Table of Contents

Advertisement

Quick Links

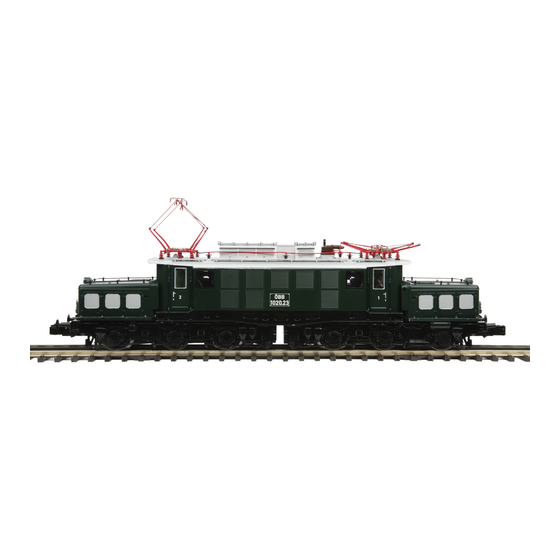

Premier E94 Crocodile

Electric Engine

OPERATOR'S MANUAL

Compatibility

3

This engine will operate on any

traditional O-Gauge track system,

including M.T.H.'s RealTrax® or

ScaleTrax™ or traditional tubular track.

The Hi-rail wheel version operates on

O-54 curves and the Scale wheel

version operates on 36" radius curves.

It is also compatible with most standard

AC transformers and DC power packs.

(See page 52 and 53 for a complete list

PFA

Passenger/Freight

of compatible transformers, power

Announcements

packs, and wiring instructions.)

PLEASE READ BEFORE USE AND SAVE

Advertisement

Table of Contents

Summary of Contents for M.T.H. Premier E94 Crocodile

- Page 1 Premier E94 Crocodile Electric Engine OPERATOR’S MANUAL Compatibility This engine will operate on any traditional O-Gauge track system, including M.T.H.’s RealTrax® or ScaleTrax™ or traditional tubular track. The Hi-rail wheel version operates on O-54 curves and the Scale wheel version operates on 36” radius curves.

-

Page 2: Table Of Contents

Table of Contents Set Up Checklist ............... 3 Unpacking . -

Page 3: Set Up Checklist

DCS, DCC or Conventional Features as if was on the track. Please remember that if you plan to operate you engine on the display stand for any length of time, you will need to lubricate all of the moving parts. Premier E94 Crocodile Electric Engine... -

Page 4: Removing The Engine From The Display Stand

Your MTH electric type engine is equipped with Automatic Operating Pantographs. The Automatic Operating Pantographs must be unlatched before power is applied to the engine. To unlatch the pantographs, hold the base of the pantograph and gently pull up on the contact slider. Premier E94 Crocodile Electric Engine... -

Page 5: Conventional Mode

Every time the direction button is pushed, the pantographs will alternately rise and lower. DCS Command Mode- Manual Operation Using the DCS handheld, each pantograph can be raised and lowered individually by pressing appropriate softkeys (buttons S1 through S5). Premier E94 Crocodile Electric Engine... - Page 6 Premier E94 Crocodile Electric Engine...

-

Page 7: Coupler Systems

DSP Code for the new coupler using the MTH DCS control system and a PC.. You will need a TIU running software version 4.20 or higher and the Consumer Loader version 2.3 or higher. Premier E94 Crocodile Electric Engine... -

Page 8: Ps 3.0 Enhancements

DCC systems. Most DCC systems can support the current requirements of the engine as long as it’s not started up. If you plan on powering up the MTH engine on your programming track, you may want to consider a DCC Programming Track Booster. Premier E94 Crocodile Electric Engine... -

Page 9: Loading Engine Firmware

A short interruption (approximately 1 to 2 seconds) in the track voltage will cause the engine to cycle in the sequence for each track voltage interruption (neutral – forward – neutral – reverse) Premier E94 Crocodile Electric Engine... - Page 10 By using combinations of button presses, different commands besides blowing the whistle and ringing the bell can be initiated. Premier E94 Crocodile Electric Engine...

-

Page 11: Proto-Sound 3.0 Conventional Ac Operating Instructions

Turning the master volume control completely counterclockwise will turn of all of the engine sounds and announcements. The master volume control is located on the underside of the chassis as shown in figure 10. Premier E94 Crocodile Electric Engine... -

Page 12: Manual Volume Control

Rear Rear By default your engine’s lights will look like those above. This is the Road setting. To toggle between Road and Push service using your AC transformer, follow the Bell/ Whistle instructions below. PUSH/ROAD Premier E94 Crocodile Electric Engine... -

Page 13: Pfa

Once the bell turns off, the operator regains control of the transformer's bell and Horn buttons and can ring the bell or blow the Horn as usual. Premier E94 Crocodile Electric Engine... -

Page 14: Proto-Coupler Operation

DSP Code for the new coupler using the MTH DCS control system and a PC.. You will need a TIU running software version 4.20 or higher and the Consumer Loader version 2.3 or higher. Premier E94 Crocodile Electric Engine... -

Page 15: Speed Control

1 horn, 3 bells code to return the engine to its normal condition, even if the engine is kept without power for extended periods of time. Direction Lock Place Two Horn Blasts Engine into Horn Bell Bell Bell Horn (indicates change is made) Desired Repeat to Return Direction to Normal Condition Premier E94 Crocodile Electric Engine... -

Page 16: Reset To Factory Default

Two horn blasts will indicate that the engine has made the change. Reset Place Two Horn Blasts Horn Bell Bell Bell Bell Bell Engine in (indicates change is made) Repeat to Return Neutral to Normal Condition Premier E94 Crocodile Electric Engine... -

Page 17: Automatic Sound Effects

Simply lower the track voltage down below 9.0VDC and then back up to get your engine moving. This applies only when you start up your engine. Premier E94 Crocodile Electric Engine... -

Page 18: Dcs Operation

PS3.0-equipped engine. Below is a lighting table and diagram to help with setting the correct lighting you desire. Lighting Operation LMK Softkey LBE Softkey Road (Default) Push Pull Yard ROAD ENGINE IN FORWARD ENGINE IN REVERSE R e d Rear Rear Premier E94 Crocodile Electric Engine... - Page 19 R e d Rear Rear PULL ENGINE IN FORWARD ENGINE IN REVERSE Red (Austrian Red (Austrian version only) version only) R e d R e d Rear Rear YARD ENGINE IN FORWARD ENGINE IN REVERSE Rear Rear Premier E94 Crocodile Electric Engine...

-

Page 20: Dcc/Digital Command Control

As long as there is DCC power still on the track the engine can be started up again by pressing the F3 button twice. Premier E94 Crocodile Electric Engine... -

Page 21: Sounds

At this point, increase speed to depart station. Note: In order to maximize the realism, we recommend that you reduce the engine's speed to a slow pace just prior to hitting the F4 button the first time (to activate PFA) Premier E94 Crocodile Electric Engine... -

Page 22: Lights

Pressing F9 twice (toggling on then off) will sound the Forward Signal. This is two whistle/horn blasts F10 – Reverse Signal Pressing F10 twice (toggling on then off) will sound the Reverse Signal. This is three whistle/horn blasts Premier E94 Crocodile Electric Engine... -

Page 23: Crossing Signal

F19 – Road/Push This function will toggle between Road and Push service. To see how toggling F19 will affect your lights please refer to page 18 and 19. Premier E94 Crocodile Electric Engine... - Page 24 F24 – Single Whistle/Horn Blast To play a Single Horn Blast press the F24 button twice (toggling in on then off). This plays a single, short horn blast. Premier E94 Crocodile Electric Engine...

- Page 25 Extended Shut Down ROAD/PUSH * ROAD/PULL * One Shot Doppler Coupler Slack Coupler Close Single Horn Blast Engine Sounds Brake Sounds On/Off Cab Chatter On/Off *Toggling both F19 & F20 OFF Feature Reset results in YARD lighting. Premier E94 Crocodile Electric Engine...

-

Page 26: Cv29

2. Hit the PROG button twice to enter PoM mode 3. Hit Enter twice so the LCD displays “Adr” 4. Type in the new Short Address (1-127) that you want and hit Enter 5. The engine will give you a two whistle/horn blast response Premier E94 Crocodile Electric Engine... -

Page 27: Feature/Factory Resetting

• Send a decimal 128 to reset only address values back to factory default • This is the same as writing 55 to CV55 to engine address 55 Note: The engine address has to be something other than address 55 Premier E94 Crocodile Electric Engine... - Page 28 55 on your DCC handheld and sending a value of 55 to CV55. Again, MTH engine's will listen to the 55-55-55 reset command even though the engine's address isn't actually 55 (and it can't be for the 55-55-55 reset to work). Premier E94 Crocodile Electric Engine...

-

Page 29: Proto-Sound 3.0 Expanded Dcc Functionality

User ID #2 – General Purpose use for customer CV115- MTH Function Assignments – See table of supported CV’s and manual section on how CV170 to re-arrange them for further information 1. CV52, bit0 must = 1. This will enable PWM Mode. Premier E94 Crocodile Electric Engine... - Page 30 Cab Chatter On/Off Low Byte 0-255 Alternate Speed Curve Step 27 Feature Reset High Byte 0-255 Alternate Speed Curve Step 28 Feature Reset Low Byte 0-255 Reverse Trim 0-255 User ID #1 0-255 User ID #2 Premier E94 Crocodile Electric Engine...

- Page 31 LIGHTS SCRIPTS Lights Extended Shut Down Marker (ROAD/PUSH) Extended Start Up Beacon (ROAD/PULL) Start Up/Shut Down ELECTRIC SMOKE Train Wreck Electric Boiler Start-Up Trolley Manual Mode Electric Pressure Release Trolley Learn Mode Trolley Auto Mode Premier E94 Crocodile Electric Engine...

- Page 32 Function ID table above you can see that Feature Reset is a value of 29 8. Using your DCC system, enter a value of 29 for CV122 and hit Enter. Your engine will give you a two horn blast indication Premier E94 Crocodile Electric Engine...

-

Page 33: Cv Programming - Marklin 6021 Controller

CV contents on the keypad. For example, to program a CV with the value 128, enter 12 on the keypad then press the function key to tell the engine that a number greater than 79 is being entered Premier E94 Crocodile Electric Engine... - Page 34 Function/Off button on the Marklin 6021 controller toggles Start-up/Shut-Down. For the New Motorola format the Function/Off button on the Marklin 6021 Controller toggles the Headlight/Taillight and F1-F4 are supported. Please see page 22 for the engine's F-Function List. Premier E94 Crocodile Electric Engine...

- Page 35 5 you would need to call up engine address 6 and then you can use Function/Off and F1-F4 to control functions F5-F9. The same applies to consists as they would be consist address + 1. Also, you can re-map F5-F9 via CV123-CV130. Premier E94 Crocodile Electric Engine...

-

Page 36: Advanced Consisting

Setting the MSB (Bit 7) of CV19 tells the engine that it is facing reverse in the consist Setting CV21 and CV22 determine which F Functions the consist responds to See diagram below for example Premier E94 Crocodile Electric Engine... - Page 37 CV change. Some DCC systems may already do this for you but the instructions assume your system does not. If you are in doubt then go ahead and follow step 5 as it will do no harm Premier E94 Crocodile Electric Engine...

- Page 38 MTH models). Likewise, you'll want your Rear engine to respond to the Rear Coupler command (F8 on most MTH models). Please refer to the table below to see which bits have what decimal value and which F Function they correspond to. Premier E94 Crocodile Electric Engine...

- Page 39 CV21's bits are shown in the table below – the decimal value is shown in parenthesis: (Decimal 7 (128) 6 (64) 5 (32) 4 (16) 3 (8) 2 (4) 1 (2) 0 (1) Value) Function Premier E94 Crocodile Electric Engine...

-

Page 40: Programming Track

Main (PoM). MTH engines support PoM to write any CV on the main. However, read back is not supported on the main. Check with your DCC system's manufacturer to see about any limitations they may have to PoM. Premier E94 Crocodile Electric Engine... - Page 41 128) for the engine you want to reverse. To do this - take 128 (the new bit you want to set) + 5 (the existing bit that you do not want to alter) = 133. You would then write a value of 133 to CV19. Premier E94 Crocodile Electric Engine...

-

Page 42: Maintenance

5. After repeating the procedure for the other motor, reassemble the chassis and body, being careful that the wire harnesses are not caught between the chassis and body, and reinstall the body mount screws. Premier E94 Crocodile Electric Engine... -

Page 43: Cleaning The Wheels, Tires And Track

Thereafter, keep an eye on the track and clean it when it gets dirty to ensure good electrical contact and to lengthen the life of the tires. Premier E94 Crocodile Electric Engine... -

Page 44: Traction Tire Replacement Instructions

The PS 3.0 headlights and other associated lights are small LEDs that require a lot less power and generate a lot less heat than incandescent bulbs, resulting in extremely long life compared to the incandescent bulbs. The LEDs are not user serviceable Premier E94 Crocodile Electric Engine... -

Page 45: Troubleshooting Proto-Sound 3.0 Problems

The coupler does not fire or stay denatured alcohol (not rubbing alcohol) and coupled. let dry. Cab Chatter Solution Sometimes the Cab Chatter sounds Cab Chatter plays only in neutral at random don't play. intervals. Premier E94 Crocodile Electric Engine... - Page 46 PFA cycle. Wait at least 30 play or the engine does not come out of seconds in each PFA sound clip before PFA after fourth press of the direction pressing the direction button. button. Premier E94 Crocodile Electric Engine...

- Page 47 Check to see if a screw or some other There's a crackling sound from my material hasn't lodged itself in the underside engine of the chassis or tender Make sure smoke volume pot is turned full Premier E94 Crocodile Electric Engine...

- Page 48 New engines even after they are lubricated may take a little bit to get everything run in. Be a little patient and let it run for a bit. It should clear up shortly after lubricating and running. Premier E94 Crocodile Electric Engine...

- Page 49 This is normal. You will need to press the F21 button again to turn Doppler off. Your engine Doppler shift but then the engine sounds sounds will now return to normal. fade out and I can’t get them back. Premier E94 Crocodile Electric Engine...

- Page 50 Try to get a hold of the engine on its last known long address Place the engine on the Programming Track output on your DCC system and write a value of 3 to CV1 Premier E94 Crocodile Electric Engine...

- Page 51 I can't get them engine sounds will now return to normal back *Make sure that you have the DCC/DCS Switch set to ‘DCS’. Otherwise your engine will not function properly in DCS Mode. Premier E94 Crocodile Electric Engine...

- Page 52 I can't call up my engine on the address Delete the engine from your DCS remote, I believe it to be set at and attempt to re-add it. On the DCS Remote, hit Menu System Engine Setup Recover Engine Premier E94 Crocodile Electric Engine...

-

Page 53: Transformer Compatibility And Wiring Chart

Lionel SW Unknown 130-Watt Standard Lionel TW 8-18v 175-Watt Standard Lionel ZW A,B,C or D 8-20v 275-Watt Standard Lionel Post-War A,B,C or D Common 0-20v 135/190 Watt Electronic Celebration Series ZW * Conventional Mode Only Premier E94 Crocodile Electric Engine... -

Page 54: Dc Power Supply Chart

DO NOT Use with the DCS System (TIU) at Controller CRE-55401 Controller PWM Output from this power supply Will DAMAGE the TIU * Use 22 volts maximum track voltage when operating a MTH locomotive equipped with Proto-Sound, Loco-Sound, or Proto-Sound 2.0 Premier E94 Crocodile Electric Engine... -

Page 55: Additional Features Accessible Of Dcs Remote Control System

Direction Control Set Up-User can set initial individual start-up direction (start in forward or reverse) for double-heading operations • Locomotive Consist Set-up-User can determine locomotive values for consist make-ups, allowing multiple locomotives belonging to a consist to operate together Premier E94 Crocodile Electric Engine... -

Page 56: Service & Warranty Information

Service & Warranty Information How to Get Service Under the Terms of the Limited One-Year Warranty When you suspect an item is defective, please check the operator's manual for standard operation and trouble- shooting techniques that may correct the problem. Additional information may be found on the M.T.H. Website. Should you still require service, follow the instructions below to obtain warranty service.

Need help?

Do you have a question about the Premier E94 Crocodile and is the answer not in the manual?

Questions and answers