Table of Contents

Advertisement

Quick Links

OWNER'S MANUAL

FOR PROFESSIONAL

USE ONLY

313 - 1014

Rev. B 0799

DO NOT USE EQUIPMENT BEFORE READING THIS MANUAL

PowrTwin 3500™

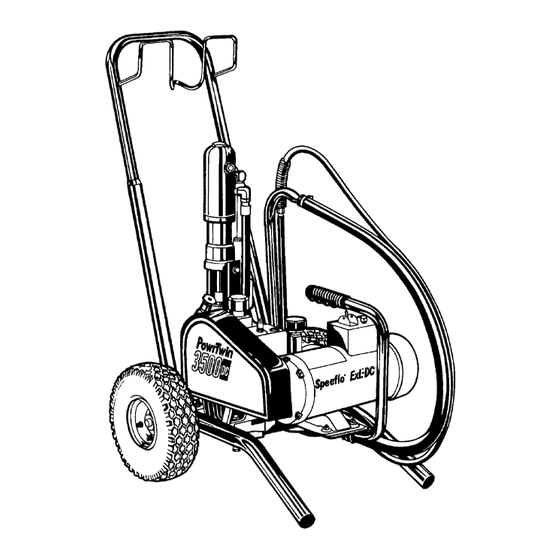

PowrTwin 3500™ Airless Sprayer

WARNING HIGH PRESSURE DEVICE

Model Numbers 335-500

335-501

335-502

335-503

This manual contains important warnings and instructions.

Please read and retain for reference. Never operate this unit unless it is properly grounded.

Advertisement

Table of Contents

Summary of Contents for Titan 335-501

- Page 1 DO NOT USE EQUIPMENT BEFORE READING THIS MANUAL PowrTwin 3500™ PowrTwin 3500™ Airless Sprayer WARNING HIGH PRESSURE DEVICE Model Numbers 335-500 335-501 335-502 335-503 This manual contains important warnings and instructions. Please read and retain for reference. Never operate this unit unless it is properly grounded.

-

Page 2: Table Of Contents

More than 75,000 of these pumps are in opera- make you money year after year. We thank you for your purchase tion around the world. and welcome you to our large and growing family of Titan/Speeflo PowrTwin 3500™ offers other cost saving features: users. - Page 3 Your sprayer has the English language Warning Label shown on Page 5 in the location indicated below. If you require this label in French, German, or Spanish, or require additional English labels, order directly from Titan free of charge. Call toll free 1-800-526-5362.

- Page 4 DO NOT USE EQUIPMENT BEFORE READING THIS SECTION WARNING HIGH PRESSURE SPRAY CAN CAUSE SERIOUS INJURY Maximum Working Pressure 3000 psi, 207 bar An airless spray gun requires that fluid be the following: plug is necessary, do not connect the ground- introduced to it at very high pressure.

- Page 5 NO USE EL EQUIPO ANTES DE LEER ESTA SECCION ADVERTENCIA LA ROCIADURA A PRESION ALTA PUEDE CAUSAR LESION GRAVE. Presión de Trabajo Máxima 3000 libras por pulgada cuadrada (psi), 207 bar Una pistola rociadora sin aire requiere que se le 4) Antes de lavar el sistema, siempre quite la un circuito de tensión nominal de 120 voltios y introduzca líquido a presión muy alta.

- Page 6 NE PAS UTILISER LE MATERIEL AVANT D’AVOIR LU CETTE SECTION ATTENTION! LES PULVERISATEURS A HAUTE PRESSION PEUVENT PROVOQUER DE SERIEUSES LESIONS Pression de travail maximale: 3000 psi — 207 bar Le liquide introduit dans un pistolet pulvérisateur soupape de surpression. règlements locaux.

-

Page 7: Specifications

FIGURE 1 4. Fill the Wet-Cup 1/2 full with Titan/Speeflo's Piston Lube, Part No. 700-925, supplied by the factory. This extends packing life. 5. Electric Models - Use a 20 amp service outlet. Always locate the AC electric model within 10 to 15 feet of the service outlet. -

Page 8: Startup

Maintenance Instructions on Page 11 for changing or adding tip, changing a tip, servicing any part of the system, or shut- hydraulic fluid. Do not overfill. Use only Titan/Speeflo Coolflo™ ting down. Follow the steps below: Hydraulic Fluid, Part No. 430-361. -

Page 9: Maintenance

1. Check the hydraulic fluid daily. It should read "Full" on the dip- stick. If it is low, add only Titan/Speeflo Coolflo™ Hydraulic Fluid, Part # 430-361. Never add or change hydraulic fluid except in a clean dust free area. Contamination of the hydraulic fluid will short- en Hydraulic pump life and may void warranty. - Page 10 HYDRAULIC MOTOR & FLUID PUMP SERVICE See Page 22 for maintenance and service instructions on the reci- procating hydraulic motor and Page 26 for the fluid pump. BASIC ENGINE MAINTENANCE • For detailed engine maintenance and technical specifications refer to the separate Kawasaki engine manual. •...

-

Page 11: Powrtwin

ELECTRIC 3.5 HP 1.5 HP GAS/ 1.5 HP ITEM PART Kawasaki 50/60 Hz 115 V ELECTRIC 50/60 Hz 220 V DESCRIPTION 335-500 335-501 335-502 335-503 335-108 Motor/Pump Assembly Hydraulic System Cart Assembly 506-103 Convertokit, 3.7 HP, Kawasaki, Gas 506-238 Convertokit, 1.5 HP, DC Electric 50/60 Hz 115V 506-244 Convertokit, 1.5 HP, DC Electric 50/60 Hz 220V... - Page 12 PowrTwin 3500™ DC - Electric Convertokits DC - ELECTRIC CONVERTOKITS 506-238 506-244 115 V 220 V ITEM PART DESCRIPTION 978-355 Motor, DC-Electric, 1.5 HP, 50 / 60 Hz, 115 V 978-346 Motor, DC-Electric, 1.5 HP, 50 / 60 Hz, 220 V 860-501 Nut Stop 860-002...

- Page 13 PowrTwin 3500™ Electric Convertokits - Service Instructions WARNING: Before servicing the electric motor, follow the Pressure Relief Procedure on Page 10. Once you have completed this procedure, unplug the power supply cord. Failure to reduce pressure can result in serious injury. Observe all warnings. Note: Brushes should be replaced when they are worn to less than 1/2 inch.

-

Page 14: Cart Assembly

PowrTwin 3500™ Cart Assembly CART ASSEMBLY CART ASSEMBLY (Continued) ITEM PART ITEM PART DESCRIPTION QUANTITY DESCRIPTION QUANTITY 590-502 Handle 335-562 Axle 590-508 Roll Pin 449-051 Motor/Pump Bracket 590-507 Snap Button 335-558 Frame, Right 856-002 Washer 862-460 Screw 856-921 Screw 854-020 Screw 590-504 Sleeve... -

Page 15: Hydraulic Motor

PowrTwin 3500™ Hydraulic Motor ITEM PART solvent and will severely damage seals and O-Rings of the DESCRIPTION QUANTITY hydraulic motor. 235-018 Retainer, Trip 141-007 O-Ring 325-005 Spring, Trip Gently push the Spool Sleeve Set (5) into Cylinder Head (11) using 569-016 Ball, SS a nylon driver and a rubber mallet until sleeve has reached its full... - Page 16 The use of Titan/Speeflo Piston Lube, Part # 700-925, is recommended as an upper packing lubricant. DO NOT SUBSTITUTE OIL, WATER, OR SOLVENT for an upper packing lubricant.

- Page 17 Inlet Accessories 840-211 BLEED LINE ASSEMBLY WITH VALVE ITEM PART Hoses and Valves DESCRIPTION QUANTITY 944-620 Bleed Valve 103-111 Bleed Line Assembly 539-078 Hose Assembly 103-117 Tube 944-620 BLEED VALVE ASSEMBLY ITEM PART DESCRIPTION QUANTITY 944-005 Knob 860-721 Nut, Lock 944-023 Valve Stem 944-004...

-

Page 18: Outlet Manifold Filter Assembly

Outlet Accessories 930 Outlet Manifold Filter Assembly with Check Valve OUTLET MANIFOLD FILTER ASSEMBLY PART NO. 920-560 ITEM PART DESCRIPTION 920-917 Filter Cap Assembly 920-103 Ball 920-004 Filter Element, 50 M 920-001 Filter Element, 5 Mesh 920-005 Filter Element, 100 Mesh 920-006 Gasket, (Thick) - Page 19 PowrTwin 3500™ Outlet Accessories (Optional) 2 Gun Manifold 2 GUN MANIFOLD PART NO. 970-110 ITEM PART DESCRIPTION QTY. 970-098 Manifold 227-027 Plug, Pipe 814-004 Nipple, Hex...

-

Page 20: Warranty

The terms of this warranty con- by Titan Tool Inc. Titan Tool Inc. shall not be liable for damage or wear stitute purchaser's sole and exclusive remedy. In no case shall Titan caused by incompatibility with Titan Tool Inc.

Need help?

Do you have a question about the 335-501 and is the answer not in the manual?

Questions and answers