Summary of Contents for Trane TC*150-301

- Page 1 Installation Operation Maintenance Packaged Electric/Electric 12 ½ - 25 Ton Model Number TC*150-301 RT-SVX25C-EN December 2008...

- Page 2 CFCs such as HCFCs and HFCs. Responsible Refrigerant Practices! Trane believes that responsible refrigerant practices are important to the environment, our customers, and the air conditioning industry. All technicians who handle refrigerants must be certified. The Federal Clean Air Act (Section 608) sets forth the requirements for handling, reclaiming, recovering and recycling of certain refrigerants and the equipment that is used in these service procedures.

-

Page 3: Table Of Contents

Table of Contents Model Number Description ..........5 General Information . - Page 4 ... . . 43 Table 9. Belt tension measurement and deflection reanges Monthly Maintenance ..........44 Final Process .

-

Page 5: Model Number Description

180 = 15 tons standard efficiency 0C = Downflow economizer/oversized motor 181 = 15 tons high efficiency 0F = Trane communications interface (TCI) 210 = 17 1/2 tons standard efficiency 0G = Downflow economizer/TCI 211 = 17 1/2 tons high efficiency... -

Page 6: General Information

General Information Overview of Manual Note: One copy of this document ships inside the control panel of each unit and is customer property. It must be retained by the unit’s maintenance personnel. This booklet describes proper installation, operation, and maintenance procedures for air cooled systems. -

Page 7: Unit Nameplate

General Information CAUTION Ultraviolet (UV) Lights! The manufacturer does not recommend field installation of ultraviolet lights in its equipment for the intended purpose of improving indoor air quality. High intensity C-band ultraviolet light is known to severely damage polymer (plastic) materials and poses a personal safety risk to anyone exposed to the light without proper personal protective equipment. -

Page 8: System Input Devices & Functions

It is capable of delivering up to 25 inch pounds of torque and is powered by 24 VAC. RTCI -- ReliaTel™ Trane Communication Interface (Optional) This module is used when the application calls for an ICSTM building management type control system. -

Page 9: Phase Monitor

General Information If this circuit is open before the compressor is started, the compressor will not be allowed to operate. Anytime this circuit is opened for 1 continuous second during compressor operation, the compressor for that circuit is immediately turned “Off” . The compressor will not be allowed to restart for a minimum of 3 minutes should the contacts close. -

Page 10: Evaporator Frost Control

General Information Zone Sensor (BAYSENS110A) This electronic sensor features four system switch settings (Heat, Cool, Auto, and Off) and two fan settings (On and Auto) with four system status LED’s. It is a manual or auto changeover control with dual setpoint capability. It can be used with a remote zone temperature sensor BAYSENS017B. Programmable Zone Sensor - BAYSENS019C This 7 day programmable sensor features 2, 3 or 4 periods for Occupied or Unoccupied programming per day. -

Page 11: Unit Inspection

General Information Note: The supply and return air smoke detectors are designed to shut off the unit if smoke is sensed in the supply air stream or return air stream. This function is performed by sampling the airflow entering the unit at the return air opening. Follow the instructions provided below to assure that the airflow through the unit is sufficient for adequate sampling. -

Page 12: Storage

General Information Request an immediate joint inspection of the damage by the carrier and the consignee. Do not remove damaged material from the receiving location. Take photos of the damage, if possible. The owner must provide reasonable evidence that the damage did not occur after delivery. -

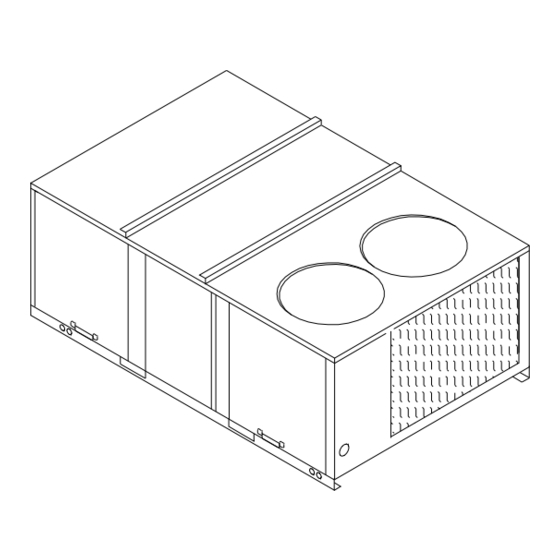

Page 13: Unit Dimensions

Unit Dimensions Figure 1. WITHOUT ECONOMIZER 5' 8" WITH ECONOMIZER 5' 0" RT-SVX25C-EN... - Page 14 Unit Dimensions Figure 2. Unit dimensional data for 12 1/2 ton, 15 ton, 17 1/2 ton standard efficiency R22 units - 12 1/2 ton high efficiency R22 units - 12 1/2 ton standard efficiency R410A units Figure 3. Unit dimensional data for 12 1/2 ton, 15 ton, 17 1/2 ton standard efficiency R22 units - 12 1/2 ton high efficiency R22 units - 12 1/2 ton standard efficiency R410A units RT-SVX25C-EN...

- Page 15 Unit Dimensions Figure 4. Unit dimensional data 20 ton, 25 ton standard efficiency R22 units- 15 - 25 ton high efficiency R22 units - 15 - 25 ton standard efficiency R410A units, 12½ - 15 ton high efficiency R410a Figure 5. Roofcurb dimensional data 20 ton, 25 ton standard efficiency R22 units- 15 - 25 ton high efficiency R22 units - 15 - 25 ton standard efficiency R410A units, 12½...

- Page 16 Unit Dimensions Figure 6. Unit dimensional data 17½ - 25 ton high efficiency R410A units 64 1/8”) 1629mm Figure 7. Unit dimensional data for 12 1/2 ton, 15 ton, 17 1/2 ton standard efficiency R22 units - 12 1/2 ton high efficiency R22 units - 12 1/2 ton standard efficiency R410A units, 12 1/2 - 15 ton high efficiency R410A units RT-SVX25C-EN...

- Page 17 Unit Dimensions Figure 8. Unit dimensional data 20 ton, 25 ton standard efficiency R22 units- 15 - 25 ton high efficiency R22 units - 15 - 25 ton standard efficiency R410A units, 17 1/2 - 25 ton high efficiency R410A units RT-SVX25C-EN...

-

Page 18: Unit Weights

Unit Weights Table 1. Typical unit weights and point loading data lbs. Corner Wts. (lbs.) Weight Unit Models (lbs) TC*150D 1319 TC*150E 1482 TC*151C 1452 TC*151E 1981 TC*151E 2000 Reheat unit TC*155B 1371 TC*180B 1498 TC*180E 1909 TC*181C 1902 TC*181E 1984 TC*181E 2002... - Page 19 Unit Weights Table 2. Typical unit weights and point loading data kg. (continued) Corner Wts. (kg.) Weight Unit Models (lbs) TC*180B TC*180E TC*181C TC*181E TC*181E Reheat unit TC*200B TC*210C TC*210E TC*211C TC*211E TC*240B TC*240E TC*241C TC*241E TC*241E Reheat unit TC*250B TC*300B TC*300E TC*301C...

-

Page 20: Rigging

Unit Weights Figure 10. Rigging and center of gravity data WARNING Heavy Objects! Do not use cables (chains or slings) except as shown. Each of the cables (chains or slings) used to lift the unit must be capable of supporting the entire weight of the unit. Lifting cables (chains or slings) may not be of the same length. - Page 21 Unit Weights 6. Downflow units; align the base rail of the unit with the curb rail while lowering the unit onto the curb. Make sure that the gasket on the curb is not damaged while positioning the unit. RT-SVX25C-EN...

-

Page 22: Installation

Installation Foundation Horizontal Units If the unit is installed at ground level, elevate it above the snow line. Provide concrete footings at each support location with a “full perimeter” support structure or a slab foundation for support. Refer to Table 1, p. 18and Table 2, p. -

Page 23: Factory Installed Economizer

Installation Factory Installed Economizer • Ensure the economizer has been pulled out into the operating position. Refer to the economizer installers guide for proper position and setup. • Install all access panels. Main Electrical Power Requirements • Verify that the power supply complies with the unit nameplate specifications. •... -

Page 24: Filter Installation

Installation Figure 11. Condensate trap installation Filter Installation Each unit ships with 2 inch filters installed. The quantity of filters is determined by unit size. Access to the filters is obtained by removing the indoor fan access panel. Refer to the unit Service Facts (shipped with each unit) for filter requirements. Note: Do not operate the unit without filters. -

Page 25: Main Unit Power

Installation 1. Protection devices must be sized according to the electrical data on the nameplate. 2. If the unit is not equipped with an optional factory installed nonfused disconnect switch or circuit breaker, a field supplied disconnect switch must be installed at or near the unit in accordance with the National Electrical Code (NEC latest edition). -

Page 26: Electromechanical Thermostat 24V Ac Conductors With Reliatel

Installation Note: All field wiring must conform to NEC guidelines as well as state and local codes. Control Power Transformer The 24 volt control power transformers are to be used only with the accessories called out in this manual. Transformers rated greater than 50 VA are equipped with internal circuit breakers. If a circuit breaker trips, turn “Off”... -

Page 27: Zone Sensor Module Wiring

Installation 3. Do not run the electrical wires transporting DC signals in or around conduit housing high voltage wires. Table 4. Zone sensor module wiring Distance from Unit Recommended Wire to Control Size 0 - 150 feet 22 gauge 0 - 45.7 m .33 mm2 151 - 240 feet 20 gauge... - Page 28 Installation Figure 14. Reliatel conventional thermostat field wiring diagram RTRM Figure 15. ReliaTel relative humidity sensor (dehumidification option) RT-SVX25C-EN...

-

Page 29: Smoke Detector

Installation Figure 16. ReliaTel humidistat (dehumidification option) Smoke Detector Customer Low Voltage Wiring- When interlocking System Sensor smoke detectors together, all of the detectors must be powered from the same power supply. If multiple smoke detectors are required, all detectors must be disconnected from the HVAC unit power supply and connected together from another single source supply. - Page 30 Installation Figure 17. 10 HVAC units 5 HVAC units RT-SVX25C-EN...

- Page 31 Installation Figure 18. Typical field wiring diagrams for optional controls (ReliaTel™ only) RT-SVX25C-EN...

-

Page 32: Space Temperature Averaging

Installation Space Temperature Averaging Space temperature averaging is accomplished by wiring a number of remote sensors in a series/ parallel circuit. Using the BAYSENS016* or BAYSENS017*, at least four sensors are required to accomplish space temperature averaging. Example #1 illustrates two series circuits with two sensors in each circiut wired in parallel. The square of any number of remote sensors required. - Page 33 Installation Figure 19. Space temperature averaging examples Use the checklist provided below in conjunction with the “General Unit Requirements” checklist to ensure that the unit is properly installed and ready for operation. WARNING Hazardous Voltage! Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/tagout procedures to ensure the power can not be inadvertently energized.

-

Page 34: Voltage Imbalance

Installation Voltage Imbalance Three phase electrical power to the unit must meet stringent requirements for the unit to operate properly. Measure each leg (phase-to-phase) of the power supply. Each reading must fall within the utilization range stamped on the unit nameplate. -

Page 35: Compressor Crankcase Heaters

Installation • Turn the field supplied disconnect switch that provides power to the main power terminal block or to the “Line” side of the optional factory mounted disconnect switch to the “Off” position. • Connect the phase sequence indicator leads to the terminal block or to the “Line” side of the optional factory mounted disconnect switch as follows;... -

Page 36: Reliatel Controls

Installation WARNING Live Electrical Components! During installation, testing, servicing and troubleshooting of this product, it may be necessary to work with live electrical components. Have a qualified licensed electrician or other individual who has been properly trained in handling live electrical components perform these tasks. Failure to follow all electrical safety precautions when exposed to live electrical components could result in death or serious injury. -

Page 37: Pre Start

Pre Start Test Modes There are three methods in which the “Test” mode can be cycled at LTB-Test 1 and LTB-Test 2. 1. Step Test Mode - This method initiates the different components of the unit, one at a time, by temporarily shorting across the two test terminals for two to three seconds. -

Page 38: Reliatel Control

Pre Start Before starting the SERVICE TEST, set the minimum position setpoint for the economizer to 0 percent using the setpoint potentiometer located on the Economizer Control (ECA), if applicable. ReliaTel Control Using the Service Test Guide in Table 6, p. 37, momentarily jump across the Test 1 &... -

Page 39: Start Up

Start Up Economizer Start-Up ReliaTel Control Using the Service Test Guide in Table 6, p. 37, momentarily jump across the Test 1 & Test 2 terminals on LTB1 one time to start the Minimum Ventilation Test. 1. Set the minimum position setpoint for the economizer to the required percentage of minimum ventilation using the setpoint potentiometer located on the Economizer Control (ECA). -

Page 40: Compressor Types

9 and 10 ton compressor is 8 pints. For a 14 and 15 ton scroll compressor use 14 pints. Note: The Copeland, SSA and SPA scroll compressors for R410A units use Trane OIL00094. The correct Oil for Trane CSHD is Trane OIL00079 or OIL00080. Compressor types are listed in the following table. -

Page 41: Dehumidification Option

Start Up Dehumidification Option Momentarily jump across the Test 1 and Test 2 terminals of the LTB1 until the unit enters test mode (Table 6, p. Once the unit is in the reheat test mode, verify that the 3 way valve has shifted to the reheat position and that the supply temperature rises 10 deg F more than when in cooling mode stage 2. -

Page 42: Maintenance

Maintenance WARNING Rotating Components! During installation, testing, servicing and troubleshooting of this product it may be necessary to measure the speed of rotating components. Have a qualified or licensed service individual who has been properly trained in handling exposed rotating components, perform these tasks. Failure to follow all safety precautions when exposed to rotating components could result in death or serious injury. - Page 43 Maintenance Figure 21. Belt tension gauge Table 9. Belt tension measurement and deflection reanges Deflection Force (lbs.) Super Gripbelts Steel Cable Belts Small P.D (in) Gripnotch (in) Gripbelts (in) Cross Range Section (in) Min. Max. Min. Min. Max. 3.0 - 3.6 4 1/2 3 7/8 5 ½...

-

Page 44: Monthly Maintenance

Maintenance Monthly Maintenance Before completing the following checks, turn the unit OFF and lock the main power disconnect switch open. WARNING Hazardous Voltage! Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/tagout procedures to ensure the power can not be inadvertently energized. Failure to disconnect power before servicing could result in death or serious injury. -

Page 45: Heating Season

Maintenance • With the unit running, check and record the: ambient temperature; compressor suction and discharge pressures (each circuit); superheat (each circuit); Record this data on an “operator’s maintenance log” like the one shown in Table 9, p. 43. If the operating pressures indicate a refrigerant shortage, measure the system superheat. -

Page 46: Final Process

Maintenance 6. Spray the leaving-airflow side of the coil first; then spray the opposite side of the coil. Allow the cleaning solution to stand on the coil for five minutes. 7. Rinse both sides of the coil with cool, clean water. 8. - Page 47 Maintenance Table 10. Sample maintenance log Refrigerant Circuit #1 Refrigerant Circuit #2 Current Suct. Disch. Liquid Suct. Disch. Liquid Ambient Compr. Press. Press Press Super- Sub-cool Compr. Press. Press Press Super- Sub-cool Date Temp F/C Oil Level Psig/kPa Psig/kPa Psig/kPa heat F/C Oil Level Psig/kPa...

-

Page 48: Troubleshooting

Troubleshooting ReliaTel Control The RTRM has the ability to provide the service personnel with some unit diagnostics and system status information. Before turning the main power disconnect switch “Off” , follow the steps below to check the ReliaTel Refrigeration Module (RTRM). All diagnostics & system status information stored in the RTRM will be lost when the main power is turned “Off”... -

Page 49: System Status Checkout Procedure

Troubleshooting System Status Checkout Procedure “System Status” is checked by using one of the following two methods: Method 1 If the Zone Sensor Module (ZSM) is equipped with a remote panel with LED status indication, you can check the unit within the space. If the ZSM does not have LED’s, use Method 2. BAYSENS010B, BAYSENS011B, BAYSENS019B, BAYSENS020B, BAYSENS021A &... -

Page 50: Method 2

Troubleshooting Service Failure 1. If the supply fan proving switch has closed, the unit will not operate (when connected to RTOM), check the fan motor, belts, and proving switch. 2. Clogged filter switch has closed, check the filters. Simultaneous Heat and Cool Failure 1. -

Page 51: Clogged Filter Switch

Troubleshooting Note: Before resetting Cooling Failures and Heating Lockouts check the Failure Status Diagnostics by the methods previously explained. Diagnostics will be lost when the power to the unit is disconnected. Method 1 To reset the system from the space, turn the “Mode” selection switch at the zone sensor to the “Off” position. - Page 52 Troubleshooting Table 11. Temps and resistance values Nominal CSP Nominal ZTEMP or HSP Zone Temperature Resistance Resistance 50 F° 10.0 C° 19.9 K-Ohms 889 Ohms 55 F° 12.8 C° 17.47 K-Ohms 812 Ohms 60 F° 15.6 C° 15.3 K-Ohms 695 Ohms 65 F°...

- Page 53 Troubleshooting Note: Measurements should be made from LED common (ZSM terminal 6 to respective LED terminal). Refer to the Zone Sensor Module (ZSM) Terminal Identification table at the beginning of this section. Table 12. System mode and fan selection Resistance Valves Zone Sensor Unit/ (Ohms) Fan Mode...

- Page 54 Troubleshooting 4. Locate the RTRM (J6). Connect two (2) wires to terminals J6-1 and 2. 5. Connect the sensor (OAS) using two wire nuts to the two (2) field supplied wires that were connected to terminals 1 and 2 on J6. Unit Economizer Control (ECA) Troubleshooting ReliaTel Control Verify Economizer Status by Economizer Actuator (ECA) LED indicator: •...

-

Page 55: Wiring Diagrams

Wiring Diagrams Note: For easier access, published unit wiring diagrams (individual, separate diagrams for unitary product lines)after 2007 will become available via e-Library instead of through wiring manuals. Prior to 2008, wiring diagrams will be in wiring manuals RT-SVE03A-EN and RT- SVE06A-EN. - Page 56 Wiring Diagrams Table 13. Wiring diagrams for R-22 units and heaters (continued) Drawing Description Number 2309-3162 Connection Electrical - 400 - 575v (TC 155, 175, 180, 181, 210) 2309-3163 Diagram; Connection Electrical TC 210 2309-3164 Connection Electrical - 380v - Cooling / Gas Heat (YC 180, 210) 2309-3165 Diagram;...

- Page 57 Wiring Diagrams Table 13. Wiring diagrams for R-22 units and heaters (continued) Drawing Description Number 2309-3366 Connection Electrical - 400 - 575v (TC 151 - With Dehumidification Option) 2309-3367 Connection Electrical - 208 - 230v - Cooling / Gas Heat (YC 151 With Dehumidication Option) 2309-3368 Connection Electrical - 400 - 575v - Cooling / Gas Heat (YC 151- With Dehumidification Option) 2309-3369...

- Page 58 Wiring Diagrams Table 14. Wiring diagrams for R-410A units Drawing Number Description 2313-0001 Connection Electrical - 208 - 230V - Cooling / Mod Gas Heat (YC 210E, 240E) 2313-0002 Connection Electrical - 208 - 230V - Cooling / Mod Gas Heat (YC 150E, 151E) 2313-0003 Connection Electrical - 400 - 575V- Cooling (TC 150E, 151E) 2313-0004...

- Page 59 Wiring Diagrams Table 14. Wiring diagrams for R-410A units (continued) Drawing Number Description 2313-0057 Power Schematic - 380V ReliaTel (TC 150E, 180E, 210E, 240E, 300E) 2313-0058 Power Schematic - 380V ReliaTel (TC 150E, 180E, 210E, 240E, 300E) 2313-0059 Power Schematic - 208 - 230V Mod Heat ReliaTel (YC 150E, 180E, 181E, 210E, 211E) 2313-0060 Power Schematic - 400 - 575V Mod Heat ReliaTel (YC 150E, 155E, 175E, 180E, 181E, 210E, 211E) 2313-0061...

-

Page 60: Warranty

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. Trane 2701 Wilma Rudolph Blvd. Clarksville, TN 37040-1008... -

Page 63: Standard Equipment Warranty Terms And Conditions Commercial Equipment Warranty And Liability

In no event shall the Company be liable for any incidental or consequential damages. Trane 2701 Wilma Rudolph Blvd. Clarksville, TN 37040-1008... - Page 64 Literature Order Number RT-SVX25C-EN Date December 2008 Supersedes RT-SVX25C-EN July 2008 The manufacturer has a policy of continuous product and product data improvement and reserves the right to change design and specifications without notice.

Need help?

Do you have a question about the TC*150-301 and is the answer not in the manual?

Questions and answers