Table of Contents

Advertisement

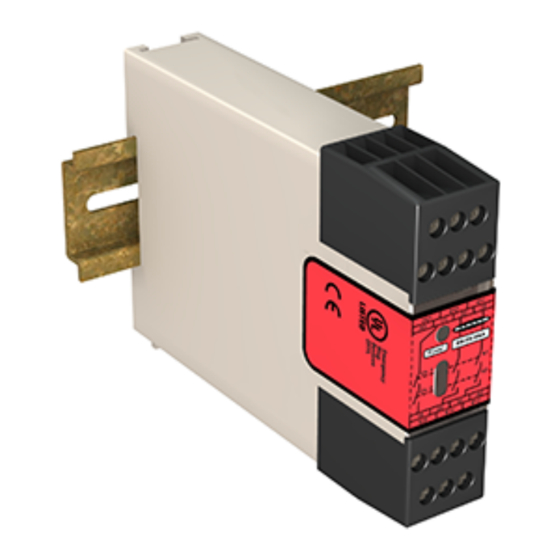

ES-FA-9AA and ES-FA-11AA E-Stop Safety

Module

Instruction Manual

Original Instructions

Models

Models

Supply Voltage

ES-FA-9AA

24 V ac/dc

ES-FA-11AA

WARNING: Not a Stand-Alone Safeguarding Device

This Banner device is not a stand-alone point-of-operation guarding device, as defined by

OSHA regulations. It is necessary to install point-of-operation guarding devices, such as safety light

screens and/or hard guards, to protect personnel from hazardous machinery. Failure to install point-

of-operation guards on hazardous machinery can result in a dangerous condition which could

lead to serious injury or death.

Important: Read this First

The user is responsible for satisfying all local, state, and national laws, rules, codes, and regulations relating to

the use of this product and its application. Banner Engineering Corp. has made every effort to provide complete

application, installation, operation, and maintenance instructions. Please contact a Banner Applications Engineer with any

questions regarding this product.

The user is responsible for making sure that all machine operators, maintenance personnel, electricians, and

supervisors are thoroughly familiar with and understand all instructions regarding the installation, maintenance, and use of

this product, and with the machinery it controls. The user and any personnel involved with the installation and use of this

product must be thoroughly familiar with all applicable standards, some of which are listed within the specifications.

Banner Engineering Corp. makes no claim regarding a specific recommendation of any organization, the accuracy or

effectiveness of any information provided, or the appropriateness of the provided information for a specific application.

Applicable U.S. Standards

ANSI B11 Standards for Machine Tools Safety

Contact: Safety Director, AMT – The Association for Manufacturing Technology, 7901 Westpark Drive, McLean, VA 22102,

Tel.: 703-893-2900

Original Document

60606 Rev. G

•

Monitors emergency stop devices, such as palm buttons and rope/cable pulls,

and positive-opening safety switches used for guard/gate interlocking

•

The safety inputs can monitor:

◦

A +24 V dc source switched by hard/relay contacts in single-channel

hookup, or

◦

Hard/relay contacts in a dual-channel hookup using terminals S11-

S12 and S21-S22

•

The ES-FA-9AA has three normally open output switching channels for

connection to control-reliable power interrupt circuits

•

The ES-FA-11AA has two normally open output switching channels for

connection to control-reliable power interrupt circuits and one normally

closed auxiliary output channel

•

Automatic reset or monitored manual reset

•

Design complies with standards ANSI B11.19, UL991, ISO 13850 (EN418),

and ISO 13849-1 (EN954-1) (Safety Category 4)

•

For use in functional stop category 0 applications per ANSI NFPA 79 and IEC/

EN60204-1

•

6 or 7 amp safety output contacts, depending on model

•

Plug-in terminal blocks

•

24 V ac/dc operation

Outputs

3 Normally Open (NO)

2 Normally Open and 1 Normally Closed (NC)

12 August 2016

Output Contact Rating

6 A

7 A

60606

Advertisement

Table of Contents

Summarization of Contents

Original Instructions

Safety Warning: Not a Stand-Alone Safeguarding Device

Device is not a point-of-operation guarding device; requires additional guarding.

Important: Read This First

User responsibility for compliance with laws, codes, regulations, and familiarity with instructions.

Applicable U.S. Standards

Lists U.S. standards relevant to machine tool safety.

Overview

Risk Assessment Warning

Risk assessment is crucial for determining appropriate safety circuit integrity.

Safety Circuit Integrity and ISO 13849-1 Principles

Discusses safety circuit integrity, fault tolerance, and design considerations.

Safety Circuit Integrity Levels

Explains ISO 13849-1 categories (B, 1-4) and US control reliability.

Fault Exclusion

Monitoring of Safety Devices

Details requirements for control reliability and safety category per ISO 13849-1.

Emergency Stop Functions Warning

Do not mute or bypass E-stop devices; function must remain active.

E-Stop and Rope/Cable Pull Switches

Interfacing with positive-opening switches, mounting, and accessibility requirements.

Interlocked Guards (Gates)

Monitoring position of guards/gates using positive-opening switches.

Mechanical Installation

Heat Dissipation Considerations

Ensuring adequate heat dissipation for reliable operation and avoiding overheating.

Electrical Installation

Wiring and connection must be done by qualified personnel adhering to standards.

Electrical Shock Hazard Warning

Disconnect power before any connections or replacements.

Lockout/Tagout Procedures

Guidance on controlling hazardous energy during maintenance.

Safety Input Device Hookup Options

Details single-channel and dual-channel hookup configurations for safety inputs.

Connection of Multiple Switches

Multiple Switching Devices Warning

Never connect switches in parallel; test each device individually.

Connection of Safety Switches

Connection of Reset Switch

Wiring specifications for the reset switch, including voltage and current requirements.

Reset Switch Location Warning

Reset switches must be accessible from outside, in view of, and out of reach of hazardous areas.

Automatic Reset Mode

Configuring the module for automatic reset; requires alternate procedures for safety.

Reset Routine Required Warning

A reset routine is required after clearing a stop condition to prevent unsafe restarts.

Wiring

Machine Control Connection

Generic connection of safety module's output circuits to master stop control elements (MSCs).

External Device Monitoring

Overvoltage Category II and III Installations

Guidelines for installations with applied voltages from 151 V to 250 V ac/dc and overvoltage reduction.

Auxiliary Monitor Contact (ES-FA-11AA)

Use of the auxiliary monitor contact for non-safety-related control functions.

Interfacing MSCs Warning

Avoid intermediate devices that could compromise safety function.

Wiring of Arc Suppressors Warning

Install arc suppressors across actuator coils, never across output contacts.

Initial Checkout Procedures

Checkout Power Disconnect Caution

Always disconnect power to machine control elements before checkout.

Multiple Safety Devices Checkout Warning

Test each safety device individually during checkout to detect faults.

Periodic Checkout Procedure

Repairs and Troubleshooting

Contact Banner Engineering for troubleshooting; no field-replaceable parts.

Module Abuse After Failure Caution

Do not tap or strike a module that will not reset; internal relay may have failed.

Specifications

Details power, output configuration, construction, operating conditions, and certifications.

Need help?

Do you have a question about the ES-FA-11AA and is the answer not in the manual?

Questions and answers