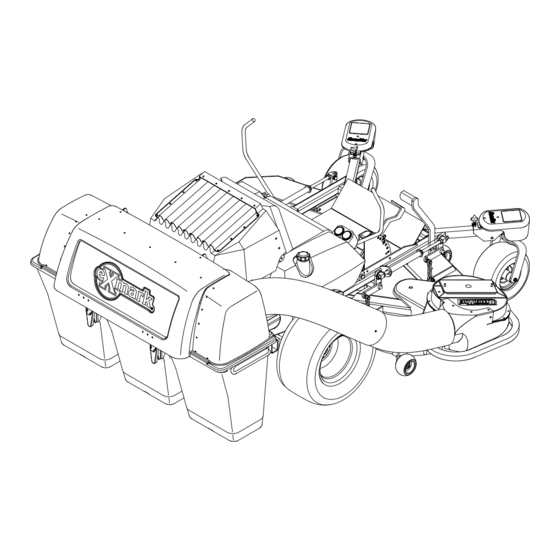

Exmark Laser Z Ultra Vac Operator's & Parts Manual

Hide thumbs

Also See for Laser Z Ultra Vac:

- Parts manual (40 pages) ,

- Operator's & parts manual (40 pages) ,

- Instruction sheet (5 pages)

Table of Contents

Advertisement

on the purchase of your new Exmark

equipment. This product has been carefully designed and

manufactured to give you a maximum amount of dependability

and years of trouble-free operation. If additional information

is needed, or should you require trained mechanic service,

contact your authorized Exmark equipment dealer or distributor.

If you need to order replacement parts from your dealer, always

give the model number and serial number of your equipment

as well as the part number, description and quantity of the part

needed.

The Serial No. plate is located on the rear of the blower

assembly. For ease of ordering and reference, we suggest

that you record the information requested in the following

identification table.

MFG. CO. INC.

®

Place Model No. and Serial No. Label Here

(Included in Literature Pack)

or Fill in Below

Model No.

Serial No.

For Serial Nos.

370,000 & Higher

®

TM

Advertisement

Table of Contents

Summary of Contents for Exmark Laser Z Ultra Vac

- Page 1 If additional information or Fill in Below is needed, or should you require trained mechanic service, contact your authorized Exmark equipment dealer or distributor. Model No. If you need to order replacement parts from your dealer, always...

- Page 2 ♦ Keep off mower unless seat platform is provided. ♦ Keep others off mower. Exmark reserves the right to make changes or add improvements to its products at any time without incurring any obligation to make such changes to products manufactured previously. Exmark, or its distributors and dealers, accept no responsibility for variations which may be evident in the actual specifications of its products and the statements and descriptions contained in this publication.

- Page 3 (6) line items or less. If order is received by 3:00 p.m. central time, Exmark ships part(s) direct to dealer or customer, as requested by distributor, same day, overnight UPS Exmark bills the distributor for parts and shipping charges, where applicable.

- Page 4 If additional information is needed, or should you require trained mechanic service, contact your authorized Exmark equipment dealer or distributor. All Exmark equipment dealers and distributors are kept informed of the latest methods of servicing and are equipped to provide prompt and efficient service in the field or at their service stations.

-

Page 5: Table Of Contents

TABLE OF CONTENTS Description Page 1. Safety Safety Alert Symbol ................6 Training ....................6 Preparation..................6-7 Safety Signs ..................7-8 2. Specifications Dimensions..................... 8 Bagging System ..................8 Model Numbers ..................9 Drive Kits ....................9 3. Assembly Instructions .1 Assembly Diagram ................ -

Page 6: Safety

MAY result in minor or moderate injury. 1.2 TRAINING 1.2.1 Regard the Exmark Ultra Vac as a piece of power equipment and teach this regard to all who operate this unit. 1.2.2 Before operating your Ultra Vac, carefully read and understand this manual and the operator’s manual for your mower in their entirety. -

Page 7: Safety Signs

When new components are installed, be sure that current safety signs are affixed to the replaced components. 1.4.4 New safety signs may be obtained from your authorized Exmark equipment dealer or distributor or from Exmark Mfg. Co. Inc. 1.4.5 Safety signs may be affixed by peeling off the backing to expose the adhesive surface. -

Page 8: Specifications

PART NO. 103-0878 LZUV60 & LZUV72 Only LOCATION: Top of Weights PART NO. 103-3507 LOCATION: Top of Blower 2. SPECIFICATIONS 2.1 DIMENSIONS 2.1.1 Overall unit length w/ Ultra Vac 52" Deck 60" Deck 72" Deck Lazer Z - Air Cooled 105.70"... -

Page 9: Model Numbers

2.3 MODEL NUMBER: LZUV52 – Fits Lazer Z with 52” deck LZUV60 – Fits Lazer Z and Lazer Z XP with 60” deck LZUV72 – Fits Lazer Z and Lazer Z XP with 72” deck 2.4 COMPLETING KITS NEWER UNITS UNIT SERIAL NUMBER DESCRIPTION... -

Page 10: Assembly Instructions

3 ASSEMBLY INSTRUCTIONS – LAZER Z & LAZER Z XP 3.1 ASSEMBLY DIAGRAM Ref . No. Description (52 LZ) (60 & 72 LZ) (60 & 72 XP) Bag Assembly Upper Tube Lower Tube #10-24 X .62 CRPH Screw #10-24 Nyloc Nut #10 Flat Washer Hood Assembly Blower Assembly... - Page 11 1369. Follow the instructions included in the kit when noted in the following steps. • 72” units below serial number 260,000 require the deck to be modified by adding the accessory mounting tube. Exmark kit 103-0583 contains the parts and templates to do this.

-

Page 12: Install Hood Assembly And Bags

3.2 INSTALL THE HOOD ASSEMBLY AND BAGS Lazer Z units only (Lazer Z XP units skip to step 6) 1. When installing the Ultra Vac onto a liquid cooled Lazer Z, the rear bumper plate must be removed. Remove rear bumper plate. Use two of the original bolts, washers and whizlock nuts to attach the lower side bumper bars to the vertical “HOT”... -

Page 13: Install Blower Assembly

5. Install the side plates (Items 14 and 15) loosely to the mount weldment and the wheel channels of the Lazer Z frame. The flanges on the side plates should face in towards the unit to provide the maximum tire clearance. Use the 3/8-16 x 1.00 bolts (Item 23), 3/8 spring disk washers (Item 25) and 3/8-16 whizlock nuts (Item 24). - Page 14 NOTE: On units with wrench flats on the spindle just above the blade use a 1-inch wrench on the flat sides of the spindle shaft to prevent the spindle from turning. On units that do not have a wrench flat, block the blade rotation with a block of wood between the blade and baffles as indicated in the blade service section of the Lazer Z operator’s manual.

- Page 15 14. The front right deck stiffener must be trimmed for belt clearance on 52” Lazer Z units with serial numbers less than 220,000. Measure and mark the deck stiffener (see figure 5). Trim off the indicated portion of the stiffener. Touch up the trimmed area with Exmark red touchup paint – P/N 1-850337.

- Page 16 14. Using the knob that was removed with the original belt cover stud and the knob included with the completing kit (Item 40), mount the two belt cover supports (Item 39) to the plastic belt cover (Item 10). Position the belt cover on the mower deck. The lower ends of the belt cover supports should rest on the outside of the deck stiffeners.

-

Page 17: Assemble Tubes

20. 72” units below serial number 260,000 will require the deck to be modified by adding the accessory mounting tube. Exmark kit 103-0583 contains the parts and templates required. Follow the instructions in this kit. These decks will also require drilling the hole at the front upper corner of the discharge opening to ½... -

Page 18: Install Weight Plates

3.5 INSTALL THE WEIGHT PLATES The four weight plates (Item 35) must be installed under the front panel of the floor pan. These weights give proper balance to the machine when the removable portions of the bagger are removed. Locate the position of the mounting holes. On some machines the hole positions are indicated by tool marks on the floor pan. -

Page 19: Run In - 52" Units Only

Tighten knob on weight assembly until the weight is clamped securely to the caster arm. 3.7 RUN IN – 52” UNITS ONLY 1. Follow the operation instructions in Section 5 to run the unit. Run the unit with the blades and blower engaged for 2 minutes. -

Page 20: Mowing

1. Read the operator’s manual for your mower and familiarize yourself with all controls before operating the machine. Make sure that you understand the controls, their locations, their functions, and their safety requirements. 2. Ensure the blower, belt cover, bags, tube and hood are in good condition, properly attached, and latched. -

Page 21: Transporting

7. Re-install the plastic belt cover and tighten the knobs. 8. Remove the hair pins and clevis pins holding the hood assembly to the mount weldment. 9. Lift the bag and hood assembly off the mount. 10. The removable weights must be removed from above the caster wheels. Loosen the clamping knobs until the weight can be moved relative to the caster arm. -

Page 22: Maintenance

WARNING POTENTIAL HAZARD ♦ Loading a unit on a trailer or truck increases the possibility of backward tip-over. WHAT CAN HAPPEN ♦ Backward tip-over of the unit could cause serious injury or death. HOW TO AVOID THE HAZARD ♦ Use extreme caution when operating a unit on a ramp. ♦... - Page 23 5.1.2 Idler Bushings: Service Interval: 25 Hours. Lubricate with 1-2 pumps of SAE No. 2 multi-purpose grease. 5.1.3 Bags: Service Interval: Daily Inspect the bags for wear, tears, or damage. WARNING POTENTIAL HAZARD ♦ Under normal use the bag will deteriorate and wear. Objects could exit a worn bag at high speeds.

-

Page 24: Tips And Troubleshooting

6. Tips and Troubleshooting Your Exmark Ultra Vac has been designed to be the most productive bagging system on the market. The following tips have been collected to help you get the most out of your Ultra Vac right from the start. -

Page 25: Parts Lists

Req'd. 103-3508 Decal, Warning 52.……...1 1-653558 Decal, Hot Sheave……..1 1-653546 Decal, Exmark 52 ……… 1 103-0438 Decal, Exmark 60 & 72 .. 1 98-5954 Decal, Missing Cover…...1 1-653557 Decal, Ultra Vac………..1 103-0878 Decal, Caster Weights..3 103-3507 Decal, Warning 60 & 72.. 1... -

Page 26: Blower Assembly -Lazer Z 52

BLOWER ASSEMBLY – LAZER Z 52... -

Page 27: Blower Assembly –Lazer Z 52

Tube, upper LZ 52” ....1 321-3 1/4-20x.62 Hex SCREW..8 103-1209 Blower Assy, LZ 52 32128-33 1/4-20 whizlock nut....15 (includes items 1-55)....1 Exmark red touch up spray paint - P/N 1-850337 Use grease on bore of sheave. ∇ Includes items 43 and 44. -

Page 28: Hood And Bag Assembly -Lazer Z 52

7.3 HOOD AND BAG ASSEMBLY – LAZER Z 52... -

Page 29: Hood And Bag Assembly –Lazer Z 52

7.3 HOOD AND BAG ASSEMBLY – LAZER Z 52 (cont.) Ref. Qty. Ref. Qty. Part No. Description Req'd. Part No. Description Req'd. 1-653396 Hood ........1 114974-03 Clamp ........1 1-653397-03 Stiffener, bagger top ..... 1 3230-1 5/16-18x.75 Carriage bolt ..2 103-0825-03 Hinge wldmt RH.... - Page 30 7.4 BLOWER ASSEMBLY – LAZER Z 60 & 72 and LAZER Z XP 60 & 72...

- Page 31 3257-32 5/8x3/16 #61 Woodruff key ..1 Exmark red touch up spray paint - P/N 1-850337 Use grease on bore of sheave. Kit 103-0583 is available to add or repair the welded on accessory mounting tube on all 44”-72” decks.

-

Page 32: Hood And Bag Assembly - Lazer Z 60, 72 & Lazer Z Xp 60,72

7.5 HOOD AND BAG ASSEMBLY – LAZER Z 60 & 72 and LAZER Z XP 60 & 72... - Page 33 7.5 HOOD AND BAG ASSEMBLY – LAZER Z 60 & 72 and LAZER Z XP 60 & 72 (cont.) Ref. Qty. Ref. Qty. Part No. Description Req'd. Part No. Description Req'd. 103-0437 Hood Assembly..... .1 114973-03 Hanger, bag ......1 103-0382-03 Stiffener, Bagger top....1 114974-03 Clamp ........1 103-0430-03 Hinge wldmt ......

-

Page 34: Completing Kit Assembly - Lazer Z 52,60,72 & Lazer Z Xp

7.6 COMPLETING KIT ASSEMBLY – LAZER Z 52, 60, & 72; Lazer Z XP 60 & 72... - Page 35 7.6 COMPLETING KIT ASSY - LAZER Z 52, 60, & 72; LAZER Z XP 60 & 72 (cont.) LAZER LAZER XP Ref. Part No. Description 52” 60” 72” 60” 72” 103-2997 103-2973 103-2974 103-2976 103-2977 103-0453 Pin, Chute Pivot 1-806003 Pin, Hair 103-2792♦...

-

Page 36: Warranty

(ix) damage or defects due to or arising out of repair of turf equipment by person or persons other than an authorized Exmark service dealer or the installation of parts other than genuine Exmark or Exmark recommended parts. - Page 37 MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), NOT SPECIFIED HEREIN, RESPECTING THE EQUIPMENT WHICH IS THE SUBJECT OF THIS WARRANTY. This warranty applies to all Exmark turf equipment sold in the United States and Canada and intended to be used for commercial purposes.

- Page 38 NOTES...

-

Page 39: Service Record

SERVICE RECORD Date Description of Work Done Service Done By... - Page 40 ULTRA VAC ™ ULTRA VAC ™ GRASS CATCHER ™ MICRO-MULCH ACCESSORY ©2000 - 2003 EXMARK MFG. CO. INC. PART NO. 103-4456 INDUSTRIAL PARK BOX 808 (402) 223-6300 BEATRICE, NE 68310 FAX (402) 223-5489 ALL RIGHTS RESERVED PRINTED IN U.S.A. ®...

Need help?

Do you have a question about the Laser Z Ultra Vac and is the answer not in the manual?

Questions and answers