occur, resulting in property damage, serious injury or death. - Page 16 Safety • Always travel slowly and use extra caution when operating on unfamiliar terrain. Be alert when traveling on changing terrain. • Never operate on terrain that you are not comfortable with. Avoid terrain that is so rough, slippery or loose that you feel like you could tip over. •...

- Page 17 Safety Driving on a Slope • Never use on a slope steeper than 25 degrees for the CMX224 and 15 degrees for the CM225 and CM184. • Driving on a slope can be dangerous. It can result in a tip over and cause serious injury or death.

- Page 18 Safety Cutting When conducting cutting operation, take the following precautions. • Always follow the proper procedures for cutting as described in this manual. • Shutt off the work site. Post signs to inform of the cutting operation. Close off the site with rope if necessary to keep people, especially children, off the work site.

-

Page 19: Servicing

Safety Servicing • Do not service the machine when the engine is running. If it is absolutely necessary to run the engine while servicing, pay attention to the moving parts. • Do not operate the engine in a confined space where dangerous carbon monoxide fumes can accumulate. -

Page 20: Controls And Components

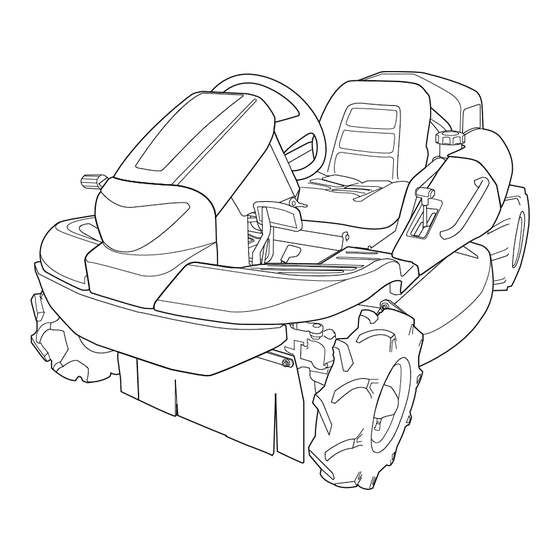

Controls and Components Name and Function of Controls Front Cover Seat Tool Box (Under Front Cover) Fuel Filler Cap Head Lamp Handrail Side Cover, Left Front Bumper Cutting Blade Shield, Left Forward Front Tire Plastic Bottle Holder Steering Wheel Engine Hood Rear Lamp (CMX224 Only) Cutting Blade... - Page 21 Controls and Components 15 17 (Right Pedal Model) 4 (Right Lever Model) 5332M-0201-010E -12-...

- Page 22 Controls and Components 1 Main Switch ... . Main switch is used to start or stop engine. 2 Throttle Lever ..Throttle lever is used to control engine speed. 3 Drive Pedal .

- Page 23 Controls and Components 10 Cutting Height Adjust ..Cutting height adjust lever is used to adjust the cutting Lever height. Grab and hold cutting height adjust lock and move 11 Cutting Height Adjust cutting height adjust lever back or forth to adjust cutting Lock height.

-

Page 24: Specifications

Specifications Product Specifications · Use this product properly after understanding its specifications thoroughly. Model and Type CMX224 CM225 CM184 Machine Mass Mowing Rate 7300 7100* Overall Length 1947 Overall Width 1020 Overall Height Wheelbase 1300 Front Tread Rear Ground Clearance Model Robin EH65DS Robin EH63DS... -

Page 25: Contents Of Tool Bag

Specifications Model and Type CMX224 CM225 CM184 Main Transmission HST (Continuously Variable)1947 Auxiliary Transmission Constant Mesh Left AGR 4.00-7 (2PR) AGR 3.50-7 (2PR) Tires Right 17X8.00-8 (4PR) 16X7.00-8 (2PR) Rack and Pinion Steering Round Steering Wheel Brakes Internally Expanding Cutting Width Cutting Height 0~150 (21 Steps) 0~130 (21 Steps) -

Page 26: Operation

Operation Preparation Pre-start up Inspection Always perform an inspection before use. Refer to the Maintenance Schedule (page 40) for the inspection schedule and procedure. Checking and Filling Fuel • Keep fire and spark away when handling fuel. • Always stop engine before refueling. •... -

Page 27: Adjusting Steering Wheel

Operation Adjusting Steering Wheel • After adjusting steering wheel, try moving steering wheel back and forth and up and down to make sure it is securely locked in its position. Adjusting Angle (Tilting) Steering Wheel Pull up tilt lever to adjust steering wheel angle. - Page 28 Operation Remove fixing pin from steering column in Steering Column the front of machine. NOTE • If fixing ping is in the difficult direction to Fixing Pin remove, steer the steering wheel to change direction of the pin so that the pin can be easily removed.

-

Page 29: Adjusting Seating Position

Operation Adjusting Seating Position • Beware of pinch points when adjusting seating position. • After adjusting seat, try moving seat back and forth and up and down to make sure it is securely locked in its position. Sliding seat Seat Pull slide lever to the right to slide seat forward or backward. - Page 30 Operation Adjusting Height (Rear Part) Safety Pin Slide seat to the rear-most position. Pull up seat and push safety pin toward inside to hold seat lifted. NOTE • Pulling up seat bracket: Page 52. • Move seat and to check if the seat is locked 5332M-0401-080E securely.

-

Page 31: Adjusting Drive Pedal

Operation Adjusting Drive Pedal • Always check if the drive pedal is fixed firmly after adjusting. Remove two bolts fixing forward pedal with Pedal (Forward) drive pedal. Drive Pedal Adjust the pedal (forward) into the desired position and fix with bolts. NOTE •... - Page 32 This machine cannot perform adequately above that altitude. Using this machine under such conditions may result in an accident or cause damage to machine. If you need to use this machine above that altitude, contact your CANYCOM representative. -23-...

- Page 33 Operation Make certain brake pedal is depressed and locked. If it is not, depress brake pedal and pull lock lever to lock it. NOTE • Safety feature: engine cannot be started unless brake pedal is depressed. Brake Pedal Brake Lock Lever 5332M-0402-010E Make sure cutting rotary clutch lever is in Cutting Rotery...

- Page 34 Operation Open engine hood (see page 51). Open fuel cock. Close Open Fuel Cock 5332M-0402-060E Make sure throttle lever is in the [ (slow)] position. In the cold weather below 10 Throttle Lever degrees celsius when engine revolution is not stable, position throttle lever 1/3 toward the [ (fast)] position.

-

Page 35: Driving

Operation Driving • Always wear protective footwear, long trousers, hardhat, safety glasses and ear protection when operating or servicing the machine. Proper clothing will minimize the chance of injury. Do not operate the equipment if you have long hair, loose clothing, or jewelry; all of which may get tangled in moving parts. Do not operate the machine barefoot or with open sandals. - Page 36 Operation M a k e c e r t a i n o f t h e s a f e t y o f y o u r surroundings. Move auxiliary transmission shift lever to either [H (high speed)] or [L (low speed)] position.

-

Page 37: Stopping

Operation Driving with Drive Lever Drive Lever Move drive lever gradually forward or backward to move in the corresponding direction. NOTE • Speed can be adjusted continunously by the position of drive lever. 5332M-0402-140E Turn steering wheel to turn. Steering Wheel 5332M-0402-150E Stopping... - Page 38 Operation When Driving with Drive Pedal Drive Pedal Gradually return drive pedal to slow down. Take foot off drive pedal. NOTE • Drive pedal automatically returns to neutral when released. 5332M-0402-160E When Driving with Drive Lever Drive Lever Gradually return drive lever to nutral position Nutral Position to slow down.

-

Page 39: Shifting

Operation Shifting • Always shift gears firmly. When transmission is not firmly shifted, it may jump out of gear, resulting in loss of control of machine. • Always stop machine to shift gears. Shifting gears while machine is in motion can damage transmission. -

Page 40: Locking Differential

Operation Stop machine. 2WD/AWD Shift Lever Move 2WD/AWD shift lever to [2WD] or [AWD] position firmly. 5332M-0402-170E Locking Differential Differential can be locked to minimize slipping o slippery surface. • Always stop machine to operate differential lock lever. Operating differential lock lever while machine is in motion can damage differential. -

Page 41: Parking

Operation Once machine is out of the slippery area, Differential Lock Lever stop and move differential lock lever to [OFF] position. 5332M-0402-190E Parking • Always park on a firm, level place. Never park on a potentially dangerous place. • Avoid parking on a slope. Never park on a slope with an incline of 10 degrees or steeper. - Page 42 Operation Depress brake pedal and pull brake lock lever to lock brake pedal in depressed position. Brake Pedal Brake Lock Lever 5332M-0402-010E Move auxiliary transmission shift lever to [N (neutral)] position. Auxiliary Transmission Shift Lever 5332M-0402-030E Turn main switch to [ (off)] to stop engine.

-

Page 43: Working

Operation Working Inspecting Cutting Blade Inspect cutting blade before work. Refer to Cutting Blades (page 63) for inspection procedure. Adjusting Cutting Height Grab cutting height lock to unlock cutting Cutting Height Adjust Lever height adjust lever. Cutting Height Lock 5332M-0403-010E With lock button pulled up, move cutting Cutting Height Adjust Lever height adjust lever to a desired position. -

Page 44: Cutting

Operation Cutting • Never place any part of body under cutting blade shield. • Always wear protective footwear, long trousers, hardhat, safety glasses and ear protection when operating or servicing the machine. Proper clothing will minimize the chance of injury. Do not operate the equipment if you have long hair, loose clothing, or jewelry;... - Page 45 Also inspect overhead obstacles such as the branches of a tree. Pay special attention when working near these areas. • Do not use this machine on an incline steeper than 25 degres for the CMX 224 or 15 degrees for the CM225 / 184.

- Page 46 Operation Make sure cutting blade shield is closed. Cutting Blade Shield 5332M-0403-060E Turn throttle lever to [ (fast)] position to raise engine speed. Throttle Lever 5332M-0402-110E Move auxiliary transmission shift lever to [L (low speed)]. Auxiliary Transmission Shift Lever 5332M-0403-070E -37-...

- Page 47 Operation Move cutting height adjust lever to a desired Cutting Height Adjust Lever height. 5332M-0403-020E Move rotary clutch lever to [ON] to start Cutting Rotary cutting blade. Clutch Lever NOTE • Safety feature: engine stops automatically if operator leaves seat while cutting blade is rotating.

- Page 48 Operation Move cutting rotary clutch lever to [OFF] to Cutting Rotery stop cutting blade. Clutch Lever NOTE • Moving cutting rotary clutch lever to [OFF] applies brake on cutting blade to stop. 5332M-0402-020E Move cutting height adjust lever to the highest position.

-

Page 49: Maintenance

Every 500 hours (clean more frequently in dusty place) Clean carburator Every 500 hours (clean more frequently in dusty place) Perform valve lapping Every 500 hours (clean more frequently in dusty place) Replace fuel hose Every two years Overhaul 1000 hours (contact Canycom representative for overhaul) -40-... -

Page 50: Chassis

• Perform a pre-startup inspection (PSI) before each use, a monthly inspection once a month, and a yearly inspection once a year. • Some maintenance procedures described below may require special knowledge or tools and instruments. Contact your CANYCOM representative to perform such procedures. Schedule... - Page 51 Maintenance Schedule Item Description Note Belt tension shall be properly adjusted. √ √ Belt shall be free of damage or excessive V-belt √ √ wear. Brake shall work properly. √ √ √ Page 62 Brake Parking brake shall be able to hold the √...

- Page 52 Maintenance Schedule Item Description Note Charging system shall charge battery. Charging √ System Battery fluid (electrolyte) shall be of proper √ √ Page 68 level. Battery Terminals shall be free of looseness or √ √ excessive corrosion. Head and tail lamps shall work. √...

-

Page 53: List Of Fluids And Lubricants

Maintenance List of Fluids and Lubricants Item Schedule Grade Cap. Fuel As needed. Automotive Unleaded Gasoline 20 L Engine Oil Gasoline Engine Oil Fill API rating: SE or better. Inspect daily. Fill as needed. SAE rating: 10W-30 Change 1.4L Initially - After 20 hours of use. Every 50 hours afterwards. -

Page 54: Greasing Points

• When using a manual grease pump, push handle five to six times. When handle becomes heavy, stop pushing. • When using a pneumatic grease pump, charge for two to three seconds. • Set cutting rotary height to the lowest to grease link pivots. Greasing Points (CMX 224) Location Schedule Grade... -

Page 55: Greasing Points (Cm225 / Cm184)

Maintenance Greasing Points (CM 225 / CM 184) Location Schedule Grade Cutting rotary link pivots Every 6 Months Chassis Grease Cutting rotary drive shaft Every 6 Months Chassis Grease 5332M-0503-020E -46-... -

Page 56: List Of Consumables And Spares

Maintenance List of Consumables and Spares • When replacing consumable or spare, always use CANYCOM genuine parts. Using non-CANYCOM parts may reduce machine's performance or service life. Note that it may also void warranty and certification for relevant standards. Item Part No. - Page 57 Maintenance Item Part No. Schedule Qty. Drive Train Wire (Differential Lock) 53323402000 Replace if defective. Wire (AWD)*1 53323452000 Replace if defective. Cooling Fan 73061137000 Replace if defective. Cutting System Blade Set (Iai) Z3324202010 Replace if defective. Rubber Plate (Front Skirt, Center)*1 53322114000 Replace if defective.

-

Page 58: Removing And Installing Body Panels

Maintenance Removing and Installing Body Panels • Cut or pinch hazard exists when removing or installing body panels; beware of sharp edges and pinch points. • Make certain to reinstall panels after removing for repairs or inspection. Front Cover Pull top side of front cover to unlock latch. Front Cover Latch 5332M-0401-040E... -

Page 59: Head Lamp

Maintenance Head Lamp Remove front cover. Remove 2 knob bolts fixing the tray. Tray Knob Bolt Remove fixing bracket and lift tray. Fixing Bracket 5332M-0509-030E Remove 3 knob bolts fixing head lamp unit to Knob Bolt remove head lamp unit. Head Lamp Unit 5332M-0509-040E Insert projections at the bottom of head lamp... -

Page 60: Engine Hood

Maintenance Engine Hood Pull lever and open engine hood. Lever Engine Hood 5332M-0505-030E Lower Rear Cover Remove 4 bolts. Remove lower rear cover. Rear Cover 5332M-0505-040E Step Remove 3 bolts fixing step. Step Remove step. Remove step on the other side in the same way. -

Page 61: Seat Bracket

Maintenance Seat Bracket • Always slide seat to the rear-most position when lifting seat. If seat is not in the rear-most position, slide lever may interfere with step, preventing seat to be lifted to the holding position. Slide seat to the rear-most position. Safety Pin Lift seat and push safety pin toward inside to hold seat. -

Page 62: Engine

Maintenance Engine • Always stop engine and remove ignition key before servicing. • An engine that has been running is very hot. Allow engine to cool before servicing, or severe burns may result. • Keep fire and spark away when servicing. Engine Oil •... - Page 63 Maintenance Visually inspect oil level. Make sure oil level is between upper and lower limits. If it is Upper Limit below lower limit, add oil. Visually inspect condition of oil. If it is too dirty or viscosity is not normal, change oil. Lower Limit Put dipstick back in place.

-

Page 64: Oil Filter Cartridge

Maintenance Oil Filter Cartridge Open engine hood. Follow the instructions in Operator's Manual Oil Filter Cartridge for the engine to change oil filter cartridge. Close engine hood. 5332M-0506-050E Air Cleaner • Clean air cleaner element daily. Dirty air cleaner element causes poor starting, reduces engine performance and shortens engine life. -

Page 65: Spark Plugs

Maintenance Spark Plugs • Never pull ignition cable when removing a spark plug cap. Conductor in the cable may be severed or damaged. • If a spark plug is damaged, replace it with a new one. Open engine hood. Spark Plug Cap (On both sides) Follow the instructions in Operator's Manual for the engine to inspect, clean, or change... -

Page 66: Drive Train

Maintenance Drive Train • Stop engine when servicing drive train. • Allow machine to cool off before servicing. Engine and its ancillaries are very hot after operation and may pose a burn hazard. • Dispose of drained oil properly. Tires •... -

Page 67: Transmission Oil

Maintenance Transmission Oil NOTE • Oil to Use: Page 44. • Oil Capacity: Page 44. Park machine on a level ground. Filler Cap Have an appropriate oil drain pan. Remove transmission oil drain plug to drain oil. Install drain plug back in place. 5332M-0507-020E Open engine hood. -

Page 68: Front Axle Oil

Maintenance Front Axle Oil NOTE • Oil to Use: Page 44. • Oil Capacity: Page 44. Park machine on a level ground. Have an appropriate oil drain pan. Remove drain plug on the left front knuckle to drain oil. Knuckle Remove drain plug on the right front knucle to drain oil as well. -

Page 69: Hst (Hydrostatic Transmission) Fluid

Maintenance HST (Hydrostatic Transmission) Fluid NOTE • To obtain correct reading, check HST fluid level before starting, or wait until HST fluid cools off sufficiently. Hot HST fluid expands in volume and does not provide correct reading. • If oil level is on [MIN] the oil amount is enough when oil is sufficiently cooled. •... -

Page 70: Drive Belt

10 to 20 mm. If it is out of this range, adjust with adjust nut. Visually inspect belt. Replace belt if it is damaged. For replacement, contact your CANYCOM representative. Spring Close engine hood. Adjust Nut... -

Page 71: Parking Brake

. P l e a s e c o n t a c t y o u r C A N Y C O M representative for replacement. Front Brake (CMX 224) Adjust Nut Lock brake pedal and Inspect that the strech Lock Nut of spring is between 5mm and 8mm. -

Page 72: Cutting System

Damage due to vibration may occur. • When replacing blades, inspect blade stay. If stay is worn beyond wear limit, damaged or deformed, replace it immediately. Contact your CANYCOM representative. • Blades and blade stay can become sharp due to wear. When handling blade or blade stay, always wear thick gloves and handle carefully. - Page 73 • Wear Limit: Up to the solid line in the When New left figure (should have more than 15mm 5332M-0508-040E clearance between edge of rotor stay and mounting slot.) • Contact your CANYCOM representative for replacement of rotor stay. Mounting, Dismounting Hole Rotor Stay Mounting Slot Wear Area...

- Page 74 Maintenance Replacing Mounting Slot Open cutting blade shield. Noting the direction of the flat faces on Flat Face mounting pin, shift blade along mounting slot to remove blade. Flat Face 5332M-0508-050E Install new mounting pin and wave washer Mounting Pin to blade and shift blade along mounting slot, noting the direction of the flat faces.

-

Page 75: Cutting Rotary Drive Belt

10 to 15 mm. If it is out of this range, adjust with adjust nut. A Visually inspect belt. Replace belt if it is damaged. For replacement, contact your CANYCOM representative. Move cutting rotor clutch lever to [OFF]. 5332M-0508-110E Close engine hood. Adjusting Open engine hood. -

Page 76: Cutting Rotary Brake

Maintenance Cutting Rotary Brake • Never place any part of body under cutting blade shield when cutting blade is rotating. • Do not allow bystanders to come near machine when inspecting cutting rotary brake. • Ride on machine when inspecting. •... -

Page 77: Electrical System

Maintenance Electrical System • Always stop engine and remove ignition key when servicing electrical system. • Shock hazard. Do not handle electrical components with wet hands. Battery • Never charge battery when the fluid level is below "lower level" line. Charging battery with insufficient fluid may shorten battery life or cause an explosion. - Page 78 Maintenance • Always remove battery from machine before charging. Failure to do so causes damage to electrical components and wiring. • Follow battery charger user's manual when charging. Inspecting Park machine on level ground. Battery Remove front cover. UPPER Visually inspect that battery fluid level is between "UPPER"...

-

Page 79: Fuses

Maintenance Charging Remove front cover. Remove battery from machine. Follow instructions in battery charger user's manual to charge battery. When battery is fully charged, install battery back in place. Install front cover back in palce. 5116M-0509-040E Fuses • If a fuse blows, investigate the cause before replacing. •... -

Page 80: Light Bulbs

Maintenance Light Bulbs • When light bulb is burnt out, replace it with a new bulb. • When replacing, always use a bulb of the correct rating. Malfunction or damge in electrical system may result. • Do not touch bulb when it is hot. It may cause burns. •... - Page 81 Maintenance Replace with a new light bulb. Install lens back in place. Light Bulb 5332M-0509-080E -72-...

-

Page 82: After Use Care

Maintenance After Use Care Cutting System • Never place any part of body under cutting blade shield when cutting blade is rotating. • Do not allow bystanders to come near machine when cutting blade is rotating. • Always stay on machine when performing this opeartion •... -

Page 83: After Normal Use

Maintenance Turn throttle lever to [ (slow)] to raise engine speed. 10. Stop machine and remove hose. NOTE • Do not set cutting height too low. It may hit ground. After Normal Use • Fire hazard; clean machine of cut grass and similar material after use. Cut grass that is accumulated on the machine can catch fire. -

Page 84: After Cold Weather Use

Maintenance After Cold Weather Use • Fire hazard; clean machine of cut grass and similar material after use. Cut grass that is accumulated on the machine can catch fire. • Do not wash engine or control panel with running water; water may enter inside and cause rust or damage. -

Page 85: Storage

Maintenance Storage • Fire hazard; do not store machine where there is a possiblity of ignition. • Do not wash engine or control panel with running water; water may enter inside and cause rust or damage. • Clean machine before storage; dirt or foreign objects may freeze and cause damage. -

Page 86: Troubleshooting

Troubleshooting chart below. If the malfunction or abnormal condition is not listed in the chart, or the suggested measure does not solve the problem, consult with your CANYCOM representative. • Some corrective measures listed below require special knowledge and/or equipment. - Page 87 Loose drive belt. →Adjust Page 61 Poor power or Excessive load →Reduce load. acceleration Other (other than the →Please contact above). your CANYCOM representative. →Please contact Irregular noise or your CANYCOM vibration from or representative. around the engine →Please contact Excessive oil...

- Page 88 V-belt is loose. →Adjust V-belt. Page 61 or pedal is operated. Other (other than the →Please contact above). your CANYCOM representative. HST is out of neutral. →Please contact Machine moves when your CANYCOM drive lever or pedal is representative.

- Page 89 →Replace fuse. Page 70 Electrical Head lamp does not Other (other than the →Please contact System illuminate properly. above). your CANYCOM representative. Cutting rotary drive →Replace. Cutting blade does not belt is severed. rotate Brake lining is worn. →Replace. Cutting blade does not stop Belt is loose.

- Page 90 Troubleshooting Area Malfunction Possible Cause Corrective Measure Ref. Cutting height is too →Raise cutting height. low. Machine turns too fast. →Turn slowly. Cutting blade cuts into Work site has →Raise cutting height. ground. undulations. Cutting blade (knives →Replace. Cutting or stay) is bent. System Engine speed is too low.

-

Page 91: Transporting

Transporting Hauling Loading and Unloading • Park transporter (truck) on a level ground. Always apply parking brake and use chocks to secure wheels. • Do not allow bystandars to come close to machine or transporter when loading or unloading machine. •... -

Page 92: Hoisting

Transporting Place loading ramps. Secure hooks oframps firmly and flush with loading deck. Shift auxiliary transmission shift lever to [Low] and drive machine slowly forward onto loading deck. Set cutting height adjust lever to [150] for CMX224, CM225, and [130] for CM184. - Page 93 NOISE LEVEL Model Engine Type Type Speed rpm CMX224 / CM225 Robin EH65DS 3000 rpm 100 dB (A) CM 184 Robin EH63DS 3000 rpm 100 dB (A) NOISE LEVEL evaluated based on factory standard. VIBRATION Vibration Engine Steering Model Mower Blade Steering Rated revolution wheel...

Need help?

Do you have a question about the CMX 224 and is the answer not in the manual?

Questions and answers