Lexmark MX310 Series Service Manual

Lexmark machine type 7015-270, -470, -6xx printers service manual

Hide thumbs

Also See for MX310 Series:

- Service manual (510 pages) ,

- User manual (267 pages) ,

- Quick reference manual (17 pages)

Summary of Contents for Lexmark MX310 Series

-

Page 1: Service Manual

Lexmark MX310, MX410, & MX510 Machine Type 7015-270, -470, -6xx Service Manual • Start diagnostics • Maintenance • Safety and notices • Trademarks • Index November 28, 2012 www.lexmark.com P/N 12G2376... -

Page 2: November

November 28, 2012 The following paragraph does not apply to any country where such provisions are inconsistent with local law: LEXMARK INTERNATIONAL, INC., PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. -

Page 3: Table Of Contents

7015 Table of contents Product information..................2 Edition notice....................2 Notices and safety information..............15 Laser notices............................15 Safety...............................18 Preface.......................23 Service manual conventions........................23 General information...................25 Media guidelines.............................25 Paper guidelines ...............................25 Using recycled paper and other office papers ....................28 Using specialty media ............................28 Supported paper sizes, types, and weights ......................30 Data security notice..........................33... - Page 4 7015 200 paper jams ..............................202 paper jams ..............................23y paper jams ..............................24y paper jams ..............................25y paper jams ..............................28y paper jams ..............................29y.xx paper jams ............................. Understanding printer messages......................76 Cartridge low [88.xy]............................76 Cartridge nearly low [88.xy]..........................76 Cartridge very low, [x] estimated pages remain [88.xy] ...................76 Change [paper source] to [custom string] load [paper orientation]..............76...

- Page 5 Network [x] software error [54] ........................84 No analog phone line connected to modem, fax is disabled................84 Non‑Lexmark [supply type], see User’s Guide [33.xy] ..................84 Not enough free space in flash memory for resources [52] ................85 Printer had to restart. Last job may be incomplete..................85...

- Page 6 7015 Insufficient memory service check ........................95 Printer hardware errors..........................95 1xx error messages ............................97 111.xx LSU service check ..........................100 Fuser service check ............................100 LVPS service check ............................101 Toner density sensor service check ........................101 CTLS service check ............................102 Main drive gearbox service check........................102 ACM service check ............................103...

- Page 7 7015 ADF duplex service check..........................137 Modem/fax card service check........................138 Fax reception service check ..........................139 Fax transmission service check ........................141 Fax error log codes ............................143 Escalating a fax issue to second‑level support....................Service menus..................149 Understanding the control panel and menus (MX310dn)..............149 Using the printer control panel........................149 Understanding the colors of the indicator and Sleep button...

- Page 8 7015 PPDS Emulation ..............................176 Download Emuls .............................176 Safe Mode............................... Factory Defaults.............................. Energy Conserve .............................176 Fax low power support ...........................177 Min copy memory............................177 Num pad job assist............................177 Format fax storage............................177 ADF edge erase ............................... Flatbed edge erase............................178 Scanner manual registration...........................178 Disable scanner............................... Paper Prompts ..............................

- Page 9 Left cover removal ............................209 Main drive gearbox removal...........................211 MPF solenoid removal ............................213 MPF gearbox removal.............................215 Reverse solenoid removal..........................218 ACM clutch removal (MX310, MX410) ......................219 Cartridge gearbox removal ..........................224 Duplex gear assembly removal ........................224 Right side removals..........................226 Right cover removal............................226 Memory access door removal ........................229...

- Page 10 Power supply removal ............................272 Power supply shield removal..........................273 Duplex removal............................... Duplex sensor and input sensor removal .......................275 Duplex sensor and input sensor (MX310, MX410) removal ................278 Index sensor removal............................279 Media present sensor removal ........................280 Toner density sensor removal ........................282 Trailing edge sensor removal..........................282...

- Page 11 7015 Laser scanning unit (LSU) removal........................309 ADF/scanner removals..........................311 ADF separator pad removal ...........................311 ADF separator roll removal ..........................312 Flatbed cushion removal ..........................314 Scanner front cover removal ..........................315 Scanner rear cover removal..........................315 ADF input tray removal...........................316 ADF unit removal ............................316 Scanner assembly removal ..........................319 ADF top cover assembly ..........................323...

- Page 12 7015 Parts catalog....................354 Legend..............................354 Assembly 1: Covers..........................355 Assembly 2: Imaging..........................357 Assembly 3: Control panel (MX41x, MX51x)..................361 Assembly 4: Control panel (MX31x)......................363 Assembly 5: Electronics 1........................365 Assembly 6: Electronics 2........................367 Assembly 7: Frame..........................369 Assembly 8: Option trays........................371 Assembly 9: Maintenance kits.......................373 Assembly 10: Power cords........................375 Assembly 11:...

- Page 13 7015 Sensors................................Other key components ...........................389 Electrophotographic process (EP process)....................390 theory.............................394 ADF theory of operation ..........................394 Appendix D: Acronyms................397 Acronyms...............................397 Index......................399 Part number index...................409 Part name index..................415 Table of contents...

- Page 14 7015 Table of contents...

-

Page 15: Notices And Safety Information

7015 Notices and safety information Laser notices Laser notice The printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR, Chapter I, Subchapter J for Class I (1) laser products, and elsewhere is certified as a Class I laser product conforming to the requirements of IEC 60825-1. Class I laser products are not considered to be hazardous. - Page 16 7015 Aviso de láser Esta impresora se ha certificado en EE. UU. de conformidad con los requisitos de DHHS 21 CFR, capítulo I, subcapítulo J, para los productos láser de Clase I (1), y en otros países está certificada como un producto láser de Clase I de acuerdo con los requisitos de IEC 60825-1.

- Page 17 7015 Luokan I lasertuotteita ei pidetä haitallisina. Tulostimen sisällä on luokan IIIb (3b) laser, joka on nimellisteholtaan 7 mW:n galliumarsenidilaser ja toimii 655–675 nanometrin aallonpituuksilla. Laserjärjestelmä ja tulostin ovat rakenteeltaan sellaisia, että käyttäjä ei joudu alttiiksi luokkaa 1 suuremmalle säteilylle normaalin käytön, ylläpidon tai huollon aikana.

-

Page 18: Safety

7015 Class I 레이저 제품은 위험한 제품으로 간주되지 않습니다. 프린터에는 655-675 나노미터의 파장 영역에서 작동 하는 공칭 7 밀리와트 갈륨 비소 레이저인 클래스 IIIb(3b) 레이저가 내부에 포함되어 있습니다. 레이저 시스템 과 프린터는 정상적인 작동, 사용자 유지 관리 또는 사전 설명된 서비스 조건에는 사람에게 클래스 I 수준 이상 의... - Page 19 7015 AVERTISSEMENT—RISQUE DE BLESSURE La batterie lithium de ce produit n'est pas destinée à être remplacée. Il existe un risque d'explosion si une batterie lithium est placée de façon incorrecte. Ne rechargez pas, ne démontez pas et n’incinérez pas une batterie lithium.

- Page 20 7015 Informações de Segurança • A segurança deste produto baseia-se em testes e aprovações do modelo original e de componentes específicos. O fabricante não é responsável pela segunrança, no caso de uso de peças de substituição não autorizadas. • As informações de segurança relativas a este produto destinam-se a profissionais destes serviços e não devem ser utilizadas por outras pessoas.

- Page 21 7015 当心一可能的伤害: 本产品中的锂电池不可更换。如果不正确更换锂电池,可能会有爆炸危险。不要再 充电、拆解或 焚烧锂电池。丢弃旧的锂电池时应按照制造商的指导及当地法规进行处理。 Notices and safety information...

- Page 22 7015...

-

Page 23: Preface

7015 Preface This manual contains maintenance procedures for service personnel. It is divided into the following chapters: • General information contains a general description of the printer. Special tools and test equipment are discussed. • Diagnostic information contains diagnostic aids you can use to isolate failing FRUs. These diagnostic aids include error code tables, symptom tables, and service checks. - Page 24 7015...

-

Page 25: General Information

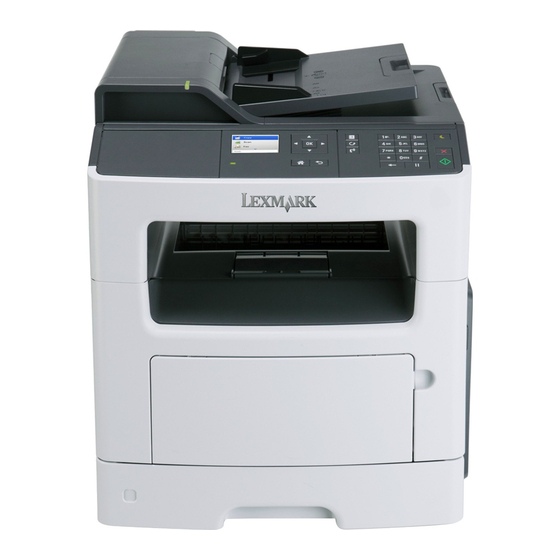

7015 General information The Lexmark MX310dn, MX410, and MX510 (7015‑xxx) are network‑capable, multi‑function laser printers that print monochrome print jobs. All information in this service manual pertains to all models unless explicitly noted. The printers are available in the following models:... -

Page 26: Moisture Content

7015 Weight The printer trays can automatically feed paper weights up to 120‑g/m (32‑lb) bond grain long paper. The multipurpose feeder can automatically feed paper weights up to 163‑g/m (43‑lb) bond grain long paper. Paper lighter than 60 g/m (16 lb) might not be stiff enough to feed properly, causing jams. For best performance, use 75‑g/m (20‑lb) bond grain long paper. -

Page 27: Selecting Paper

7015 • Preprinted papers that require a registration (the precise print location on the page) greater than ±2.4 mm (±0.9 inch), such as optical character recognition (OCR) forms In some cases, registration can be adjusted with a software application to successfully print on these forms: •... -

Page 28: Using Recycled Paper And Other Office Papers

Lexmark consistently tests its printers with recycled paper (20–100% post-consumer waste) and a variety of test paper from around the world, using chamber tests for different temperature and humidity conditions. Lexmark has found no reason to discourage the use of today's recycled office papers, but generally the following property guidelines apply to recycled paper. - Page 29 Print samples on the labels being considered for use before buying large quantities. Note: Use only paper label sheets. Vinyl, pharmacy, and two‑sided labels are not supported. For more information on label printing, characteristics, and design, see the Card Stock & Label Guide available at http://support.lexmark.com. When printing on labels: •...

-

Page 30: Supported Paper Sizes, Types, And Weights

7015 • Make sure the adhesive backing does not reach to the edge of the sheet. Zone coating of the adhesive should be at least 1 mm (0.04 inches) away from edges. Adhesive material contaminates the printer and could void the warranty. - Page 31 7015 Paper size and dimension Standard Optional 250‑ or Multipurpose Scanner Duplex 250‑sheet tray 550‑sheet tray feeder glass mode 105 x 148 mm (4.13 x 5.83 in.) JIS B5 182 x 257 mm (7.17 x 10.1 in.) Letter 215.9 x 279.4 mm (8.5 x 11 in.) Legal 215.9 x 355.6 mm...

-

Page 32: Supported Paper Types And Weights

7015 Paper size and dimension Standard Optional 250‑ or Multipurpose Scanner Duplex 250‑sheet tray 550‑sheet tray feeder glass mode DL Envelope 110 x 220 mm (4.33 x 8.66 in.) C5 Envelope 162 x 229 mm (6.38 x 9.01 in.) B5 Envelope 176 x 250 mm (6.93 x 9.84 in.) Other Envelope... -

Page 33: Data Security Notice

7015 Paper type 250‑ or Multipurpose feeder Duplex mode Scanner glass 550‑sheet tray Colored paper Light paper Heavy paper Rough/Cotton Custom Type [x] One‑sided paper labels designed for laser printers are supported for occasional use. We recommend printing only up to 20 pages of paper labels per month. -

Page 34: Tools Required For Service

7015 Tools required for service Flat-blade screwdrivers, various sizes #1 Phillips screwdriver, magnetic #2 Phillips screwdriver, magnetic #2 Phillips screwdriver, magnetic short-blade Needle‑nose pliers Diagonal side cutters Spring hook Feeler gauges Analog or digital multimeter Flashlight (optional) General information... -

Page 35: Diagnostic Information

7015 Diagnostic information • “Troubleshooting overview” on page 35 • “Fixing print quality issues” on page 37 • “Paper jams” on page 45 • “Understanding printer messages” on page 76 • “User attendance messages (0–99.99)” on page 91 • “Printer hardware errors” on page 95 •... -

Page 36: Power-On Reset (Por) Sequence

7015 Power‑on Reset (POR) sequence When you turn the printer on, it performs a POR sequence. Check for correct POR functioning of the base printer by observing the following: The control panel indicator light turns on. The control panel display turns on. A splash screen appears on the display. -

Page 37: Fixing Print Quality Issues

7015 Safe Mode engine features Engine behavior Control panel behavior Ignore all input options Will report that only Tray 1 is installed. Only Tray 1 and the MPF will be selectable. Ignore all output options Will not report any installed finishing Finishing options will not be selectable. -

Page 38: Gray Background Or Toner Fog On Prints

7015 Print a Print quality test page, and then look for variations in the print from what is expected. Verify if the settings under EP Setup are set to their default values. See “EP Defaults” on page 166. Check to ensure the correct printer driver for the installed software is being used. An incorrect printer driver for the installed software can cause problems. -

Page 39: Repeating Defects

7015 Repeating defects Actions Step 1 Replace the imaging Go to step 2. unit. Measure the distance between defects. Is the distance between defects equal to any of the following? • 3.82 in. (97 mm) • 1.85 in. (47 mm) •... -

Page 40: Printer Is Printing Solid Black Pages

7015 Actions Step 4 Go to step 5. Replace the printer. Check the transfer roll left contact spring for damage. Is it free of damage? Step 5 Replace the power The problem is solved. supply. Reseat the cables JLSU1 and J6 on the controller board. Does the problem remain? Printer is printing solid black pages Actions... -

Page 41: Skewed Print

7015 Actions Step 1 Go to step 2. Go to step 3. Does the shadow image appear every two pages? Step 2 Go to step 3. Replace the redrive assembly. See “Redrive Check the redrive assembly for wear or damage. assembly removal”... - Page 42 7015 Actions Step 1 Go to step 2. The problem is solved. POR into the Diagnostics menu and perform a print test: Diagnostics Menu > Print Tests > Tray 1 Adjust the margins if necessary: Diagnostics Menu > Registration Does the error remain? Step 2 Go to step 9.

-

Page 43: Streaked Horizontal Or Vertical Lines Appear On Prints

7015 Actions Step 10 Go to step 11. Replace the reverse solenoid. See “Reverse Remove the left cover. solenoid removal” on POR into the Diagnostics menu and perform a duplex test: page 218. Diagnostics Menu > Duplex Tests Observe the reverse solenoid for proper operation. Does it properly operate? Step 11 Contact the next level... -

Page 44: Toner Rubs Off

7015 Actions Step 4 Go to step 5. Replace the fuser. Remove the fuser and check for damage or debris on the rollers and belts. Is it free of damage and debris? Step 5 Replace the LSU. The problem is solved. Reseat the cables JLSU1 and J6 on the controller board. -

Page 45: Toner Specks Appear On Prints

7015 Toner specks appear on prints Actions Step 1 Go to step 2. Replace the imaging unit. Check the imaging unit for wear or damage. Is it free of wear or damage? Step 2 Go to step 3. The problem is solved. Make sure the paper path is free of debris or toner contamination. -

Page 46: Avoiding Jams

7015 Avoiding jams Load paper properly • Make sure paper lies flat in the tray. Correct loading of paper Incorrect loading of paper • Do not remove a tray while the printer is printing. • Do not load a tray while the printer is printing. Load it before printing, or wait for a prompt to load it. •... -

Page 47: Understanding Jam Messages And Locations

7015 • Flex, fan, and straighten paper before loading it. • Do not use paper that has been cut or trimmed by hand. • Do not mix paper sizes, weights, or types in the same tray. • Make sure the paper size and type are set correctly on the computer or printer control panel. •... -

Page 48: 200 Paper Jams

7015 Jam access area Printer control panel message What to do Tray 1 [x]‑page jam, remove tray 1 to Pull out tray 1 completely, then push the front duplex clear duplex. [23y.xx] flap down, and then remove the jammed paper. Note: You may need to open the rear door to clear some 23y.xx paper jams. - Page 49 7015 Lift the green handle, and then pull the imaging unit out of the printer. Warning—Potential Damage: Do not touch the shiny blue photoconductor drum under the imaging unit. Doing so may affect the quality of future print jobs. Place the imaging unit aside on a flat, smooth surface. Warning—Potential Damage: Do not expose the imaging unit to direct light for more than 10 minutes.

- Page 50 7015 Firmly grasp the jammed paper on each side, and then gently pull it out. Note: Make sure all paper fragments are removed. Insert the imaging unit by aligning the arrows on the side rails of the unit with the arrows on the side rails inside the printer, and then insert the imaging unit into the printer.

- Page 51 7015 Close the front door. From the printer control panel, touch to clear the message and continue printing. For non‑touch‑screen printer models, select Next > > Clear the jam, press OK > 200 paper jam messages Error code Description Action 200.01 Input sensor covered during warm-up sequence.

- Page 52 7015 Error code Description Action 200.23 Laser servo never started due to potential conflict Go to “Sensor (input) image jam service check” on with the transfer servo. page 200.24 Measured gap at input sensor too small to meet video delivery requirements. (Not enough time since prior image finished to start new image).

- Page 53 7015 Action Step 4 Go to step 5. Replace the input sensor. See “Duplex POR into the Diagnostics menu and perform a sensor test: sensor and input Diagnostics Menu > Base Sensor Test > Input. sensor removal” on page 275. Does the sensor state on the control panel display change when it is toggled? Step 5...

- Page 54 7015 Action Step 6 Replace the jam access Go to step 7. cover. See “Jam access Check the jam access cover if it is blocking the input sensor. cover removal” on page 264 Is it blocking the input sensor? Step 7 Go to step 8.

-

Page 55: Main Drive Motor Control Jam Service Check

7015 Action Step 5 Go to step 6. Replace the input sensor. See “Duplex POR into the Diagnostics menu and perform a sensor test: sensor and input Diagnostics Menu > Base Sensor Test > Input sensor removal” on page 275. Does the sensor state on the control panel display change when it is toggled? Step 6... -

Page 56: 202 Paper Jams

7015 202 paper jams [x]‑page jam, open rear door. [20y.xx] Open the front door to loosen the jammed paper in the rear door. Gently pull down the rear door. CAUTION—HOT SURFACE: The inside of the printer might be hot. To reduce the risk of injury from a hot component, allow the surface to cool before touching it. -

Page 57: X]‑Page Jam, Clear Standard Bin. [20Y.xx

7015 Close the rear door, and then the front door. From the printer control panel, touch to clear the message and continue printing. For non‑touch‑screen printer models, select Next > > Clear the jam, press OK > [x]‑page jam, clear standard bin. [20y.xx] Firmly grasp the jammed paper on each side, and then gently pull it out. - Page 58 7015 202 paper jam messages Error code Description Action 202.01 Exit sensor is covered during warm up. Go to “Sensor (fuser exit) jam service check” on page 202.03 Media did not reach the fuser exit sensor. 202.05 Fuser exit sensor covered too long by the current sheet.

- Page 59 7015 Action Step 3 Go to step 4. Replace the fuser. See “Fuser removal” on Check the fuser exit sensor for damage. page 305. Is it free of damage? Step 4 Go to step 5. Replace the fuser. See “Fuser removal” on Check the fuser gears and rollers for damage.

-

Page 60: 23Y Paper Jams

7015 23y paper jams [x]‑page jam, remove tray 1 to clear duplex. [23y.xx] CAUTION—HOT SURFACE: The inside of the printer might be hot. To reduce the risk of injury from a hot component, allow the surface to cool before touching it. Pull the tray completely out of the printer. - Page 61 7015 Insert the tray. From the printer control panel, touch to clear the message and continue printing. For non‑touch‑screen printer models, select Next > > Clear the jam, press OK > 23y.xx paper jam messages Error code Description Action 230.01 Sheet covering internal duplex sensor during warm Go to “Duplex service check”...

-

Page 62: 24Y Paper Jams

7015 Duplex service check Action Step 1 Go to step 2. Replace the redrive assembly. See “Redrive Remove the rear cover. assembly removal” on Check the redrive rollers for wear or damage. page 304. Are they free of wear or damage? Step 2 Go to step 3. - Page 63 7015 Firmly grasp the jammed paper on each side, and then gently pull it out. Note: Make sure all paper fragments are removed. Insert the tray. From the printer control panel, touch to clear the message and continue printing. For non‑touch‑screen printer models, select Next >...

- Page 64 7015 Error code Description Action 241.14 The media is late reaching the sensor (input) within Go to “Tray 1 jam service check” on page the specified time from tray 1. 241.15 Media tray 1, tray pulled jam. 241.16 The engine timed out waiting for the tray 1 to report 'ready' before the 1st pick attempt.

- Page 65 7015 Error code Description Action 242.01 Paper over tray 2 pass thru sensor on warmup. Go to “Option tray jam service check” on page 242.02 Input sensor detected late feed during a pick retry from tray 2. 242.03 Tray 2 pass thru sensor never became covered when feeding a sheet from an option below.

- Page 66 7015 Error code Description Action 242.42 Motor 1 (Pick/Lift) Elevator motor PWM overflow Go to “Option tray jam service check” on page error (underspeed). Motor underspeed (max PWM and motor underspeed, typical accordion jam). 242.43 Motor 1 (Pick/Lift) motor ramp (end ramp - did not reach speed, typical pack feed paper jam).

- Page 67 7015 Error code Description Action 243.17 Page was not properly picked from tray 3. Have not Go to “Option tray jam service check” on page exhausted all pick retry attempts as there are sheets committed to the paper path from below. 243.19 Tray 3 fail to feed error.

- Page 68 7015 Error code Description Action 244.06 Failed to feed from tray. Paper present sensing Go to “Option tray jam service check” on page supported and indicates media still in tray. 244.07 Option tray 4 pass thru sensor never became uncovered when feeding a sheet from an option below.

- Page 69 7015 Error code Description Action 244.44 Motor 2 (Separator/Passthru) motor stalled. Go to “Option tray jam service check” on page 244.45 Motor 2 (Separator/Passthru) motor PWM overflow error (underspeed). Motor underspeed (max PWM and motor underspeed, typical accordion jam). 244.46 Motor 2 (Separator/Passthru) motor ramp (end ramp - did not reach speed, typical pack feed paper jam).

- Page 70 7015 Action Step 6 Go to step 7. Replace the trailing edge sensor. See Observe the location of the jammed paper. “Trailing edge sensor removal” on page Are the first page fed to the output bin, the second page jammed in the 282.

-

Page 71: 25Y Paper Jams

7015 Action Step 4 Go to step 5. Replace the pick roller assembly. See “Pick Check the pick roller assembly. roller removal” on page 333. Is it free of wear or damage? Step 5 Go to step 6. Replace the separator roll assembly. - Page 72 7015 Flex the sheets of paper back and forth to loosen them, and then fan them. Do not fold or crease the paper. Straighten the edges on a level surface. Reload paper into the multipurpose feeder. Note: Make sure the paper guide lightly rests against the edge of the paper. From the printer control panel, touch to clear the message and continue printing.

-

Page 73: Mpf Service Check

7015 25y.xx paper jam messages Error code Description Action 250.06 Input sensor did not detect sheet picked from MPF. Go to “MPF service check” on page No other sheets should be in the path. 250.10 Input sensor did not detect sheet picked from MPF. No other sheets should be in the path. -

Page 74: 28Y Paper Jams

7015 Action Step 4 Go to step 5. Replace the MPF solenoid. See “MPF Remove the left cover. solenoid removal” on POR into the Diagnostics menu and perform a feed test: page 213. Diagnostics Menu > Input Tray Tests > Feed Tests > Multi‑Purpose Feeder Check the MPF solenoid for proper operation. -

Page 75: 29Y.xx Paper Jams

7015 28y.xx paper jams 28x.xx paper jams Error code Description Action 280.06 Paper Missing—Posted when paper is Ensure that the ADF document sensor is in the proper position removed from input tray after job is initiated. and clear of dust and deris. Retry the job. If the error recurs, then “ADF paper jam service check”... -

Page 76: Understanding Printer Messages

7015 Understanding printer messages Cartridge low [88.xy] You may need to order a toner cartridge. If necessary, select Continue on the printer control panel to clear the message and continue printing. For non‑touch‑screen printer models, press to confirm. Cartridge nearly low [88.xy] If necessary, select Continue on the printer control panel to clear the message and continue printing. -

Page 77: Change [Paper Source] To [Paper Size] Load [Orientation]

7015 Change [paper source] to [paper size] load [orientation] Try one or more of the following: • Load the correct paper size and type in the tray, verify the paper size and type settings are specified in the Paper menu on the printer control panel, and then select Finished changing paper. For non‑touch‑screen printer models, press to confirm. -

Page 78: Complex Page, Some Data May Not Have Printed [39]

7015 From the printer control panel, select Continue to clear the message. For non-touch-screen printer models, press to confirm. Complex page, some data may not have printed [39] Try one or more of the following: • From the printer control panel, select Continue to ignore the message and continue printing. For non‑touch‑screen printer models, press to confirm. -

Page 79: Fax Server 'To Format' Not Set Up. Contact System Administrator

7015 Fax server 'To Format' not set up. Contact system administrator. Try either of the following: • From the printer control panel, select Continue to clear the message. For non‑touch‑screen printer models, press to confirm. • Complete the Fax Server setup. If the message appears again, then contact your system support person. Fax Station Name not set up. -

Page 80: Incorrect Paper Size, Open [Paper Source] [34]

7015 Incorrect paper size, open [paper source] [34] Try one or more of the following: • Load the correct size of paper in the tray. • From the printer control panel, select Continue to clear the message and print using a different tray. For non‑touch‑screen printer models, press to confirm. -

Page 81: Insufficient Memory To Support Resource Save Feature [35]

7015 Insufficient memory to support Resource Save feature [35] Install additional printer memory or select Continue on the printer control panel to disable Resource Save, clear the message, and continue printing. For non‑touch‑screen printer models, press to confirm. Load manual feeder with [custom string] [paper orientation] Try one or more of the following: •... -

Page 82: Load Manual Feeder With [Paper Type] [Paper Size] [Paper Orientation]

7015 Load manual feeder with [paper type] [paper size] [paper orientation] Try one or more of the following: • Load the multipurpose feeder with the correct size and type of paper. • Depending on your printer model, touch Continue or press to clear the message and continue printing. -

Page 83: Load [Paper Source] With [Paper Type] [Paper Size] [Paper Orientation]

Maintenance kit low [80.xy] You may need to order a maintenance kit. For more information, contact customer support at http://support.lexmark.com or your service representative. If necessary, select Continue to clear the message and continue printing. For non‑touch‑screen printer models, press to confirm. -

Page 84: Memory Full, Cannot Send Faxes

The printer has detected a non‑Lexmark supply or part installed in the printer. Your Lexmark printer is designed to function best with genuine Lexmark supplies and parts. Use of third-party supplies or parts may affect the performance, reliability, or life of the printer and its imaging components. -

Page 85: Not Enough Free Space In Flash Memory For Resources [52]

For non‑touch‑screen printer models, press to confirm. For more information, visit http://support.lexmark.com or contact customer support. Reinstall defective or unresponsive cartridge [31.xy] Remove and reinstall the toner cartridge. For more information, see the instruction sheet that came with the supply. -

Page 86: Replace Cartridge, 0 Estimated Pages Remain [88.Xy]

“Replacing supplies” section of the User’s Guide. Note: If you do not have a replacement cartridge, then see the “Ordering supplies” section of the User’s Guide or visit www.lexmark.com. Replace cartridge, printer region mismatch [42.xy] Install a toner cartridge that matches the region number of the printer. -

Page 87: Replace Jammed Originals If Restarting Job

“Replacing supplies” section of the User’s Guide. Note: If you do not have a replacement imaging unit, then see the “Ordering supplies” section of the User’s Guide or visit www.lexmark.com. Replace maintenance kit, 0 estimated pages remain [80.xy] Contact customer support at http://support.lexmark.com... -

Page 88: Replace Unsupported Imaging Unit [32.Xy]

“Replacing supplies” section of the User’s Guide. Note: If you do not have a replacement imaging unit, then see the “Ordering supplies” section of the User’s Guide or visit www.lexmark.com. Restore held jobs? Try one or more of the following: •... -

Page 89: Serial Option [X] Error [54]

7015 Serial option [x] error [54] Try one or more of the following: • Make sure that the serial cable is properly connected and is the correct one for the serial port. • Make sure that the serial interface parameters (protocol, baud, parity, and data bits) are set correctly on the printer and computer. -

Page 90: Supply Needed To Complete Job

7015 Supply needed to complete job Do either of the following: • Install the missing supply to complete the job. • Cancel the current job. Too many flash options installed [58] Turn off the printer. Unplug the power cord from the electrical outlet. Remove the extra flash memory. -

Page 91: User Attendance Messages (0-99.99)

7015 User attendance messages (0–99.99) User attendance messages (0‑99.99) Error code Description Action 31.40 Toner cartridge smart chip error Make sure that the toner cartridge is properly installed. 31.41 Toner cartridge I2C packet timeout Check if the toner cartridge is supported. Replace 31.42 Toner cartridge I2C packet has been sent but code with a supported toner cartridge if necessary. - Page 92 7015 Error code Description Action Media size mismatch (too short or too narrow) Make sure the media size setting matches the paper in the tray. Restore the engine settings to their defaults: Diagnostics Menu > Printer Setup > Defaults Restore the EP setup settings to their defaults: Diagnostics Menu >...

-

Page 93: Toner Cartridge Smart Chip Contact Service Check

7015 Error code Description Action Toner cartridge low Make sure the toner cartridge smart chip contact cable JARW1 is properly connected to the controller board. Make sure the contacts are free of debris. Check the contacts for damaged pins. If damaged, replace the toner cartridge smart chip contact. -

Page 94: Media Size Mismatch Service Check

7015 Media size mismatch service check Action Step 1 Go to step 2. Replace the input tray. Check the input tray for damage. Is it free of damage? Step 2 Go to step 3. Replace the index sensor. See “Index Make sure the index sensor is free of debris. -

Page 95: Printer/Cartridge Mismatch Service Check

7015 Printer/cartridge mismatch service check Action Step 1 Go to step 2. Replace the toner cartridge smart chip Make sure the toner cartridge smart chip contact cable JARW1 is contact. See “Toner properly connected to the controller board. cartridge smart chip Make sure the toner cartridge smart chip contact is free of debris. -

Page 96: Printer Hardware Errors

7015 • “Cartridge gearbox service check” on page 103 • “Tray 1 pick/lift motor gearbox service check” on page 104 • “171.xx Cooling fan service check” on page 104 • “9xx error messages” on page 105 • “System software error service check” on page 108 •... -

Page 97: 1Xx Error Messages

7015 1xx error messages Error code Description Action 111.00 Pel clock check failed. Go to “111.xx LSU service check” on page 100. 111.01 Downlevel ASIC detected. 111.31 Printhead never delivered HSYNCs. 111.32 Printhead lost HSYNCs. 111.40 Wrong printhead installed 111.50 Open-loop printhead error, open-loop sweep state. - Page 98 7015 Error code Description Action 121.07 Fuser has been on for more than allowed after a gap Restore the engine settings to their defaults: blowout, and the temperature is still too cold. Diagnostics Menu > Printer Setup > Defaults 121.08 Fuser was under temp when page was in fuser.

- Page 99 7015 Error code Description Action 132.01 TDS baseline too low. Go to “Toner density sensor service check” on page 101. 132.02 TDS baseline too high. 132.03 TDS baseline excessive range. 132.16 TDS calibration at maximum. 132.17 TDS calibration too low. 132.18 TDS calibration too close to baseline.

-

Page 100: 111.Xx Lsu Service Check

7015 111.xx LSU service check Action Step 1 Go to step 2. Reseat the cables. Check the LSU cables JLSU1 and J6 for proper connection. Are they properly connected? Step 2 Replace the controller Replace the LSU. See board. See “Controller “Laser scanning unit Inspect the LSU cables and connectors. -

Page 101: Lvps Service Check

7015 LVPS service check Action Step 1 Go to step 2. Reseat the cables. Check if the power supply cable is properly connected to the controller board. Is it properly connected? Step 2 Contact your next level Replace the power of support. -

Page 102: Ctls Service Check

7015 CTLS service check Action Step 1 Go to step 2. Clean the CTLS. Check for loose toner blocking the CTLS. Is it free of any loose toner? Step 2 Go to step 3. Reseat the cables. • Check the cable PCN3 for proper connection to the power supply. •... -

Page 103: Acm Service Check

7015 ACM service check Action Step 1 Go to step 2. Replace the pick/lift motor gearbox. See Check the pick/lift motor gearbox for proper operation. “Pick/lift motor POR into the Diagnostics menu and perform a feed test: gearbox removal” on Diagnostics Menu >... -

Page 104: Tray 1 Pick/Lift Motor Gearbox Service Check

7015 Tray 1 pick/lift motor gearbox service check Action Step 1 Go to step 2. Replace the tray insert. Remove Tray 1. Check the lift plate and gears for proper operation by moving the metal plate. Do the lift plate and gears move freely, and are they free of wear or damage? Step 2 Go to step 3. -

Page 105: 9Xx Error Messages

7015 9xx error messages Error code Description Action 900.xx RIP firmware errors Go to “System software error service check” on page 108. 912.xx Unrecoverable Engine firmware error POR the machine. If the error re‑occurs, then update the firmware. If the error continues occurring, then replace the controller board. - Page 106 7015 Error code Description Action 953.xx NVRAM chip failure with mirror part Replace the controller board. Go to “Controller board removal” on page 231. 954.xx NVRAM chip failure with system part 955.xx The Code ROM or NAND flash failed the Cyclic Redundancy Check (CRC) or the NAND experienced an uncorrectible multi-bit failure.

- Page 107 7015 Error code Description Action 959.30 Pensive library flagged an invalid argument(s) Replace the controller board. Go to “Controller board removal” on page 231. 959.31 Pensive library flagged an invalid device address 959.32 Failure to init physical interface 959.33 Unknown/unexpected Error 959.34 System Pensive Bus Busy Error 959.35...

-

Page 108: System Software Error Service Check

Note: Before troubleshooting, determine the operating system used when the error occurred. If possible determine whether a PostScript or PCL file was sent to the device when the error occurred. Ask the customer which Lexmark Solutions applications are installed on the device. - Page 109 7015 Action Step 4 Go to step 5. Go to step 6. Properly connect the cables to the controller board. POR the printer into the Diagnostics menu. Does the error remain during startup? Step 5 Go to step 31. The problem is solved. Replace the controller board.

- Page 110 Send a print job to the printer. Does the error remain? Step 15 Go to step 31. The problem is solved. Install a Lexmark recommended memory option. Send a print job to the printer. Does the error remain? Step 16 Go to step 17.

- Page 111 7015 Action Step 18 Go to step 19. The problem is solved. Upgrade the firmware if it was not upgraded in a previous step. Note: Contact your next level of support for the correct firmware level to use. POR the printer. Send the printer a print job.

-

Page 112: Nvram Mismatch Failure Service Check

7015 Action Step 26 Go to step 27. The problem is solved. Are there any more ISP options to install? Step 27 Go to step 29. Go to step 28. Install the next ISP option. POR the printer. Does the error remain? Step 28 Go to step 29. - Page 113 7015 Replace only one component at a time. Replace the required component and perform a POR before replacing a second component listed above. If this procedure is not followed, the printer will be rendered inoperable. Never replace two or more of the components listed above without a POR after installing each one or the printer will be rendered inoperable.

-

Page 114: Base Printer Symptoms

7015 Base printer symptoms Symptom Action Buttons on the control panel failed to respond Go to “Control panel button service check” on page 117. No Display Go to “Control panel service check” on page 116. Fuser parts melted Go to “LVPS service check”... -

Page 115: Controller Board Service Check

7015 Action Step 5 Go to the controller Replace the LVPS. Go to board service check. Go “Power supply Check the voltages on the LVPS card. “Controller board removal” on page • +5V at pins 17 and 19 service check” on 272. -

Page 116: Control Panel Service Check

7015 Action Step 6 The problem is solved. Go to step 7. Replace the power supply. Did this ix the problem? Step 7 Go to step 9. Go to control panel service check. Go to Is the control panel functioning properly? “Control panel service check”... -

Page 117: Control Panel Button Service Check

Did the device pass the test? Step 3 The problem is solved. Go to step 4. Replace the UICC. Go to “UICC (MX310) removal” on page 252. Did this fix the problem? Step 4 The problem is solved. Contact the next level of support. -

Page 118: Usb Print Service Check

7015 USB print service check Action Step 1 Go to step 2. Go to step 7. Enter Diagnostic mode and perform a print test to make sure the printer prints correctly. Verify that the indicator light is on, then print the Menu Settings Page, navigate to: Reports >... -

Page 119: Front Door Not Closed Service Check

7015 Front door not closed service check Action Step 1 Go to step 2. Go to step 3. Open the the front access cover and inspect the interlock switch actuator. Is the actuator damaged? Step 2 The problem is solved. Go to step 3. Replace the front access cover. -

Page 120: Network Service Check

Have the network administrator verify that the device is using the correct SSID, and wireless security protocols. For more network troubleshooting information, consult the Lexmark Network Setup Guide. Actions Step 1 Go to step 3. - Page 121 7015 Actions Step 10 Go to step 12. Go to step 11. Have the network admin verify that the printer and PC’s IP address have identical subnet addresses. Are the subnet addresses the same? Step 11 The problem is solved. Go to step 12. Using the subnet address supplied by the network administrator, assign a unique IP address to the printer.

-

Page 122: Input Option Hardware Errors

7015 Actions Step 21 The problem is solved. Go to step 22. Replace the antenna. Did this fix the problem? Step 22 Go to step 24. Go to step 23. Verify that the antenna is properly connected to the wireless card. Is it connected correctly? Step 23 The problem is solved. -

Page 123: Option Tray Acm Motor Service

7015 Error code Description Action 325.60 Hardware error—Board ID unknown Go to “Option tray controller card service check” on page 125. 325.61 Hardware error—Option type unknown 325.62 Hardware error—Product ID unknown 325.63 Hardware error—Sensors are not plugged on the board. 331.51 Motor 1 (Pick/Lift) motor no first encoder Go to... -

Page 124: Option Tray Pick/Lift Motor Service Check

7015 Option tray pick/lift motor service check Action Step 1 Go to step 2. Replace the tray insert. Remove the option tray insert. Check the lift plate and gears for proper operation by moving the metal plate. Do the lift plate and gears move freely, and are they free of wear or damage? Step 2 Go to step 3. -

Page 125: Option Tray Acm Motor Service Check

7015 Option tray ACM motor service check Action Step 1 Go to step 2. Reseat the cable. Check the cable J11 on the option tray controller card. Is it properly connected? Step 2 Go to step 3. Replace the ACM assembly. -

Page 126: Adf/Scanner Hardware Errors

7015 ADF/Scanner hardware errors 8xx service error messages Error code Description Action 840.xx Scanner error 840.01 The scanner is disabled and can’t be used. Perform the Scanner disabled service check. Go to “Scanner disabled error service check” on page 127. 840.02 This message is posted when the MFP PORs. -

Page 127: Scanner Disabled Error Service Check

7015 Scanner disabled error service check Actions Step 1 Go to step 2. The problem is solved. POR the machine into Configuration menu > Disable Scanner. From there, select Enabled to change the setting to re-enable the scanner module and then save the setting. -

Page 128: Adf Service Check

7015 Actions Step 7 Go to step 8. The problem is solved. Replace the ADF unit. See “ADF unit removal” on page 316. POR the machine into Configuration menu > Disable Scanner. From there, select Enabled to change the setting to re-enable the scanner module and then save the setting. -

Page 129: Scan/Fax/Copy Symptoms

7015 Action Step 3 Go to step 4. Go to step 8. Enter diagnostics mode and navigate to: SCANNER TESTS >Sensor Test Perform the scanner sensor tests. Navigate to: SCANNER TESTS > Motor Tests Perform the scanner motor tests. Did any test fail? Step 4 Go step 5. -

Page 130: Black Or Blank Page Copy Service Check

7015 Symptom Action No dial tone “Modem/fax card service check” on page 138. Machine dials a number but fails to make a connection with another The other fax machine may be turned off. Ask the fax fax machine. recipient to check their machine. Incoming fax has blank spaces or poor quality. -

Page 131: Ccd Service Check

7015 Actions Step 6 The problem is solved. Go to step 7. Replace the flatbed unit. See “Flatbed assembly removal” on page 328. Did this fix the problem? Step 7 The problem is solved. Consult the next level of support. Replace the controller board. -

Page 132: Flatbed Home Position Service Check

7015 Flatbed home position service check Actions Step 1 The problem is solved. Go to step 2. POR the MFP. Does the CCD move and return to the home position? Step 2 Go to step 3. Go to step 5. Perform the home position sensor test. -

Page 133: Adf Cover Open Service Check

7015 Action Step 3 Go to step 5. Go to step 4. Enter diagnostics mode and navigate to: SCANNER TESTS > Sensor Test Select Paper FB Long to perform the sensor test. Did it pass? Step 4 The problem is solved. Go to step 5. Replace the flatbed. -

Page 134: Adf Streak Service Check

7015 Actions Step 6 Go to step 7. Go to step 8. Remove the ADF rear cover and inspect the ADF cover closed sensor for dirt and debris. Is there dirt and debris present? Step 7 The problem is solved. Go to step 8. Clean the dirt and debris from the sensor. - Page 135 7015 Actions Step 1 Clean them with a lint Replace the separator free cloth and isopropyl pad and restraint pad. If the ADF is multi-feeding or shingle feeding, then check for dirt on the alcohol. ADF separator pad, restraint pad, and ADF separator rollers. Are they dirty? Step 2 Go to step 3.

-

Page 136: Adf Feed Errors Service Check

7015 Actions Step 10 Clean the sensors, or Go to step 8. remove debris from the Is there dirt in the sensors, or is the paper present actuator stuck? actuators. Step 11 Replace the ADF. Go to step 9. Are the sensor actuators on the ADF mechanism cover damaged? Step 12 Go to step 10. -

Page 137: Adf Duplex Service Check

7015 Actions Step 5 Go to step 6. Go to step 8. Perform the ADF pick motor and ADF feed motor tests. Are the motors working properly? Step 6 Go to step 7. Go to step 8. Perform the ADF paper present sensor test. See “Scanner tests”... -

Page 138: Modem/Fax Card Service Check

7015 Actions Step 1 Go to step 2. Go to step 4. Perform the ADF motor tests to verify that the motors are working properly. See “Motor tests” on page 169. Are the motors operating properly? Step 2 Go to step 3. Go to step 4. -

Page 139: Fax Reception Service Check

7015 Actions Step 1 Go to step 2. Go to step 3. Is the phone line properly connected to the modem card and the wall jack? Step 2 Problem resolved. Go to step 3. Properly connect the phone line to the modem card and wall jack. Did this fix the problem? Step 3 Go to step 5. - Page 140 7015 Actions Step 1 Go to step 2. Go to step 3. Is the phone line properly connected to the modem card and the wall jack? Step 2 The problem is solved. Go to step 3. Properly connect the phone line to the modem card and wall jack. Did this fix the problem? Step 3 Go to step 5.

-

Page 141: Fax Transmission Service Check

7015 Actions Step 14 The problem is solved. Go to step 15. Press **411 to enter the Fax/SE Menu. Select “Print Logs”. Print the T30 transmission log. Check the error being reported with the fax error code table. See “Fax error log codes” on page 143. - Page 142 7015 Actions Step 6 The problem is solved. Go to step 7. Use the MFP on a properly functioning phone jack. Did this fix the problem? Step 7 Go to step 9. Go to step 8. In <diags / config menu>, verify that the Enable Fax Receive setting is on. Is the setting set to on? Step 8 The problem is solved.

-

Page 143: Fax Error Log Codes

7015 Actions Step 17 Go to step 18. Go to step 19. Go to the Administrator menu. Enter the Fax settings - Analog Fax Settings submenu. Verify the remote device number is not in the Banned Fax List user setting. Is the remote device number in the banned fax list? Step 18 The problem is solved. - Page 144 7015 Error code Description Action Error occurred when sending image data. • Check line quality. • Adjust ‘Transmit Level’. • Select a lower ‘Max Speed’ value under Fax Receive settings. Received unknown response from remote fax No action needed. Issue is with the other device.

- Page 145 7015 Error code Description Action Received too many requests from remote end • Check line quality. to repeat the previous command sent. • Adjust ‘Transmit Level’. • Check if line conditions on remote end will facilitate a good connection. Functional limitation-Remote fax device does No action needed.

- Page 146 7015 Error code Description Action Failure to transmit training successfully in V29, • Select a lower “Max Speed” under Fax V27 terminal modulation schemes. Send settings. • Adjust the “Transmit Level”. • Check line quality. Failure to transmit training successfully in V17 •...

-

Page 147: Escalating A Fax Issue To Second-Level Support

7015 Error code Description Action Modem detected a digital line connection. Verify the MFP is connected to an analog line. “Fax transmission service check” on page 141. Phone line was disconnected Restore phone line connection. Received request for unsupported function No action needed. - Page 148 7015 Fill in the requested information. This is where you will type in the information you retrieved in step 3. Second-level support can assist you if you have questions about the information requested on the page. Note: The fields requesting the code levels, model number, type of problem are auto‑filled. If the information is not in the fields, it can be retrieved from the SE menu.

-

Page 149: Service Menus

7015 Service menus Understanding the control panel and menus (MX310dn) Using the printer control panel Use the Display • View the printer status and messages. • Set up and operate the printer. Arrow buttons Scroll up and down or left and right. Select button •... -

Page 150: Understanding The Colors Of The Indicator And Sleep Button Lights

7015 Understanding the colors of the indicator and Sleep button lights The colors of the indicator and Sleep button lights on the printer control panel signify a certain printer status or condition. Indicator light color and its corresponding printer status Indicator light Printer status The printer is off or in Hibernate mode. -

Page 151: Understanding The Colors Of The Indicator And Sleep Button Lights

7015 Use the Keypad Enter numbers, letters, or symbols. Sleep button Enable Sleep mode or Hibernate mode. Do one of the following to wake the printer from Sleep mode: • Press any hard button. • Open a door or cover. •... - Page 152 7015 Touch Copy Access the Copy menus and make copies. Access the Fax menus and send faxes. E‑mail Access the E-mail menus and send e‑mails. Access the File Transfer Protocol (FTP) menus and scan documents directly to an FTP server. Menu icon Access printer menus.

-

Page 153: Using The Touch-Screen Buttons

7015 Feature Description Printer IP address The IP address of your printer is located at the top left corner of the home screen and appears as four sets of numbers separated by periods. You can use the IP address Example: 123.123.123.123 when accessing the Embedded Web Server to view and remotely configure printer settings even when you are not physically near the printer. -

Page 154: Menus List

7015 Touch Scroll to the right. Menus list Paper Menu Reports Network/Ports Security Settings Default Source Menu Settings Page Active NIC Confidential Print General Settings Paper Size/Type Device Statistics Copy Settings Standard Network Disk Wiping Configure MP Fax Settings Network Setup Page Security Audit Log Standard USB Substitute Size... -

Page 155: Diagnostics Menu

7015 Diagnostics menu The Diagnostics menu group contains the settings and operations used while manufacturing and servicing the printer. Entering the Diagnostics menu Turn off the printer. Press and hold 3 and 6. Turn on the printer. Release the buttons when the splash screen appears. Registration **These topic is still under construction. -

Page 156: Registration

7015 This test should not be performed unless it is on a replacement scanner. To reset a scanner calibration value, do the following: Navigate to Diagnostics > Scanner Calibration, and touch Scanner Calibration. Select the value to reset (Flatbed, ADF Front, ADF Rear) by touching the selection. A screen warning displays. -

Page 157: Hardware Tests

7015 HARDWARE TESTS If the hardware test fails, replace the failing part. Panel Test This test verifies the control panel display function. To run the Panel test: From the Diagnostics menu, navigate to: Hardware Tests > Panel Test Press X to exit the test. Button Test This test verifies the control panel button function except for the Sleep button. -

Page 158: Serial Wrap Test

7015 To run the DRAM test: From the Diagnostics menu, navigate to: Hardware Tests > DRAM Test Testing… appears, followed by Resetting the Printer. After the printer resets, the results of the test appear: DRAM Test [x] P:###### F:######. • [x]—Represents the size of the installed DRAM. -

Page 159: Duplex Tests

7015 CTS Error CTS PIO Error CTS Interrupt Error After the maximum count is reached or a failure occurs, the test stops. Press Stop (X) to cancel the test. USB HS Test Mode From the Diagnostics menu, navigate to: Hardware Tests > USB HS Test Mode Choose the desired port, and then choose the desired test. -

Page 160: Duplex Tests

7015 • Horizontal lines for skew adjustment • General printer information, including current page count, installed memory, processor speed, serial number, engine ID, and controller board ID Check the Quick test page for the correct offset between the placement of the first scan line on the front and back side of a duplexed sheet. -

Page 161: Input Tray Tests

7015 To run this test: From the Diagnostics menu, navigate to: Duplex Tests > Sensor Test Testing… appears while the printer is verifying the state of the sensor. The control panel displays the current state of the sensor. Manually actuate the sensor to make it toggle between Open and Closed. If the sensor does not toggle, then it is malfunctioning. -

Page 162: Output Bin Tests

7015 Sensor Test Use this test to determine if the input tray sensors are working correctly. From the Diagnostics menu, navigate to: Input Tray Tests > Sensor Test Select the input source. All installed sources appear. Not all sensors appear for all trays. The following table indicates which tray sensors are available for each input source: Input source Tray empty sensor Pass through sensor... -

Page 163: Base Sensor Test

7015 Press X to exit the test. BASE SENSOR TEST Use the Base Sensor Test to determine that the sensors located inside the printer are operating correctly. The following sensors can be checked using this test: • Narrow Media • Input •... -

Page 164: Printer Setup

7015 Disk Test/Clean Warning—Potential Damage: This test destroys all data on the disk and should not be attempted on a good disk. This test may run approximately 1.5 hours, depending on the disk size. Note: This test is available only for the MX410, MX510, and MX511. From the Diagnostics menu, navigate to: DEVICE TESTS >... -

Page 165: Printed Page Count

7015 Printer default values US value Non-US value Paper Sizes setting in the General Settings menu U.S. Metric Default Paper Size (paper feeding sources which do not Letter have hardware size sensing capabilities) Default Envelope Size (envelope feeding sources which do 10 Envelope DL Envelope not have hardware size sensing capability) -

Page 166: Ep Setup

7015 EP SETUP EP Defaults This setting restores each printer setting listed in EP SETUP to its factory default value. Sometimes this is used to help correct print quality problems. To restore the EP defaults: From the Diagnostics menu, navigate to: EP Setup >... -

Page 167: Ep Setup

7015 To adjust this setting: From the Diagnostics menu, navigate to: EP Setup > Charge Roll Press OK or touch to save any changes. Gap Adjust The setting adjusts the minimum gap between sheets. Increasing this value may reduce curl of some printed media and eliminate some output bin stacking problems. -

Page 168: Reports

7015 REPORTS Menu Settings Page This setting prints the Menu Settings Page. The report prints the Diagnostics Menu settings and their current values. EVENT LOG Display Log This version of the Event log displays the panel text that appeared when the event occurred. To view the Event log: From the Diagnostics menu, navigate to: Event Log >... -

Page 169: Event Log

7015 To clear the event log: From the Diagnostics menu, navigate to: Event Log > Clear Log Choose any of the following: • Yes—To clear the Event log • No—To exit the Clear log menu Scanner tests • “ASIC test” on page 169 •... -

Page 170: Scanner Tests

7015 To perform this test, do the following: Navigate to Scanner Tests >Motor Tests. Select Flatbed Scanner Motor. The test will run. ADF feed motor forward When Motor On is selected, the device runs the motor forward continuously until Motor Off is selected. To perform this test, do the following: Navigate to Scanner Tests >Motor Tests. -

Page 171: Scanner Tests

7015 • Scan 1st sensor (paper feed sensor) • Paper FB long To test a flatbed or ADF sensor, perform the following steps: Navigate to Scanner Tests > Sensor Tests > <sensor to test>. The following is displayed: Select the sensor to be tested. Actuate the sensor you selected. - Page 172 7015 ADF cover open Flatbed cover open Paperfeed sensor Service menus...

-

Page 173: Exit Diags

7015 Scanner calibration reset This is test is run to reset the scanner calibration. This test should only be run after a flatbed or ADF unit has been replaced. To perform this operation, do the following: Navigate to Scanner Tests. Select Scanner Calibration Reset. -

Page 174: Configuration Menu

7015 Configuration menu The Configuration menu group consists of menus, settings, and operations that are used to configure a printer for operation. Entering the Configuration menu The Configuration Menu group contains a set of menus, settings, and operations which are infrequently required by a user. -

Page 175: Print Quality Pages

7015 Once initiated, the operation cannot be canceled. Print Quality Pages This option is a limited version of the Print quality pages setting that appears in the Diagnostics menu. See “Print Quality Pages” on page 156. This setting reports the values of a broad range of printer settings and tests the ability of the printer to generate acceptable printed output. -

Page 176: Ppds Emulation

7015 PPDS Emulation The value of this option determines if a printer can recognize and use the PPDS data stream. Available options: • Deactivate • Activate Download Emuls This appears only if at least one download emulator (DLE) is installed. The default setting is Disable. All download emulators (DLEs) are reenabled automatically after two PORs. -

Page 177: Fax Low Power Support

7015 To change the setting: From the Configuration menu, navigate to Energy Conserve. Select On or Off. If On (default), then the Sleep Mode cannot be turned off. If Off, then Disabled appears on the Sleep Mode menu, and it can be turned off. Fax low power support Fax Low Power support allows you to select one of three power settings for the fax. -

Page 178: Adf Edge Erase

7015 To change this setting: Select Format Fax Storage from the Configuration Menu. Note: If an advanced password has been established, then you must enter this password to change the setting. If no advanced password exists, then you can establish one by using the keyboard that appears on the LCD. Select Submit to save the change. -

Page 179: Disable Scanner

7015 Use the plus to increase or the minus to decrease the settings value for horizontal adjust and top margin. Note: Each button press moves the margin values one pixel in the respective direction. Select Submit to accept the value. Save changes by placing the print quick test page face up and selecting Copy Quick Test. -

Page 180: Paper Prompts

7015 Paper Prompts This controls which tray a change prompt is directed to when paper is sensed to be the wrong size. Note: The value of “Action for Prompts” on page 180 may override the value of this setting. To change this setting: From the Configuration menu, navigate to Paper Prompts. -

Page 181: Jobs On Disk

7015 To change this setting: From the Configuration menu, navigate to Action for Prompts. Select from the available options to change the setting. • Prompt User (default) • Continue • Use Current Depending on the printer model, press OK or touch to save the setting, or press X to return to the Configuration menu without saving any changes. -

Page 182: Erase All Information On Disk

7015 Erase All Information on Disk Note: This setting is available on the MS610de model only. This setting performs a wipe of the printer hard disk, erasing all data. Warning—Potential Damage: This deletes all data on the printer hard disk, including downloaded fonts, macros, and held jobs. -

Page 183: A5 Loading

LES Applications Note: This setting is for touchscreen models only. This menu setting is used to enable or disable Lexmark Embedded Solutions (LES) applications. To change the settings, perform the following steps: From the Configuration menu, navigate to LES applications. -

Page 184: Key Repeat Initial Delay

7015 Touch Submit. Press Back to return to the Configuration menu. Key Repeat Initial Delay Note: This setting is available on the MS610de model only. This setting determines the length of delay before a repeating key starts repeating. The range is 0.25–5 seconds, with increments of 0.25. -

Page 185: Usb Speed

7015 USB Speed This setting is used to set the throughput of the USB port on the printer. Available options: • Auto • Full—Forces the USB port to run at full speed and also disables its high‑speed capabilities. Automatically Display Error Screens If On, the panel automatically displays any existing printer-related IR after the printer remains inactive on the home screen for a length of time equal to the Screen timeout setting in the Timeouts section of the General settings menu. -

Page 186: Entering Recovery Mode

7015 Entering recovery mode This mode will allow the printer to boot from a secondary set of instructions to allow a code flash to the printer. Code can be flashed from a PC via USB. Turn off the printer. Press and hold the 7, 2, and 8 buttons simultaneously. Turn on the printer. -

Page 187: Fax Service Engineer (Se) Menu

7015 Top level menu Intermediate menu NVRAM • Dump NVRAM • Reinit NVRAM TCP/IP • netstat‑r • arp‑a • Allow SNMP Set • • Meditech Mode • RAW LPR Mode • Gather Debug • Enable Debug Fax service engineer (SE) menu The Fax SE menu is used for the Fax transmission service check and the Fax reception service check. - Page 188 7015...

-

Page 189: Repair Information

7015 Repair information • “Removal precautions” on page 189 • “Removal procedures” on page 209 • “Left side removals” on page 209 • “Right side removals” on page 226 • “Front removals” on page 240 • “Bottom removals” on page 272 •... -

Page 190: Handling Esd-Sensitive Parts

7015 • controller board • optional hard drives Note: The printer control panel and controller board contain NVRAM. After removing the old part, it must be returned to your next level of support. Handling ESD‑sensitive parts Many electronic products use parts that are known to be sensitive to electrostatic discharge (ESD). To prevent damage to ESD-sensitive parts, use the following instructions in addition to all the usual precautions, such as turning off power before removing logic boards: •... -

Page 191: Esf Solutions Backup

7015 After the printer has completed startup, turn off the printer and replace the operator panel. Note: If the operator panel display has failed, the printers’ startup cycle is complete when the driver motor and fans shut down, and the machine is quiet. After installing the new operator panel, start the printer into diagnostics mode, and allow the printer to go through a complete startup cycle and the display to go to Ready. -

Page 192: Ribbon Cable Connectors

7015 Ribbon cable connectors Zero Insertion Force (ZIF) connectors Zero Insertion Force (ZIF) connectors are used on the boards and cards used in this printer. Before inserting or removing a cable from these connectors, read this entire section. Great care must be taken to avoid damaging the connector or cable when inserting or removing the cable. -

Page 193: Horizontal Top Contact Connector

7015 Horizontal top contact connector This FRU contains a horizontal top contact cable connector. Read the instructions before proceeding. The horizontal top contact connector uses a back flip locking actuator to lock the ribbon cable into the Zero Insertion Force (ZIF) connector. The cable is inserted horizontally into the connector. Warning—Potential Damage: When opening or closing this type of actuator, gently lift or close the two tabs located on each end of the actuator. - Page 194 7015 Inserting a cable into the horizontal top contact connector When installing the cable, check the locking actuator to ensure it is in the unlocked position. The tabs on the ends of the actuator are vertical when the actuator is unlocked. Insert the cable with the contacts on the cable facing up.

- Page 195 7015 Rotate the locking actuator to the locked position. The cable should not move while this step is performed. If the cable moves, open the actuator, reposition the cable, and then close the actuator to the down position. Repair information...

-

Page 196: Horizontal Bottom Contact Connector

7015 Horizontal bottom contact connector This FRU contains a horizontal bottom contact cable connector. Read the instructions before proceeding. The horizontal bottom contact connector uses a flip locking actuator to lock the ribbon cable into the Zero Insertion Force (ZIF) connector. The cable is inserted horizontally into the connector. Warning—Potential Damage: When opening or closing this type of actuator, gently lift the center of the actuator using your finger. - Page 197 7015 Inserting a cable into the horizontal bottom contact connector Check the actuator to verify it is in the open position. Insert the cable into the ZIF connector with the contacts facing downward and away from the locking actuator. The cable needs to be inserted below the actuator.

- Page 198 7015 Place your finger in the middle of the actuator, and then rotate the locking actuator to the locked position. Repair information...

-

Page 199: Vertical Mount Contact Connector

7015 Vertical mount contact connector This FRU contains a vertical mount contact connector. Read the instructions before proceeding. The vertical mount contact connector uses a back flip locking actuator to lock the ribbon cable into the Zero Insertion Force (ZIF) connector. The cable is inserted vertically into the connector. Warning—Potential Damage: When opening or closing this type of actuator, gently lift the center of the actuator using your finger. - Page 200 7015 Inserting a cable into the vertical mount contact connector When installing the cable, check the locking actuator to verify it is in the open position. Insert the cable with the contacts on the cable away from the locking actuator. Insert the cable on top of the actuator. Note: Verify that the cable is installed squarely into the connector.

- Page 201 7015 Rotate the locking actuator to the locked position by pressing down on both ends of the actuator. The cable should not move when this step is performed. If the cable moves, open the actuator, reposition the cable, and then close the actuator to the down position.

-

Page 202: Horizontal Sliding Contact Connector

7015 Horizontal sliding contact connector This FRU contains a horizontal sliding contact connector. Read the instructions before proceeding. The horizontal sliding contact connector uses a slide locking actuator to lock the ribbon cable into the Zero Insertion Force (ZIF) connector. The cable is inserted horizontally into the connector. Warning—Potential Damage: When opening or closing this type of actuator, gently push or pull the two tabs located on each end of the actuator. - Page 203 7015 Inserting a cable into the horizontal sliding contact connector When installing the cable, check the locking actuator to verify it is in the open position. If you are opening the connector, pull back on both end tabs using equal force to avoid breaking the connector. Insert the cable with the contacts on the cable facing away from the locking actuator.

- Page 204 7015 Slide the locking actuator towards the connector, locking the cable into place. The cable should not move when this step is performed. If the cable moves, open the actuator, reposition the cable, and then close the actuator to the down position. Repair information...

-

Page 205: Low Insertion Force (Lif) Connector

7015 Low Insertion Force (LIF) connector This FRU contains a Low Insertion Force (LIF) connector. Read the instructions before proceeding. Warning—Potential Damage: When installing a cable into an LIF connector, care must be taken to avoid bending the edges of the cables and damaging the contacts on the cables. Inserting a cable into the LIF connector Looking at the connector, take note on which side the contacts are located. -

Page 206: Printhead Assembly Adjustments

7015 Printhead assembly adjustments Printhead assembly mechanical adjustment A printhead needs to be correctly positioned after it has been removed. Use a pencil to mark the screw locations of the old printhead on the metal frame. Align the new printhead relative to the location of the old printhead. Note: Skew is caused by a sheet being fed through the printer while misaligned. - Page 207 7015 If the grid lines of the right flap align below the corresponding lines on the left flap, then adjust the printhead clockwise relative to the printer, and recheck. If the grid lines of the left flap align below the corresponding lines of the right side, then adjust the printhead counterclockwise.

- Page 208 7015 Sample Quick test page. Use the actual sheet. From the Registration menu, select the Right margin setting: Diagnostics Menu > Registration > Right Margin To determine the Right margin setting: Choose the value of the darkest bar on the right side of the Quick test page. Add that value to the current Right margin setting found on the left side of the Quick test page.

-

Page 209: Removal Procedures

7015 Removal procedures Keep the following tips in mind as you replace parts: • Some removal procedures require removing cable ties. You must replace cable ties during reassembly to avoid pinching wires, obstructing the paper path, or restricting mechanical movement. •... - Page 210 7015 Release the two tabs (B) on the bottom of the cover. Pull the cover forward, and remove it from the printer. Repair information...

-

Page 211: Main Drive Gearbox Removal

7015 Main drive gearbox removal Remove the left cover. See “Left cover removal” on page 209. Squeeze the latch, and then detach the link from the front door. Repair information... - Page 212 7015 Remove the 4 screws (A), and then remove the main drive gearbox. Disconnect the cable from the main drive gearbox. Repair information...

-

Page 213: Mpf Solenoid Removal

7015 Remove the spring (B) and the fuser gear (C). MPF solenoid removal Remove the left cover. See “Left cover removal” on page 209. Remove the main drive gearbox. See “Main drive gearbox removal” on page 211. Disconnect the MPF solenoid cable from the controller board. Remove the screw (A). - Page 214 7015 Cut the cable (B). Remove the other half of the cable from the printer. Installation notes: Install the MPF solenoid. Secure the cable to the holder (A). Repair information...

-

Page 215: Mpf Gearbox Removal

7015 Insert the cable into the hole (B). Route the cable using the new path, and secure it with a cable tie (C). MPF gearbox removal Remove the left cover. See “Left cover removal” on page 209. Remove the main drive gearbox. See “Main drive gearbox removal”... - Page 216 7015 Disconnect the spring from the printer (A). Remove the three screws (B), and then remove the front left mount. Repair information...

- Page 217 7015 Remove the three screws (C), and then remove the MPF gearbox. Release the two latches (D), and then remove the main input drive gears. Repair information...

-

Page 218: Reverse Solenoid Removal

7015 Remove the E-clip (E), and then remove the MPF sector gear (F). Reverse solenoid removal Remove the right cover. See “Right cover removal” on page 226. Remove the left cover. See “Left cover removal” on page 209. Remove the rear door and cover. See “Rear exit door removal”... -

Page 219: Acm Clutch Removal (Mx310, Mx410)

7015 Remove the two screws (A) securing the reverse solenoid. ACM clutch removal (MX310, MX410) Remove the left cover. See “Left cover removal” on page 209. Remove the main drive gearbox. See “Main drive gearbox removal” on page 211. Position the printer on its rear. - Page 220 7015 While blocking the roller, remove the screw (B). Pull out the ACM clutch, and cut cable close to the clutch to detach it. Installation notes: Pull the cable to remove any slack, and remove any shrink tubing holding the wires together. Repair information...

- Page 221 7015 On the replacement clutch, measure 4 inches from the clutch, and then cut the cable. Pull out the shaft. Install the replacement clutch on the shaft. Insert the red wire from the printer into the insulated displacement connector (IDC). Note: Make sure that the wire is positioned under the contact element.

- Page 222 7015 Insert the red wire from the clutch into the IDC. Note: Make sure that the wire is positioned under the contact element. Repair information...

- Page 223 7015 Squeeze the IDC to partially lock the wires in place, and then use a pair of pliers to crimp the IDC. Repeat steps e–g for the black wire. Tuck the IDCs securely above the duplex. Note: If needed, use a cable tie to secure the cable in place. Make sure cable tie does not obstruct the paper path.

-

Page 224: Cartridge Gearbox Removal

7015 Cartridge gearbox removal Remove the left cover. See “Left cover removal” on page 209. Remove the four screws (A) securing the cartridge gearbox. Disconnect the cable from the cartridge gearbox. Duplex gear assembly removal Remove the left cover. See “Left cover removal”... - Page 225 7015 Remove the three gears. From behind the three gears, remove the duplex coupling (D). Repair information...

-

Page 226: Right Side Removals

7015 Remove the duplex link (E) from the duplex. Right side removals Right cover removal Remove the paper tray. Remove the screw (A) securing the the right cover to the front of the printer frame. Repair information... - Page 227 7015 Open the memory access cover. Remove the two screws (B) securing the right cover to the RIP shield. Open the front cover. Repair information...

- Page 228 7015 Slightly lift the printer, slide the right cover forward, and pull out and away from the printer. Repair information...

-

Page 229: Memory Access Door Removal

7015 Memory access door removal Open the memory access door. Gently release the latches (A) securing the access door to the right cover. Slide the access door to release the hinges, then remove it from the right cover. Tray present sensor removal Remove the right cover. -

Page 230: Cooling Fan Removal

7015 Pry to remove the sensor retainer (B). Note: The retainer is secured to the sensor by an adhesive. Release the three latches (C), and then pry to remove the tray present sensor. Cooling fan removal Remove the right cover. See “Right cover removal”... -

Page 231: Controller Board Removal

7015 Remove the two screws (A), and then remove the fan. Controller board removal Remove the right cover. See “Right cover removal” on page 226. Remove the controller board shield. See “Controller board shield removal” on page 234. Disconnect all cables from the controller board. Installation warning: The cables (JCART1 and JLIFT) are not interchangeable. - Page 232 7015 Remove the screw (A) from the rear side of the printer. Repair information...

- Page 233 7015 Remove the seven screws (B) securing the controller board. Installation note: After the new controller board is installed, perform scanner manual registration, see “Scanner manual registration” on page 178 and printhead registration, see “Printhead assembly adjustments” on page 206. Repair information...

-

Page 234: Controller Board Shield Removal

7015 Controller board shield removal Remove the right cover. See “Right cover removal” on page 226. Remove the two screws (A). Repair information... - Page 235 7015 Remove the screw (B) securing the shield to the printer. Remove the screw (C) securing the shield to the printer. Repair information...

-

Page 236: Upper Shield Removal