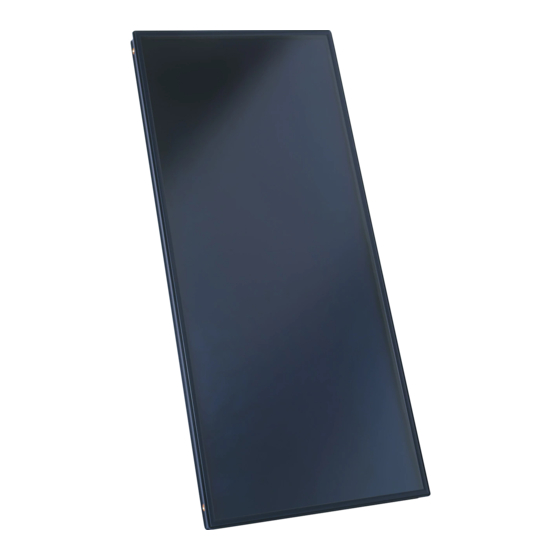

Viessmann VITOSOL-F Service Instructions Manual

Solar panels

Hide thumbs

Also See for VITOSOL-F:

- Installation instructions manual (80 pages) ,

- Service instructions manual (24 pages) ,

- Installation instructions for contractors (24 pages)

Summary of Contents for Viessmann VITOSOL-F

- Page 1 VIESMANN Service instructions for contractors Vitosol-F For applicability, see the last page VITOSOL-F Please keep safe. 5692 887 GB 8/2010...

-

Page 2: Safety Instructions

■ All legal instructions regarding envi- tem. ronmental protection, Replace faulty components only ■ The Code of Practice of relevant trade with original Viessmann spare associations parts. ■ All current safety regulations as defined by DIN, EN, DVGW, VDE and all locally applicable standards a ÖNORM, EN and ÖVE... - Page 3 Installing non-author- ised components and making non-approved modifications or conversions can compromise safety and may invalidate our warranty. For replacements, use only orig- inal spare parts supplied or approved by Viessmann.

-

Page 4: Table Of Contents

Index Index Commissioning, inspection, maintenance Steps - commissioning, inspection and maintenance.......... Further details regarding the individual steps............Scope of inspection................... 14 Parts lists Parts list........................ 15 Specification Vitosol 200-F......................17 Vitosol 300-F......................17 Certificates Declaration of conformity..................18... -

Page 5: Commissioning, Inspection, Maintenance

Commissioning, inspection, maintenance Steps - commissioning, inspection and maintenance For further information regarding the individual steps, see the page indicated Commissioning steps Inspection steps Maintenance steps Page • 1. Checking pressure conditions and pre-charge pressure................• • • 2. Checking the function of the safety equipment •... -

Page 6: Further Details Regarding The Individual Steps

Cover the collectors. Note A manual pressure gauge can be found Note in the solar service case available as an The glass cover of Viessmann flat-plate accessory. collectors is coated with a protective foil. Enter values into the following table. - Page 7 Commissioning, inspection, maintenance Further details regarding the individual steps (cont.) Documentation of pressure System pressure of the solar thermal system 1 bar Supplement per metre static ceiling + 0.1 bar/m System operating pressure (pressure gauge) ....bar Pressure reserve for venting + 0.1 bar Filling pressure ....

-

Page 8: System

Note Note The glass cover of Viessmann flat- To flush and fill the solar thermal plate collectors is coated with a pro- system, use the filling container or tective foil. filling station available as acces- For vacuum tube collectors, use the sories. - Page 9 Commissioning, inspection, maintenance Further details regarding the individual steps (cont.) Solar-Divicon (accessory) L/Min A Thermometer/non-return valve, C Safety assembly, with 6 bar safety flow valve B Thermometer/non-return valve, D Flow indicator return Fill valve (accessory) E Shut-off tap F Drain & fill taps...

- Page 10 Commissioning, inspection, maintenance Further details regarding the individual steps (cont.) A Pressure gauge C Container for heat transfer medium B Drain & fill taps D Shut-off valve 1. Open shut-off taps or valves. With the 2. Close shut-off tap E; open drain & Solar-Divicon, open the non-return fill taps F on the fill valve (see dia- valves by turning the thermometers...

-

Page 11: Determining The Flow Rate And Adjusting If Required

Commissioning, inspection, maintenance Further details regarding the individual steps (cont.) 3. Use a high speed pump to flush the 5. Close the fill tap on the fill valve; open system. Observe the fluid level in the the fill pump. container and top up with heat trans- Pressure must not drop for at least 30 fer medium if necessary to prevent minutes. -

Page 12: Starting The System

Commissioning, inspection, maintenance Further details regarding the individual steps (cont.) High flow operation, 40 l/(h·m Low flow operation, 15 l/(h·m Number of Flow rate in l/min Number of Flow rate in l/min collectors collectors 10.5 12.5 15.5 18.5 10.5 21.5 11.5 23.5 Vitosol 200-F, type 5DIA... - Page 13 Tyfocor G-LS. Never mix with water or third party media. 2. Check the frost protection tempera- ture of the heat transfer medium with a Viessmann antifreeze tester or the manual refractometer in the solar service case. Solar service case operating instructions...

-

Page 14: Scope Of Inspection

Scope of inspection Scope of inspection The solar thermal system should be inspected once a year to ensure opera- tional reliability. In addition to this, a visual check of all essential components (e.g. collectors and pipework) is recommended every 3 to 5 years. -

Page 15: Parts Lists

Parts lists Parts list When ordering spare parts: 033 Air vent plug Quote the part and serial numbers (see 034 Cross union with support sleeve type plate) and the position number of 035 Repair panel the required part (as per this parts list). 037 Fixing clamp Obtain standard parts from your local supplier. -

Page 16: Parts Lists Parts List

Parts lists Parts list (cont.) -

Page 17: Specification

Specification Vitosol 200-F Type SV2A/ SV2B/ 5DIA SH2A SH2B Absorber area 2.32 2.32 4.76 Aperture area 2.33 2.33 4.96 Thermal capacity c 6.40 kJ/(m ·K) Max. idle temperature °C Permiss. operating pres- sure Content, heat transfer litres 1.83/2.48 1.83/2.48 3.34 medium Vitosol 300-F Type... -

Page 18: Certificates

Certificates Declaration of conformity We, Viessmann Werke GmbH&Co KG, D-35107 Allendorf, declare as sole respon- sible body, that the product Vitosol-F conforms to the following standards: DIN 1055 EN 12975 to solar KEYMARK In accordance with the following directives, these products are designated _:... - Page 20 Vitosol 300-F, type SH3A Part no. 7374 163 Vitosol 300-F, type SV3B Part no. 7417 765 Vitosol 300-F, type SH3B Part no. 7417 766 Viessmann Werke GmbH&Co KG Viessmann Limited D-35107 Allendorf Hortonwood 30, Telford Telephone: +49 6452 70-0 Shropshire, TF1 7YP, GB...

Need help?

Do you have a question about the VITOSOL-F and is the answer not in the manual?

Questions and answers