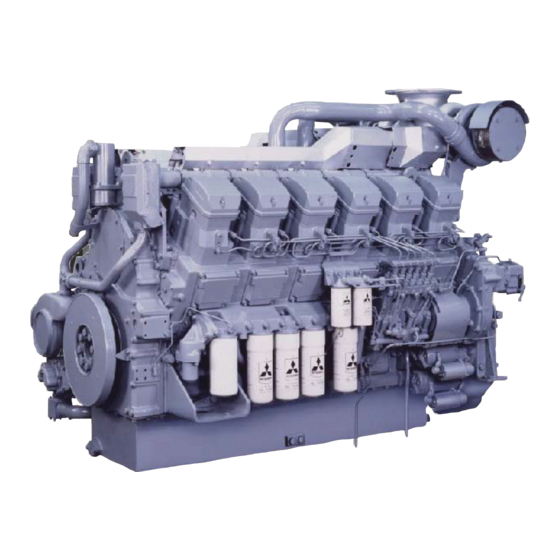

Mitsubishi S12A2 Manuals

Manuals and User Guides for Mitsubishi S12A2. We have 1 Mitsubishi S12A2 manual available for free PDF download: Service Manual

Mitsubishi S12A2 Service Manual (355 pages)

Brand: Mitsubishi

|

Category: Engine

|

Size: 38 MB

Table of Contents

-

-

-

-

Service Data43

-

-

-

-

Belt Tension62

-

-

-

-

-

-

Tappet - Inspect113

-

-

-

Piston Weight119

-

-

-

-

Piston - Install150

-

-

-

-

Tappet - Install164

-

Fuel System173

-

-

-

-

-

Changeover Spec188

-

-

-

Rubber - Install204

-

-

-

-

-

-

-

-

Bolt - Tighten259

-

Fan - Assemble291

-

-

-

-

-

Engine - Adjust

323-

-

Belt - Inspect326

-

Advertisement