Viessmann VITOSOL-F Service Instructions Manual

Hide thumbs

Also See for VITOSOL-F:

- Installation instructions manual (80 pages) ,

- Installation instructions for contractors (24 pages) ,

- Service instructions manual (20 pages)

Summary of Contents for Viessmann VITOSOL-F

- Page 1 VIESMANN Service instructions for contractors Vitosol-F/-FM For applicability, see the last page VITOSOL-F/-FM Please keep safe. 5687 433 GB 8/2016...

- Page 2 Note For replacements, use only original spare parts Details identified by the word "Note" contain additional supplied or approved by Viessmann. information. Target group These instructions are exclusively intended for author- ised contractors.

-

Page 3: Table Of Contents

Index Index Information Symbols ....................Intended use ..................Product information ................Commissioning, inspec- Steps - commissioning, inspection and maintenance ......tion, maintenance Parts lists Ordering parts ..................13 Parts list ....................14 Scope of inspection ........................ 18 Specification Vitosol 100-F ..................19 Vitosol 100-FM .................. -

Page 4: Information Symbols

Information Symbols The steps in connection with commissioning, inspec- Symbol Meaning tion and maintenance are found in the "Commission- Reference to other document containing ing, inspection and maintenance" section and identified further information as follows: Step in a diagram: Symbol Meaning The numbers correspond to the order in Steps required during commissioning... -

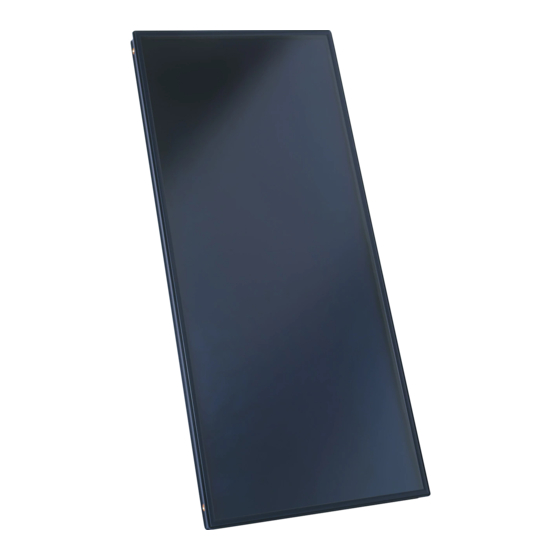

Page 5: Product Information

Information Product information Vitosol-F/-FM are high performance flat-plate collec- tors. Universal application, for flat and pitched roofs, or free- standing. For heating DHW, heating water and swimming pool water via a heat exchanger. -

Page 6: Commissioning, Inspec-Steps - Commissioning, Inspection And Maintenance

Commissioning, inspection, maintenance Steps - commissioning, inspection and maintenance Commissioning steps Inspection steps Maintenance steps Page • 1. Checking pressure conditions, adjusting the expansion vessel pre-charge pressure if necessary........................... • • • 2. Checking the function of the safety equipment..............•... -

Page 7: Checking Pressure Conditions, Adjusting The Expansion Vessel Pre-Charge Pressure If Necessary

Commissioning, inspection, maintenance Checking pressure conditions, adjusting the expansion vessel pre-charge pressure if necessary This process cannot be carried out while the solar 4. Check the pre-charge pressure and adjust if thermal system is in operation. required. The solar service case (accessories) contains a 1. -

Page 8: Checking The Function Of The Safety Equipment

Commissioning, inspection, maintenance Checking pressure conditions, adjusting the… (cont.) The following values result at 10 m static head (example) Vitosol-FM Vitosol-F Solar thermal system pressure 3.0 bar 1.0 bar Supplement, static head 0.1 bar/m 1.0 bar 1.0 bar System pressure (pressure gauge) 4.0 bar... - Page 9 Commissioning, inspection, maintenance Filling, flushing and checking the solar… (cont.) The following description is in conjunction with Solar-Divicon (see separate installation and service instructions) Fig. 2 Solar-Divicon Drain valve Shut-off valve (flow) Flow indicator Non-return valves Fill valve Solar circuit pump Stagnation heat sink Air separator Expansion vessel...

-

Page 10: Determining The Flow Rate And Adjusting It If Required

Commissioning, inspection, maintenance Filling, flushing and checking the solar… (cont.) 09. Close drain valve 11. Open shut-off valve . Leave the fill pump of flush- : Using a screwdriver, turn ing and filling facility running until the required the slot on the adjusting screw above the flow indi- charge pressure is reached. -

Page 11: Performing A Test Flush

Commissioning, inspection, maintenance Determining the flow rate and adjusting it if… (cont.) High-flow operation, specific flow rate 40 l/(h Low-flow operation, specific flow rate 25 l/(h · · Number of collectors Flow rate in l/min Number of collectors Flow rate in l/min 10.5 10.5 12.5... -

Page 12: Checking And Replacing The Heat Transfer Medium If Required

Commissioning, inspection, maintenance Checking and replacing the heat transfer medium if required The heat transfer medium provided is a liquid based ■ on 1,2-propylene glycol with a pH value of 9.0 to 10.5 and frost protection down to: – 28 °C, Tyfocor LS −... -

Page 13: Parts Lists Ordering Parts

Parts lists Ordering parts The following details are required when ordering parts: ■ Serial no. (see type plate on the collector) ■ Position number of the part... -

Page 14: Parts List

Parts lists Parts list 0003 0001 0002 0004 0006 0007 0008 0005 0009 0012 0014 0015 0016 0021 0022 0020 0028 0023 0025 0026 0027 0029 0031 0032 0033 0030 0034 0035 0037 0036 Fig. 6... - Page 15 Parts lists Parts list (cont.) Pos. Part 0001 Connection pipe 0002 Connection pipe (short) 0003 Connection pipe (long) 0004 Plug 0005 Locking ring fitting with support sleeves 0006 Elbow fitting with support sleeves 0007 Clamping bracket, complete 0008 Connecting part 0009 Mounting plate 0012...

- Page 16 Parts lists Parts list (cont.) 0039 0040 0043 0038 0048 0044 0046 0042 0047 0041 0049 0050 0051 0053 0052 0054 0057 0055 0056 Fig. 7...

- Page 17 Parts lists Parts list (cont.) Pos. Part 0038 90° elbow and sensor well (long) 0039 Tee (short connection pipe) 0040 Elbow fitting, 2 x 22 mm 0041 90° elbow and sensor well (short) 0042 90° elbow (long connection pipe) 0043 Corner tee 0044 Corner tee and sensor well (long)

-

Page 18: Scope Of Inspection

Scope of inspection Scope of inspection The solar thermal system should be inspected once a year to ensure operational reliability. In addition to this, a visual inspection of all essential components (e.g. collectors and pipework) is recom- mended every 3 to 5 years. Vent the solar thermal system. -

Page 19: Specification

Specification Vitosol 100-F Type SV1A/SH1A SV1B/SH1B Absorber area 2.32 2.32 Aperture area 2.33 2.33 Thermal capacity c kJ/(m · Collector efficiency at a 57.6 η temperature differential of 40 K Max. stagnation temperature °C Permiss. operating pressure Heat transfer medium content 1.48/2.33 1.48/2.33 Vitosol 100-FM... - Page 20 Specification Vitosol 300-F (cont.) Type SV3C/SH3C Permiss. operating pressure Heat transfer medium content 2.04/2.65...

-

Page 21: Final Decommissioning

Final decommissioning Final decommissioning and disposal Viessmann products can be recycled. Components and substances from the system are not part of ordi- nary household waste. For decommissioning the system, isolate the system from the power supply and allow components to cool down where appropriate. -

Page 22: Certificates Declaration Of Conformity

Certificates Declaration of conformity Vitosol-F/-FM We, Viessmann Werke GmbH & Co. KG, D-35107 Allendorf, declare as sole responsible body that the named product complies with the provisions of the following directives and regulations: 2014/35/EU Low Voltage Directive 2014/30/EU EMC Directive... - Page 24 7571217 7571556 7571557 7637796 7637797 7637798 7637799 7637804 7637900 Viessmann Werke GmbH & Co. KG Viessmann Limited D-35107 Allendorf Hortonwood 30, Telford Telephone: +49 6452 70-0 Shropshire, TF1 7YP, GB Fax: +49 6452 70-2780 Telephone: +44 1952 675000 www.viessmann.com Fax: +44 1952 675040...

Need help?

Do you have a question about the VITOSOL-F and is the answer not in the manual?

Questions and answers