Table of Contents

Advertisement

Quick Links

Fine Finish

Model No. 0292003

OWNER'S MANUAL

APPROVED

FOR ELECTROSTATIC FINISHING APPLICATION

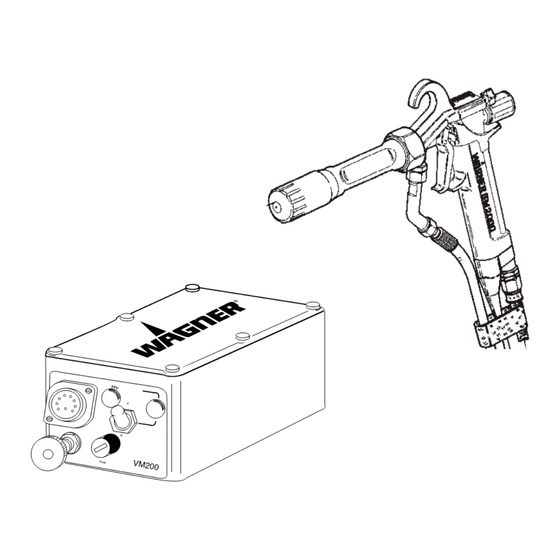

POWER PACK , VM 200

P/N 0179637

, EPP 200

POWER PACK

P/N 0179633

POWER PACK, EPP 2000

SPRAY GUN ,

P/N 0179673

GM 2000 EAC

P/N 0128510

AIR HOSE

FLUID HOSE

P/N 9984482

SPRAY GUN ,

GM 2000 EA

P/N 0179221

AIR HOSE

FLUID HOSE

P/N 0179248

P/N 0179966

T.M.

STATI-KIT

ELECTROSTATIC

SPRAYING SYSTEM

Read Rules for

Safe Operation

and Instructions

Carefully

1

T.M.

2000

CAUTION

Form No.0292522-4/91A

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for WAGNER Fine Finish Stati-Kit 2000 0292003

- Page 1 Fine Finish T.M. T.M. STATI-KIT 2000 ELECTROSTATIC SPRAYING SYSTEM Model No. 0292003 OWNER'S MANUAL CAUTION APPROVED FOR ELECTROSTATIC FINISHING APPLICATION POWER PACK , VM 200 P/N 0179637 , EPP 200 POWER PACK P/N 0179633 Read Rules for POWER PACK, EPP 2000 SPRAY GUN , P/N 0179673 GM 2000 EAC...

-

Page 2: Table Of Contents

CONTENTS SAFETY PRECAUTIONS ..............3-6 SPECIFICATIONS................7 INTRODUCTIONS ................7 GENERAL DESCRIPTION ..............8 MOUNTING ARRANGEMENT ............. 9 SET UP ....................9 OPERATION ..................10 CLEAN UP ................... 11 TIP CHANGE ..................12 FILTER REPLACEMENT ..............13 FRONT & REAR PACKING REPLACEMENT ........13 TROUBLE SHOOTING ................ -

Page 3: Safety Precautions

SAFETY PRECAUTIONS This manual contains information which must be read and understood before using the equipment. When you come to an area which has one of the following symbols, pay particular attention and make certain to heed the safeguard. WARNING Important safety information indicates a hazard which may cause serious injury or loss of life. - Page 4 WARNING PREVENTION HAZARD Electrostatic arcing may cause an explosion or fire. • Operator must be grounded. Grounding straps must be Solvent and paint fumes can explode or ignite causing used when wearing rubber soled shoes. property damage and/or severe injury. •...

- Page 5 WARNING HAZARD PREVENTION Toxic Substances: Some materials may be harm- • Follow the requirements of the Material Safety Data ful if inhaled or come in contact with the skin. Sheet supplied by the coatings manufacturer. • Exhaust and fresh air introduction must be provided within the spray area to keep the air free of accumula- tions of toxic materials.

- Page 6 WARNING PREVENTION HAZARD Injection (Con't) • All accessories must be rated at or above the maximum pressure rating of spray pump (includes spray tips, guns, extensions and fluid hose. • If you are injected, see a physician immediately. DO NOT TREAT AS A SIMPLE CUT! It can lead to amputation.

-

Page 7: Specifications

SPECIFICATIONS INTRODUCTION GM2000 EAC SPRAYGUN (P/N 0179673) INTRODUCTION TO ELECTRO-STATIC SPRAYING Air Pressure, max. 145 psi Material Pressure, max. 3625 psi The spraying medium is atomized using a pneumatic or Air Volume 10 CFM@ 45 PSI diaphragm pump and a booster air feed supply. A high DC Material Volume Varies due to Tip size voltage (up to 80 kV), applied across the grounded compo-... -

Page 8: General Description

GENERAL DESCRIPTION VM 200 ELECTROSTATIC POWER PACK GM2000 EAC SPRAY GUN The heavy metal case is water tight. All external compo- The GM2000 EAC Electrostatic Air Coat Spraygun is nents and operating controls, as well as the case finish are very light and easy to service. -

Page 9: Mounting Arrangement

TYPICAL MOUNTING RANGEMENT WAGNER AIRLESS SPRAYER MOUNTING INSTRUCTIONS Use the allen wrench provided, attach the mounting bracket (1) to the power pack (2) with the 2.4mm lockwashers (3) and socket head screws (4). Place the power pack/mounting bracket assembly on any 1"... -

Page 10: Set Up

SET-UP OPERATION SET-UP VM 200 POWER PACK: Set the VM 200 Power Pack Switch to the “I” position (the green light turns on) 1. GM 2000 EAC Socket Outlet 2. Ground Connection Knob Adjust the fluid pressure to achieve maximum atomi- 3. -

Page 11: Clean Up

CLEAN UP CAUTION WARNING WHEN CLEANING THE ELECTROSTATIC • Clean equipment immediately after use. SYSTEM, THESE SAFETY PROCEDURES • NEVER IMMERSE SPRAY GUN IN ANY FLUID MUST BE FOLLOWED. FAILURE TO FOL- AT ANY TIME. LOW THESE PROCEDURES MAY RESULT •... -

Page 12: Tip Change

ASSEMBLY OF FLAT SPRAY TIP TIP CHANGE If the round nozzle body is attached: Fig. 7. CHANGING THE ROUND SPRAY TIP • Remove tip body (D) from the spray gun body (F). Using (OPTIONAL): the procedure described in changing the round nozzle body. -

Page 13: Filter Replacement

MAINTENANCE VALVE SEAL REPLACEMENT WARNING To replace valve seals you must remove the entire valve rod. Turn off Power Pack and unplug from power source. Actuate trigger (3) and unscrew trigger lock knob (2), Relieve pressure to the Spray Gun, Lockout trigger and remove the compression spring. -

Page 14: Troubleshooting

TROUBLESHOOTING Problem Cause Solution • No green light on Power Pack • Dead outlet. • Live outlet. • Fuse blown. • Replace fuse. • Not plugged in. • Plug in. • Faulty circuit board. • Take to Authorized Service Center. •... -

Page 15: Trouble Shooting

TROUBLESHOOTING Problem Cause Solution • Air leaking at tip without pulling • Air valve is faulty. • Replace air valve. trigger. • Air leaks between gun body and • Gun Barrel Nut. • Tighten nut. gun barrel. • No air at tip when trigger is pulled. •... -

Page 16: Parts List

Figure 9... - Page 17 GM 2000 EAC Item Description Part Number Spray gun barrel 0179500 Bushing 0128336 Screw countersunk 0179354 Type plate 9900962 Screw flathead 9900810 O-ring 9971003 Knob, Air Adjustment 0179416 Trigger sleeve 0179396 Valve rod complete 0179254 Valve sealing element 0179236 O-ring 9971182 Compression ring 0179343...

-

Page 18: Spare Tips

Flat Tip Round Tip Part Orifice Size Orifice Number Marking (Inch) Width Size 0128550 9/15 .009 15° Part .001 Volume @ 250 PSI 0128216 9/20 .009 20° Number Marking (Inch) oz./Min G.P.M. 0128552 11/15 .011 15° 0128217 11/20 .011 20° 0132720 R11/2 .0066... -

Page 20: Warranty

LIMITED WARRANTY ELECTROSTATIC PAINT SPRAY EQUIPMENT To validate this warranty, the completed registration card must be mailed within one week of the date of purchase to Wagner Spray Tech Corporation. Wagner Spray Tech Corporation extends to the original purchaser of its electrostatic paint spray equipment a one year warranty against defects in material or workmanship provided that the equipment is installed and operated in accordance with the recommendations and instructions of Wagner Spray Tech Corporation.

Need help?

Do you have a question about the Fine Finish Stati-Kit 2000 0292003 and is the answer not in the manual?

Questions and answers