Table of Contents

Advertisement

Installation, Operation, and Maintenance

Split System Air Conditioners

Odyssey™ with Symbio™

Controls

Air Handler — 5 to 25 Tons

M M o o d d e e l l ( ( 6 6 0 0 H H z z ) )

TWE0604*A/B

TWE0724*B

TWE0904*A/B

TWE1204*A/B

TWE1504*B

TWE1804*B

TWE2404*B

TWE3004*B

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-conditioning

equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person

could result in death or serious injury. When working on the equipment, observe all precautions in the literature and on the tags, stickers, and labels that

are attached to the equipment.

March 2020

M M o o d d e e l l ( ( 5 5 0 0 H H z z ) )

TWE0514DA

TWE0724DB

TWE0764DA/B

TWE1014DA/B

TWE1264DB

TWE1564DB

TWE2014DB

TWE2514DB

S S A A F F E E T T Y Y W W A A R R N N I I N N G G

S S S S A A - - S S V V X X 0 0 6 6 H H - - E E N N

Advertisement

Table of Contents

Summary of Contents for Trane Odyssey TWE0604*A/B

- Page 1 Installation, Operation, and Maintenance Split System Air Conditioners Odyssey™ with Symbio™ Controls Air Handler — 5 to 25 Tons M M o o d d e e l l ( ( 6 6 0 0 H H z z ) ) M M o o d d e e l l ( ( 5 5 0 0 H H z z ) ) TWE0604*A/B TWE0514DA...

- Page 2 A A L L W W A A Y Y S S r r e e f f e e r r t t o o a a p p p p r r o o p p r r i i a a t t e e S S a a f f e e t t y y D D a a t t a a impact to the environment. Trane advocates the...

- Page 3 . . property of Trane, and may not be used or reproduced in whole or in part without written permission.

-

Page 4: Table Of Contents

Table of Contents Model Number Description ....5 Low Voltage Wiring ..... . 29 Air Handler. -

Page 5: Model Number Description

Model Number Description Air Handler Digit 1–3 — Unit Function Digit 8 — Voltage Digit 14 — Efficiency Generation TWE = Air Handler 1 = 208-230VAC - 1 PH (60Hz) A = Generation A (2018 DOE) 3 = 208-230VAC - 3 PH (60Hz) 4 = 460VAC - 3 PH (60Hz) Digit 4–6 —... -

Page 6: General Information

General Information This manual describes proper installation, operation, manual should remain weather-protected with the unit and maintenance procedures for air cooled systems. By until all installation procedures are complete. carefully reviewing the information within this manual N N o o t t e e : : It is not the intention of this manual to cover all and following the instructions, the risk of improper possible variations in systems that may occur or operation and/or component damage will be... -

Page 7: Pre-Installation

Pre-Installation The final position for the air handler must be dictated 3. Install gauges to determine if the circuits are still by required service access to it, weight distribution pressurized. If not, the charge has escaped and over structural supports, and by the locations of should be repaired as required to obtain a leak-free electrical, refrigerant and condensate drainage circuit. - Page 8 P P r r e e - - I I n n s s t t a a l l l l a a t t i i o o n n is done as follows: Figure 2. Drain pan relocation a.

-

Page 9: Field Conversion To 460 Volt

P P r r e e - - I I n n s s t t a a l l l l a a t t i i o o n n Field Conversion to 460 Volt voltage selection and re-insert plug. I I m m p p o o r r t t a a n n t t : : When re-inserting voltage selection W W A A R R N N I I N N G G plug, ensure it is fully seated. -

Page 10: Piping

P P r r e e - - I I n n s s t t a a l l l l a a t t i i o o n n Figure 4. Evaporator coil reorientation for TWE126, 150, 156, 180 Top bracket screws Rotate 4°... -

Page 11: Clearances

P P r r e e - - I I n n s s t t a a l l l l a a t t i i o o n n Clearances I I m m p p o o r r t t a a n n t t : : When installing these units “free standing” with discharge grills and isolators, a top Allow the following minimum clearances for support with isolator should be added to... -

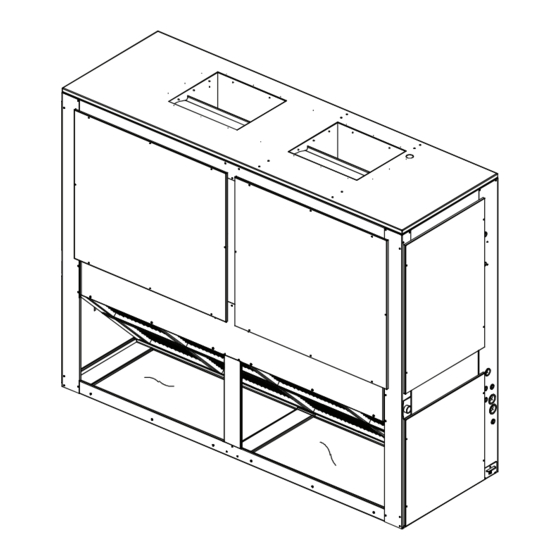

Page 12: Dimensional Data

Dimensional Data Figure 5. Height, width and depth measurements Right Side Back Front Left Side H - in. (mm) W - in. (mm) D - in. (mm) Model Number TWE051, 060 48-1/8 (1222.4) 39-5/8 (1006.5) 23-5/8 (600.0) TWE072, 076, 090 54-1/8 (1374.8) 49-1/8 (1247.8) 26-1/2 (673.1) - Page 13 D D i i m m e e n n s s i i o o n n a a l l D D a a t t a a Figure 6. 4.6, 5 ton air handler, single circuit N N o o t t e e : : Duct flange is a field-installed accessory. NOTES: 1.

- Page 14 D D i i m m e e n n s s i i o o n n a a l l D D a a t t a a Figure 7. 5 ton air handler, dual circuit N N o o t t e e : : Duct flange is a field-installed accessory. NOTES: 0.50”...

- Page 15 D D i i m m e e n n s s i i o o n n a a l l D D a a t t a a Figure 8. 6.25, 7.5 ton air handler, single circuit N N o o t t e e : : Duct flange is a field-installed accessory. NOTES: 25 1/2”...

- Page 16 D D i i m m e e n n s s i i o o n n a a l l D D a a t t a a Figure 9. 6, 6.25, 7.5 ton air handler, dual circuit N N o o t t e e : : Duct flange is a field-installed accessory.

- Page 17 D D i i m m e e n n s s i i o o n n a a l l D D a a t t a a Figure 10. 8.33, 10 ton air handler, single circuit N N o o t t e e : : Duct flange is a field-installed accessory. NOTES: 1.

- Page 18 D D i i m m e e n n s s i i o o n n a a l l D D a a t t a a Figure 11. 8.33, 10 ton air handler, dual circuit N N o o t t e e : : Duct flange is a field-installed accessory. NOTES: 1.

- Page 19 D D i i m m e e n n s s i i o o n n a a l l D D a a t t a a Figure 12. 10.4, 13, 12.5, 15 ton air handler, dual circuit N N o o t t e e : : Duct flange is a field-installed accessory.

- Page 20 D D i i m m e e n n s s i i o o n n a a l l D D a a t t a a Figure 13. 16.7, 20.9, 20, 25 ton air handler, dual circuit N N o o t t e e : : Duct flange is a field-installed accessory.

-

Page 21: Weights

Weights Air Handler Table 1. Constant volume air handler (TWE) — unit and corner weights - (60 Hz) Corner Weights - Corner Weights - Vertical Shipping Net Max Model Horizontal Tons Max (lbs) (lbs) Number TWE0604*A/B TWE0724*B TWE0904*A/B TWE1204*A/B 12.5 TWE1504*B TWE1804*B TWE2404*B... - Page 22 W W e e i i g g h h t t s s Figure 15. Vertical — TWE126, 156, 201, 251, 150, 180, 240, 300 Control Box Access Top View Figure 16. Horizontal — TWE051, 072, 076, 101, 060, 072, 090, 120 Top View Control Box Access...

-

Page 23: Accessories

W W e e i i g g h h t t s s Accessories Table 4. Accessory weights (net lbs.) Discharge Discharge Plenum Discharge Plenum Unit and Grille Plenum and Grille Used with and Grille with Electric Isolator Hot Water Hydronic without Electric... -

Page 24: Installation

Installation Horizontal Suspension N N O O T T I I C C E E E E q q u u i i p p m m e e n n t t D D a a m m a a g g e e ! ! If the air handler will be suspended, use a suspension mounting kit to isolate the unit from the structure. -

Page 25: Condensate Piping

I I n n s s t t a a l l l l a a t t i i o o n n Condensate Piping W W A A R R N N I I N N G G F F i i b b e e r r g g l l a a s s s s W W o o o o l l ! ! The drain pan condensate connection is a female slip joint type for 1”... -

Page 26: Filter Replacement

I I n n s s t t a a l l l l a a t t i i o o n n Filter Replacement filter track 180° to increase the width of the filter opening. W W A A R R N N I I N N G G Figure 20. -

Page 27: Electrical Wiring

I I n n s s t t a a l l l l a a t t i i o o n n Electrical Wiring Figure 21. Electrical entries W W A A R R N N I I N N G G H H a a z z a a r r d d o o u u s s V V o o l l t t a a g g e e w w / / C C a a p p a a c c i i t t o o r r s s ! ! F F a a i i l l u u r r e e t t o o d d i i s s c c o o n n n n e e c c t t p p o o w w e e r r a a n n d d d d i i s s c c h h a a r r g g e e c c a a p p a a c c i i t t o o r r s s b b e e f f o o r r e e s s e e r r v v i i c c i i n n g g c c o o u u l l d d r r e e s s u u l l t t i i n n d d e e a a t t h h o o r r... -

Page 28: Symbio™ Controls

I I n n s s t t a a l l l l a a t t i i o o n n N N O O T T I I C C E E N N o o t t e e s s : : 1. -

Page 29: Low Voltage Wiring

I I n n s s t t a a l l l l a a t t i i o o n n ☐ Inspect all field wiring connections. All connections ☐ Instruct owner/operator on proper system should be clean and tight. operating and maintenance procedure. -

Page 30: Field Wiring

Note: Gray shaded cells indicate older legacy units. Contact the local Trane Commercial Sales office to receive a copy of Hub Case details. 2-Speed Air Handler (identified by a “C” in digit 15) is specifically designed as a replacement air handler for a system with a legacy electromechanical condenser. -

Page 31: Pairing C: Legacy Electromechanical

I I n n s s t t a a l l l l a a t t i i o o n n Field Control Wiring refer to Air Handler unit schematic and Electric Heat Accessory Installation Guide (ACC- Figure 23. -

Page 32: Edc Switch Wiring

I I n n s s t t a a l l l l a a t t i i o o n n Figure 26. MODBUS wiring COMMON SYMBIO Air Handler CONDENSER MODBUS- Relay Board ADAPTER BOARD MODBUS+ RB-P7 Figure 27. -

Page 33: Startup

Startup Heating and Cooling Setpoint Figure 29. Supply Fan speed setpoints Arbitration All control function setpoints are set through one of the Symbio™ 700 user interfaces. If no changes are made, the controller will operate, as configured, based on the default settings. - Page 34 S S t t a a r r t t u u p p Parameter 6-15 in the VFD = 60Hz VFD output will be 25Hz. If the user chooses to increase the supply Fan Minimum Speed Setpoint, it will Supply Fan Maximum Speed Setpoint = 80% effectively increase the minimum VFD output from its Effective Supply Fan Maximum VFD Output = 80% x...

-

Page 35: Symbio™ Condenser Configuration

S S t t a a r r t t u u p p Table 9. Minimum VFD speed ranges Effective Minimum Speed Range Effective Minimum Speed Range Supply Fan (60 Hz) Supply Fan (60 Hz) Maximum Maximum VFD Output VFD Output (Hz) (Hz) - Page 36 S S t t a a r r t t u u p p Figure 30. Edit configuration Figure 31. Select multi speed and apply changes SSA-SVX06H-EN...

- Page 37 S S t t a a r r t t u u p p Figure 32. Verify changes SSA-SVX06H-EN...

-

Page 38: Szvav Air Handler Systems

S S t t a a r r t t u u p p SZVAV Air Handler Systems 2. Tap E E d d i i t t . 3. Tap S S y y s s t t e e m m T T y y p p e e . To configure the Symbio 700 for SZVAV air handler systems use the following steps and refer to through 4. - Page 39 S S t t a a r r t t u u p p Figure 34. System type Figure 35. Verify changes SSA-SVX06H-EN...

-

Page 40: Field Installed Electric Heat Kits

S S t t a a r r t t u u p p Field Installed Electric Heat Kits 2. Tap E E d d i i t t . 3. Tap P P r r i i m m a a r r y y H H e e a a t t i i n n g g S S o o u u r r c c e e . When Electric Heat Kits are installed into an Odyssey Air Handler paired with a Symbio 700 controlled 4. - Page 41 S S t t a a r r t t u u p p Figure 37. Select primary heating source Figure 38. Apply edits Figure 39. Verify changes SSA-SVX06H-EN...

-

Page 42: Electric Heat As Secondary Heat (Heat Pump Systems)

S S t t a a r r t t u u p p Electric Heat as Secondary Heat (Heat 3. Tap S S e e c c o o n n d d a a r r y y H H e e a a t t i i n n g g S S o o u u r r c c e e . Pump Systems) 4. - Page 43 S S t t a a r r t t u u p p Figure 41. Select secondary heating source Figure 42. Apply changes Figure 43. Verify changes SSA-SVX06H-EN...

-

Page 44: Maintenance

Maintenance Perform all of the indicated maintenance procedures at deflection value determined in Step the intervals scheduled. This will prolong the life of the 3. Set the small O-ring at zero on the force scale of the unit and reduce the possibility of costly equipment gauge plunger. -

Page 45: Monthly

M M a a i i n n t t e e n n a a n n c c e e Monthly W W A A R R N N I I N N G G F F i i b b e e r r g g l l a a s s s s W W o o o o l l ! ! The following warning complies with State of California law, Proposition 65. -

Page 46: Annually (Cooling Season)

M M a a i i n n t t e e n n a a n n c c e e Annually (Cooling Season) ☐ Check refrigerant piping and fittings for leaks. ☐ Inspect the evaporator coils for dirt and debris. If The following maintenance procedures must be the coils appear dirty, clean them. -

Page 47: Maintenance Log

M M a a i i n n t t e e n n a a n n c c e e Maintenance Log SSA-SVX06H-EN... -

Page 48: Location

Wiring Diagram Matrix and Device Location Table 11. Wiring schematics and device location Description Applicability Part Number Wiring Schematics Schematics; TWE - SZVAV/2-Speed Fan All TWE Units with Digit 15 = "D" 121332700001 All TWE Units with Digit 8 = 3, 4, W, D, K Schematics;... -

Page 49: Warranty

Central Air Conditioner THE WARRANTY AND LIABILITY SET FORTH HEREIN ARE IN LIEU OF ALL OTHER WARRANTIES AND This warranty is extended by Trane to the original LIABILITIES, WHETHER IN CONTRACT OR IN purchaser and to any succeeding owner of the real... - Page 50 N N o o t t e e s s SSA-SVX06H-EN...

- Page 51 N N o o t t e e s s SSA-SVX06H-EN...

- Page 52 For more information, please visit trane.com or americanstandardair.com. Trane and American Standard have a policy of continuous product and product data improvement and reserve the right to change design and specifications without notice. We are committed to using environmentally conscious print practices.

Need help?

Do you have a question about the Odyssey TWE0604*A/B and is the answer not in the manual?

Questions and answers