Summary of Contents for FLENDER B H 23 28 Series

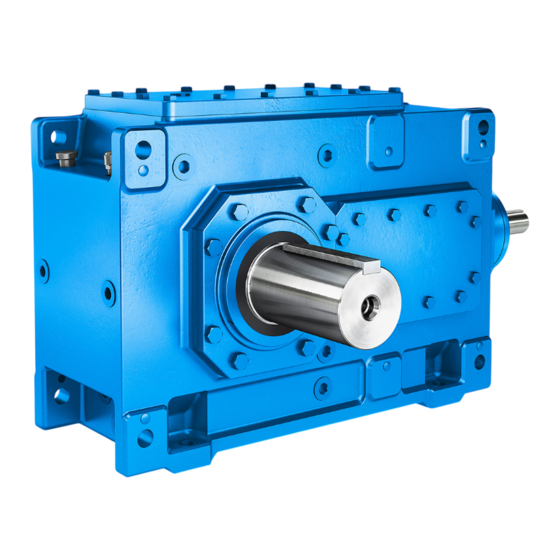

- Page 1 FLENDER GEAR UNITS Belt-conveyor gear unit Assembly and operating instructions A5033en Edition 06/2020 B..H 23...28, B..M 23...28, B3.E 13...22...

- Page 2 09.12.2020 23:20 V24.01...

- Page 3 Introduction Safety instructions Description FLENDER GEAR UNITS Application planning Belt-conveyor gear unit A5033en Assembly Commissioning Assembly and operating instructions Operation Servicing Service & Support Disposal Spare parts B..H 23...28, B..M 23...28, B3.E 13...22 Declaration of incorporation Declaration of conformity Technical data...

- Page 4 Note the following: WARNING Flender products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Flender. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Table Of Contents

Table of contents Introduction ............................11 General information......................11 Lubricants.......................... 12 Safety instructions ..........................15 Security notes ........................15 The five safety rules ......................15 General information......................16 General warnings and symbols................... 17 Special types of danger and personal protective equipment ..........18 Correct use in hazardous zones (explosive atmospheres) ............ - Page 6 Table of contents 3.12 Heating ..........................47 3.12.1 Oil-level monitoring system for the heating elements ............48 3.13 Oil level indicator ....................... 49 3.14 Oil level monitoring system ....................49 3.15 Oil temperature monitoring ....................50 3.16 Bearing monitoring ......................51 3.16.1 Bearing monitoring using a Pt 100 resistance thermometer ..........

- Page 7 Table of contents 5.6.1 Assembly ........................... 96 5.6.1.1 Pulling on with integrated DU bushing ................97 5.6.1.2 Axial locking ........................98 5.6.2 Dismantling the shaft-mounted gear unit ................98 Shaft-mounted gear unit with flange coupling..............99 Couplings ........................100 Connecting components ....................101 5.9.1 Gear units with mounted components ................

- Page 8 Table of contents 8.3.6 Checking the auxiliary drive ..................... 121 8.3.7 Checking the speed monitoring of the auxiliary drive............122 8.3.8 Measuring the vibration levels of the rolling-contact bearings........... 122 8.3.9 Checking the ignition protection system ................123 8.3.10 Cleaning the fan and gear unit ..................123 8.3.11 Checking the cooling coil ....................

- Page 9 Table of contents Table C-2 Enveloping surface sound pressure level................146 Table C-3 Enveloping surface sound pressure level................146 Table C-4 Enveloping surface sound pressure level................147 Figures Figure 3-1 Output shaft versions......................25 Figure 3-2 Sign: Lubrication point......................26 Figure 3-3 Gear unit equipment on gear units of types B..H ≤...

- Page 10 Table of contents Figure 4-6 Position of the attachment points for gear units, type B... / T3.. with motor:......66 Figure 4-7 Position of the attachment points for gear units, type B... / T3.. with gear unit swing base:..66 Figure 5-1 Stone bolt..........................

-

Page 11: Introduction

Failure to observe these operating instructions can cause product or property damage or personal injury. Flender does not accept any liability for damage or operating failures which are due to non- adherence to these operating instructions. The gear unit described in these instructions reflects the state of technical development at the time these operating instructions went to print. -

Page 12: Lubricants

The quality of the oil used must meet the requirements of the operating instructions BA 7300, which is provided as a separate item, otherwise the warranty provided by Flender will be void. Flender urgently recommends using one of the oils listed in BA 7300, all of which have been appropriately tested and meet the requirements. - Page 13 Flender recommends regular inspection to ascertain whether the selected lubricating oil is still approved by Flender. If it is not, another brand of oil should be selected instead. Assembly and operating instructions A5033en...

- Page 14 Introduction 1.2 Lubricants Assembly and operating instructions A5033en Edition 06/2020...

-

Page 15: Safety Instructions

In order to safeguard plants, systems, machines and networks against cyber threats it is necessary to implement (and continually maintain) a holistic industrial security concept that corresponds to the current state of the art. Flender products and solutions undergo continuous development in this respect. -

Page 16: General Information

Safety instructions 2.3 General information General information Introduction All work on the gear unit should be performed with care and only by qualified personnel. Symbols on the gear unit The following symbols apply to the gear unit; some of which are found as coloured markings on the gear unit: Table 2-1 Symbols and markings... -

Page 17: General Warnings And Symbols

Safety instructions 2.4 General warnings and symbols Points labelled on the gear unit Symbol Coloured markings Do not unscrew Alignment surface, horizontal Alignment surface, vertical These symbols indicate the oil level check‐ ing procedure using the oil dipstick. These symbols indicate that the oil dipstick must be firmly screwed in. -

Page 18: Special Types Of Danger And Personal Protective Equipment

Safety instructions 2.5 Special types of danger and personal protective equipment Special types of danger and personal protective equipment Requirements Fulfil the following requirements before commencing work on the gear unit: • Ensure that the oil pressure lines are depressurised. •... - Page 19 Safety instructions 2.5 Special types of danger and personal protective equipment Switch the gear unit to standstill immediately if inexplicable changes are noticed during operation. Such changes may include unusual gear unit noise or a significant increase in operating temperature. WARNING Risk of falling There is an increased risk of falling when standing or walking on the gear unit during operation.

-

Page 20: Correct Use In Hazardous Zones (Explosive Atmospheres)

Flender will accept no liability or warranty whatsoever for damage occurring as a result of the use of non-approved spare parts. The same applies to any accessories which were not supplied by Flender. - Page 21 Safety instructions 2.6 Correct use in hazardous zones (explosive atmospheres) If you have any queries, please contact Customer Services (Page 131). WARNING An explosive atmosphere can be ignited An explosive atmosphere can be ignited if mounted components are used that do not comply with the ATEX directive.

- Page 22 Safety instructions 2.6 Correct use in hazardous zones (explosive atmospheres) • In the case of gear units that are operated in combination with electrical machines that generate current or through which current flows (e.g. motors and generators), take measures to ensure that no current can flow through the gear unit. Current flowing through the gear unit can result in irreparable damage to rolling-contact bearings and gearing.

-

Page 23: Description

It can essentially be operated in both directions of rotation. Gear units equipped with backstop or overrunning clutch are the exceptions in this case. Flender must be consulted if, for these versions, the direction of rotation is to be reversed. Type B3.E is equipped with an axial fan, and can only be operated in one direction. -

Page 24: Output Shaft Versions

Description 3.2 Output shaft versions Design Type B2.H, B2.M B3.H, B3.M, B3.E, T3.H, T3.M When an auxiliary drive is mounted (as maintenance or load drive), the assignment of the direction of rotation to the specific version is defined in the dimension drawing. NOTICE Destruction of the gear unit or parts of the gear unit due to incorrect direction of rotation is possible. -

Page 25: Housing

Description 3.3 Housing Solid shaft Hollow shaft for shrink disk Flange shaft Hollow shaft with spline according to DIN 5480 Hollow shaft with parallel keyway Figure 3-1 Output shaft versions Further information Further information, a detailed illustration of the gear unit and the position of the mounted components can be found in the dimension drawing in the complete documentation for the gear unit. -

Page 26: Figure 3-2 Sign: Lubrication Point

Description 3.3 Housing The lubrication points are designated using the following sign: Figure 3-2 Sign: Lubrication point Gear unit equipment Housings for types B2.. and B3.. up to and including size 12 are monolithic. Type T3.., and sizes 13 to 28 of types B2.. and B3.. have a split housing. The diagram below shows the available gear unit equipment on gear units of types B..H ≤... -

Page 27: Figure 3-4 Gear Unit Equipment On Gear Units Of Types B

Description 3.3 Housing ① ⑦ Shaft seal Rating plate ② ⑧ Bearing neck Alignment thread ③ ⑨ Inspection and assembly cover Cover ④ ⑩ Housing Gear unit fastening ⑤ ⑪ Alignment surfaces Fan cover ⑥ ⑫ Lifting eyes Figure 3-4 Gear unit equipment on gear units of types B..H ≥... -

Page 28: Figure 3-6 Gear Unit Equipment On Gear Units Of Type T3.H ≤ 12

Description 3.3 Housing ① ⑥ Shaft seal Rating plate ② ⑦ Bearing neck Cover ③ ⑧ Inspection and assembly cover Gear unit fastening ④ ⑨ Housing Air guide cover ⑤ ⑩ Lifting eye and/or eye bolt Figure 3-6 Gear unit equipment on gear units of type T3.H ≤ 12 The diagram below shows the available gear unit equipment on gear units of type T3.M ≤... -

Page 29: Oil Supply To The Gear Unit

Description 3.4 Oil supply to the gear unit ① ⑦ Shaft seal Cover ② ⑧ Bearing neck Gear unit fastening ③ ⑨ Housing Fan cover ④ ⑩ Lifting eyes ⑤ ⑪ Rating plate Inspection and assembly cover ⑥ Alignment thread Figure 3-8 Gear unit equipment on gear units of types B3.E ≥... -

Page 30: Pressure Lubrication

Description 3.4 Oil supply to the gear unit 3.4.2 Pressure lubrication At high input speeds or high gear circumferential velocities, depending on the particular contract, splash lubrication can be supplemented or replaced by pressure lubrication. With pressure lubrication, the rolling-contact bearings and gears located above the oil level are adequately supplied with oil through pipes. -

Page 31: Bearing Arrangement Of The Shafts

Description 3.6 Shaft seal Further information Further information, a detailed illustration of the gear unit and the position of the mounted components can be found in the dimension drawing in the complete documentation for the gear unit. Bearing arrangement of the shafts All shafts are mounted on rolling-contact bearings. -

Page 32: Taconite Seal

Description 3.6 Shaft seal The diagram below shows a rotary shaft sealing ring Figure 3-10 Rotary shaft sealing ring 3.6.2 Taconite seal The taconite seal is a combination of two sealing elements: • Rotary shaft sealing ring to prevent the escape of lubricating oil •... -

Page 33: Figure 3-12 Design Variants Of Taconite Seals

Description 3.6 Shaft seal ① ③ Taconite F-F Taconite F-K ② ④ Taconite F-H Output Figure 3-12 Design variants of taconite seals The various taconite seals are described in the following table: Table 3-2 Taconite seal versions Taconite seal versions Application Remarks "E"... -

Page 34: Backstop

Description 3.7 Backstop Taconite seal versions Application Remarks "F-H" Output shaft • Regreasable labyrinth on the output side, dust-proof protection cover on the oppo‐ Design H: (hollow shaft with parallel keyway) site side Design K: (hollow shaft with spline according to DIN 5480) "F-K"... -

Page 35: Figure 3-13 Backstop

Description 3.7 Backstop Principle of operation The backstop is fitted with centrifugally-operated sprags. If the gear unit rotates in the specified direction, the inner ring rotates together with the sprag cage in the direction of rotation of the shaft, while the outer ring remains stationary. Above a certain speed (disengagement speed) the sprags disengage from the outer ring. -

Page 36: Torque Limiting Backstop (Special Version)

3.8 Torque limiting backstop (special version) The blocking direction of the backstop can be changed by turning over the cage. You must always contact Flender in advance if you wish to change the blocking direction. NOTICE Damage to the backstop and gear unit due incorrect direction of rotation Damage to the backstop and gear unit due incorrect direction of rotation possible. -

Page 37: Figure 3-14 Torque Limiting Backstop

You can change the blocking direction of the backstop by turning over the cage. You must always contact Flender in advance if you wish to change the blocking direction. NOTICE Damage to the backstop and gear unit due incorrect direction of rotation Damage to the backstop and gear unit due incorrect direction of rotation possible. -

Page 38: Cooling

It is not permissible that dimension "x “ specified on the backstop type plate is fallen below. min. Flender must be contacted once this dimension is reached. WARNING Risk of injury as a result of moving system parts There is a risk that after the motor is switched off the load cannot be securely kept in position, and that it can accelerate in the reverse direction. -

Page 39: Fan

Description 3.9 Cooling 3.9.1 Principle of operation Generally, the fan is mounted on the high-speed shaft of the gear unit and is protected from accidental contact using an air guide cover. The fan draws in air through the protective grille of the air guide cover and blows it along the lateral air ducts on the gear unit housing. -

Page 40: Cooling Coil

Description 3.9 Cooling 3.9.2 Cooling coil Introduction The gear unit can be equipped with a cooling coil in the oil sump. The cooling coil is connected to a cooling water supply. The cooling water connection must be provided by the operator. The cooling water can be fresh water, sea water or brackish water. -

Page 41: Mounted Oil Supply System

Description 3.9 Cooling The diagram below shows the cooling coil connections: ① ③ Output shaft Reducer screw ② Cooling water connection Figure 3-16 Cooling coil connections Further information For further information and a detailed illustration of the gear unit and the connection dimensions, please refer to the dimension drawings in the complete gear unit documentation. -

Page 42: Figure 3-17 Oil Supply System With Air-Oil Cooler Mounted On Gear Unit, Type B2

Description 3.9 Cooling • Temperature control valve • Piping Note Observe the flow direction of the pump When connecting the valves, observe the flow direction of the pump. Refer to the pump operating instructions in the complete gear unit documentation to ascertain whether the flow direction of the pump used depends on the direction of rotation. -

Page 43: Mounted Oil Supply System With Water-Oil Cooler

Description 3.9 Cooling Additional information about the oil supply system and control notes can be found in the separate data sheet, in the list of equipment and in the oil supply system operating instructions provided in the complete gear unit documentation. Temperature control valve A temperature control valve is installed in the air-oil cooler bypass. -

Page 44: Figure 3-18 Oil Supply System With Water-Oil Cooler Mounted On Gear Unit, Type B2

Description 3.9 Cooling The operating company must establish the cooling water connection required. Note Observe the flow direction of the pump When connecting the valves, observe the flow direction of the pump. Refer to the pump operating instructions in the complete gear unit documentation to ascertain whether the flow direction of the pump used depends on the direction of rotation. -

Page 45: Pump

Description 3.9 Cooling Further information Additional information such as connection dimensions and a detailed illustrated description of the gear unit and the oil supply system with water-oil cooler can be found in the dimension drawing in the complete gear unit documentation. Additional information about the oil supply system, control notes, the required cooling water quantity and the maximum permissible water intake temperature can be found in the separate data sheet, in the list of equipment and in the oil supply system operating instructions provided... -

Page 46: Separate Oil Supply System

Description 3.11 Shrink disk 3.9.4 Separate oil supply system A separate oil supply system can be used for cooling the oil. Note Oil supply system according to the ATEX Directive The oil supply system must be designed and manufactured in compliance with the ATEX Directive. -

Page 47: Heating

Description 3.12 Heating Further information Further information about the shrink disk can be found in the shrink disk operating instructions. These are included in the complete documentation for the gear unit. 3.12 Heating Introduction At low ambient temperatures it may be necessary to preheat the gear unit oil before switching on the drive or while it is in operation. -

Page 48: Oil-Level Monitoring System For The Heating Elements

Description 3.12 Heating The diagram below shows gear unit heating: ① ② Temperature monitor Heating element Figure 3-19 Heating for gear units, types B... and T3.. Heating element control Heating elements can be controlled by a temperature monitor. The temperature monitor provides a signal to be amplified when the minimum and maximum temperatures are reached. -

Page 49: Oil Level Indicator

Description 3.14 Oil level monitoring system Principle of operation The "Oil level too low" signal should be connected up so that the heating elements are switched off. This guarantees that the heating elements are only operated if they are completely immersed in the oil. -

Page 50: Oil Temperature Monitoring

Description 3.15 Oil temperature monitoring The oil-level monitoring system has been designed to check the oil level when the gear unit is at a standstill before it starts. Mounting position When using an oil-level monitoring system it is especially important to ensure that the gear unit is in a horizontal mounting position. -

Page 51: Bearing Monitoring

Description 3.16 Bearing monitoring The following diagram shows an oil temperature monitor mounted on the gear unit: ① Pt 100 resistance thermometer Figure 3-21 Oil-level monitoring system for gear units, types B... and T3.. Further information Further information, a detailed illustration of the gear unit and the position of the mounted components can be found in the dimension drawing in the complete documentation for the gear unit. -

Page 52: Bearing Monitoring By Shock-Pulse Transducer

Description 3.16 Bearing monitoring The following diagram shows bearing monitoring using a Pt 100 resistance thermometer: ① Pt 100 resistance thermometer Figure 3-22 Bearing monitoring using a Pt 100 resistance thermometer: Further information Further information, a detailed illustration of the gear unit and the position of the mounted components can be found in the dimension drawing in the complete documentation for the gear unit. -

Page 53: Speed Encoder

Description 3.17 Speed encoder The following diagram shows a bearing monitoring system that uses a shock-pulse transducer: ① Shock-pulse transducer Figure 3-23 Bearing monitoring using shock-pulse transducer Further information Further information, a detailed illustration of the gear unit and the position of the mounted components can be found in the dimension drawing in the complete documentation for the gear unit. -

Page 54: Auxiliary Drive

Either Flender or the customer provides the auxiliary drive. The auxiliary drive is connected to the main gear unit through an overrunning clutch. The auxiliary drive is mounted onto a connection flange, which in turn is attached to the main gear unit. -

Page 55: Auxiliary Drive, Designed As Maintenance Drive

Description 3.18 Auxiliary drive The basic configuration of the gear unit with main and auxiliary drive is shown in the following diagram. ① ⑤ Main gear unit Main motor ② ⑥ Output shaft of the main gear unit Auxiliary motor ③... - Page 56 Description 3.18 Auxiliary drive Oil supply for the auxiliary gear unit The auxiliary gear unit has its own oil circuit, which is separate from that of the main gear unit. The auxiliary gear unit is already filled with oil when delivered. Speed monitoring To avoid overspeeds if the overrunning clutch was to malfunction, for safety reasons, customers should equip the drive combination with a speed monitoring system.

-

Page 57: Figure 3-26 Gear Unit Design

Description 3.18 Auxiliary drive ① ⑤ Pulse encoder for speed monitoring Main gear unit ② ⑥ Auxiliary gear unit Backstop ③ ⑦ Overrunning clutch Output shaft of the main gear unit ④ Intermediate flange Figure 3-26 Gear unit design The diagram below shows the available gear unit equipment for types B3.H / T3.H ≤ 12: ①... -

Page 58: Auxiliary Drive, Designed As A Load Drive

Description 3.18 Auxiliary drive Figure 3-27 Gear unit equipment for types B3.H / T3.H ≤ 12 The diagram below shows the available gear unit equipment for types B3.H ≥ 13: ① ⑧ Shaft seal ② ⑨ Lifting eye and/or eye bolt Electric motor ③... -

Page 59: Overrunning Clutch

Description 3.18 Auxiliary drive Oil supply for the auxiliary gear unit The auxiliary gear unit has its own oil circuit, which is separate from that of the main gear unit. The auxiliary gear unit is already filled with oil when delivered. Brake at the auxiliary drive motor The motors of the auxiliary drives are equipped with a spring-actuated brake so that if the overrunning clutch malfunctions, dangerous overspeeds can be avoided. -

Page 60: Gear Units With Auxiliary Drive And Torque-Limiting Backstop

Description 3.18 Auxiliary drive of rotation. In this case, the input shaft of the main gear unit and the main motor simultaneously also slowly rotate when a flexible coupling is used between the main motor and gear unit. Note Electrically interlock the main motor and the auxiliary drive motor so that only one of the two motors can be switched on. -

Page 61: Application Planning

Application planning Scope of delivery The scope of delivery is listed in the shipping documents. Immediately upon receiving the gearbox, check that everything has been delivered. Report any damaged and/or missing parts to Customer Services (Page 131) immediately. WARNING Serious injury through defective product Serious injury may occur. - Page 62 Application planning 4.2 Transport WARNING Risk of crushing There is a risk of being crushed by a component that becomes detached because the hoisting gear and load suspension device are not suitable for handling it. When lifting, please observe the load distribution information on the packaging. When the product is in a raised position, transport it slowly and carefully to avoid injury to persons or damage to the gear unit.

-

Page 63: Attachment Points

Application planning 4.3 Attachment points • Loads must not be suspended from the tip of a load hook • Always place the products down on a level, non-slip and stable base DANGER Falling load There is a risk of fatal injury from falling loads if these have not been securely attached to the lifting equipment. -

Page 64: Figure 4-2 Shear And Lateral Pulling When Using Eye Bolts

Application planning 4.3 Attachment points The shear pulling must not exceed 45° when the lifting equipment is attached to sling swivels. Note Damage to the gear unit during transport Using the wrong attachment points can cause damage when transporting large gear units. Always use sling swivels for gear units larger than size 23. -

Page 65: Figure 4-3 Position Of The Attachment Points For Gear Units, Type B

Application planning 4.3 Attachment points Position of attachment points The following diagram shows the position of the attachment points for gear units, type B... / T3..: Figure 4-3 Position of the attachment points for gear units, type B... / T3..: The following diagram shows the position of the attachment points for gear units, type B3.E: Figure 4-4 Position of the attachment points for gear units, type B3.E... - Page 66 Application planning 4.3 Attachment points Figure 4-6 Position of the attachment points for gear units, type B... / T3.. with motor: The following diagram shows the position of the attachment points for gear units, type B... / T3.. with gear unit swing base: Figure 4-7 Position of the attachment points for gear units, type B...

-

Page 67: Assembly

Assembly General assembly instructions The assembly work must be performed very carefully by authorised, trained and suitably instructed personnel. Liability will be disclaimed for damage caused by the incorrect performance of this work. Requirements Improper use can damage the gear unit. Be sure to take the following precautions: •... - Page 68 Assembly 5.1 General assembly instructions DANGER Danger of explosion due to gear unit heating caused by environmental effects. Danger to life through ignition of a potentially explosive atmosphere possible if gear unit becomes overheated due to environmental effects. The gear unit must not be heated by external heat sources (exposure to direct sunlight, for example) while it is in operation and measures must be taken where necessary to protect it.

-

Page 69: Unpacking The Gear Unit

Assembly 5.2 Unpacking the gear unit Unpacking the gear unit Introduction The scope of delivery is listed in the shipping documents. WARNING Severe injury caused by the content of the packing sliding When opening the packing in which the part is transported, there is a risk of being crushed. While being transported, the content of the packing can slide. -

Page 70: Gear Unit Assembly

Assembly 5.3 Gear unit assembly Gear unit assembly 5.3.1 Foundation Properties of the foundation The foundation must have the following properties: • Stability • Designed for torsional rigidity • Reaction forces from the gear unit must be braced Requirements of the foundation The foundation must meet the following requirements: •... -

Page 71: Mounting On A Concrete Foundation

Assembly 5.3 Gear unit assembly 5.3.1.1 Mounting on a concrete foundation Installation on a foundation frame Use of incorrect attachment points Use of incorrect attachment points may result in damage to the gear unit. To transport the gear unit, only attach slings to the attachment points provided for this purpose. The threads in the end faces of the shaft ends may not be used for attaching lifting equipment. - Page 72 Assembly 5.3 Gear unit assembly NOTICE Damage caused by unevenly tightening the fastening bolts The gear unit can be damaged by unevenly tightening the fastening bolts. Evenly tighten the fastening bolts. When tightening the fastening bolts, make sure that the gear unit is free of mechanical stress.

- Page 73 Assembly 5.3 Gear unit assembly NOTICE Damage caused by unevenly tightening the hexagon nuts The gear unit can be damaged by unevenly tightening the hexagon nuts. Evenly tighten the hexagon nuts. Ensure that the gear unit is not deformed or distorted when tightening the fastening bolts.

- Page 74 Assembly 5.3 Gear unit assembly 8. After the concrete has set, tighten the fastening bolts of the foundation blocks with the specified tightening torque (Page 108). 9. Record the alignment dimensions and keep the report in a safe place together with these operating instructions.

- Page 75 Assembly 5.3 Gear unit assembly 3. Attach the pressure plate and tighten the nuts. 4. Place a piece of wood under the anchor bolt so that it is approximately 10 mm from the upper edge of the support. 5. Place the gear unit down. NOTICE Use of incorrect attachment points Use of incorrect attachment points may result in damage to the gear unit.

-

Page 76: Mounting On A Gear Unit Swing Base

Assembly 5.3 Gear unit assembly 4. Align the gear unit with the supports (Page 79). – Observe the values on the alignment strips. – Maintain the alignment tolerances to the units connected at the input and output according to the permissible angular and axial displacements of the couplings. 5. - Page 77 Assembly 5.3 Gear unit assembly The threads in the end faces of the shaft ends may not be used for attaching lifting equipment. Lifting equipment must be adequately designed to accommodate the weight of the gear unit. NOTICE Poor stability Damage to the gear unit is possible if it is not mounted on a stable foundation.

- Page 78 Damage to the gear unit due to incorrectly mounting the motor and gear unit swing base is possible. The motor and swing base may only be mounted after prior consultation with Flender. The torque arm must be attached on the machine side without resulting in any distortion or deformation.

-

Page 79: Mounting

Assembly 5.3 Gear unit assembly 5.3.2 Mounting 5.3.2.1 Mounting on a housing foot Description of assembly work Measures to be taken prior to assembly CAUTION Risk of chemical burns due to chemical substances There is a risk of chemical burns when handling aggressive cleaning agents. Please observe the manufacturer's guidelines on how to handle cleaning agents and solvents. - Page 80 Assembly 5.3 Gear unit assembly NOTICE Damage as a result of blows or impact Damage in the gear unit as a result of blows or impact as possible. Pull on the coupling using the appropriate pulling equipment. Avoid damaging the shaft sealing rings and the shaft running surfaces when fitting coupling parts.

- Page 81 Assembly 5.3 Gear unit assembly Alignment Depending on the order specification, the top of the housing has machined surfaces (alignment surfaces) to assist with provisional alignment of the gear unit in the horizontal direction. DANGER Risk of fatal injury from flying fragments Failure to align the unit with the required degree of accuracy can cause the shaft to rupture.

- Page 82 Assembly 5.3 Gear unit assembly Figure 5-7 Alignment surfaces for gear units up to size 12: For gear units, sizes 13 to 28, in addition there are also special alignment surfaces on the upper part of the housing for realigning the gear unit. To make it even simpler to align, gear units of these sizes have alignment threads in the housing feet.

-

Page 83: Mounting The Torque Arm For The Gear Unit Housing

Damage to the gear unit due to incorrect mounting of the motor and torque arm is possible The motor and torque arm may only be mounted after prior consultation with Flender. Mount the torque arm to the machine side without causing any distortion or deformation. -

Page 84: Preparations

Assembly 5.4 Shaft-mounted gear unit with hollow shaft and parallel keyway 5.4.1 Preparations Preparatory measures To facilitate dismantling (Page 86), insert a pressure oil connector into the shaft end of the driven machine until it is flush with the bore of the hollow shaft. This connector can also be used to feed in rust remover. -

Page 85: Mounting

Assembly 5.4 Shaft-mounted gear unit with hollow shaft and parallel keyway • If necessary, rework the components with an appropriate tool and then clean them again. • Apply an appropriate lubricant to the contact surfaces to protect them against fretting corrosion. -

Page 86: Axial Locking

Assembly 5.4 Shaft-mounted gear unit with hollow shaft and parallel keyway The diagram below shows the mounting process with screw spindle for gear units with a hollow shaft and parallel keyway: ① ⑤ Machine shaft ② ⑥ End plate Hollow shaft ③... - Page 87 Assembly 5.4 Shaft-mounted gear unit with hollow shaft and parallel keyway Note Reducing the risk of corrosion When using jacking screws or screw spindles, to avoid the risk of corrosion, round off and grease the end of the thread (head) that presses against the driven machine. Procedure In order to dismantle a shaft-mounted gear unit from the machine shaft, proceed as follows: 1.

- Page 88 Assembly 5.4 Shaft-mounted gear unit with hollow shaft and parallel keyway The following diagram shows the dismantling procedure using hydraulic pulling equipment for gear units with hollow shaft and parallel keyway: ① ⑤ Screw spindle Machine shaft ② ⑥ Hydraulic pulling equipment Hollow shaft ③...

-

Page 89: Table

Assembly 5.4 Shaft-mounted gear unit with hollow shaft and parallel keyway Threaded holes at the face sides of gear unit hollow shafts Refer to the following table for the dimensions of the threaded holes at the face sides of gear unit hollow shafts: Table 5-1 Dimensions for the threaded holes at the face sides of gear unit hollow shafts... -

Page 90: 5.5 Shaft-Mounted Gear Unit With Hollow Shaft And Spline According To Din 5480

Assembly 5.5 Shaft-mounted gear unit with hollow shaft and spline according to DIN 5480 Shaft-mounted gear unit with hollow shaft and spline according to DIN 5480 Introduction The shaft end of the driven machine must have a spline according to DIN 5480. Furthermore, it should have a hole centred in its end face as defined by DIN 332, form DS (with thread). -

Page 91: Assembly

Assembly 5.5 Shaft-mounted gear unit with hollow shaft and spline according to DIN 5480 5.5.2 Assembly Measures to be taken prior to assembly CAUTION Risk of injury due to chemical substances Observe the manufacturer’s guidelines on how to handle lubricants and solvents. Wear suitable protective clothing. - Page 92 Assembly 5.5 Shaft-mounted gear unit with hollow shaft and spline according to DIN 5480 NOTICE Damage to the rolling-contact bearings The rolling-contact bearings can become damaged if the gear unit skews during mounting. The hollow shaft may be mounted on a machine shaft shoulder only if the gear unit features one of the following: •...

-

Page 93: Axial Locking

Assembly 5.5 Shaft-mounted gear unit with hollow shaft and spline according to DIN 5480 Special aspects of shaft-mounted gear unit with hollow shaft and spline according to DIN 5480 Hydraulic pulling equipment can be used instead of the nut and screw spindle shown in the diagram. - Page 94 Assembly 5.5 Shaft-mounted gear unit with hollow shaft and spline according to DIN 5480 4. Wait for the rust remover to work and then use a fixture to dismantle the gear unit. 5. Depending on the conditions on site, you can use one of the following methods to remove the gear unit from the machine shaft: –...

-

Page 95: Shaft-Mounted Gear Unit With Hollow Shaft And Shrink Disk

Assembly 5.6 Shaft-mounted gear unit with hollow shaft and shrink disk Refer to the following table for the maximum forcing pressures: Table 5-3 Maximum forcing pressures Gear unit size Maximum forcing Gear unit size Maximum forcing pressures in N pressures in N 22 600 113 600 33 000... -

Page 96: Assembly

Assembly 5.6 Shaft-mounted gear unit with hollow shaft and shrink disk 5.6.1 Assembly Measures to be taken prior to assembly CAUTION Risk of injury due to chemical substances Observe the manufacturer’s guidelines on how to handle lubricants and solvents. Wear suitable protective clothing. Improper use can damage the gear unit. -

Page 97: Pulling On With Integrated Du Bushing

Assembly 5.6 Shaft-mounted gear unit with hollow shaft and shrink disk DANGER Danger of explosion Danger to life through ignition of a potentially explosive atmosphere caused by sparks or hot surfaces. If there is slip between the hollow shaft and stub shaft, or if the shrink disk slips on the hollow shaft, this can cause sparks and/or hot surfaces. -

Page 98: Axial Locking

Assembly 5.6 Shaft-mounted gear unit with hollow shaft and shrink disk 3. Pull on the gear unit with hollow shaft up to the seat below the shrink disk on the machine shaft. The machine shaft centres itself in the seat below the shrink disk and in the DU bushing. 4. -

Page 99: Shaft-Mounted Gear Unit With Flange Coupling

Assembly 5.7 Shaft-mounted gear unit with flange coupling NOTICE Use of incorrect attachment points Use of incorrect attachment points may result in damage to the gear unit. • Only attach the gear unit at the lifting eyes provided for this purpose. •... -

Page 100: Couplings

Assembly 5.8 Couplings Couplings Introduction The coupling parts might become misaligned as a result of: • Failure to accurately align the parts during assembly • During operation of the system: – Due to thermal expansion – Due to shaft deflection –... -

Page 101: Connecting Components

Further information You can find additional information about the permissible alignment errors for Flender couplings in the complete documentation for the gear unit. If couplings from other manufacturers are to be used, then, specifying the radial loads that occur, ask the manufacturer which alignment errors are permissible. -

Page 102: Connecting The Cooling Coil

Assembly 5.9 Connecting components Further information You can find additional information on operation and maintenance in the associated operating instructions, provided in the complete gear unit documentation. You can find the technical data of the mounted components in the contract-list of equipment provided in the complete gear unit documentation. -

Page 103: Connecting The Water-Oil Cooler

Assembly 5.9 Connecting components Further information You can find additional information on the air-oil cooler in the air-oil cooler operating instructions, provided in the complete gear unit documentation. Note Observe the information provided in chapter of the Mounted oil supply system with air-oil cooler (Page 41). -

Page 104: Installing A Separate Oil Supply System

Assembly 5.9 Connecting components 5.9.5 Installing a separate oil supply system Procedure To connect the oil supply system to the gear unit, proceed as follows: 1. Remove the dummy flange from the suction and delivery line before connecting the system. 2. -

Page 105: Connecting The Oil-Level Monitoring System

Assembly 5.9 Connecting components 5.9.8 Connecting the oil-level monitoring system Procedure To connect the oil-level monitoring system to the gear unit, proceed as follows: 1. Ensure that the filling level limit switch connection is not damaged. 2. Electrically connect the filling level limit switch. 3. -

Page 106: Electrical Connections

Assembly 5.10 Tightening procedure Further information You can find additional information on the speed encoder in the speed encoder operating instructions, provided in the complete gear unit documentation. 5.9.11 Electrical connections Procedure DANGER Electric shock Live parts can cause electric shock. Ensure that the entire plant is de-energised before starting electrical installation work. -

Page 107: Bolt Connection Classes

Assembly 5.10 Tightening procedure Note Replacing bolts Replace any bolts that are no longer fit for use by bolts of the same type and strength class. Mating threads The mating threads must have the following properties: • Made of steel or cast iron •... -

Page 108: Tightening Torques And Preload Forces

Assembly 5.10 Tightening procedure Further information You can find additional information about tightening torques when mounting motor and brake in the operating instructions from the particular manufacturer. 5.10.3 Tightening torques and preload forces The specified bolted connections must be tightened to the torques stated in the table below: The tightening torques apply to friction values of μ... -

Page 109: Final Work

Assembly 5.11 Final work Nominal Bolt Preload force for bolt connection Tightening torque for bolt connec‐ thread di‐ strength classes from the table in tion classes from the table in chap‐ ameter class chapter Bolt connection classes ter Bolt connection classes (Page 107). - Page 110 Assembly 5.11 Final work • Perform potential equalisation in accordance with the applicable regulations and guidelines. If no threaded holes are available on the gear unit for an earth connection, please take suitable alternative measures. This work must always be done by specialist electricians. •...

-

Page 111: Commissioning

Commissioning Measures prior to commissioning Take the following measures before commissioning the gear unit: • Read and observe the operating instructions. • Replace the screw plug with the air filter or the wet-air filter. Read operating instructions BA 7300 for further information. •... -

Page 112: Gear Unit With Auxiliary Drive

Commissioning 6.1 Measures prior to commissioning NOTICE The backstop and the gear unit can be damaged If you operate the gear unit adversely to the blocking direction of the backstop, the backstop and the gear unit can be damaged. Do not operate the gear unit adversely to the blocking direction of the backstop. Observe the information on the plate attached to the gear unit. -

Page 113: Gear Units With Oil Supply System

Carefully ensure that the pre-lubrication phase is not longer than 5 minutes as the oil can foam up at low temperatures. For oil temperatures below 10 °C, heat up the oil using suitable measures and contact Flender in this regard. Further information You can find additional information on the oil cooling system in the separate data sheet, and in the equipment list in the complete gear unit documentation. -

Page 114: Heating

Commissioning 6.2 Measures during commissioning • Check all the connection lines are securely tightened and leak-free. • For gear units with bearing monitoring by measuring the vibration: Measure the vibration levels of the rolling-contact bearings (Page 122) to create initial and comparison values. •... -

Page 115: Operation

Operation Operating data Introduction To ensure correct, trouble-free operation of the system, observe the operating data of the gear unit. The valid operating data can be found in the annex Technical data. The following operating data apply to the oil: Table 7-1 Operating data Maximum operating tempera‐... -

Page 116: Taking The Unit Out Of Service

1. Switch off the drive assembly if it exhibits irregular behaviour during operation. 2. Refer to the Fault information (Page 126) to find the cause of the fault. 3. If you still cannot determine the fault cause, contact Flender Customer Services. DANGER An explosive atmosphere can be ignited An explosive atmosphere can be ignited if the gear unit overheats as the oil level is too low. -

Page 117: Servicing

Servicing General maintenance information The operator must ensure compliance with the stipulated time limits. This also applies if the maintenance activities are included in the operator’s internal maintenance schedules. The gear unit could be damaged if the stipulated time limits for maintenance and servicing are not observed. -

Page 118: Maintenance Schedule

Servicing 8.2 Maintenance schedule Maintenance schedule Maintenance and servicing activities The following table provides an overview of all maintenance and servicing activities which you are required to perform continuously or at regular intervals. Table 8-1 Maintenance and servicing activities Intervals and time limits Measures As required Replace the wet-air filter... -

Page 119: Maintenance And Servicing Work

Servicing 8.3 Maintenance and servicing work Intervals and time limits Measures Every 2 years Carry out a general inspection of the gear unit Check the cooling coil Check that all of the fastening bolts are tight Clean the fan and gear unit Every 20 000 operating hours, at least every Change the oil if using semi-synthetic oil of API Group III, 4 years... -

Page 120: Checking The Oil Temperature

3. Measure the temperature of the oil in the oil sump. 4. Compare the measured value with the maximum permissible oil temperature (Page 115). 5. Immediately stop the gear unit if the maximum permissible oil temperature is exceeded. Contact Flender Customer Services. 8.3.3 Replacing the backstop... -

Page 121: Filling The Backstop With Oil

Servicing 8.3 Maintenance and servicing work 8.3.4 Filling the backstop with oil Oil type and filling filter When filling the backstop with oil, observe the following points: • Use the same oil type and oil viscosity as for the gear unit itself. •... -

Page 122: Checking The Speed Monitoring Of The Auxiliary Drive

Servicing 8.3 Maintenance and servicing work 8.3.7 Checking the speed monitoring of the auxiliary drive Procedure Proceed as follows to check the speed monitoring of the auxiliary drive: 1. Switch on the auxiliary drive. 2. Check whether the speed monitor switches. Result If the speed monitor does not switch, repair it or if necessary replace it. -

Page 123: Checking The Ignition Protection System

Servicing 8.3 Maintenance and servicing work 8.3.9 Checking the ignition protection system Procedure Proceed as follows to check the ignition protection system: 1. Check the ignition protection system for temperature monitoring to ensure that it is functioning correctly. 2. Check the ignition protection system for temperature monitoring for measurement accuracy. Further information You can find additional information on checking the ignition protection system in the operating instructions for the ignition protection system, provided in the complete gear unit... -

Page 124: Checking The Cooling Coil

Before you use a cleaning agent, check whether it is suitable for use on the cooling coil materials. You must consult Flender Customer Services. Carefully read the instructions for use supplied by the manufacturer before using different kinds of cleaning agent. -

Page 125: Inspecting The Shrink Disk

General inspection of the gear unit General inspection of the gear unit by Customer Services Arrange for Flender Customer Services to perform a general inspection on the gear unit. Thanks to their experience, these engineers are best placed to assess which gear unit components need to be replaced. -

Page 126: Possible Faults

Possible faults The faults listed below are only intended as a troubleshooting guide. If any faults occur while the unit is still under warranty, do not allow anyone except Flender Customer Services to attempt a repair. Even after the warranty period has expired, you should still arrange for faults to be rectified by Flender Customer Services. - Page 127 Servicing 8.4 Possible faults Possible faults Causes Possible remedies Outer surface of gear Inadequate sealing of the housing • Seal housing cover or joints unit soiled with oil cover or joints Labyrinth seals soiled with oil, incor‐ • Check oil filling rect transport position •...

- Page 128 Servicing 8.4 Possible faults Possible faults Causes Possible remedies Oil is foaming in the Preservation agent not completely • Change the oil gear unit drained off Oil supply system left in operation • Switch off the oil supply system for too long at low temperatures •...

- Page 129 Servicing 8.4 Possible faults Possible faults Causes Possible remedies Elevated temperature Oil level in the gear unit housing too • Check the oil level during operation high • Correct the oil level if necessary Oil is too old • Check when the last oil change was done •...

- Page 130 Servicing 8.4 Possible faults Possible faults Causes Possible remedies Contamination indica‐ Double change-over filter clogged • Changeover the double change-over filter corresponding tor of the double to the separate operating instructions change-over filter trig‐ • Clean the filter element gers an alarm Water in the oil Oil supply system or cooling coil de‐...

-

Page 131: Service & Support

Am Industriepark 2 46562 Voerde Germany Tel.: +49 (0)2871 / 92‐0 Fax: +49 (0)2871 / 92‐1544 Further information Further information about service and support can be found on the Internet. Service & Support (https://www.flender.com/service) Assembly and operating instructions A5033en Edition 06/2020... - Page 132 Service & Support Assembly and operating instructions A5033en Edition 06/2020...

-

Page 133: Disposal

Disposal Disposal of the gear unit When disposing of the gear unit after its useful life, please observe the following measures: • Remove operating oil, preservative agents and coolant from the gear unit and dispose of it according to regulations. •... - Page 134 Disposal Assembly and operating instructions A5033en Edition 06/2020...

-

Page 135: Spare Parts

Note Damage to the gear unit due to use of unsuitable spare parts Only use original spare parts from Flender. Flender shall not accept any warranty claims for spare parts that are not supplied by Flender. Other spare parts are not tested and approved by Flender. Non-approved spare parts may possibly change the design characteristics of the gear unit and thus impair its active or passive safety. - Page 136 Spare parts Assembly and operating instructions A5033en Edition 06/2020...

-

Page 137: Declaration Of Incorporation

Declaration of incorporation Assembly and operating instructions A5033en Edition 06/2020... - Page 138 Declaration of incorporation Assembly and operating instructions A5033en Edition 06/2020...

-

Page 139: Declaration Of Conformity

Declaration of conformity Assembly and operating instructions A5033en Edition 06/2020... - Page 140 Declaration of conformity Assembly and operating instructions A5033en Edition 06/2020...

-

Page 141: Technical Data

Rating plate The limits of the intended use of the gear unit are defined on the basis of these data and the contractual agreements concerning the gear unit concluded between Flender and the customer. Assembly and operating instructions A5033en Edition 06/2020... - Page 142 Technical data C.1 General technical data Further information Further information about these technical data can be found in the separate data sheet and the dimension drawings in the complete documentation for the gear unit. Further information about all major accessories including their technical data can be found in the order-specific list of equipment in the complete documentation for the gear unit.

-

Page 143: Table C-1 Atex Marking

Technical data C.1 General technical data ATEX marking The ATEX marking for open-cast mining applications is shown in the following table: Table C-1 ATEX marking Equi Equip Explosive Explo‐ Tem‐ Maximum Marking example ment atmos‐ sion pera‐ surface tem‐ cate‐ phere group/ ture... -

Page 144: Ambient Temperature

-20 °C up to 40 °C. By applying various suitable measures, the gear unit can be used in the ambient temperature range extending from -40 °C up to 60 °C. However, this must always be authorised by Flender. In each individual case, the ambient temperature range stamped on the rating plate always applies. -

Page 145: Weights

The sound pressure level applies to a gear unit in the warm condition at an input speed n output power P according to the rating plate, for measurements carried out on a Flender test bench. If several values are given, then the highest speed and power values apply. -

Page 146: Enveloping Surface Sound Pressure Level

Technical data C.5 Enveloping surface sound pressure level Refer to the following table for the enveloping surface sound pressure level L in dB(A) for bevel helical gear units with fan. Table C-2 Enveloping surface sound pressure level Type in rpm Gear unit size 5 - 8 1500... -

Page 147: Table

Technical data C.5 Enveloping surface sound pressure level Type in rpm Gear unit size 12.5 1500 - 31.5 1000 35.5 1500 - 56 1000 63 - 1500 1000 You can obtain information about the enveloping surface sound pressure levels for gear unit sizes 27 and 28 on request. - Page 148 Technical data C.5 Enveloping surface sound pressure level Type in rpm Gear unit size 5 - 8 1500 1000 9 - 14 1500 1000 16 - 1500 22.4 1000 12.5 1500 - 31.5 1000 35.5 1500 - 56 1000 63 - 1500 1000 You can obtain information about the enveloping surface sound pressure levels for gear unit...

-

Page 149: Index

Index Air-oil cooler, 42 Dip lubrication, 29 Principle of operation, 41 Directions of rotation, 23 Alignment Disclaimer, 11 Alignment surface, 81 Disposal, 133 Prealignment, 81 Documentation landscape, 12 ATEX Directive, 11 Attachment points, 67 Auxiliary drive Checking, 121 Environmental protection, 133 Checking the speed monitoring, 122 Equipment features, 25 Commissioning, 112... - Page 150 Index Function, 47 Operating data, 115 Heating elements, 47 Oil, 115 Oil level monitoring system, 48 Ordering spare parts, 131, 135 Temperature monitor, 48 Output shaft versions, 24 Interval, 118 Pressure lubrication, 30 Irregularities in operation, 115 Pressure monitor, 45 Pressure monitoring, 45 Protective equipment, 18 Pump, 45...

- Page 151 Index Temperature control valve, 43 Transport information, 61 Transport symbols, 63 Troubleshooting, 126 Types of danger, 18 Unpacking, 69 Used oil, 133 Using the gear unit, 21 Venting screw Cleaning, 119 Warning symbols, 17 Water-oil cooler, 43, 44 Assembly and operating instructions A5033en Edition 06/2020...

- Page 152 Index Assembly and operating instructions A5033en Edition 06/2020...

- Page 154 FLENDER GEAR UNITS Belt-conveyor gear unit Assembly and operating instructions A5033en Edition 06/2020 Flender GmbH Alfred-Flender-Straße 77 46395 Bocholt GERMANY...

Need help?

Do you have a question about the B H 23 28 Series and is the answer not in the manual?

Questions and answers