Summary of Contents for Newport i8-AL

- Page 1 Temperature/Process Limit Alarm Controller i8-AL, i16-AL, i32-AL Operator’s Manual www.newportUS.com/manuals...

- Page 2 In Mexico: (95) 800-NEWPORT Or call your local NEWPORT Office. The information contained in this document is believed to be correct but NEWPORT Electronics, Inc. accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.

-

Page 3: Table Of Contents

TABLE OF CONTENTS Part 1: Introduction ..................1 Description ..................2 Safety Considerations ..............3 Before You Begin ................4 Part 2: Setup ....................5 Front Panel ...................5 Disassembly ...................6 Electrical Installation ..............7 2.3.1 Power Connections ............7 2.3.3 Thermocouple - Input Connection ........8 2.3.4 Two / Three / Four Wire RTD-Hookups ......9 2.3.5 Process Current - Wiring Hookup ........10 2.3.6 Process Voltage - Wiring Hookup ........10 2.3.7 Wiring Outputs - Wiring Hookup ........11... -

Page 4: List Of Figures

LIST OF FIGURES: Figure 2.1 Front Panel Display ................5 Figure 2.2 Rear Panel Input Connector Labels ..........6 Figure 2.4 Main Power Connections ..............7 Figure 2.5 Thermocouple Wiring Hookup ............8 Figure 2.6 Two/Three/Four-Wire RTD Wiring Hookup a) RTD-1000 ohm/RTD-500 ohm ...........9 b) RTD-100 ohm ................9 Figure 2.7 Process Current Wiring Hookup... -

Page 5: Part 1: Introduction

NOTES, WARNINGS and CAUTIONS Information that is especially important to note is identified by the following labels: • NOTE • WARNING or CAUTION • IMPORTANT • TIP NOTE: Provide you with information that is important to successfully setup and use the Programmable Digital System. CAUTION or WARNING: Tells you about the risk of electrical shock. -

Page 6: Safety Considerations

1.2 Safety Considerations This device is marked with the international caution symbol. It is important to read this manual before installing or commissioning this device as it contains important information relating to Safety and EMC (Electromagnetic Compatibility). This device is a panel mount device protected in accordance with EN 61010-1:2001, electrical safety requirements for electrical equipment for measurement, control and laboratory. -

Page 7: Before You Begin

1.3 Before you Begin Inspecting Your Shipment: Remove the packing slip and verify that you have received everything listed. Inspect the container and equipment for signs of damage as soon as you receive the shipment. Note any evidence of rough handling in transit. -

Page 8: Part 2: Setup

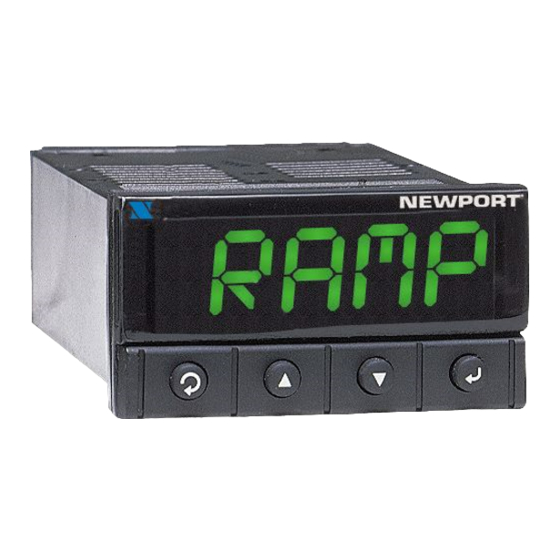

PART 2 SETUP 2.1 Front Panel Figure 2.1 Front Panel Display Table 2.1 Front Annunciators Setpoint 1/ Alarm 1 indicator Setpoint 2/ Alarm 2 indicator ºC °C unit indicator ºF °F unit indicator Changes display to Configuration Mode and advances through menu items* Used in Program Mode and Peak Recall* Used in Program Mode and Valley Recall*... -

Page 9: Figure 2.2 Rear Panel Input Connector Labels

2.2 Rear Panel Connections 3 4 5 6 3 4 5 6 1 2 3 4 5 6 7 8 9 10 7 6 5 4 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 -OUTPUTS- -OUTPUTS- -INPUTS-... -

Page 10: Electrical Installation

2.3 Electrical Installation 2.3.1 Power Connections Caution: Do not connect power to your device until you have completed all input and output connections. Failure to do so may result in injury! Connect the main power connections as shown in Figure 2.4. Use copper conductors only for power connections Figure 2.4 Main Power Connections... -

Page 11: Figure 2.5 Thermocouple Wiring Hookup

2.3.2 Thermocouple The figure below shows the wiring hookup for any thermocouple type. For example, for Type K hookup, connect the yellow wire to the “2” terminal and the red wire to the “1(-)” terminal. When configuring your device, select Thermocouple and Thermocouple Type in the Input Type menu (see Part 3). -

Page 12: Two / Three / Four Wire Rtd-Hookups

2.3.3 Two/Three/Four-Wire RTD The figures below show the input connections and input connector jumpers (shown in bold lines) required to hookup a 2-, 3- or 4-wire RTD. RTD (100) 4-Wire RTD (1000/500) 4-Wire RTD (100) 3-Wire RTD (1000/500) 3-Wire RTD (100) 2-Wire RTD (1000/500) 2-Wire Figure 2.6 a) RTD-100 ohm and b) RTD-100 ohm Wiring Hookup... -

Page 13: Process Current - Wiring Hookup

2.3.4 Process Current The figure below shows the wiring hookup for Process Current 0 – 20 mA. Figure 2.7 Process Current Wiring Hookup (Internal and External Excitation) When configuring your device, select Process Type in the Input Type Menu (see Part 3). 2.3.5 Process Voltage The figure below shows the wiring hookup for Process Voltage 0 –... -

Page 14: Figure 2.9 Mechanical Relay Outputs Wiring Hookup

2.3.6 Wiring Outputs This device has two factory installed outputs. The SPDT Mechanical Relay Connection is shown below. Use copper conductors only for power connections Figure 2.9 Mechanical Relay Output Wiring Hookup... -

Page 15: Part 3: Operation: Configuration Mode

PART 3 OPERATION: Configuration Mode 3.1 Introduction The device has two different modes of operation. The first, Run Mode, is used to display values for the Process Variable, and to display or clear Peak and Valley values. The other mode, Menu Configuration Mode, is used to navigate through the menu options and configure the device. -

Page 16: Table 3.1 Button Function In Configuration Mode

3.1 Introduction (continued) Table 3.1 Button Function in Configuration Mode • To enter the Menu, the user must first press a button. • Use this button to advance/navigate to the next menu item. The user can navigate through all the top level menus by pressing a . -

Page 17: Menu Configuration

3.2 Menu Configuration Figure 3.1 Flow Chart for ID and Set Points Menu... -

Page 18: Id Number

3.2.1 ID Number Menu SEE ID MENU SELECTION IN CONFIGURATION SECTION FOR ENABLE/DISABLE OR CHANGE ID CODE. If ID Code is Disabled or set as Default (0000) the menu will skip ID step to Setpoint Menu. If ID Code is set to Full Security Level and user attempts to enter the Main Menu, they will be prompted for an ID Code. -

Page 19: Setpoints

3.2.2 Set Points Menu SETPOINT 1: Press a 1) Press a, if necessary until SP1 prompt appears. Press d 2) Display shows previous value of “Setpoint 1”. Press b & c 3) Press b and c to increase or decrease Setpoint 1 respectively. -

Page 20: Configuration Menu

3.2.3 Configuration Menu Figure 3.2 Flow Chart for Configuration Menu ENTER CONFIGURATION MENU: Press a 1) Press a, if necessary until CNFG prompt appears. Press d 2) Display advances to INPT Input Menu. Press b & c 3) Press and release a to scroll through all available menus of Configuration section. -

Page 21: Input Type (Thermocouple)

3.2.4.1 Input Type (Thermocouple) ENTER INPUT TYPE MENU: Press a 1) Press a, if necessary until CNFG prompt appears. Press d 2) Display advances to INPT Input Menu. 3) Display flashes T.ç , RTD or PROC (Thermocouple, RTD or Press d Process). -

Page 22: Input Type (Rtd)

3.2.4.2 Input Type (RTD) ENTER INPUT TYPE MENU: Press a 1) Press a, if necessary until CNFG prompt appears. Press d 2) Display advances to INPT Input Menu. Press d 3) Display flashes T.ç , RTD or PROC (Thermocouple, RTD or Process). -

Page 23: Input Type (Process)

3.2.4.3 Input Type (Process) ENTER INPUT TYPE MENU: Press a 1) Press a, if necessary until CNFG prompt appears. Press d 2) Display advances to INPT Input Menu. Press d 3) Display flashes T.ç , RTD or PROC (Thermocouple, RTD or Process). -

Page 24: Reading Configuration Menu

3.2.5 Reading Configuration Menu Figure 3.4 Flow Chart for Reading Configuration Menu ENTER READING CONFIGURATION MENU: Press a 1) Press a, if necessary until CNFG prompt appears. Press d 2) Display advances to INPT Input Menu. Press a 3) Press and release RDG Reading Configuration Menu. 4) Display advances to DEC Decimal Point. - Page 25 3.2.5 Reading Configuration Menu (continued) TEMPERATURE UNIT SUBMENU: 8) Display flashes previous Temperature Unit selection. Press d 9) Scroll though the available selections to the Temperature Press b Unit of your choice: °F or °C . 10) Display shows STRD stored message momentarily and Press d then advances to FLTR Filter Constant.

- Page 26 3.2.5 Reading Configuration Menu (continued) Reading Configuration (If Process was selected) INPUT/READING (SCALE AND OFFSET) SUBMENU: Input Voltage or Current can be converted or scaled into values appropriate for the process or signal being measured. So, a reading may be displayed, for example, in units of weight or velocity instead of in amperes or volts.

-

Page 27: Table 3.2 Conversion Table

3.2.5 Reading Configuration Menu (continued) Conversion number is a coefficient of conversion between input values and real full display range (10000 counts). See Table 3.2 below for proper conversion number. Table 3.2 Conversion Table RANGE CONVERSION NUMBER 100 mV 10000 / (100 x 1) = 100 10000 / (1000 x 1) = 10 10 V 10000 / (1000 x 10) = 1... -

Page 28: Alarm 1 Menu

3.2.6 Alarm 1 Menu Figure 3.5 Flow Chart for Alarm 1 Menu ENTER ALARM 1 MENU: Press a 1) Press a, if necessary until CNFG prompt appears. Press d 2) Display advances to INPT Input Menu. Press a 3) Press a, if necessary, until display advances to ALR1 Alarm 1 Menu. - Page 29 3.2.6 Alarm 1 Menu (continued) ALARM 1 ENABLE/DISABLE SUBMENU: Press b 5) Scroll though the available selection until ENBL displays to use Alarm 1. Press d 6) Display shows STRD stored message momentarily and then advances to ABSo only if it was changed, otherwise press a to advance to ABSo Alarm 1 Absolute/Deviation Submenu.

- Page 30 3.2.6 Alarm 1 Menu (continued) ACTIVE SUBMENU: Press d 11) Display flashes previous selection. Press b to scroll through the available selections: ABoV Above, BELo Below, HI.Lo HI/Low and BAND Band. (Band is active if _DEV Deviation was selected). Press d 12) Display shows STRD stored message momentarily and then advances to A.P.oN only if it was changed, otherwise press a to advance to A.P.oN Alarm Enable/Disable at Power...

- Page 31 3.2.6 Alarm 1 Menu (continued) ALARM ENABLE/DISABLE AT POWER ON: Press d 13) Display flashes previous selection. Press b to ENBL enable or DSBL disable. Press d 14) Display shows STRD stored message. momentarily and then advances to ALR.L only if it was changed, otherwise press a to advance to the ALR.L Alarm 1 Low Value Submenu.

-

Page 32: Alarm 2 Menu

3.2.7 Alarm 2 Menu Figure 3.6 Flow Chart for Alarm 2 Menu ENTER ALARM 2 MENU: Press a 1) Press a, if necessary until CNFG prompt appears. Press d 2) Display advances to INPT Input Menu. Press a 3) Press a ,if necessary, until display advances to ALR1 Alarm 2 Menu. -

Page 33: Reading Adjust Menu

3.2.8 Reading Adjust Menu For Temperature Reading only, not Process Figure 3.7 Flow Chart for Reading Adjust Menu ENTER READING ADJUST MENU: Press a 1) Press a, if necessary until CNFG prompt appears. Press d 2) Display advances to INPT Input Menu. Press a 3) Press a ,if necessary, until display advances to R.ADJ Reading Adjust Menu. -

Page 34: Figure 3.8 Flow Chart For Setpoint Deviation/Field Calibration

3.2.9 Setpoint Deviation Menu / Field Calibration (continued) ENTER READING ADJUST MENU: Press d 4) Display advances to Setpoint Deviation ENBL Enable or DSBL . Disable Submenu and flashes the previous selection. Press b 5) Scroll through the available selections: ENBL or DSBL . Press d 6) Display shows STRD stored message momentarily and then advances to the next menu item. -

Page 35: Id Code Menu

3.2.10 ID Code Menu Figure 3.6 Flow Chart for Alarm 2 Menu ENTER ID CODE MENU: Press a 1) Press a , if necessary, until CNFG prompt appears. Press d 2) Display advances to INPT Input Menu. 3) Press a , if necessary, until display advances to ID ID Press a Code Menu. - Page 36 ENTERING OR CHANGING YOUR (DEFAULT) ID CODE: Enter ID menu (Repeat steps from 1 to 3). Press d 10) Display advances to CH.ID Change ID Code Submenu. Press d 11) Display shows 0000 message with flashing first digit. If you want to change your default “ID Code” you can do it now, otherwise press a and menu will skip to FULL Full Security Submenu.

-

Page 37: Display Color Selection Menu

3.2.12 Display Color Selection Menu This submenu allows the user to select the color of the display. Figure 3.11 Flow Chart for Display Color Selection Menu ENTER DISPLAY COLOR SELECTION MENU: Press a 1) Press a , if necessary, until CNFG prompt appears. Press d 2) Display advances to INPT Input Menu. - Page 38 ALARM 2 DISPLAY COLOR SUBMENU: Press d 11) Display flashes previous selection for “Alarm 2 Color Display”. Press b 12) Scroll through the available selections: GRN , RED or AMBR . Press d 13) Display shows STRD stored message momentarily and then momentarily shows the software version number, followed by RST Reset, and then proceeds to the Run Mode.

- Page 39 Example 3: Setpoint 1 = 300, Setpoint 2 = 200 Alarm 1 & 2 Setup: Deviation, Band, “ALR.H” = 10 Color Display Setup: “N.CLR” = Green, “1.CLR” = Amber, “2.CLR” = Display Colors change sequences: AMBER | AMBER | AMBER GREEN | AMBER •...

-

Page 40: Part 4: Specifications

PART 4 SPECIFICATIONS Accuracy: Current Input: ±0.5°C temp; 0.03% reading process 0 to 20 mA (5 ohm shunt) Resolution: 1°/0.1°; 10 µV process Configuration: Single-ended Temperature Stability: Polarity: Unipolar 1) RTD: 0.04°C/°C Step Response: 0.7 sec for 99.9% 2) TC @ 25°C (77°F): 0.05°C/°C - Cold Junction Compensation Decimal Selection: None, 0.1 for temperature;... -

Page 41: Environmental Conditions

INSULATION Dimensions Power to Input/Output 1/8 DIN: 48 H x 96 W x 127 mm D 2300 Vac per 1 min. test (1.89 x 3.78 x 5”) 1500 Vac per 1 min. test 1/16 DIN: 48 H x 48 W x 127 mm D (Low Voltage/Power Option) (1.89 x 1.89 x 5”) Power to Relay Outputs... -

Page 42: Table 4.1 Input Properties

Table 4.1 Input Properties Input Type Range Accuracy* -210 to 760°C 0.4°C Iron-Constantan -346 to 1400°F 0.7°F -270 to -160°C 1.0°C -160 to 1372°C 0.4°C CHROMEGA®-ALOMEGA® -454 to -256°F 1.8°F -256 to 2502°F 0.7°F -270 to -190°C 1.0°C -190 to 400°C 0.4°C Copper-Constantan -454 to -310°F... -

Page 43: Part 5: Factory Preset Values

PART 5 FACTORY PRESET VALUES Table 5.1 Factory Preset Values MENU ITEMS FACTORY PRESET VALUES NOTES Set Point 1 (SP1) 000.0 Set Point 2 (SP2) 000.0 Input: Input Type (INPT) TC, type K Reading Configuration (RDG): Decimal Point (DEC.P) FFF.F Temperature unit (TEMP) °F Filter value (FLTR) -

Page 44: Ce Approval Information

PART 6 CE APPROVALS INFORMATION This product conforms to the EMC directive 89/336/EEC amended by 93/68/EEC, and with the European Low Voltage Directive 72/23/EEC. Electrical Safety EN61010-1:2001 Safety requirements for electrical equipment for measurement, control and laboratory. Double Insulation Pollution Degree 2 Dielectric withstand Test per 1 min •... - Page 45 NOTES...

- Page 46 NOTES...

- Page 47 Warranty/Disclaimer NEWPORT Electronics, Inc. warrants this unit to be free of defects in materials and workmanship for a period of one (1) year from the date of purchase. In addition to NEWPORT’s standard warranty period, NEWPORT Electronics will extend the warranty period for four (4) additional years if the warranty card enclosed with each instrument is returned to NEWPORT.

- Page 48 M5290/N/0613...

Need help?

Do you have a question about the i8-AL and is the answer not in the manual?

Questions and answers