kozy heat 944 SEE-THRU Installation & Operating Instructions Manual

Direct vent see-thru / pier gas fireplace

Hide thumbs

Also See for 944 SEE-THRU:

- Installation instructions manual (35 pages) ,

- Installation and operation manual (35 pages) ,

- Installation instructions manual (35 pages)

Table of Contents

Advertisement

Quick Links

INSTALLATION & OPERATING INSTRUCTIONS

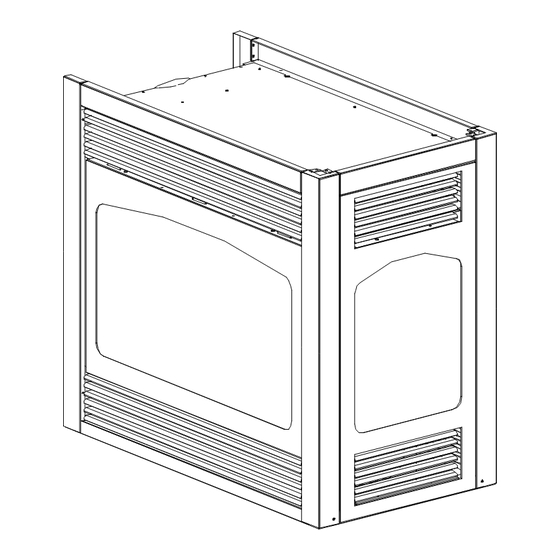

See-Thru Model

U.S. Patent Number: 5,931,154

U.S. Patent Number: 6,004,493

MODEL #944 DIRECT VENT

SEE-THRU / PIER GAS FIREPLACE

Front view

READ INSTRUCTIONS CAREFULLY BEFORE INSTALLATION. FAILURE TO

INSTALL THIS FIREPLACE CORRECTLY CAN CAUST SERIOUS STRUCTURAL

AND FIRE HAZARDS AND MAY VOID YOUR WARRANTY.

www.kozyheat.com

IMPORTANT:

Pier Model

January 2007

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for kozy heat 944 SEE-THRU

- Page 1 INSTALLATION & OPERATING INSTRUCTIONS MODEL #944 DIRECT VENT SEE-THRU / PIER GAS FIREPLACE See-Thru Model Pier Model U.S. Patent Number: 5,931,154 U.S. Patent Number: 6,004,493 Front view IMPORTANT: READ INSTRUCTIONS CAREFULLY BEFORE INSTALLATION. FAILURE TO INSTALL THIS FIREPLACE CORRECTLY CAN CAUST SERIOUS STRUCTURAL AND FIRE HAZARDS AND MAY VOID YOUR WARRANTY.

-

Page 2: Table Of Contents

INDEX SAFETY REQUIREMENTS ........... . . 1-2 SPECIFICATIONS . -

Page 3: Safety Requirements

IMPORTANT: READ THIS MANUAL BEFORE INSTALLING AND USING THIS FIREPLACE KOZY HEAT MODEL #944 DIRECT VENT See-Thru / Pier Fireplace INSTALLATION INSTRUCTIONS This appliance has been tested to and complies with ANSI Z21.88-2002CCSA 2.33-M02 ‘VENTED GAS FIREPLACE HEATER’. Installation must conform with local building codes, or, in the absence of local building codes, with the National Fuel Gas Code, ANSI Z223.1-NFPA 54 (Current Edition). -

Page 4: Specifications

This fireplace is factory-shipped as a see-thru fireplace. A pier conversion kit is available from your dealer. IMPORTANT: DO NOT DIRECTLY ATTACH FACING MATERIAL ONTO THE EXTERIOR FACES. THE FACES WILL EXPAND WHEN HEATED AND WILL CAUSE CRACKING OF THESE MATERIALS. WARNING: ONLY NON- COMBUSTIBLE MATERIALS MAY BE USED OVER THE FACE. -

Page 5: Venting & Clearance Requirements

Please contact your dealer VENT SYSTEMS: IMPORTANT: THIS FIREPLACE IS APPROVED FOR USE ONLY WITH ONE OF THE FOLLOWING DIRECT VENT SYSTEMS: KOZY HEAT #700 SERIES DIRECT VENT CHIMNEY SYSTEM: SIMPSON DURA-VENT DV-GS DIRECT VENT CHIMNEY SYSTEM*: 4" X 6 5/8". -

Page 6: Minimum Clearance To Combustibles

- Heat Outlet Grill to Mantel: (See Diagram A) Diagram A NOTE: The following clearances apply to both the Kozy Heat #700 Series flexible chimney system and the Simpson Dura-Vent DV-GS chimney system for horizontal terminations. Flue Vent Top: 2"... -

Page 7: Prepare The Fireplace

B) PREPARE THE FIREPLACE Note: This fireplace is shipped as a standard see-thru model. When a pier model is desired, a pier conversion kit is used and installed later in this manual. Follow the instructions below for glass assemblies, regardless of which model you are installing: REMOVE THE GLASS ASSEMBLY: Figure 2 Figure 2. -

Page 8: Rough-In Dimensions

HORIZONTAL TERMINATIONS: Determine width & depth of the hearth (optional). Determine the vent run and termination cap location. If possible, place the fireplace in such a manner that the piping will be placed between two studs so additional framing is not necessary. NOTE: Allow a minimum of 18"... - Page 9 PIER INSTALLATIONS: Refer to Figures 4A & 4B. Rough opening dimensions are 36 1/4" wide x 32 1/2" high (above the height of the optional hearth). Depth is determined by the thickness of facing materials being used. IMPORTANT! The fireplace depth is 20". Figure 4A Figure 4B PIER MODEL SHOWN IN FIGURE ABOVE.

-

Page 10: Venting Requirements

D) VENTING REQUIREMENTS HORIZONTAL & VERTICAL VENTING CHART HORIZONTAL TERMINATIONS: Minimum horizontal run: 15" (18" length of pipe) (This is directly off the collars on the fireplace running at a 45-degree angle.) Maximum horizontal run: 20 Ft. Total run cannot exceed 20 Ft. The first 15"... - Page 11 TERMINATION VENT CAP LOCATION: This gas appliance must not be connected to a chimney flue serving another type of appliance. GENERAL: Terminations against vinyl siding must use a vinyl siding protector. Follow instructions included. DO NOT RECESS TERMINATION KIT INTO OUTSIDE BUILDING MATERIALS - i.e.: brick, stone, etc.. If necessary, extend framing so that termination kit will be exposed once building materials are installed.

-

Page 12: Restrictor Installation Instructions

RESTRICTOR INSTALLATION The restrictor plate included in the fireplace components packet can be installed as either a large or small restrictor, depending on your specific venting configuration. There are several factors which can affect proper draft of the vent system and the burner operation of a fireplace. Installing a restrictor may be necessary to resolve the Figure 6A problem, even though it may not be required under ‘normal... -

Page 13: Horizontal Venting Instructions

Simpson Dura-Vent DV-GS chimney system. The included firestop adaptor is attached to the pass-thru framing / wall materials first. The firestop or wall thimble from the chimney system is then attached to the firestop adaptor. Refer to Figure 4C, page 7. KOZY HEAT #700 SERIES DIRECT VENT SYSTEM: Figure 7A... - Page 14 INSTALLATION OF THE #700 SERIES HORIZONTAL DIRECT VENT TERMINATION KIT(S) NOTE: THE FLEX PIPE IS PERMANENTLY ATTACHED TO THE EXTERIOR WALL PLATE. DO NOT ATTACHED THE #745 OR #718 TERMINATION KIT TO THE FIREPLACE (OR EXTENSION KIT) UNTIL IT HAS PASSED THROUGH THE WALL.

-

Page 15: Vertical Venting Instructions

VERTICAL VENTING REQUIREMENTS MAXIMUM VERTICAL RISE: 40 Ft. Vertically position the chimney by connecting (1) 45-degree elbow onto the #923-C Dura-vent adaptor. Connect the adaptor to the stacks on the fireplace and seal with the sealant provided MINIMUM CLEARANCE FROM CHIMNEY SYSTEM TO COMBUSTIBLES: 1" ELBOWS: ) Included within maximum vent runs - For each additional 90 elbow, the maximum horizontal... -

Page 16: Rotating The Control Valve

E) ROTATE THE GAS CONTROL VALVE - OPTIONAL IMPORTANT: THE CONTROL VALVE MAY BE ROTATED SO THAT IT IS ACCESSIBLE FROM THE OPPOSITE SIDE FROM WHICH IT WAS MANUFACTURED. THIS MUST BE DONE PRIOR TO CONNECTING THE GAS LINE. FOLLOW THE INSTRUCTIONS BELOW TO ROTATE THE CONTROL VALVE ASSEMBLY: NOTE: Although not necessary, it may be easier to rotate the control valve if the millivolt board is removed first. -

Page 17: Fan Installation

F) FAN INSTALLATION KIT (OPTIONAL INSTALLATION OF THIS FAN SHOULD BE DONE ONLY BY A QUALIFIED INSTALLER. This following items are included with this fan kit: (1) Left fan assembly with wire harness and fan cord attached. (1) Right fan assembly (1) Temperature control switch already wired (1) Electrical / Speed control box. - Page 18 Figure 11A WIRING INSTRUCTIONS: IMPORTANT: The electrical / speed control box is mounted to the left side of the gas valve bracket and secured with (2) phillips head screws. The electrical wiring should be sufficiently run to allow ample wire for proper connection to the electrical / speed control box once secured to the bracket.

-

Page 19: Minimum / Maximum Gas Supply Pressure / Run The Gas Line

G) RUN THE GAS LINE: CAUTION: Installation of the gas line must only be done by a qualified person in accordance with local building codes. NOTE: This fireplace is equipped with a 3/8" flexible gas connection, 18" long. NOTE: The gas line should be run to the point of connection where the shut-off valve and flexible gas line will connect. -

Page 20: Millivolt Board Removal / Installation

IMPORTANT: ALL CONNECTIONS WHETHER FIELD OR FACTORY MADE MUST BE CHECKED FOR LEAKS! NOTE: The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of ½ psi. NOTE: The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than ½... - Page 21 INSTALLING THE MILLIVOLT BOARD. NOTE: This fireplace is fitted with a gasket to seal the millivolt board. Make certain this gasket is properly placed around the opening before installing the millivolt board. 1. Grasp the burner with both hands and place into the unit, lining up the (8) 1/4" holes in the millivolt board to the (8) mounting studs on the firebox bottom.

-

Page 22: Log Installation

LOG INSTALLATION. See Figures 13A & 13B. This #944-500 log set includes: (2) L-Logs (2) AU-Logs (2) G-Logs (1) S-Log (1) D-Log (1) AK-Log (1) AL-Log (1) A-Log (2) Rockwool embers pkg. (1) Klinker pkg. LOG GRATE: 1. Place the log grate into position around Base Logs the burner / cover assembly. -

Page 23: Thermostat, Wall Switch, Remote Control Installation

J) THERMOSTAT, WALL SWITCH OR REMOTE CONTROL INSTALLATION CAUTION: DO NOT CONNECT HIGH VOLTAGE (115V) TO ANY OF THESE SYSTEMS. If desired, a thermostat, wall switch, or remote control assembly may be used to turn the fireplace ‘OFF’ and ‘ON’. ONLY one of these may be installed. -

Page 24: Pier Conversion

PIER CONVERSION Pier Model Installations: This kit includes: Figure 15A (1) 14 ½" x 17" glass with gasket (1) Arched valance with screen & grills installed. Remove the end panel: 1. Loosen, but do not remove, the nuts securing the end panel from inside the upper grill opening. -

Page 25: Complete The Installation

OPTIONAL SCREEN REMOVAL: Determine if removal of the factory installed screen on the pier end panel is desired prior to installation. If may become damaged and is very difficult to re-install once it has been removed. Figure 15D Replace the arched frame/screen/grill assembly. 1. -

Page 26: Seasonal Heat Dump Operation

WARNING: DO NOT ENCLOSE THE AIR SPACE AT THE BOTTOM OF THE FIREPLACE. THIS COULD CAUSE THE AREA TO OVERHEAT. MASONRY CONSTRUCTION: If using a lintel iron, follow instructions included with the lintel iron for proper placement. CAUTION: The surrounding wood chase of the outside wall MUST be insulated to prevent cold air from entering the room. -

Page 27: Replace The Glass Assemblies

FIREPLACE ‘BACK’ SIDE: A. Secure the assembly to the fireplace by pushing the two latch handles (located under the firebox) up. WARNING: DO NOT OPERATE THIS FIREPLACE WITH THE GLASS ASSEMBLY REMOVED, CRACKED OR BROKEN. Replacement of the glass assembly should be done by a licensed or qualified service person. 5. -

Page 28: Lighting And Shutdown

LIGHTING AND SHUTDOWN PROCEDURES NOTE: Prior to lighting, check all fittings for leakage. This is accomplished by applying soapy water on all connections made. If there is any leakage, bubbles will appear at the point of connection. If bubbles occur, tighten the fittings until the bubbles no longer appear. IMPORTANT: TEST ALL CONNECTIONS WHETHER FIELD OR FACTORY MADE. - Page 29 Turn gas control knob counterclockwise to the "ON" position. 10. The burner can now be turned ‘ON’ or lit by depressing the bottom of the ON/OFF rocker switch (C) located beside the valve OR by setting the thermostat or remote control to the desired setting. 11.

-

Page 30: Pressure Testing

PRESSURE TEST - MANIFOLD & INLET PRESSURE IMPORTANT NOTICE: A pressure check tap for both the manifold (outgoing) and inlet (incoming) pressure has been incorporated into the valve by Honeywell. The right pressure tap is the manifold pressure and the left pressure tap measures the incoming pressure. -

Page 31: Maintenance Requirements

N) MAINTENANCE REQUIREMENTS MILLIVOLT BOARD SYSTEM 1. The appliance should be inspected at least once a year by a professional service person. 1. Annual cleaning of the burner is required. NOTE: INSTALLATION REPAIR The burner tube / cover may be removed for SHOULD BE DONE ONLY BY A QUALIFIED easier access. -

Page 32: Trouble Shooting

TROUBLE SHOOTING GUIDE NOTE: The millivolt board includes the following items: Valve, pilot assembly, piezo, electrode, rocker switch, burner, orifice and orifice holder. If any of these items are defective, contact your dealer for the appropriate repair / replacement procedures to follow. WARNING: DO NOT ATTEMPT TO SERVICE THIS UNIT IF YOU ARE NOT A QUALIFIED INSTALLER OR REPAIRMAN. - Page 33 PROBLEM CAUSE SOLUTION Burner won't light. Pilot not lit. Relight pilot. Regulator valve not turned “on”. Turn valve to "on". Rocker switch not turned “on”. Press bottom of switch. Rocker switch wire not connected. Check wiring diagram Figure 20 to ensure that all wires are secure.

-

Page 34: Replacement Parts

REPLACEMENT PARTS Replacement parts are available through your local Kozy Heat dealer. Please contact them for availability and pricing. MILLIVOLT BOARD AND PARTS 944-800 #944 Millivolt Board - Natural Gas 700-203 Manual Shut off Valve 944-801 #944 Millivolt Board - LP Gas 700-213B 18"... -

Page 35: Warranty Policy

Page 33... - Page 36 Page 34...

Need help?

Do you have a question about the 944 SEE-THRU and is the answer not in the manual?

Questions and answers