Summarization of Contents

Introduction

Legal information

Provides legal information and outlines the warning system used in the instructions.

General information

Details about qualified personnel, intended use, trademarks, and liability.

Lubricants

Information on the quality and selection of lubricants for the gear unit.

Safety instructions

Security notes

Addresses industrial security functions and protection against cyber threats.

The five safety rules

Lists the five essential safety rules for electrical work.

General information

Emphasizes careful work by qualified personnel on the gear unit.

General warnings and symbols

Explains general warning symbols and their meanings.

Special types of danger and personal protective equipment

Details hazards like electric shock, eye injury, falling, and required PPE.

Intended use

Defines the correct usage of the gear unit and risks of improper use.

Description

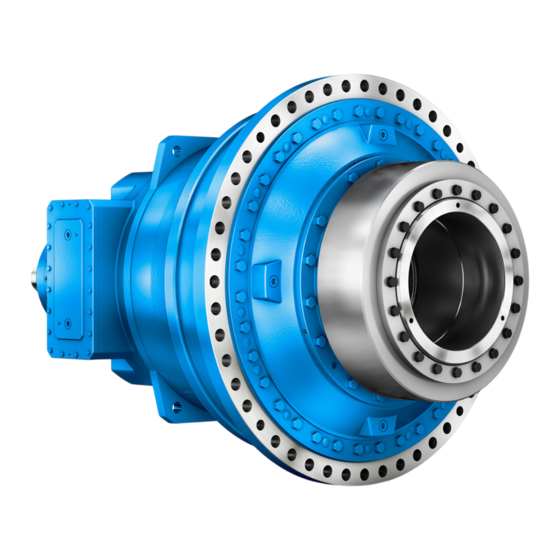

General description

Provides an overview of the planetary gear unit and its applications.

Housing

Describes the housing material and its features like attachment points.

Oil supply to the gear unit

Explains different oil supply versions: splash, pressure, and circulating.

Bearing arrangement of the shafts

States that all shafts are mounted in rolling-contact bearings.

Shaft seals

Details shaft seals, including rotary shaft sealing rings and taconite seals.

Backstop

Describes the mechanical backstop and its principle of operation.

Torque limiting backstop (special version)

Explains the torque-limiting backstop for special applications like twin drives.

Cooling

Covers cooling types like fan, air-oil, and water-oil coolers.

Couplings

Details elastic couplings, their alignment, and balancing requirements.

Shrink disk

Explains the shrink disk as a frictional clamping connection.

Heating

Describes heating elements for preheating gear unit oil at low temperatures.

Oil level indicator

Lists components for checking the oil level visually.

Oil temperature monitoring system

Details the use of Pt 100 resistance thermometers for oil temperature measurement.

Bearing monitoring

Covers bearing monitoring methods: Pt 100, shock-pulse, and acceleration sensor.

Speed encoder

Describes the function and connection of an incremental speed encoder.

Torque monitoring system

Explains telemetry systems and the DX500GL for speed and torque measurement.

Application planning

Scope of delivery

Lists items included in the shipping documents and checks upon receipt.

Transport

Provides instructions for safe transport to avoid damage.

Attachment points

Details how to use sling swivels and the location of attachment points.

Special aspects relating to lubrication

Covers oil filling and oil drain procedures for the gear unit.

Assembly

General assembly instructions

Emphasizes careful mounting by authorized personnel and general precautions.

Unpacking the gear unit

Provides instructions and safety notes for unpacking the gear unit.

Gear unit assembly

Covers foundation requirements and various mounting procedures.

Gear unit dismantling

Details procedures for dismantling gear units with and without shrink disks.

Couplings

Explains coupling installation, alignment, and potential misalignments.

Connecting components

Guides on connecting various components like coolers, sensors, and hoses.

Tightening procedure

Details bolt properties, connection classes, and tightening torques.

Final work

Covers final checks and measures after assembly and connection.

Commissioning

Measures prior to commissioning

Lists essential steps before commissioning the gear unit.

Measures during commissioning

Outlines checks and documentation required during commissioning.

Operation

Operating data

Specifies operating data for the gear unit and its oil.

Anomalies

Lists common anomalous behaviors during operation and initial responses.

Taking the unit out of service

Provides instructions for taking the gear unit out of service for prolonged periods.

Servicing

General maintenance information

Highlights the importance of adhering to stipulated maintenance intervals.

Maintenance schedule

Provides an overview of maintenance and servicing activities at regular intervals.

Service and maintenance work

Details specific tasks like cleaning filters, checking oil, and replacing parts.

Possible faults

Offers a troubleshooting guide for common faults and their remedies.

Service & Support

Contact

Provides contact information for ordering parts or technical queries.

Declaration of incorporation

UK Declaration of Incorporation

Formal declaration regarding the partly completed machine's compliance.

Technical data

General technical data

Explains rating plate information and technical data sources.

Ambient temperature

Specifies the permissible ambient temperature range for gear unit operation.

Types

Lists the available standard gear unit types.

Weights

Provides approximate weights for standard gear units.

Enveloping surface sound pressure level

Lists enveloping surface sound pressure levels according to ISO 9614 Part 2.

Need help?

Do you have a question about the P3DH and is the answer not in the manual?

Questions and answers