Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for GCC Technologies LaserPro C180

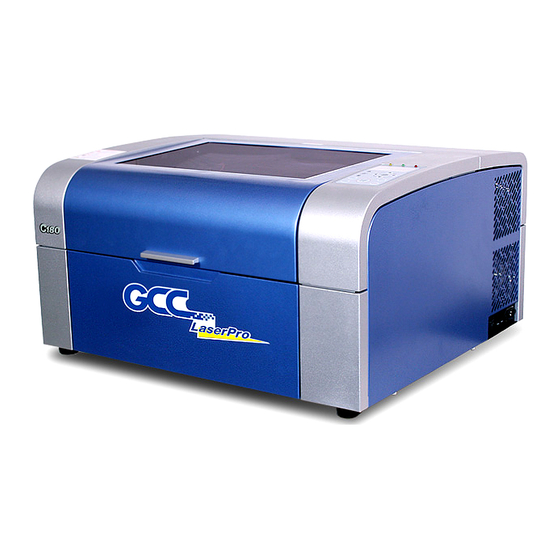

- Page 3 Dear Sir or Madam, Thank you for choosing GCC and the LaserPro C180. You can be assured that this machine meets all of the highest safety standards while using technological innovations shared by no other laser engraver. The LaserPro C180 is backed by GCC, a truly international company that is dedicated to helping your business grow.

-

Page 4: Table Of Contents

Recommended Computer Configuration..............4.2.2 Installation of the LaserPro USB Driver..............4.2.3 Installation of the LaserPro Print Driver..............Chapter 5 - Operating the LaserPro C180 ............- 27 - Using the Hardware......................5.1.1 Adjusting the LCD Display Screen’s Contrast Setting..........5.1.2 Graphic Control Panel Overview (Description)............ - Page 5 Table of Contents 5.2.3.5 LaserPro C180 Print Driver >> Language Page..........67 5.2.3.6 LaserPro C180 Print Driver >> Raster Page............. 67 5.2.3.7 LaserPro C180 Print Driver >> Stamp Page............70 Chapter 6 - Engraving and Cutting Techniques............ - 73 - Raster Engraving......................

-

Page 7: Chapter 1 - Safety

Chapter 1 Safety Principles of CO Laser Safety Ratings The Safety Interlock System Safety Labels Safety Measures Operating Environment LaserPro C180 User Manual... -

Page 8: Safety Ratings

One of the key safety features found on the LaserPro C180 is a Class 3R red dot safety guidance pointer (similar to a laser-pointer presentation pen) allowing the operator to see the exact location where the laser beam will fire. -

Page 9: Product Label

In compliance with CDRH standards, the required warning labels are affixed at the time of manufacture to the LaserPro C180 in the appropriate locations. These labels are not to be modified in any way or removed for any reason. Please familiarize yourself with the specific labels and their locations on the machine. Below is a list of all the safety labels and their locations on the machine. -

Page 10: Warning Label

The warning label reminds operators to take precaution against possible mishaps during machine operation. Laser Path Warning Label LaserPro machines are very safe under normal use. Furthermore, Laser Path Warning Labels are displayed at the proximities of possible laser paths as a reminder. Operators should exercise caution when working close to these laser paths to avoid possible injury while machine is turned on. -

Page 11: Safety Measures

Severe eye damage may occur if appropriate safety goggles are not worn. NOTE Each LaserPro laser machine is shipped with a single pair of safety goggles. If additional safety goggles are required, please contact GCC directly or an authorized GCC distributor. -

Page 12: Operating Environment

1.6 Operating Environment Please follow the guidelines when considering a suitable location to set the LaserPro C180. Improper work environments may lead to operational malfunction and/or unsafe working conditions. The LaserPro C180 should be placed and operated in a standard office-type environment. - Page 13 Chapter 2 Unpacking & Contents Unloading and Unpacking Contents and Accessories Checklist LaserPro C180 User Manual...

-

Page 14: Unloading And Unpacking

2.1 Unloading and Unpacking The LaserPro C180 & C180S is shipped in one crate that contains the machine, the software, and all of the necessary accessories. The following section contains detailed step-by-step instructions for unpacking and assembly of the machine. - Page 15 3) Open the carton box. 4) Carefully lift the machine out of the box with the help of another person. LaserPro C180 User Manual...

-

Page 16: Contents And Accessories Checklist

USB Port Cable Focusing Tool # 900 Goggles 2 inch to 4 inch Hose Adaptor 2 inch tubing Installation CD ( LaserPro C180 user manual, driver, and firmware ) Pencil Sample Butterfly Sample Card Promise Card LaserPro C180 User Manual... -

Page 17: Chapter 3 - Mechanical Overview

Chapter 3 Mechanical Overview Front View Top View Right ( Profile ) View Left ( Profile ) View Rear View Difference between C180 and C180S View LaserPro C180 User Manual... -

Page 18: Front View

Please take some time to familiarize yourself with this section regarding the mechanical overview of the LaserPro C180 / C180S. References will be made back to the different parts of the LaserPro C180 / C180S in later sections. 3.1 Front View Lower Front Door 3.2 Top View... -

Page 19: Right (Profile) View

3.3 Right (Profile) View Power Cable Inlet Power Switch 3.4 Left (Profile) View LaserPro C180 User Manual... -

Page 20: Rear View

3.5 Rear View Air Valve Exhaust Port USB Port Parallel Port Laser Access Panel 3.6 Difference between C180 and C180S View ˙ C180 LED lighting Internal side covers Openings for jigs and air suction Built-in SmartBOX *Note: Working platform can be removed from SmartBOX for extra 2" engraving depth allowing work done on 6"... - Page 21 ˙ C180S No LED lighting No Internal side No Openings for jigs and air suction No Built-in SmartBOX * Note: Without the SmartBOX, the maximum engravable depth of the object is 4". LaserPro C180 User Manual...

-

Page 23: Chapter 4 - Setup And Installation

Chapter 4 Setup and Installation Machine Setup Powering Up the Machine Power Cable Connection Connecting the Computer Graphics Software Setup Recommended Computer Configuration Installation of the LaserPro USB Driver Installation of the LaserPro Print Driver LaserPro C180 User Manual... -

Page 24: Machine Setup

LCD adjustment wheel is located underneath the control panel. 4.1.3 Connecting the Computer The LaserPro C180 can communicate with a computer through a USB Port or Parallel Printer Port connection interface. The USB Port connection offers faster file transfer rates and greater flexibility over the Parallel Printer Port connection. -

Page 25: Graphics Software Setup

• CorelDRAW • Illustrator • AutoCAD Other software such as EngraveLab and PhotoGrav may work with the LaserPro C180, but these are not supported. Any software that can output to the LaserPro Print Driver should work. NOTE • Support will not be offered, if you experience output problems with non-supported graphics software. -

Page 26: Installation Of The Laserpro Usb Driver

Windows. 1) Turn on your computer and insert the LaserPro CD. 2) From the auto run menu, select C180 → USB Driver to start the LaserPro USB Driver installation. 3) The LaserPro USB Driver installation program will update your Windows USB driver. When the notification pops up, select Yes to continue the installation. - Page 27 <Step 2> Please do the following steps to install the USB driver. 1. Run the remove.exe ( right click and click ”Run as Administrator”) to make sure that we remove any previous versions of the USB driver. LaserPro C180 User Manual...

- Page 28 2. Run the “USBSETUP.EXE” file ( right click and click ”Run as Administrator”) LaserPro C180 User Manual...

- Page 29 • Attention: Remove previous installations if any. ( Right click on previous installations and select remove driver, then unplug and plug USB cable from laser engraver again.) Fig: If the USB Print Support has been installed on the computer, it will be shown on the above screen LaserPro C180 User Manual...

- Page 30 “Upgrader.exe” file. Example 1: If we run the "Upgrader.exe" file but did not use "Run as Administrator". The GCC USB driver port will not show up in the pull down menu of the Com Setup. LaserPro C180 User Manual...

- Page 31 Example 2: Under the same situation as sample 1, right click on the "Upgrader .exe" and click” Run as Administrator”, you can see the GCC USB Port in the pull down list of the Com Setup. LaserPro C180 User Manual...

-

Page 32: Installation Of The Laserpro Print Driver

CD (xxx are numbers representing the driver version). Click OPEN to have C180 displayed as a valid printer. 7) Now select C180 from the list of printers (The C180 should be the only printer displayed on the list) and click Next to continue. -

Page 33: Chapter 5 - Operating The Laserpro C180 ............................................................

Page Setup and Orientation Color Management Using the LaserPro C180 Print Driver - LaserPro C180 Print Driver >> Options Page - LaserPro C180 Print Driver >> Pen Page - LaserPro C180 Print Driver >> Advanced Page - LaserPro C180 Print Driver >> Paper Page - LaserPro C180 Print Driver >>... -

Page 34: Using The Hardware

LaserPro C180 to your computer, you will need to familiarize yourself with the LaserPro C180’s control panel and LaserPro Print Driver. The print driver will be where you spend most of your time configuring specific laser parameters for your jobs, while the control panel will allow you to set repeat times, manipulate the file order, perform auto / manual focusing, configure the start point, and more. - Page 35 LED INDICATOR LIGHTS Three indicator lights on the LaserPro C180’s control panel are part of the system’s safety interlock system. • DOOR - The door light will illuminate when either the top lid or external pass through doors on the LaserPro C180 are open or improperly closed.

-

Page 36: Graphic Control Panel Navigation Chart

Select Focus Lens Page Recall Position Page Command Mode Page Tune Auto Focus Page Save Position Page Laser Tube Model Page Carriage Free Page SmartMemory Page SmartGUARD setting Page USB Setup Wizard Page Others Page Reset Page LaserPro C180 User Manual... -

Page 37: Graphic Control Panel Function

Main Work Page The main work page is the page that the LaserPro C180 will default to upon startup and will be the “home base” for when navigating through the various functions of the control panel. This will be the page that is displayed when you are processing your jobs. - Page 38 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Back to Main Work Page Stop Back to Main Work Page Back Back to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

- Page 39 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Go to Main Work page Stop Go to Main Work page Back Go to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

- Page 40 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Go to Main Work page Stop Go to Main Work page Back Go to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

- Page 41 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Go to Main Work page Stop Go to Main Work page Back Go to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

- Page 42 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Go to Main Work page Stop Go to Main Work page Back Go to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

- Page 43 The SmartMEMORY Page allows you to read and write data with the optional SmartMEMORY module installed. Selecting <Save to File> will copy all current jobs on the LaserPro C180 to the SmartMEMORY module. Selecting <Load from File> will copy all job files from the SmartMEMORY module to the LaserPro C180.

- Page 44 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Go to Main Work page Stop Go to Main Work page Back Go to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

- Page 45 Remember to save your settings after you have made the proper changes. Now by pressing the Auto Focus button, the LaserPro C180 will auto focus properly using the new lens. The LaserPro C180’s default setting is <2.0">...

- Page 46 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Go to Main Work page Stop Go to Main Work page Back Go to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

- Page 47 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Go to Main Work page Stop Go to Main Work page Back Go to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

- Page 48 For example, if the sensor delays switch is set to the 3 seconds position, the SmartGUARD will start an alarm and automatically shutdown the laser system after detecting a fire for 3 seconds. LaserPro C180 User Manual...

- Page 49 Turn Light On/Off Others Page Navigating to this page: Main Work Page Press Menu Carriage / Work Table Menu Page Adjustment Page Select <Machine Setting> from the menu Machine Setting Page Select <Others> from the menu Others Page LaserPro C180 User Manual...

- Page 50 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Go to Main Work page Stop Go to Main Work page Back Go to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

- Page 51 Reset Page The Reset Page allows you to reset all changes made to the LaserPro C180’s Machine Settings Page to their default settings. This does not affect the settings saved to an image file on the computer. The User Reset setting will set all settings back to the default.

- Page 52 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Go to Main Work page Stop Go to Main Work page Back Go to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

- Page 53 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Go to Main Work page Stop Go to Main Work page Back Go to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

- Page 54 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Go to Main Work page Stop Go to Main Work page Back Go to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

- Page 55 A/F ▲ / ▼ Directional Manually adjust the height of the work table (Z-axis) Start / Pause Go to Main Work page Stop Go to Main Work page Back Go to previous screen Light Turn Light On/Off LaserPro C180 User Manual...

-

Page 56: The Laserpro C180 Print Driver

5.2.1 Page Setup and Orientation The first thing you must do before working with the LaserPro C180 Print Driver will be to make sure the page and layout settings are properly configured within your graphics software. You will need to access and edit the Page Setup or Layout page of your graphics software to set your graphics software’s page... - Page 57 From the navigation bar on the left, click DOCUMENT → PAGE → SIZE. Ensure that NORMAL PAPER and LANDSCAPE are selected. Ensure the Paper Width and Height dimensions match the LaserPro C180’s work table dimensions of 458 mm (18 inches) and 309 mm (12 inches).

-

Page 58: Color Management

Now after you have properly set the Page and Layout and Color Management of your graphics software, you are ready to configure the details of your actual job through the LaserPro C180 Print Driver. The LaserPro C180 print driver allows you to adjust your engraving / cutting options. After you have setup your image, design, or text to be engraved in your software application, you can access the LaserPro C180 print driver by going to FILE →... - Page 59 NOTE For this screenshot example, CorelDRAW was used as the software application. The LaserPro C180 Print Driver consists of seven primary sections (pages) in which you will be able to choose various engraving / cutting options and settings: • Option Page •...

-

Page 60: Laserpro C180 Print Driver >> Options Page

PEN menu. Please refer to the next section of the manual for details regarding the PEN functions). The LaserPro C180 print driver will interpret colored and shaded areas as different shades of gray by producing a halftone effect while engraving. Instead of engraving only solid lines, gray/ halftone areas will be a collection of dots with varying density. - Page 61 3D Mode: Select this mode to attain a sculptured 3D effect on your engraving. By using images that have a range of gray areas, the LaserPro C180 print driver can manipulate the image to give it added depth, by linking the laser power (depth of engraving) to specific colors. The settings can be adjusted through the DPI setting (Option page) and PPI, power and speed settings (Pen page).

- Page 62 Checking this will instruct the LaserPro C180 to immediately begin the laser engraving process, when you select Print from your graphic software program. If Print Immediately is not checked, then selecting Print will transfer the job file to the LaserPro C180 system and will need to be initialized from the LaserPro C180 control panel.

- Page 63 SAVE: This function will save current print driver parameter settings to a file under the specified location on your computer. (Saved parameter setting files will be tagged with the “.C18” extension) • LOAD: This function allows you load previously saved print driver parameters or LaserPro parameter database. •...

- Page 64 LaserPro C180 User Manual...

-

Page 65: Laserpro C180 Print Driver >> Pen Page

5.2.3.2 C180 Print Driver >> Pen Page The LaserPro C180 incorporates the use of 16 different colors to represent 16 different laser power and speed settings when cutting and engraving. These colors are referred to as “Pens”. Think of each pen as a designated laser setting, rather than as a color. - Page 66 The speed slider controls the laser’s speed during operation (engraving speed) with a range setting from 0.1 – 100%. The LaserPro C180’s maximum laser processing speed is 40 inches per second, therefore a setting of 100% speed is equivalent to 40 inches per second and a 10% speed setting would be equivalent to 4 inches per second.

-

Page 67: Laserpro C180 Print Driver >> Advanced Page

This checkbox sets the Auto Focus for that particular job. With the Auto Focus button checked, the LaserPro C180 will automatically initialize the auto focus procedure before starting the job. This will ensure the focal distance is properly set based on the particular material you are working with and the focal lens you have installed. - Page 68 Position Mode set to Center, then the C180 will vector cut a circle around the initial position of the laser head. It is highly recommended you enable the red dot laser pointer when setting / adjusting the Position Modes, as this makes accurate positioning of your laser carriage for your particular jobs much easier.

- Page 69 Use Cluster (Advance Page) [DEFAULT SETTING: Unselected] This setting allows you to change how the LaserPro C180 interprets and processes individual / independent areas of an image in order to minimize job-processing times. The Cluster function is only...

-

Page 70: Laserpro C180 Print Driver >> Paper Page

This setting allows you to improve the engraving quality by reordering the line by line output sequence and by doing so masking the banding problems. This feature is only suitable for engraving large sized graphics. Note: The overall working time will be increased. 5.2.3.4 C180 Print Driver >> Paper Page LaserPro C180 User Manual... - Page 71 The paper size represents your total work area. Ensure that the paper size is never set greater than the C180’s worktable area of 18" x 12" (458 mm x 309 mm). The X value represents the length and the Y value represents the width.

- Page 72 3) Under Rotary Parameter, the Offset value represents distance from the open end of your work piece to the base of the padded rubber wheel. This value will be displayed on the C180’s LCD panel. Enter the proper offset value in this field.

-

Page 73: Laserpro C180 Print Driver >> Language Page

5.2.3.5 C180 Print Driver >> Language Page This page allows you to specify the language displayed by the C180 Print Driver. Available language options include: English, Spanish, French, Japanese, German, Simplified Chinese, and Traditional Chinese. 5.2.3.6 C180 Print Driver >> Raster Page NOTE The Raster Page is only available when Black &... - Page 74 As an example, selecting 2 x 2 will shade with a 5-grade halftone, where as an 8 x 8 Dithering Matrix will dither with a 65-grade halftone. The following diagram is an example of the raster effects when using the different dithering matrices. LaserPro C180 User Manual...

- Page 75 Please take some time to experiment with the multitude of raster options to get the one you feel is the best for your piece. This is where much of the fun in engraving is…. experimentation! LaserPro C180 User Manual...

-

Page 76: Laserpro C180 Print Driver >> Stamp Page

5.2.3.7 C180 Print Driver >> Stamp Page Producing stamps require different operational steps than your standard engraving or cutting jobs. The Stamp page offers dynamic options allowing you to customize your stamp production process. NOTE The Stamp page will only appear and be accessible when you have selected the Stamp Mode from the Option Page. - Page 77 NOTE The visual representations of the Pitch and Shoulder Levels in the C180 driver are an exaggerated representation to allow for easy visual guidance and precise input. Remember we are working with distances less than 1 mm here.

-

Page 79: Chapter 6 - Engraving And Cutting Techniques

Chapter 6 Engraving and Cutting Techniques Raster Engraving Vector Cutting Vector and Raster 3D Tips Modify Image Setting of a Picture for Better Engraving Quality LaserPro C180 User Manual... -

Page 80: Raster Engraving

When performing vector cutting operations, imagine the laser head as a pair of scissors cutting out the lines specified in your design. An example of a vector cut piece would be a customized dining mat, as shown in the picture below. LaserPro C180 User Manual... -

Page 81: Vector And Raster

5) Now your string of characters has been properly designated as an area to be vector cut. Simply “print” your job (output the file to the C180) and watch as your string of characters is vector cut. 6.3 Vector and Raster In some cases, you will want to process both raster engraving and vector cutting tasks within a single project. -

Page 82: Tips

6.4 3D Tips When doing 3D sample on LaserPro C180 (C180-30), acrylic or MDF wood are ideal materials for the purpose. For acrylic the suggested PWR is 100%, SPD around 30% (depends on how deep you want to cut). The perfect image for 3D is like those shown below. When image is ready, choose 3D Effect as the output mode in the driver. - Page 83 5. Convert the image to Bitmap by selecting the image and click on Bitmaps/Convert to Bitmap. LaserPro C180 User Manual...

- Page 84 6. Change the Bitmap settings by setting “Color” to Grayscale (8-bit) and “Resolution” to 300 dpi and click 7. Finally, Invert the image by selecting Effects/Transform/Invert LaserPro C180 User Manual...

- Page 85 This instruction is a simple example for general use. There are many tips and tricks to achieve a good engraving quality. It takes a lot of practice and experience to achieve a good engraving quality. Different picture may need different modifications and different material may need different parameters. LaserPro C180 User Manual...

-

Page 87: Chapter 71 - Optional Items

Chapter 7 Optional Items Air Extraction System Option Air Compressor Option Items Honeycomb Table Option SmartAIR Nozzle (Fine/Ultra) SmartGUARD Fire Alarm Option SmartMEMORY Module Option Rotary Attachment Option LaserPro C180 User Manual... -

Page 88: Air Extraction System Option

2) Mount the exhaust system in an obvious and accessible location, not too far from the C180, so it can be routinely switched on prior to laser engraving. The maximal distance you should mount the exhaust system away from the C180 depends on the blower’s vacuum capacity. -

Page 89: Air Compressor Option

1) Remove the plugs on the air compressor to expose the air inlets. 2) Fasten the included air tube fastener valve to the outgoing air inlet (indicated by 2a) and the air filter into the ingoing air inlet (indicated by 2b). Plugs LaserPro C180 User Manual... -

Page 90: Honeycomb Table Option

Honeycomb tables are important to tune out a beautiful output when working with cutting operations. The C180 has a very easy to install honeycomb table. Simply lay it on top and against the upper left corner of the working area for use. -

Page 91: Smartguard Fire Alarm Option

SmartGUARD, they will need to contact your local authorized GCC distributor to have this great feature installed. Lift top cover of the C180 using the handle. Remove the rear plate covering the Y motor and rear panel of... -

Page 92: Smartmemory Module Option

It enables to save and load your working files to and from the C180. In addition, the SmartMEMORY module is portable and can be used to transfer task settings from one machine to another. - Page 93 4MB, please do not save files that exceed this limit. SAVE files to the SmartMEMORY module: 1) Navigate to the Write Flash Memory function. From the C180 Control Panel, press the F4 (Function) → MACHINE SETTINGS → FLASH MEMORY → WRITE FLASH MEMORY.

-

Page 94: Rotary Attachment Option

7.7 Rotary Attachment Option The rotary attachment option provides the LaserPro C180 with the ability to engrave on cylindrical or spherical objects. In addition to the standard X, Y, Z axis, the rotary attachment allows for a fourth axis which rotates your object 360° to allow for engraving on cups, wine glasses, and even spherical objects. - Page 95 Rotary Attachment Port 9) Close the front panel. 10) The rotary attachment is now properly installed. Power on the LaserPro C180 and the rotary attachment will be automatically detected and the engraving table will automatically move to its lowest position.

- Page 96 X / Y location on the object you will be engraving and position the auto focus pin over the area to be engraved on your work piece. Hit the Auto Focus button and the LaserPro C180 will now properly focus at the location to be engraved.

- Page 97 Exchanging the conical fixtures on the rotary attachment: A. Remove the 2 screws shown in the picture below. Remove these screws B. Detach the circular cylindrical cone by moving it in the direction of the arrow as shown below. LaserPro C180 User Manual...

- Page 98 D. Use the flat surface as shown in picture below as a reference point and tighten the first screw against it. After doing so, tighten the second screw and the rotary attachment is ready for use. Flat surface 1. Tighten this against the flat surface 2. Tighten the second screw LaserPro C180 User Manual...

-

Page 99: Chapter 8 - Basic Maintenance

Maintaining the Work table and Motion System Cleaning the Work table and Motion System Lubrication of the Y Rails Cleaning the Optics System - Removing the Mirrors - Cleaning the Mirrors - Removing and Cleaning the Focal Lens LaserPro C180 User Manual... -

Page 100: Suggested Cleaning And Maintenance Supplies

WARNING ・ Electrical shock may occur if you do not turn off and unplug the C180 before cleaning. ・ Damage may occur to the system if you do not turn off and unplug the C180 before cleaning. ・ Always turn off and unplug the LaserPro C180 before cleaning! 8.1 Suggested Cleaning and Maintenance Supplies... -

Page 101: Cleaning The Worktable And Motion System

4) Apply a soap solution, all-purpose cleaner, or alcohol to a paper or cotton towel to wipe down the rails of the motion system. 5) Wait for all cleaning residue to dry completely before plugging in and operating the C180. CAUTION •... -

Page 102: Cleaning The Optics System

LaserPro C180 for cleaning. Mirror 1 This mirror is located inside the bottom left access panel of the LaserPro C180. 1) Use a # 2 Phillips Screwdriver to remove the access panel located on the bottom left side of the LaserPro C180. - Page 103 4) Re-install mirror 2 after cleaning. 5) Tighten the thumbscrew. 6) Replace and secure the dust cover. Mirror 3, 4 These mirrors are accessible on the worktable area of the LaserPro C180. Mirror 4 Mirror 3 Mirror 3 1) Unscrew the thumbscrew holding mirror 3 in place.

-

Page 104: Cleaning The Mirrors

6) Make sure that the mirror is completely dry before reinstalling it. CAUTION If the center of the mirror is scratched, contact your LaserPro C180 dealer for a replacement. 8.3.3 Removing and Cleaning the Focal Lens 1) Unscrew the three thumbscrews (front face of the laser head) securing the laser carriage panel and remove the laser carriage panel to reveal the focal lens. - Page 105 Clean the focal lens with a cotton swab and lens cleaner solution. Be sure to clean both sides of the focal lens (DO NOT apply any pressure or other cleaning solutions to the lens surface). After cleaning, use a cotton swab to gently dry the focal lens and lens cover. LaserPro C180 User Manual...

-

Page 107: Chapter 9 - Basic Troubleshooting

Chapter 9 Basic Troubleshooting LaserPro C180 User Manual... -

Page 108: Quality Problems

• Auto Focus Pin is Not Functioning The focus pin could be stocked by greasy residue that coats on it. Clean the probe with alcohol or acetone. Check the cable of focus pin, there might be a bad contact or breakage. LaserPro C180 User Manual... -

Page 109: Chapter 10 - Appendix.............................................................................................

Chapter 10 Appendix Glossary LaserPro C180 Series Specification Sheet LaserPro C180 User Manual... -

Page 110: Glossary

Vector – The process of cutting or engraving an image by using single horizontal, vertical and curved lines. For example: when cutting out or engraving the outline of a square, the vector setting will make the laser use a thin single line to follow the outline of the shape. LaserPro C180 User Manual... -

Page 111: Laserpro C180 Series Specification Sheet

10.2 LaserPro C180 Series Specification Sheet LaserPro C180/C180S* Work Area 18 x12 in. (458 x 309 mm) Maximum Part Size 18 x 12 x 6 in. (505 x 309 x 170 mm) (W x L x H) 20.5 x 14.8 in. (520 x 375 mm)

Need help?

Do you have a question about the LaserPro C180 and is the answer not in the manual?

Questions and answers

Will my LaserPro C180 work with Windows 11 ?