Summary of Contents for Sartorius MW1

- Page 1 Operating Instructions Sartorius Midrics ® 1| Midrics ® Models MW1 | MW2 Complete Scales 98648-014-94...

-

Page 2: Intended Use

Intended Use ® Midrics 1 and 2 are rugged complete Symbols scales for the demanding area of daily The following symbols are used quality control. They meet the highest in these instructions: requirements placed on the accuracy § denotes general operating instructions and reliability of weighing results: $ indicates instructions for exceptional –... -

Page 3: Table Of Contents

Contents Intended Use Configuring Printouts Configuring the Data Interface Warnings and Safety Precautions as a Printer Port Configuring the Layout Getting Started GMP-compliant Printouts Unpacking the Midrics Sample Printouts Equipment Supplied Installation Interface Port (Optional) Conditioning the Scale COM1 Connecting the Scale to AC Power UniCOM Leveling the Weighing Platform External Keyboard Functions... -

Page 4: Warnings And Safety Precautions

Sartorius. features at the factory. Do not use this equipment in hazardous areas. If you use electrical equipment in – Contact Sartorius for detailed operating installations and under ambient condi- specifications in accordance with the Storage and Shipping Conditions... -

Page 5: Connecting The Scale To Ac Power

If the voltage specified on the label or the plug design of the AC adapter do not match the rating or standard you use, please contact your Sartorius office or dealer. The power connection must be made in accordance with the regulations applicable in your country. -

Page 6: Leveling The Weighing Platform

Getting Started Leveling the Weighing Platform (Verified Models Only) Purpose: – To compensate for uneven areas at the place of installation – To ensure that the equipment is placed in a perfectly horizontal position for consistently reproducible weighing results Always level the weighing platform again any time after it has been moved to a different location. -

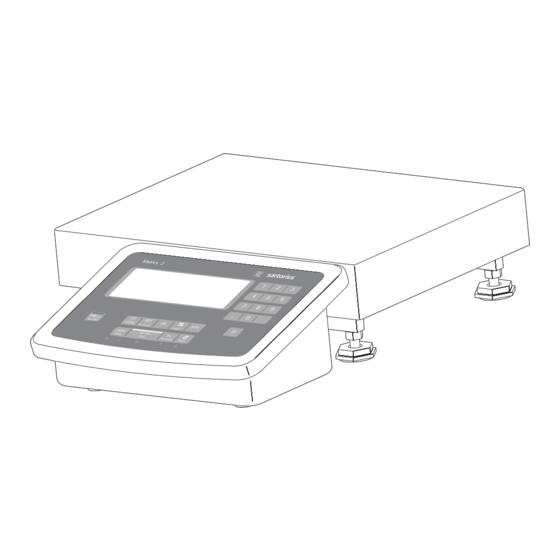

Page 7: General View Of The Equipment

General View of the Equipment Midrics 1 Display and Keypad Display (for details, see the chapter entitled “Operating Design") On/standby key Zero key Tare key Function key (e.g., toggle between gross and net values) Print key (data output) ID key (for entering product information) Numeric keypad Info key (for viewing ID codes... -

Page 8: Operating Design

Operating Design Keys ® ® Operation of the Midrics 1 or Midrics 2 scale involves just a few keys. These keys have one function during measurement and another during configuration. Some of the keys have one function when pressed briefly and another activated by pressing and holding the key for longer than 2 seconds. -

Page 9: Input Through The Digital

Numeric Input Through the Keypad (Midrics 2 only) § To enter numbers (one digit at a time): Press 0, 1, 2 …9 § To save input: press the required key (e.g., ) to save manual tare input) § To delete a digit: Press c Loading a Tare Value from the Weighing Platform... - Page 10 Operating Design Display in Weighing Mode 9. Numeric display; e.g., showing Verified models only: The illustration above shows all display reference value (Midrics 2 only) 14. The “zero-setting" symbol is displayed segments and the symbols and other after the active scale or weighing elements used during normal weighing Midrics 2: platform has been zeroed...

-

Page 11: Calculated Values

Bar graph Saving Data in Weighing Mode The bar graph shows the percentage of the All of the application parameters weighing platform's capacity that is “used saved (e.g., reference values) remain in up" by the load on the scale (gross value). memory and are still available after –... -

Page 12: Operating Menu Navigation

Operating Design Display of menu settings: Text menu (example) Display of menu settings: Numeric menu (example) Operating Menu Navigation ( – Press briefly: 3 Indication that there are other Activate character to the left submenus The keys below the readout let you of the current character 4 Highest level in numeric menu navigate the menu and define parameters... -

Page 13: Configuration

Configuration Setting the Language You can configure the Midrics scale by selecting parameters in the operating menu. The parameters are combined Example: Selecting “U.S. Mode" for the language in the following groups (this is the highest menu level): Switch on the scale –... -

Page 14: Entering Or Changing The Password

Entering or Changing the Password Example: Assign a password (in this example, ) to protect the application program settings APPL and the device parameters SETUP from unauthorized changes 1. Switch on the scale 9. Enter the second character using the p and k keys (in this example: 2. -

Page 15: Operating Menu Overview

Operating Menu Overview You can configure the Midrics to meet Menu levels are identified by texts, and numeric codes identify the individual settings. individual requirements by entering user data and setting selected parameters = Setting/function available on Midrics 2 only in the operating menu. - Page 16 Operating Menu = Setting/function available on Midrics 2 only * Factory setting Menu Application Programs appl Basic weighing function 3.5. Minimum load for automatic taring and automatic printing 3.5.1* 1 digit 3.5.2 2 digits 3.5.3 5 digits 3.5.4 10 digits 3.5.5 20 digits 3.5.6...

- Page 17 appl Z nm Neutral Measurement 3.5. Minimum load for automatic taring and automatic printing Numeric menu as for Weighing 3.6. Minimum load for initialization Numeric menu as for Counting 3.7. Automatic taring: first weight tared 3.7.1* 3.7.2 3.8. Start application and load most recent application data when the Midrics is switched on 3.8.1 Automatic (on) 3.8.2*...

- Page 18 appl Averaging (Animal Weighing) 3.21. Static display of result after load removed 3.21.1* Display is static until unload threshold reached Display is static until c is pressed 3.21.2 9.1. Factory settings for all application programs 9.1.1 9.1.2* Checkweighing 3.5. Minimum load for automatic taring and automatic printing Numeric menu as for Weighing 3.6.

- Page 19 appl Classification 3.8. Start application and load most recent application data when the Midrics is switched on 3.8.1 Automatic (on) 3.8.2* Manual (off) 4.3. Activate control line for “Set” as: 4.3.1* “Set” output 4.3.2 Ready to operate (for process control systems) 4.7.

- Page 20 appl Net-total Formulation (2 Tare Memory) 3.5. Minimum load for automatic taring and automatic printing Numeric menu as for Weighing 3.6. Minimum load for automatically saving/transferring values Numeric menu as for Counting 3.7. Automatic taring: first weight tared 3.7.1* 3.7.2 3.17.

- Page 21 Device Parameters Setup Password prompt displayed if a password is configured wp-1 Weighing platform 1 (Display designation of this menu level: 1) 1.1. Adapt weighing instrument to ambient conditions (adapt filter) 1.1.1 Very stable conditions 1.1.2* Stable conditions 1.1.3 Unstable conditions 1.1.4 Very unstable conditions 1.2.

- Page 22 Setup wp-1 Calibration and adjustment 1.9. 1.9.1* External calibration/adjustment; default weight 1.9.3 External calibration/adjustment; weight can be selected under menu item 1.18.1 No function when you press and hold ) > 2 sec 1.9.10 1.10. Calibration/adjustment sequence 1.10.1 Calibration with automatic adjustment 1.10.2* Calibration with adjustment triggered manually 1.11.

- Page 23 Setup Com1 Interface port 1 (optional) (Display designation of this menu level: 2) datProt Data protocol SBI: standard version 5.1. Baud rate 5.1.1 150 baud 5.1.2 300 baud 5.1.3 600 baud 5.1.4* 1200 baud 5.1.5 2400 baud 5.1.6 4800 baud 5.1.7 9600 baud 5.1.8...

- Page 24 Setup Com1 datProt SMA interface function 5.1. Baud rate 5.1.1 150 baud 5.1.2 300 baud 5.1.3 600 baud 5.1.4 1200 baud 5.1.5 2400 baud 5.1.6 4800 baud 5.1.7* 9600 baud 5.1.8 19,200 baud 5.2. through 5.6. Numeric menu as for SBI Printer Printer configuration YDP01IS...

- Page 25 Setup Com1 Printer Uni-pri Universal interface 5.1. Baud rate 5.1.1 150 baud 5.1.2 300 baud 5.1.3 600 baud 5.1.4 1200 baud 5.1.5 2400 baud 5.1.6 4800 baud 5.1.7* 9600 baud 5.1.8 19,200 baud 5.2. Parity 5.2.2 Space 5.2.3 5.2.4 Even 5.2.5* None Number of stop bits...

- Page 26 Setup unicom Interface port 2 (Optional) (Display designation of this menu level: 3) datprot Data protocol SBI: standard version 5.1. through 9.1. Numeric menu as for COM1 bpi-232 XBPI-232 bpi-485 XBPI-485 0 to 31 Network address: From 0 to 31 inclusive SMA interface function 5.1.

- Page 27 Setup uniCom1 Second interface (optional) Printer Printer configuration YDP01IS YDP01IS line Strip printer label Label printer lab ff Label printer with manual feed YDP02 YDP02 5.1. through 5.4. Numeric menu as for COM1 YDP03 YDP03-0CE 5.1. through 5.4. Numeric menu as for COM1 YDP02IS YDP02IS line...

- Page 28 Setup ctrl io Control inputs/outputs (Display designation of this menu level: 4) ctr inp Control inputs For YDO01M-232CO; Option A1 8.4. Function for external control inputs (TTL) Trigger p key function 8.4.1* Trigger p key (> 2 sec) function 8.4.2 Trigger ) key function 8.4.3 Trigger ) key (>...

- Page 29 Setup barcode Bar code (Display designation of this menu level: 5) Store value as reference weight tare Store as tare value (i.e., tare the scale) Store value as ID code 1 Input Enter value on display (triggered when a key is pressed) Header Store value as tare or ID code, depending on bar code header ext.keyb...

- Page 30 Setup prtprot 7.10. Optional “UniCOM” interface Print results when c pressed in Totalizing and Net-total applications 7.10.1* Header lines 1, 2 (content: see menu codes 7.4.x) 7.10.2* Date and time 7.10.4* Weighing instrument designation 7.10.5* Result from the application program 7.10.7 2 additional blank lines 7.10.8...

- Page 31 Setup time Time (optional) Format for setting the time (example): 10.07.41 (hours.minutes.seconds) date Date (optional) Format for setting the date (example): 01.05.07 (day.month.year); U.S. mode: (month.day.year) code Password Set, change and delete password here. Max. 8 characters); example: 12345678 Device information Info Service Service information...

-

Page 32: Operation

Operation Basic Weighing Function Device Parameters Automatic Taring The first weight on the scale that Weighing W exceeds the preset minimum load is Keys The basic weighing function is always stored in the tare memory at stability. The keypad can be blocked. accessible and can be used alone or in The values for subsequent loads are There are four settings to choose from:... - Page 33 Example with Midrics 2: Switch on; zero; tare container weight; place sample in container; toggle display to gross weight, second weight unit or 10-fold higher resolution; print results. 1. Switch on the scale Display with tared scale and sample in container All display segments are shown for about 1 second (self-test)

- Page 34 Example with Midrics 2 Example with Midrics 2: Tare the scale by placing a container on the weighing platform Enter the tare value using the keypad; print the results 1. Switch on the scale 1. Switch on the scale The automatic self-test runs. The automatic self-test runs.

- Page 35 Example with Midrics 2: Weigh with varying tare values; print the results; delete tare values 1. Switch on the scale Read the net weight The automatic self-test runs. Once a readout is shown, the Midrics is automatically zeroed and ready to operate. Press ( to reset the unloaded weighing platform 7.

-

Page 36: Calibration And Adjustment

Calibration and Adjustment Features Preparation You can configure the parameters § Switch on the scale: Press e Purpose listed below in the operating menu. § While all segments are lit, Perform calibration to determine the Which of the features listed here are press the ) key difference between the value displayed available depends on the connected... - Page 37 Example: External calibration and manual adjustment with default weights (weighing parameters: factory settings) The difference between 1. Zero the scale. measured value and the true mass is shown with a plus or minus sign. 2. Start calibration (e.g., after calibration prompt: flashing symbol).

-

Page 38: Data Id Codes

Data ID Codes Example with Midrics 2: Enter ID code names. Midrics 2 only: Enter “Batch no." and “Cust." as names for ID codes 1 and 2. You can assign codes (such as product name, batch number, etc.) for identifi- cation of measured values on printouts. - Page 39 4. Place sample on the platform 9. Enter the first character using 5. Print the weight value the p and k keys (in this example, the first character is “ ") ID code 2 24.02.2006 10:09 ------------------- Ser.no 12345678 1083 g 10.

-

Page 40: Application Programs

Application Programs Applications: Overview Midrics 1 Midrics 2 Keypad 5 keys 11 keys + numeric keypad Display 14-segment 14-segment plus application symbols Applications Basic weighing Averaging (animal weighing) Print/send data record to peripheral device Label printing Counting Totalizing Checkweighing Batching to a target value Functions Zero-setting Taring... - Page 41 Application: Counting Z With the Counting program you can – Restore factory settings. Configuration: determine the number of parts that Appl 9.1. each have approximately equal weight. Before the quantity on the platform Features can be calculated, the reference sample –...

- Page 42 Application: Counting Z Preparation Minimum Load Parameter for Saving Weight Values To tare container weights automati- The weight on the platform is saved § Switch on the scale: Press e cally, set the minimum load in the as a reference when the platform has §...

- Page 43 Example: Determining the number of uncounted parts. Settings (changes in the factory settings required for this example): Setup: Application: Counting Setup: PRTPROT (printout): 7.7.x (COM1) (see “Configuration” for options) In this case, reduce the mini- mum load setting or increase the number of parts in the container and reset the refer- ence sample quantity...

- Page 44 Application: Neutral Measurement Z nM With this application you can use your – Calculation: Application Parameters: Neutral Measurement weighing platform to measure the – Place the reference quantity (defined 3.5. Minimum load for automatic taring length, surface and volume of parts by the calculation factor) on the and automatic printing that have roughly the same specific...

- Page 45 Minimum Load Parameter for Saving Weight Values The minimum load required for The reference weight is saved when initialization of the weighing platform the platform has stabilized. “Stability" is configured in the operating menu is defined as the point at which under: fluctuation of a measured value lies Appl...

- Page 46 Example: Measuring 25 m electrical cable. Settings (changes in the factory settings required for this example): Setup: Application: Neutral Measurement Setup: PRTPROT (printout): 7.7.x (COM1) (see “Configuration” for options) 1. Place empty container on the platform 5. Place the desired amount of cable in the container 2.

- Page 47 Application: Averaging (Animal Weighing) V With the Averaging application, A number of measurements are Preparation § Switch on the scale: Press e. you can use your weighing platform required, as this forms the basis for § While all segments are lit, for calculating weights as the average calculation of an average weight.

- Page 48 Application Parameters: Averaging (Animal Minimum Load Display Weighing) The minimum load required for A calculated average value is shown initialization of the averaging routine continuously on the main display. The 3.5. Minimum load for automatic taring is configured in the operating menu symbol (indicating a calculated and automatic printing under:...

- Page 49 Example: Measuring the weight of one mouse. Settings (changes in the factory settings required for this example): Setup: Application: Animal weighing Setup: PRTPROT (printout): 7.7.x (COM1) (see “Configuration” for options) The averaging routine does not begin until the fluctuation in weight value remains below a defined threshold over three consecutive measurements.

- Page 50 Application: Weighing in Percent L With the Weighing in Percent – Calculation: Application Parameters: Weighing in Percent application, you can have the value of – Place the reference quantity 3.5. Minimum load for automatic the weight on the platform displayed (defined by the reference percent- taring and automatic printing as a percentage calculated in relation...

- Page 51 Minimum Load Parameter for Saving Weight Values The minimum load required for The reference weight is saved when initialization of the weighing platform the platform has stabilized. “Stability" is configured in the operating menu is defined as the point at which under: fluctuation of a measured value lies Appl...

- Page 52 Example: Weighing in 100% of a sample material. Settings (changes in the factory settings required for this example): Setup: Application: Weighing in percent Setup: PRTPROT (printout): 7.7.x (COM1) (see “Configuration” for options) If the weight is too light, the error code Inf 29 is shown on the main display.

- Page 53 Application: Checkweighing O With the Checkweighing application, you – Closing application program; Application Parameters: Checkweighing can check whether the sample on the deleting parameters: 3.5. Minimum load for automatic taring weighing platform matches a target The value for reference sample weight and automatic printing value, or lies within a given tolerance remains active in the reference memory...

- Page 54 Minimum Load Digital Input/Output Interface + Checking Range The minimum load required for Optional I/O 30 % Target weight 170% automatic taring of the container The Checkweighing application sup- Lower Upper weight on the platform (first weight), ports the digital input/output interface. limit limit or for automatic printout of results,...

- Page 55 Example: 1 Checkweighing samples with a target weight of 1250 g and a tolerance range from –10 g to +30 g Settings (changes in the factory settings required for this example): Setup: Application: Checkweighing Setup: PRTPROT (printout): 7.7.x (COM1) (see “Configuration” for options) 1280 6.

- Page 56 Application: Classification With the Classification application, – By entering a percentage: Application Parameters: Classification you can determine whether the weight The upper value of Class 1 is entered 3.5. Minimum load for automatic taring of a given sample lies within the limits using the keypad or by saving the and automatic printing of a defined weight class.

- Page 57 Minimum Load Digital Input/Output Interface Min. load Max. load The minimum load for the first class (CTTL Signal) Class is configured in the operating menu, The Classification application supports under: the digital input/output interface. Appl 3.6. The 4 control outputs are activated as Class 1 Once the limit is exceeded by the load, follows (see also the diagram on the...

- Page 58 Example: Defining three classes. Settings (changes in the factory settings required for this example): Setup: Application: Classification Setup: PRTPROT (printout): 7.7.x (COM1); printout for app; then select desired line items (see “Configuration” for options) 1. Begin input of class delimiters 6.

- Page 59 Application: Totalizing With the Totalizing application, you The Midrics has a totalizing memory for Preparation § Switch on the scale: Press e can add weight values together in the adding individual net and gross values. § While all segments are lit, totalizing memory.

- Page 60 Application Parameters: Totalizing Minimum Load The minimum load required for automatic 3.5. Minimum load for automatic taring of the container weight on the taring and automatic printing platform (“autotare first weight") is config- 3.5.1* 1 digit ured in the operating menu under: 3.5.2 2 digits Appl...

- Page 61 Example: Totalizing weight values. Settings (changes in the factory settings required for this example): Setup: Application: Totalizing Setup: PRTPROT: 7.7.x (COM1 interface) then select the desired line items Setup: PRTPROT: 7.9.x (“Print when CF pressed") then select the desired line items 4.

-

Page 62: Net-Total Formulation

Application: Net-total Formulation R With the Net-total Formulation Preparation Minimum Load § Switch on the scale: Press e application, you can weigh in different The minimum amount that a compo- § While all segments are lit, components up to a defined total. nent must weigh before it can be saved press the ) key Each component is saved in a net-total... - Page 63 Example: Weighing in 3 components of a formulation recipe. Settings (changes in the factory settings required for this example): Setup: Application: Net-total Formulation Setup: PRTPROT: 7.7.x (COM1 interface) “Printout when value is saved”; then select the desired line items Setup: PRTPROT: 7.9.x “Print when CF pressed" then select the desired line items 1.

- Page 64 The weighing platform is tared and the component counter value is increased by one. Prompt to fill and save the second component is shown. 8. Add the third component to the container, bringing the total up to the desired target (in this example, 2000 g).

-

Page 65: Configuring Printouts

Configuring Printouts Purpose – “Form feed" item in the printout footer: You can specify which data items are For advancing to the start of the next included on printouts. When using the label in print mode “YDP01IS: Label" or Totalizing or Net-total Formulation “YDP04IS: Label: Manual form feed"... -

Page 66: Configuring The Data Interface As A Printer Port

Configuring Printouts Configuring the Data Configuring Printouts Separating Block: Dotted line, blank line (for the Weighing Interface as a Printer Port Printouts are configured in the operating application). ( printer ) menu under the “Printouts" menu item This block is automatically inserted before prtprot ). -

Page 67: Gmp-Compliant Printouts

GMP-compliant Printouts Examples of GMP headers and When the corresponding menu item is one example of a footer are shown active, the measured result is bracketed in the following. on the printout by a GMP header and a GMP footer (GMP = “Good Manufactur- Weighing platform WP1: ing Practice"). -

Page 68: Sample Printouts

Sample Printouts Neutral Measurement Application Checkweighing Application The “Initialization data" block contains the The “Initialization data" block contains For details on the individual information reference sample quantity and reference the nominal, minimum and maximum blocks, see “Configuring Printouts" above. weight. The “Results" block contains gross, weights. - Page 69 Classification Application ‘Total' printout: Totalizing Application The “Initialization data" block contains -------------------- The “Initialization data" block is empty. the upper limits of Classes 1 through 4. If this block is enabled for the printout, The “Results" block contains gross, net S-Comp+ 3.200 kg a blank line is output.

- Page 70 Configuring Printouts Individual printout (menu item 3.17.2 The entire standard printout is generated for each component. Example: Print second transaction: HEADER LINE 1 HEADER LINE 2 14.01.2006 09:43 ------------------- 2.400 kg 0.200 kg 2.200 kg Standard printout The transaction counter value is not printed.

-

Page 71: Com1

Data Interface (Optional) For COM1 Standard equipment: RS-232 Computer with serial RS-232 input port SBI/XBPI protocol, Option A11: printer: YDP04IS YDP02IS YDP12IS YDP03-0CE YAM01IS external Alibi memory YBT01 external Bluetooth adapter YRD02Z second display USB adapter cable for connecting a computer over USB: YCC01IS Option: “RS-232 clock:"... -

Page 72: Error Codes

Error Codes Error codes are shown on the main display. “Err" codes are shown continuously; “Inf" messages are displayed for 2 seconds, after which the program returns automatically to the weighing mode. Error code Cause Solution Err 101 Key is stuck Release key Key pressed at power on Contact your local Service Center... -

Page 73: Care And Maintenance

In Germany and many other countries, Important note: If the equipment is still the cover is firmly seated. Sartorius AG takes care of the return and under warranty, send the entire scale to legally compliant disposal of its electrical the factory for repairs. -

Page 74: Overview

AC supply 22.8 ... 26.7 V, 50-60 Hz, 12 VA max. Operation with rechargeable battery See Sartorius Installation Instructions for Option L9 Operation via built-in or external rechargeable battery (only available as an option that must be ordered with the scale) Emissions Acc. -

Page 75: Dimensions

Dimensions (Scale Drawings) Standard and Stainless Steel Versions Model Length Width Height Height Spacing between Spacing between Cable length Standard Stainless leveling feet leveling feet version steel Standard version Stainless steel version version (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (m) ca. - Page 76 Accessories/Options Accessories/Options Printer and printer accessories: Verifiable printer with functions for date, time and statistical evaluations; connecting cable required YCC02-D09F6 YDP03-0CE Printer paper for data printer (5 rolls; length per roll: 50 m) 6906937 Replacement ink ribbon cartridge for YDP03-0CE/YDP04 6906918 YDP03-0CE Verifiable strip and label printer with thermal print head,...

- Page 77 YSW03 and verifiable electronic data storage. YCC-R12F6 RS-232 connecting cable (option M6) required SartoConnect data transfer software for connecting your Sartorius scale to a computer; YSC01L (includes cable for connecting the scale to a computer (12-pin <–> 9-pin); length: 1.5 m)

- Page 78 Accessories/Options Product Order No. Cables Connecting cable with cable gland for YDP12/04IS printers, YCC02-D09M6 open cable ends to 9-pin D-Sub male connector; 6 m Connecting cable with cable gland for a YDP03-0CE printer or a computer, YCC02-D09F6 open cable ends to 9-contact D-Sub female connector; 6 m Connecting cable with cable gland for accessories, YCC02D25F6 open cable ends to 25-contact D-Sub female connector;...

- Page 79 Drive-on ramp, painted, for equipment with the following Pit frame edges, stainless steel, for equipment with the dimensions: following dimensions: Weighing Ramp Order no. Weighing platform, Order no. platform length + width in mm size in mm 800+800 YEG01MAPS 800+800 1200+800 YAR01MAPP 1000+800...

-

Page 80: Declarations Of Conformity

The validity of the verification will become If you use electrical equipment in void in accordance with the national Sartorius complies with the EC Directives and European Standards in order to supply installations and under ambient conditions regulations of the country in which the... -

Page 87: Index

Index Page Page Access code Language, setting 13, 15, 31 Accessories 76–79 Legal metrology, use in Animal weighing 17, 47 Leveling the platform Applications, technical advice on Automatic shutoff Maintenance Averaging 17, 47 Navigation in the operating menu C marking Net-total formulation 19, 62 Calibration/adjustment... - Page 88 Appendix: General Password When you select the Setup menu item, the password prompt is displayed for 2 seconds, and then the cursor flashes in the position of the first character of the password. Repeatedly: Enter the password – Press k to enter letters and ) to save.

- Page 89 Sartorius AG Weender Landstrasse 94–108 37075 Goettingen, Germany Phone +49.551.308.0 Fax +49.551.308.3289 www.sartorius.com Copyright by Sartorius AG, Goettingen, Germany. All rights reserved. No part of this publication may be reprinted or translated in any form or by any means without the prior written permission of Sartorius AG.

Need help?

Do you have a question about the MW1 and is the answer not in the manual?

Questions and answers