Exmark Ultra VAC QDS Operator's & Parts Manual

Hide thumbs

Also See for Ultra VAC QDS:

- Operator's manual (32 pages) ,

- Operator's manual (24 pages) ,

- Operator's manual (28 pages)

Table of Contents

Advertisement

Quick Links

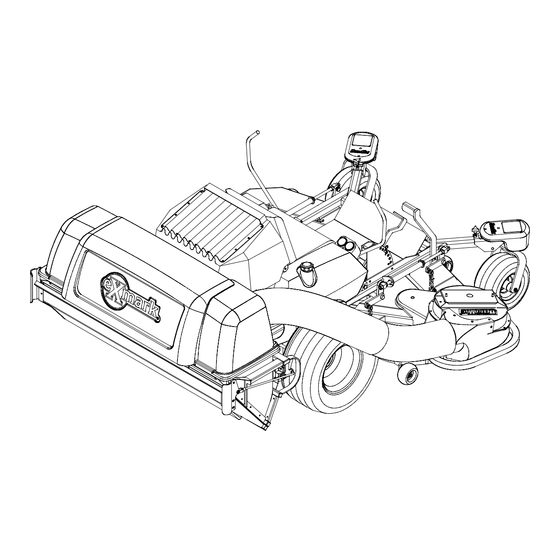

on the purchase of your new Exmark equipment. This product has been carefully designed and

manufactured to give you a maximum amount of dependability and years of trouble-free operation. If additional information

is needed, or should you require trained mechanic service, contact your authorized Exmark equipment dealer or distributor.

If you need to order replacement parts from your dealer, always give the model number and serial number of your equipment

as well as the part number, description and quantity of the part needed.

The Serial No. plate is located on the rear of the blower assembly. For ease of ordering and reference, we suggest that you

record the information requested in the following identification table.

Place Model No. and Serial No. Label Here

(Included in Literature Pack)

or Fill in Below

Model No.

Serial No.

M FG . C O . IN C.

TM

For Serial Nos.

370,000 & Higher

®

Advertisement

Table of Contents

Summary of Contents for Exmark Ultra VAC QDS

- Page 1 If additional information is needed, or should you require trained mechanic service, contact your authorized Exmark equipment dealer or distributor. If you need to order replacement parts from your dealer, always give the model number and serial number of your equipment as well as the part number, description and quantity of the part needed.

- Page 2 ♦ Keep off mower unless seat platform is provided. ♦ Keep others off mower. Exmark reserves the right to make changes or add improvements to its products at any time without incurring any obligation to make such changes to products manufactured previously. Exmark, or its distributors and dealers, accept no responsibility for variations which may be evident in the actual specifications of its products and the statements and descriptions contained in this publication.

- Page 3 (6) line items or less. If order is received by 3:00 p.m. central time, Exmark ships part(s) direct to dealer or customer, as requested by distributor, same day, overnight UPS Exmark bills the distributor for parts and shipping charges, where applicable.

- Page 4 If additional information is needed, or should you require trained mechanic service, contact your authorized Exmark equipment dealer or distributor. All Exmark equipment dealers and distributors are kept informed of the latest methods of servicing and are equipped to provide prompt and efficient service in the field or at their service stations.

-

Page 5: Table Of Contents

TABLE OF CONTENTS Description Page 1. Safety Safety Alert Symbol ................6 Training....................6 Preparation ..................... 6 Safety Signs.................... 7 2. Assembly Instructions Assembly Diagram................8-9 Install Hood Assembly and Bags ............9-11 Install Blower Assembly..............11-13 Assemble Tubes ................... 13 Install Weight Plates ................13-14 Install Removable Weights .............. -

Page 6: Safety

MAY result in minor or moderate injury. 1.2 TRAINING 1.2.1 Regard the Exmark Ultra Vac QDS as a piece of power equipment and teach this regard to all who operate this unit. 1.2.2 Before operating your Ultra Vac QDS, carefully read and understand this manual and the operator’s manual for your mower in their entirety. -

Page 7: Safety Signs

Apply only to a clean, dry surface. Smooth to remove any air bubbles. 1.4.6 Familiarize yourself with the following safety signs and instruction labels. They are critical to the safe operation of your Exmark Ultra Vac QDS. PART NO. 103-3507 LOCATION: Top of Blower PART NO. -

Page 8: Assembly Instructions

2. ASSEMBLY INSTRUCTIONS – LAZER Z & LAZER Z XP 2.1 ASSEMBLY DIAGRAM Ref . No. Description Qty (60 / 72 LZ) Qty (60 / 72 XP) Hopper Assembly Upper Tube Lower Tube #10-24 X .75 Screw 3 / 6 3 / 6 #10-24 Nyloc Nut 3 / 6... -

Page 9: Install Hood Assembly And Bags

Lazer Z units only (Lazer Z XP units skip to section 2.2.7) 2.2.1 When installing the Ultra Vac QDS onto a liquid cooled Lazer Z, the rear bumper plate must be removed. Remove rear bumper plate. Use two of the original screws, washers and whizlock nuts to attach the lower side bumper bars to the vertical “HOT”... - Page 10 2.2.3 On units with serial numbers 190,000 and higher install the mount weldment (Item 9) loosely to the rear of the machine using the two screws and nuts removed in section 2.2.2. For units with serial numbers 189,999 and below, install washers (Item 31) between the bagger mount weldment and clutch guard when installing the bagger mount weldment.

-

Page 11: Install Blower Assembly

2.2.6 Install the right and left hand frame brackets (Items 14 and 15) loosely to the mount weldment and the wheel channels of the Lazer Z frame. The flanges on the right and left hand frame brackets should face in towards the unit to provide the maximum tire clearance. - Page 12 (Item 21) and hairpin (Item 22) may be stored in the pivot holes on the discharge chute during bagging operation. 2.3.9 Install the belt cover mounting stud (Item 27) included in the Ultra Vac QDS completing kit. For 60 inch units only, install the spacer (Item 29), two 7/16 spring disk washers (Item 30) and the plastic knob as shown in Figure 3.

-

Page 13: Assemble Tubes

FIGURE 4 2.3.13 Mount the blower on the deck by sliding the mounting pin into the tube at the rear right corner of the deck. Swing the blower closed. Adjust the position of the front pin to engage the slot in the front of the deck. Use the latch to lock the blower in this position. Adjust the tension on the latch to draw the blower up to the deck, yet allow for release by hand. -

Page 14: Install Removable Weights

INSTALLATION 2.7 Adjustments: Your Ultra Vac QDS was adjusted at the factory to operate properly. However, there are three basic adjustments that can be made, should your unit require them: 2.7.1 Door closing: The closing of the door is controlled by the two hinge links (Figure 7 –... -

Page 15: Operation

2.7.2 Door opening: After adjusting the hinge links for door closing, the handle link (Figure 7 – C) can be adjusted to obtain maximum door opening. Lengthen the link to open the door farther. Shorten the link to open the door less. The maximum door opening is limited by the contacting arm hitting the stop (Figure 7 –... -

Page 16: Pre-Start

3.2 MOWING 3.2.1 The Ultra Vac QDS blower operates when deck drive is engaged. Be sure that all persons are clear of the mower deck before engaging the cutting blades. Set the throttle to “midway” position. Pull outward on the PTO switch to the “ROTATE” position. - Page 17 Note: The portions of the Ultra Vac QDS bagger that are not bolted to the mower are designed to be installed or removed in their entirety. Do not operate the mower...

-

Page 18: Transporting

CAUTION POTENTIAL HAZARD ♦ Caster weights installed without bagger may cause Loss of Traction and Steering control. WHAT CAN HAPPEN ♦ Loss of control can result in an accident, which may cause Death, Injury, or property damage. HOW TO AVOID THE HAZARD ♦... -

Page 19: Maintenance

4. MAINTENANCE: 4.1 ADJUSTMENTS Your Ultra Vac QDS was adjusted at the factory to operate properly. However, there are three basic adjustments that can be made, should your unit require them: Door closing: The closing of the door is controlled by the two hinge links (Figure 7 – A) and the two stop screws (Figure 7 –... -

Page 20: Specifications

Inspect the cloth mesh for wear, tears, or damage. WARNING POTENTIAL HAZARD ♦ Under normal use the cloth mesh will deteriorate and wear. Objects could exit through worn cloth mesh at high speeds. WHAT CAN HAPPEN ♦ Thrown objects can cause serious injury or kill you or bystanders. -

Page 21: Dimensions

5.2 DIMENSIONS 1 Overall unit length w/ Ultra Vac QDS Lazer Z XP 60" Deck 107.90" (274.1 cm) 72" Deck 112.00" (284.5 cm) Lazer Z - Air Cooled 60" Deck 106.65" (270.9 cm) 72" Deck 110.75" (281.3 cm) Lazer Z - Liquid Cooled 60"... -

Page 22: Parts Lists

6.1 DECALS Ref. Qty. Part No. Description Req'd. 103-3302 Decal, Ultra Vac QDS………….1 103-3507 Decal, Warning LZUV…….……1 103-0438 Decal, Exmark 60 & 72 ..…. 1 1-653558 Decal, Hot Sheave……………..1 103-0878 Decal, Caster Weights..…. 1 98-5954 Decal, Missing Cover ..…. 1... -

Page 23: Hitch Kit Assembly

6.2 HITCH and HANDLE ASSEMBLY – LAZER Z 60 & 72 and LAZER Z XP 60 & 72 Ref. Qty. Ref. Qty. Part No. Description Req'd. Part No. Description Req'd. 103-2738 Asm,handle w/grip ....1 98-5975 Washer,spring disc (LZ) ...12 103-3005 Grip,handle ...... -

Page 24: Blower Assembly

6.3 HOOD AND BAG ASSEMBLY – LAZER Z 60 & 72 and LAZER Z XP 60 & 72... - Page 25 Screw,HH ¼-20 x 3/4 .....22 3290-357 Nut,HHF 3/8-16 ..... 12 103-2412-03 Wld,intermediate link ....1 3296-42 Nut,Nyloc ¼-20 .......2 114439 Rivet,Pop 3/16 x 1/2 ....23 103-2365 Link,Hinge .......2 1-808285 Pin,Clevis........2 103-2434-03 Wld,Upright ......1 1-806003 Pin,Hair........2 Includes items 2 – 11 and large Exmark decal...

- Page 26 6.4 BLOWER ASSEMBLY – LAZER Z 60 & 72 and LAZER Z XP 60 & 72...

- Page 27 5/8x3/16 #61 Woodruff key..1 103-3079 Plate,backing ......1 Exmark red touch up spray paint - P/N 1-850337 Apply Mobil HTS grease (or a food-grade antisieze) on bore of sheave. Kit 103-0583 is available to add or repair the welded on accessory mounting tube on all 44”-72” decks.

-

Page 28: Completing Kit Assembly

6.5 COMPLETING KIT ASSEMBLY – LAZER Z 60, & 72; Lazer Z XP 60 & 72... -

Page 29: Completing Kit Assembly

6.5 COMPLETING KIT ASSEMBLY - LAZER Z 60, & 72; LAZER Z XP 60 & 72 (cont.) LAZER LAZER XP Ref. 60” 72” 60” 72” Part No. Description 103-2973 103-2974 103-2976 103-2977 103-0453 Pin, Chute Pivot 1-806003 Pin, Hair 103-2792 Jackshaft, LZUV 60 103-2796 Jackshaft, LZUV 72... -

Page 30: Warranty

(ix) damage or defects due to or arising out of repair of turf equipment by person or persons other than an authorized Exmark service dealer or the installation of parts other than genuine Exmark or Exmark recommended parts. - Page 31 MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), NOT SPECIFIED HEREIN, RESPECTING THE EQUIPMENT WHICH IS THE SUBJECT OF THIS WARRANTY. This warranty applies to all Exmark turf equipment sold in the United States and Canada and intended to be used for commercial purposes.

- Page 32 ™ ULTRA VAC QDS ™ GRASS CATCHER ™ MICRO-MULCH ACCESSORY ©2000 - 2002 EXMARK MFG. CO. INC. PART NO. 103-2716 Rev C INDUSTRIAL PARK BOX 808 (402) 223-6300 BEATRICE, NE 68310 FAX (402) 223-5489 ALL RIGHTS RESERVED PRINTED IN U.S.A.

Need help?

Do you have a question about the Ultra VAC QDS and is the answer not in the manual?

Questions and answers