Table of Contents

Advertisement

MASCHIO GASPARDO S.p.A.

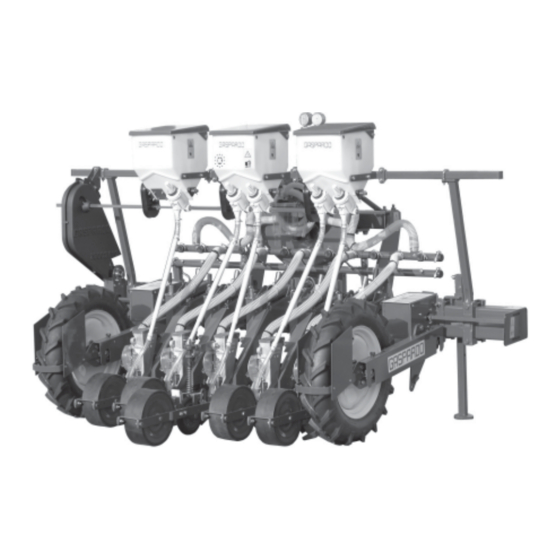

ORIETTA

OLIMPIA

IT

USO E MANUTENZIONE

EN

USE AND MAINTENANCE

DE

GEBRAUCH UND WARTUNG

FR

EMPLOI ET ENTRETIEN

ES

EMPLEO Y MANTENIMIENTO

Cod. G19502812

2011-08

*)

*) Valido per Paesi UE

*) Valid for EU member countries

*) Valable dans les Pays UE

*) Gilt für EU-Mitgliedsländer

*) Válido para Países UE

Advertisement

Table of Contents

Summarization of Contents

1.0 Introduction

Attention to Operating and Safety Instructions

Important warnings regarding machine use and operator qualifications.

1.1 Guarantee Conditions

Conditions that void the machine's warranty, including technical limits and improper use.

1.1.1 Guarantee Expiry

Conditions that void the machine's warranty, including technical limits and improper use.

1.2 Seeder Description and Safety Cautions

Operating speed and transport guidelines for safe machine use.

1.4 Machine Identification and Handling

Attention to Manual Handling Safety

Customer must apply safety rules for manual handling of loads.

1.5 Handling Safety Precautions

Guidelines for safe handling operations and proper disposal of packaging materials.

1.7 Danger and Indicator Signals

1.7.1 Warning Signals

General warnings for safe operation and maintenance.

1.7.2 Danger Signals

Specific danger signals related to machine operation and movement.

1.7.3 Indicator Signals

Indicator signals for lifting points, greasing, and transport.

2.0 Safety Regulations and Accident Prevention

General Safety Norms

General safety rules for operating the seeder, including operator conduct and machine checks.

Tractor Hitch Safety

Safety instructions for attaching and handling the tractor hitch and equipment.

Transport on Road Safety

Highway code compliance and safety for road transport.

Hydraulic System Safety Measures

Precautions for connecting and operating hydraulic systems to prevent injury.

Cardan Shaft Safety

Safety instructions for installing, using, and maintaining the Cardan shaft.

3.0 Instructions for Use

Maintenance in Safety

Guidelines for personal protective gear during maintenance and operation.

3.1 Attachment to the Tractor

Procedure for safely connecting the seeder to the tractor's three-point hitch.

Danger During Tractor Attachment

Critical safety warnings for attaching the seeder to the tractor.

3.2 Unhooking the Seed Drill from the Tractor

Danger During Tractor Unhooking

Critical safety warnings for unhooking the seeder from the tractor.

3.3 Adapting the Cardan Shaft

Caution for Cardan Shaft Fitting

Guidelines for correctly fitting and checking the Cardan shaft length and guards.

Attention to Cardan Shaft Transport

Transport instructions for the seeder.

3.4 Hydraulic Systems

Hydraulic System Regulation

Instructions for regulating oil flow in hydraulic systems using specific valves.

Warning on Hydraulic System Pressure

Caution regarding hydraulic system pressure adjustments and potential damage.

3.6 Machine Transport

Caution for Hoisting and Loading

Safety precautions for hoisting and loading the machine onto transport vehicles.

Danger During Hoisting and Transport

Hazards associated with machine hoisting and transport operations.

Transit and Transport on Public Highways

Rules for safe road transport, including signage and vehicle compatibility.

Attention to Transport Requirements

Transport requirements for the seeder, including empty tanks and speed limits.

3.7 Folding Frame Operation

Danger During Folding Frame Operation

Warning about the danger of operating near the folding frame mechanism.

3.7.1 Description of Functioning

Opening the Folding Frame

Steps for opening the folding frame, connecting hydraulics and ensuring proper alignment.

Closing the Folding Frame

Steps for closing the folding frame, securing it for transport and discharging hydraulic pressure.

Optional Two-Stage Cylinders

Information on optional two-stage cylinders for frame movement and alignment.

3.8 Planting Unit

3.8.1 Runner Shoes

Selection guide for runner shoes based on seed type and soil conditions.

Furrow Opener Depth Adjustment

Procedure for adjusting furrow opener depth using the handle and indicator.

3.9 Seed Distributor

Selector Adjustment

Adjusting the selector for seed plate changes and fine-tuning seed selection.

Micro-Selector Operation

Using and adjusting the micro-selector for precise seed selection and disabling if not needed.

Field Adjustments and Control

Steps for field adjustments of selectors, vacuum, and blow-off devices.

3.10 Seeding

3.10.1 Distribution Adjustment

Adjusting seed distribution based on seed type and longitudinal distance.

3.10.2 Seed Plates Table

Table listing seed types and corresponding hole diameters for seed plates.

1) Using the Seed Investment Table

Using the seed investment table to calculate seed quantity and longitudinal distance.

2) Using Longitudinal Seed Planting Distances Table

Using seed planting distances table to determine gear combinations for desired spacing.

3.10.4 Longitudinal Seeding Distance

Important Note on Seed Distance

Instructions for adjusting seed planting distance using gearbox and chain.

3.11 Aspirator Operation

Vacuum Gauge Functionality

Indicates suction pressure from 0 to -100 mbar for seed distribution.

Pressure Gauge Functionality

Indicates blowing pressure from 0 to 25 mbar for seed distribution.

Important Fan Cooling Advice

Fan cooling and PTO speed adjustment advice for optimal operation.

Warning on Aspirator Belt Tension

Procedure for checking and adjusting the aspirator belt tension.

3.12 Seed Aspirator Device

Using the Seed Aspirator

Instructions for using the seed aspirator to recover leftover seeds.

3.14 Floating Wheels

Floating Wheels Assembly

Assembly steps for floating wheels, including tension adjustment.

3.15 Row Marker Operation

Row Marker Disc Adjustment

Instructions for attaching and adjusting row marker discs.

Row Marker Trace on Tractor Wheel

Calculation for row marker trace distance on tractor wheel.

Row Marker Trace in Tractor Centre

Calculation for row marker trace distance in tractor centre.

3.16 Distribution of Chemical Products

Hopper and Tank Filling

Procedure for filling hoppers and tanks with fertilizer and insecticide, including safety warnings.

Hopper Capacity Details

Table detailing hopper capacities and materials.

4.0 Operations for Putting the Machine into Service

4.1 When the Machine is New

Initial assembly and checks for a new machine.

4.2 Checks and Preventative Maintenance

Routine checks and preventative maintenance for safety and operation.

4.3 Attachment to the Tractor

Procedure for safely connecting the seeder to the tractor's three-point hitch.

4.4 Preparing for Seeding - Danger

Chemical substance handling precautions and general safety warnings.

4.5 Distribution of Chemical Products

Danger During Chemical Handling

Chemical substance handling precautions and general safety warnings.

4.6 During Seeding

Caution for Seeding Operations

Safety precautions regarding non-original parts and sudden movements.

Important Seeding Recommendations

Operating recommendations for smooth and safe seeding operations.

5.0 Maintenance Overview

Caution on Maintenance Periods

Notes on maintenance periods and the importance of cleaning grease nipples.

Attenzione: Handling Oils and Greases

General warnings about handling oils, greases, and chemicals.

5.0 Maintenance Schedule

5.0.1 When the Machine is New

Initial bolt tightening check after first eight hours of operation.

5.0.2 Beginning of Seeding Season

Cleaning the air filter and clearing condensation/impurities from pipes.

5.0.3 Every Eight Hours of Operation

Greasing universal joints, row-marker pin, and transmission chains; checking belt tension.

5.0.4 Every Fifty Hours of Operation

Checking seed plates, distributor interior, row-marker arm pin, and frame joints.

5.0.5 Every Six Months

Greasing self-aligning bearings of drive wheels and Cardan shaft bevel gears.

5.0.6 Every Five Years

Replacing all hydraulic system tubes.

5.0 Maintenance Schedule Continued

5.0.7 Periodically

Checking seed drill tyre pressure.

5.0.8 Rest Periods

End-of-season maintenance, cleaning, part checks, and storage recommendations.

5.0.9 Replacing the Seed Plate

Safety precautions for replacing seed plates and cover gaskets.

Replacing the Cover Seal

Procedure for checking and replacing the seed distributor cover seal.

5.0.10 Recommended Lubricants

Recommended lubricants for general greasing and specific points.

6.0 Demolition and Disposal

EC Declaration of Conformity

Declaration of compliance with safety and health requirements per European Directive 2006/42/EC.

Need help?

Do you have a question about the OLIMPIA Series and is the answer not in the manual?

Questions and answers