Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Tennant 6080

- Page 1 6080 Operator Manual 330000 Rev. 04 é B!!£ê Home Find... Go To..

- Page 2 This manual is furnished with each new TENNANT Model 6080 sweeper. It provides necessary operating and preventive maintenance instructions. Read this manual completely and understand the machine before operating or servicing it. This machine will provide excellent service. However, the best results will be obtained at minimum costs if: The machine is operated with reasonable care.

-

Page 3: Table Of Contents

......SPARKPLUG ..... . 6080 330000 (3- -99) Home Find... - Page 4 CONTENTS 6080 330000 (9- -97) Home Find... Go To..

-

Page 5: Safety Precautions

- - Avoid contact with battery acid. The machine is suited to sweep disposable - - Use Tennant supplied or equivalent debris. Do not use the machine other than replacement parts. described in this Operator Manual. The machine is not designed for use on public roads. - Page 6 ON THE CONTROL PANEL ON THE CONTROL PANEL BACK STRAIN LABEL - - LOCATED ON THE ENGINE COMPARTMENT COVER FLYING DEBRIS WARNING LABEL - - LOCATED ON THE MOTOR COMPARTMENT COVER 350841 6080 330000 (5- -97) Home Find... Go To..

-

Page 7: Operation

AN LPG TANK section of this manual. 07324 - Fill the gas tank. FOR SAFETY: When servicing machine, keep flames and sparks away from fuel system service area. Keep area well ventilated. - Check the engine oil. 6080 330000 (5- -97) Home Find... Go To.. - Page 8 Tennant representative. - Order parts and supplies directly from your authorized Tennant representative. Use the parts manual provided when ordering parts. - After the first 50 hours of operation, follow the recommended procedures stated in the MAINTENANCE CHART.

-

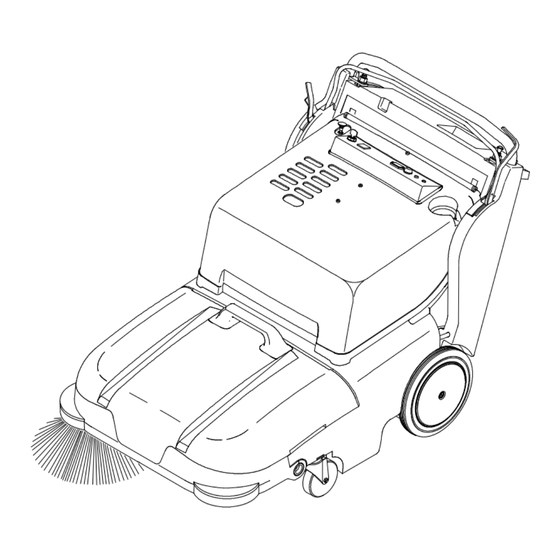

Page 9: Machine Components

OPERATION MACHINE COMPONENTS 350659 A. Debris hopper B. Vacuum wand (option) C. Filter compartment D. Main brush E. Side brush F. Accessory bin G. Engine compartment H. Vac wand extension (option) 6080 330000 (3- -99) Home Find... Go To.. -

Page 10: Symbol Definitions

Side brush(es) down and on Side brush(es) up and off Main brush down pressure Main brush down and on Main brush up and off Low engine oil indicator Low battery / alternator indicator Circuit breaker #1 6080 330000 (3- -99) Home Find... Go To.. -

Page 11: Controls And Instruments

G. Vacuum wand (option) H. Filter shaker switch Engine choke knob J. Ignition key switch K. Hourmeter L. Circuit breaker M. Low battery charge indicator N. Low oil warning indicator O. Beverage holder 6080 330000 (3- -99) Home Find... Go To.. -

Page 12: Operation Of Controls

REVERSE: Move the directional control lever to the left, then one position forward from the PARK position. The machine will move backward when the clutch handle is squeezed. 6080 330000 (5- -97) Home Find... Go To.. - Page 13 The machine will move forward when the clutch handle is squeezed. Use THIRD SPEED for sweeping in wide open areas or for transport to the dumping area when the hopper is full. 6080 330000 (5- -97) Home Find... Go To..

-

Page 14: Clutch Handle

Main brush up: Move the main brush lever backward, then to the right to raise and set the main brush in the raised position. 6080 330000 (5- -97) Home Find... Go To.. -

Page 15: Side Brush Lever

When the engine oil level is too low, the engine will automatically shut itself off. The engine will not restart and the indicator will not go out until the proper amount of engine oil has been added. 6080 330000 (5- -97) Home Find... Go To.. -

Page 16: Low Battery Charge Indicator

LOW BATTERY CHARGE INDICATOR The low battery charge indicator will illuminate when the battery charging system is not functioning properly. If the light remains on after the engine starts, contact TENNANT service personnel. STEERING BAR Use the steering bar to steer the machine. -

Page 17: Ignition Key Switch

Use the vacuum wand to pick up debris in narrow or partially enclosed areas that cannot be swept by the machine. Fully insert the vacuum wand into the machine when not in use. 6080 330000 (3- -99) Home Find... Go To.. -

Page 18: Circuit Breaker

The filter shaker motor will shake the filter for 15 seconds, then stop automatically. Remove loose debris from the panel filter compartment door when the shaker motor stops. 6080 330000 (3- -99) Home Find... Go To.. -

Page 19: How The Machine Works

- Check under the machine for fluid leaks (fuel, oil). - Check fuel level. FOR SAFETY: When servicing machine, keep flames and sparks away from fuel system service area. Keep area well ventilated. 6080 330000 (5- -97) Home Find... Go To.. - Page 20 - LPG powered machines: Check for LPG odor or frosting on hoses or components indicating an LPG leak. - Check controls for proper operation. - Check maintenance records to determine service requirements. 6080 330000 (5- -97) Home Find... Go To..

-

Page 21: Changing An Lpg Tank

NOTE: Make sure the LPG fuel tank matches the fuel system (vapor tank with vapor system). 7. Latch the security clamp to lock the tank in position. 350412 6080 330000 (5- -97) Home Find... Go To.. - Page 22 Close the service valve immediately if an LPG leak is found or if a strong LPG odor is detected. Notify the appropriate personnel regarding LPG fuel leaks. 350412 6080 330000 (5- -97) Home Find... Go To..

-

Page 23: Starting The Machine

NOTE: The farther the clutch handle is squeezed toward the steering bar, the faster the machine will travel, up to its maximum in the selected position. 5. Drive the machine to the area to be swept. 6080 330000 (3- -98) Home Find... Go To.. -

Page 24: Sweeping And Brush Information

Polypropylene Side Brush -- A good general purpose brush for sweeping of light to medium debris in both indoor and outdoor applications. This brush is recommended when bristles may get wet. 6080 330000 (5- -97) Home Find... Go To.. -

Page 25: Sweeping

4. Move the side brush lever to the right, out of the raised position, then forward to the desired brush down pressure setting. 5. Squeeze the clutch handle to begin sweeping. 6. Sweep as needed. 6080 330000 (5- -97) Home Find... Go To.. -

Page 26: Stop Sweeping

3. Move the side brush lever backward, then to the left to raise and set the side brush(es) in the raised position. 6080 330000 (5- -97) Home Find... Go To.. - Page 27 15 seconds before stopping. NOTE: Make sure the filter compartment is closed securely before activating filter shaker. 6. Turn the machine power off. 7. LPG powered machines: Ensure the LPG tank service valve is closed. 6080 330000 (3- -99) Home Find... Go To..

-

Page 28: Emptying The Debris Hopper

Dump the debris from the hopper into a pile on the floor near a trash can or dumpster, then pick the debris up with a shovel. WARNING: Heavy hopper. Get help to handle. 6080 330000 (5- -97) Home Find... Go To.. -

Page 29: Hopper Dump Assist Handle (Option)

NOTE: Do not attempt to lift the hopper when it is full of debris without assistance. Dump the debris from the hopper into a pile on the floor near a trash can or dumpster, then pick the debris up with a shovel. 6080 330000 (5- -97) Home Find... Go To.. -

Page 30: Replacing The Bag Filter

The vacuum inlet tube is located at the top of filter compartment, on the inside of the machine. Latch the filter compartment door. Fully insert the vacuum wand into the machine. 6080 330000 (3- -99) Home Find... Go To.. -

Page 31: Cleaning The Filter Compartment

Lower and remove the filter compartment door by sliding it to the left off the pivot pins. Empty the dust and debris. Replace and latch the filter compartment door. Fully insert the vacuum wand into the machine. 6080 330000 (3- -99) Home Find... Go To.. -

Page 32: Post-Operation Checklist

8_ . NOTE: To stop the machine at any time, regardless of direction of travel, release the clutch handle. The machine will immediately slow down, then stop completely. 6080 330000 (3- -99) Home Find... Go To.. -

Page 33: Options

OPERATION OPTIONS WIDE TRACK TIRES AND HEAVY DUTY CASTERS Wide track tires and heavy duty casters provide increased maneuverability and control on rough surfaces. 6080 330000 (9- -97) Home Find... Go To.. -

Page 34: Machine Troubleshooting

Machine will not start Thermo Sentryt tripped Reset Thermo Sentryt Engine oil level low Check and fill Fuel tank valve closed Open valve -- LPG tank valve or valve below gasoline tank 6080 330000 (5- -97) Home Find... Go To.. -

Page 35: Maintenance

Side brush motor(s) Check motor brushes 1 (2) LUBRICANT/FLUID ..Engine oil, 30 SAE -- CD/SF rated . . . Special lubricant, Lubriplate EMB grease (TENNANT part no. 01433--1) 6080 330000 (3- -99) Home Find... Go To.. -

Page 36: Lubrication

The heavy duty casters (option) each have one grease fitting on the caster swivel. Lubricate each caster with a grease gun containing Lubriplate EMB grease (Tennant part no. 01433--1) after every 100 hours of operation. 6080 330000 (9- -97) Home Find... -

Page 37: Fuel System

When the valve is closed, the machine will run for a short time, then stop from lack of fuel. Open the valve to start the machine. 6080 330000 (5- -97) Home Find... Go To.. -

Page 38: Engine

50 hours of operation. SPARKPLUG Replace, or clean and set the gap of the sparklug after every 200 hours of use. The proper sparkplug gap is 0.75 mm (0.03 in). 6080 330000 (5- -97) Home Find... Go To.. -

Page 39: Skirts And Seals

Check the hopper dust seal for damage or wear daily. REAR SKIRT The rear skirt, located behind the main brush, helps create a vacuum around the main brush. Check the rear skirt for damage or wear daily. 6080 330000 (5- -97) Home Find... Go To.. -

Page 40: Hopper Lip Skirt

The vacuum inlet plate prevents large pieces of debris from entering the vacuum chamber. Check the vacuum inlet plate daily. If necessary remove and wipe it clean with a damp cloth. 6080 330000 (5- -97) Home Find... Go To.. -

Page 41: Cleaning The Panel Filter

Rinse the filter until it is clean. Air dry the filter; do not use compressed air. NOTE: Be sure the dust filter is completely dry before reinstalling it in the machine. 6080 330000 (3- -99) Home Find... Go To.. -

Page 42: Brushes

Turn the main brush pin 1/4 turn counter--clockwise and remove.If the machine has the (option) wide track wheel kit, lower the main brush to remove. 6080 330000 (3- -99) Home Find... Go To.. - Page 43 7. Install the new main brush into the machine. 8. Insert the main brush pin through the hole in the frame and into the main brush hub. Turn the main brush pin 1/4 turn clockwise. 9. Replace the hopper. 6080 330000 (3- -99) Home Find... Go To..

-

Page 44: Checking And Adjusting Main Brush Pattern

Move the crossbar up or down in the slide relative to the adjustment on the other side. Tighten the nut. B. Check the brush again pattern and readjust if necessary. 6080 330000 (5- -97) Home Find... Go To.. -

Page 45: Rotating The Main Brush

6. Install the main brush into the machine. 7. Insert the main brush pin through the hole in the frame and into the main brush hub. Turn the main brush pin 1/4 turn clockwise. 8. Replace the hopper. 6080 330000 (5- -97) Home Find... Go To.. -

Page 46: Side Brush(Es)

4. Place a new side brush onto the drive shaft and secure with the cotter pin. ELECTRIC MOTORS Check the side brush motor(s) brushes every 500 hours of operation. Replace the motor brushes when they are worn 9 mm (.375 in). 6080 330000 (5- -97) Home Find... Go To.. -

Page 47: Belts And Chains

The clutch handle is connected to the clutch cable. The clutch cable may stretch over time and require adjustment. Adjust cable length by turning the nut at the base of the clutch cable. 6080 330000 (5- -97) Home Find... Go To.. -

Page 48: Tires

Slowly rotate the crankshaft to distribute the oil. Replace the spark plug. 7. Clean the engine cooling fins. 8. Store the machine in a clean dry area. 6080 330000 (9- -97) Home Find... Go To.. -

Page 49: Specifications

1588 mm (62.5 in) Minimum turning radius 794 mm (31.25 in) Maximum rated climb and descent angle Fuel consumption -- Gasoline engine 0.75 L/hr (0.2 gal/hr) Fuel consumption -- LPG engine 0.4 kg/hr (0.9 lb/hr) 6080 330000 (9- -97) Home Find... Go To.. -

Page 50: Power Type

Casters 35 mm wide x 127 mm OD (1.375 in wide x 5 in OD) Rear (2) Solid 45 mm wide x 305 mm OD (1.75 in wide x 12 in OD) 6080 330000 (5- -97) Home Find... Go To.. -

Page 51: Machine Dimensions

SPECIFICATIONS 610 mm (24 in) 820 mm (32.25 in) 815 mm (32 in) 1475 mm (58 in) 960 mm (37.7 in) 350910 MACHINE DIMENSIONS 6080 330000 (9- -97) Home Find... Go To.. -

Page 52: Index

Side brush lever, 13 LPG fuel tank, changing, 19 Lubrication Electric motors, 44 engine, 34 Electrical system, Circuit breaker, 16 heavy duty casters (option), 34 Engine Air filter, 36 Sparkplug, 36 Specifications, 48 6080 330000 (3- -99) Home Find... Go To.. - Page 53 Wide track tires and casters, 31 Thermo Sentry, 16 Tires, 46 Specifications, 48 Troubleshooting chart, 32 Panel filter, Cleaning, 39 Panel filter compartment, Cleaning, 29 Plate, vacuum inlet, 38 Vacuum inlet plate, 38 Vacuum wand (option), 15 6080 330000 (3- -99) Home Find... Go To..

- Page 54 INDEX 6080 330000 (9- -97) Home Find... Go To..

Need help?

Do you have a question about the 6080 and is the answer not in the manual?

Questions and answers