Webasto Thermo 90 Workshop Manual

Coolant heater

Hide thumbs

Also See for Thermo 90:

- Workshop manual (53 pages) ,

- Installation instructions manual (41 pages) ,

- Operating instructions (3 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Webasto Thermo 90

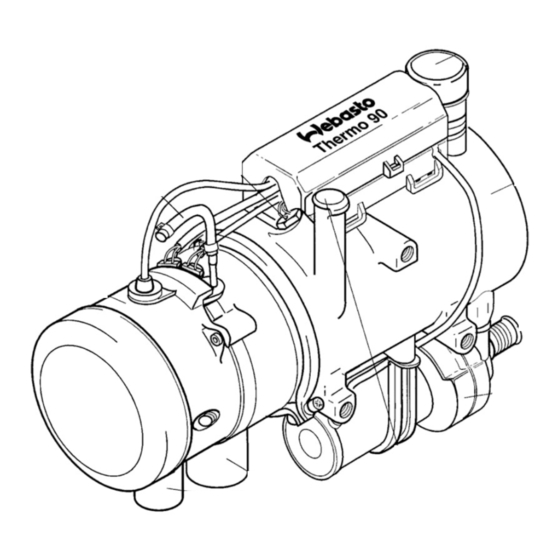

- Page 1 Coolant Heater Thermo 90 Thermo 90 S Workshop Manual...

-

Page 2: Table Of Contents

Switch-off upon Failure ......... . 3-3 3.5.2 Diagnosis after Switch-off upon Failure (Thermo 90) ....3-3 3.5.3 Diagnosis after Switch-off upon Failure (Thermo 90 S) . - Page 3 90 / 90 S HERMO ABLE OF ONTENTS 5.4.1 Reading and Removing Error Codes Stored in Memory using the PC Diagnostics Kit P.N. 92542C ........5-3 Visual Inspection for Assessment of Burner Condition .

- Page 4 90 / 90 S HERMO ABLE OF ONTENTS 8.7.1.2 Installation ........... . 8-7 8.7.2 Replacement of Circulation Pump .

-

Page 5: Introduction

This repair shop manual is intended to support be observed at all times. familiarized personnel in the repair of Thermo 90 and Thermo 90 S coolant heaters. The specific safety regulations applicable to this manual... - Page 6 NTRODUCTION Ignoring the installation instructions and its procedures This does not apply for towing vehicles with an open will void the warranty granted by Webasto. The same cockpit. applies for repairs preformed by unskilled, unauthorized personnel and repairs without using genuine Webasto All fuel containers offered in the Webasto spare parts.

- Page 7 On the Thermo 90 S heater, the control unit is flanged to controlled within a range from 1.8 to 7.6 kW (6,100 to the combustion air fan. It is possible to remote mount 26,000 Btu/hr) for Diesel operated heaters and within 2.0...

-

Page 8: General Description

7 Circulation Pump 8 Outlet, Coolant 9 Outlet, Exhaust 10 Inlet, Combustion Air 11 Control unit (may also be located Heater Thermo 90 S remotely in the vehicle) Combustion Air Fan Heat Exchanger The combustion air fan delivers the air required for... -

Page 9: Temperature Limiter

The control unit is the central controlling device for functional sequencing and monitoring of the combustion operation. It is mounted to the heat exchanger on Thermo 90 heaters and flanged to the combustion air fan on Thermo 90 S heaters. 2.11... -

Page 10: Functional Description (Fig.3-1)

90 / 90 S HERMO UNCTIONAL ESCRIPTION Functional Description Switch-off (Fig. 3-1) When switching the heater off, the operation indicator on the timer/switch extinguishes. Combustion ends and the Switch-on run-down cycle is initiated. The circulation pump and combustion air fan, however, continue operation to cool down the heater (run-down) and are automatically When operating the push button "Immediate Heating", deactivated after about 90 seconds. - Page 11 Control Idle Flame Sensor ‘cold’ (0) Run-down completed Setting of Control Temperatures - Thermo 90 S Preheating 15 - 20 sec. (cycled) Connection of a plus (+) or minus (–) signal to the control Fuel Dosing Pump Priming 5 - 7 sec. (1)

-

Page 12: Malfunctions

UNCTIONAL ESCRIPTION Malfunctions 3.5.3 Diagnosis after Switch-off upon Failure (Thermo 90 S) 3.5.1 Switch-off upon Failure When equipped with a standard timer model 1531, an error code will be indicated on the timer display: In case of a no-flame condition, fuel is delivered for a maximum of 180 seconds. -

Page 13: Technical Data (Standard Measure)

1640 ft. 3280 ft. and geographical height above SL 10.6% 11.3% Dimensions of heater Length 12.2 in. (14.0 in.) (Tolerance ± 0.11 in.) Width 05.24 in. Height 08.66 in. Weight 10.5 lb Thermo 90 S with control unit mounted on heater... -

Page 14: Technical Data (Metric Measure)

500 m 1000 m and geographical height above SL 10.6% 11.3% Dimensions of heater Length 310 mm (355 mm) (Tolerance ± 3 mm) Width 133 mm Height 220 mm Weight 4.8 kg Thermo 90 S with control unit mounted on heater... -

Page 15: Troubleshooting

The following defects are not included in the troubleshooting procedures. Before troubleshooting, This section describes troubleshooting procedures for check for and eliminate these defects: the Thermo 90 and Thermo 90 S coolant heaters. fuel supply (plugged fuel filter or no fuel) CAUTION corrosion on battery terminals... -

Page 16: Failure Symptoms After Switch-Off Upon Failure

90 / 90 S HERMO ROUBLESHOOTING Failure Symptoms after Switch-off The heater Thermo 90 S, with standard timer, outputs errors to the timer display for indication (see 3.6.3). upon Failure The following table may also be used as representative reference. -

Page 17: Storing A Fault Code In Memory

(stored) in memory. Order the appropriate interface connector for the heater The Thermo 90 S can store up to four error codes. model(s) you will likely be working with. Once the memory is “full”, any additional error code will... -

Page 18: Visual Inspection For Assessment Of Burner Condition

90 / 90 S HERMO ROUBLESHOOTING Visual Inspection for Assessment 5.5.1 Burner Housing of Burner Condition • The starting air bore (Fig. 5-3) must not be clogged, otherwise there will be no start. Burner and evaporator have specific features indicating their need for replacement or their serviceable condition. -

Page 19: Rear Wall With Metal Evaporator

90 / 90 S HERMO ROUBLESHOOTING 5.5.2 Rear Wall with Metal Evaporator 5.5.3 Combustion Chamber • The pilot flame exit bore (Fig. 5-4) must not be • The combustion chamber (Fig. 5-5) should not be clogged, otherwise there will be no start. damaged (e.g. -

Page 20: Functional Tests

NOTE: obtained: On the Thermo 90 the function of the combustion air fan can be checked with the diagnostic computer or the 990 … 1010 Ω Resistance at 25 °C (77 °F): components tester. -

Page 21: Circuit Diagrams

Deutsch connector – German version (see Fig. 7-5). Deutsch connector and blower interlock wiring with Deutsch connector – North American enclosure & Fig. 7-1 shows the pin assignment (X1) for Thermo 90 compact kits (see Fig. 7-2). and Thermo 90 S heaters. - Page 22 90 / 90 S HERMO IRCUIT IAGRAMS Fig. 7-2 Circuit Diagram – Thermo 90, 12 and 24 V Enclosure and Compact Kit with Deutsch Connector...

- Page 23 90 / 90 S HERMO IRCUIT IAGRAMS Fig. 7-3 Circuit Diagram – Thermo 90 S, 12 and 24 V Enclosure and Compact Kit with Deutsch Connector...

- Page 24 90 / 90 S HERMO IRCUIT IAGRAMS Thermo 90 Basic Kit Wiring (German) Fig. 7-4 Circuit Diagram – Thermo 90, 12 and 24 V German Version with 7-Day 3-Program digital timer...

- Page 25 90 / 90 S HERMO IRCUIT IAGRAMS Thermo 90 S Basic Kit Wiring (German) Fig. 7-4 Circuit Diagram – Thermo 90 S, 12 and 24 V German Version with 7-Day 3-Program digital timer...

-

Page 26: General

Operational Test • Operate the Webasto heater for 15 minutes or more. • Check coolant and fuel connections for leakage. Re-tighten clamps as necessary. •... - Page 27 90 / 90 S HERMO ERVICING NOTE: The manufacturer mounts the control unit of Thermo 90 S heater to the combustion air fan. With Check Valve and Thermostat 1 Heat Exchanger, Vehicle Heating System 2 Blower Switch, Vehicle Heating System...

-

Page 28: Visual Inspections And Installation Regulations

90 / 90 S HERMO ERVICING Visual Inspections and Installation 8.6.2 Connection to the Vehicle's Fuel System Regulations Fuel is tapped from the fuel reservoir of the vehicle or from a separate fuel container. 8.6.1 Connection to the Vehicle's Cooling Fuel lines must be of the type as described in section System 8.6.2.2 of this manual. -

Page 29: Fuel Tapping

For fuel tapping from the supply or return line only the specific Webasto fuel tap “T”, e.g. Ident. No. 470910 for 8 mm ID.may be used. The fuel tap must be mounted so that the air or gas bubbles can escape towards the fuel tank. -

Page 30: Fuel Lines

90 / 90 S HERMO ERVICING 8.6.2.2 Fuel lines 8.6.3 Fuel Dosing Pump Fuel lines may only be steel, copper, or plastic lines The fuel dosing pump is a combined delivery, dosing, made of unhardened, light and temperature stabilized and shut-off system and is subject to certain installation PA 11 or Pa 12 (e.g. -

Page 31: Installation And Attachment

If there is the probability of contaminated fuel, only the measured from the exhaust pipe end. Webasto filter, part number 487171, may be used. The use of fuel filters not designed for Webasto heater fuel systems may cause a vapor lock or interfere with the proper delivery of fuel. -

Page 32: Removal And Installation

1. Disconnect battery terminal leads. 8.7.4 Replacement of Temperature Sensor NOTE: On the Thermo 90 S heater, with control unit flanged to NOTE: combustion air fan, only connectors X12 and X13 require The procedure for replacement of the temperature disconnection from control unit. -

Page 33: Repair

All disassembled components must be cleaned. General 9.1.1.2 Visual Inspection This section describes the repairs that may be performed on the heater Thermo 90 Thermo 90 S when removed. • Examine all components for damages (cracks, Any further disassembly will void the warranty. -

Page 34: Disassembly And Assembly

3. Fit top cover. On the Thermo 90 S heater with flanged combustion air NOTE: fan, connector X1 on heater and connection X12 on One of the newer models Thermo 90 shown. Older... -

Page 35: Replacement Of Circulation Pump

One of the newer models Thermo 90 shown. Older models have the cable of the temperature limiter located on the side. Heater Thermo 90 S may have the control unit located on the combustion air fan not affecting the replacement of the circulation pump. -

Page 36: Replacement Of Temperature Limiter

90 / 90 S HERMO EPAIR 9.2.3 Replacement of Temperature Limiter 9.2.4 Replacement of Temperature Sensor 9.2.3.1 Removal 9.2.4.1 Removal NOTE: 1. Remove heater (see 8.7.1.1). Perform the following procedure only when the 2. Disconnect electrical connections (see 9.2.1.1). temperature limiter needs replacement. A functional check has to be performed when the WARNING temperature limiter is installed. - Page 37 One of the newer models Thermo 90 shown. Older models have the cable of the temperature limiter located on the side. Heater Thermo 90 S may have the control unit located on the combustion air fan not affecting the replacement of the temperature limiter and temperature sensor.

-

Page 38: Replacement Of Combustion Air Fan

2. Torque tighten screws (2) with 3 Nm ± 10%. NOTE: NOTE: On heater Thermo 90 S with flanged control unit remove On heater Thermo 90 S with flanged control unit install control unit as required. control unit as required. -

Page 39: Replacement Of Burner, Flame Sensor And Glow Pin

90 / 90 S HERMO EPAIR 9.2.6 Replacement of Burner, Flame Sensor CAUTION and Glow Pin When performing the following step, ensure that cables of flame sensor (7) and glow pin (6) are routed as shown 9.2.6.1 Removal in figure. 1. - Page 40 One of the newer models of Thermo 90 shown. Older models have the cable of the temperature limiter located on the side. Illustration is also applicable to the Thermo 90 S. Fig. 9-5 Replacement of Burner, Flame Sensor, and Glow Pin...

-

Page 41: Replacement Of Burner Head

NOTE: One of the newer models of Thermo 90 shown. Older models have the cable of the temperature limiter located on the side. Illustration is also applicable to the Thermo 90 S. -

Page 42: Replacement Of Heat Exchanger

90 / 90 S HERMO EPAIR 9.2.8 Replacement of Heat Exchanger 9.2.8.2 Installation 1. Clip connector housing onto heat exchanger and 9.2.8.1 Removal engage connector in connector housing. 2. Install burner head (see 9.2.7.2). 1. Remove heater (see 8.7.1.1). 3. Install burner, flame sensor, and glow pin 2. - Page 43 Webasto Thermosystems Inc. North America 3333 John Conley Drive Lapeer, MI 48446 Phone (810) 245-2400 Toll-free (800) HEATER-1 (810) 664-7720 Technical Assistance Hotline USA: (800) 555-4518 Canada: (800) 667-8900 www.webasto.com Rev. 03/2000 907400...

Need help?

Do you have a question about the Thermo 90 and is the answer not in the manual?

Questions and answers