Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Metrohm 948

- Page 1 948 Continuous IC Module 2.948.00x0 Manual 8.0948.8001EN / v5 / 2024-10-31...

- Page 3 Metrohm AG CH-9100 Herisau Switzerland +41 71 353 85 85 info@metrohm.com www.metrohm.com 948 Continuous IC Module 2.948.00x0 Manual 8.0948.8001EN / v5 / 2024-10-31...

- Page 4 Disclaimer Deficiencies arising from circumstances that are not the responsibility of Metrohm, such as improper storage or improper use, etc., are expressly excluded from the warranty. Unauthorized modifications to the product (e.g., conversions or attachments) exclude any liability on the part of the manufacturer for resulting damage and its consequences.

-

Page 5: Table Of Contents

Tubing and capillary connections ..........8 2.4.4 Flammable solvents and chemicals ........... 8 2.4.5 Recycling and disposal ............. 8 3 Overview of the device 948 Continuous IC Module ..........10 3.1.1 Functional description ............10 3.1.2 Overview ................10 3.1.3 Signal status display ............... - Page 6 Replacing the Eluent Producer cartridge or concen- trate ..................55 Replacing the continuous trap .......... 60 Replacing the high-pressure degasser ......62 Shutting down the 948 Continuous IC Module ....63 8 Troubleshooting Problems and their solutions ..........66 9 Technical specifications Ambient conditions ............

- Page 7 ■■■■■■■■■■■■■■■■■■■■■■ Table of contents Index 948 Continuous IC Module (2.948.00x0) ■■■■■■■■...

- Page 8 Figure 3 948 Continuous IC Module with accessories – Front ......12 Figure 4 948 Continuous IC Module with accessories – Rear closed ....13 Figure 5 948 Continuous IC Module with accessories – Rear open ....14 Figure 6 Sockets for cable connections ............

-

Page 9: Introduction

1 Introduction 1 Introduction Instrument description The 948 Continuous IC Module is a device for the automatic manufac- ture of eluents for ion chromatography. Isocratic eluents can be produced and gradients can be run. The 948 Continuous IC Module is operated using the MagIC Net soft- ware. -

Page 10: About The Documentation

Menu or menu item [Continue] Button or key WARNING This symbol draws attention to a possible life-threat- ening hazard or risk of injury. WARNING This symbol draws attention to a possible hazard due to electrical current. ■■■■■■■■ 948 Continuous IC Module (2.948.00x0) -

Page 11: Displaying Accessories

This symbol highlights additional information and tips. Displaying accessories Up-to-date information on the scope of delivery and on optional accesso- ries can be found on the Metrohm website. 1 Searching for a product on the website Go to https://www.metrohm.com. ■... - Page 12 1.4 Displaying accessories ■■■■■■■■■■■■■■■■■■■■■■ To download the accessories list, click on [Download accesso- ■ ries PDF] under Accessories and more. NOTE Metrohm recommends keeping the accessories list for reference purposes. ■■■■■■■■ 948 Continuous IC Module (2.948.00x0)

-

Page 13: Safety

■ The 948 Continuous IC Module is suitable for processing chemicals. There- fore, the use of the 948 Continuous IC Module requires the user to have basic knowledge and experience in handling toxic and caustic substances. Knowledge regarding the application of fire prevention measures prescri- bed for laboratories is also mandatory. -

Page 14: Responsibility Of The Operator

Safety-relevant information is communicated and understood. The per- ■ sonnel can operate the product safely. The user documentation has been read and understood. The personnel ■ operate the product according to the instructions in the user documen- tation. ■■■■■■■■ 948 Continuous IC Module (2.948.00x0) -

Page 15: Safety Instructions

The electrical safety when working with the instrument is ensured as part of the international standard IEC 61010. WARNING Only personnel qualified by Metrohm are authorized to carry out service work on electronic components. WARNING Never open the housing of the instrument. The instrument could be damaged by this. -

Page 16: Tubing And Capillary Connections

This product is covered by European Directive 2012/19/EU, WEEE – Waste Electrical and Electronic Equipment. The correct disposal of your old instrument will help to prevent negative effects on the environment and public health. ■■■■■■■■ 948 Continuous IC Module (2.948.00x0) - Page 17 ■■■■■■■■■■■■■■■■■■■■■■ 2 Safety More details about the disposal of your old instrument can be obtained from your local authorities, from waste disposal companies or from your local dealer. 948 Continuous IC Module (2.948.00x0) ■■■■■■■■...

-

Page 18: Overview Of The Device

948 Continuous IC Module 3.1.1 Functional description 948 Continuous IC Module is used for automated production of potas- sium hydroxide eluents. Isocratic eluents can be produced and gradients can be run. The 948 Continuous IC Module includes the following parts: Eluent Producer cartridge (EPC, 6.02850.2x0) (see chapter 3.2, page... -

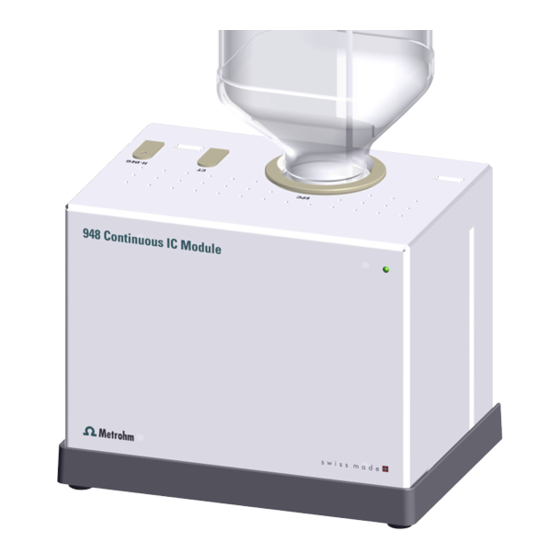

Page 19: Figure 1 948 Continuous Ic Module - Front

3 Overview of the device Figure 1 948 Continuous IC Module – Front Status display (see chapter 3.1.3, page 15) Figure 2 948 Continuous IC Module – Rear open Base tray Leak sensor Sockets for cable connections Type label (see figure 6, page 15) (see chapter 1.2, page 1) -

Page 20: Figure 3 948 Continuous Ic Module With Accessories - Front

3.1 948 Continuous IC Module ■■■■■■■■■■■■■■■■■■■■■■ Figure 3 948 Continuous IC Module with accessories – Front High-pressure degasser (H-DEG) Continuous Trap (CT) 6.02850.000 6.02850.1x0 Concentrate bottle Eluent Producer cartridge (EPC) 6.02850.2x0 Status display (see chapter 3.1.3, page 15) ■■■■■■■■ 948 Continuous IC Module (2.948.00x0) -

Page 21: Figure 4 948 Continuous Ic Module With Accessories - Rear Closed

■■■■■■■■■■■■■■■■■■■■■■ 3 Overview of the device Figure 4 948 Continuous IC Module with accessories – Rear closed Knurled screws Concentrate bottle Eluent Producer cartridge (EPC) Continuous Trap (CT) 6.02850.2x0 6.02850.1x0 High-pressure degasser (H-DEG) Type label 6.02850.000 (see chapter 1.2, page 1) 948 Continuous IC Module (2.948.00x0) -

Page 22: Figure 5 948 Continuous Ic Module With Accessories - Rear Open

3.1 948 Continuous IC Module ■■■■■■■■■■■■■■■■■■■■■■ Figure 5 948 Continuous IC Module with accessories – Rear open Slots for guide clips Base tray Leak sensor Sockets for cable connections (see figure 6, page 15) Eluent Producer cartridge (EPC) Continuous Trap (CT) 6.02850.2x0... -

Page 23: Signal Status Display

3.1.3 Signal status display The status display uses colors and/or flashing patterns to display the oper- ating status of the 948 Continuous IC Module. The meaning of the colors and flashing patterns is explained in the following table. Visual signal Meaning LED lights up orange. -

Page 24: Eluent Producer Cartridge (Epc)

In the eluent chamber, potassium (K ) and hydroxide ions (OH ) combine to form potassium hydroxide (K ). The eluent thus consists of potas- sium hydroxide (K ), water (H O), hydrogen (H ■■■■■■■■ 948 Continuous IC Module (2.948.00x0) -

Page 25: High-Pressure Pump

0.5 to 100 equivalents of potassium hydroxide can be produced up to a maximum concentration of 100 mmol/L. NOTE Concentration = equivalents/flow rate Example: Flow = 1.0 mL/min, concentration 0.5 … 100 mmol/L 948 Continuous IC Module (2.948.00x0) ■■■■■■■■... -

Page 26: Source Current

161 mA 1 mL/min 20 mmol/L 32.2 mA 0.5 mL/min 20 mmol/L 16.1 mA Example: Metrosep A Supp 18: Standard flow: 0.5 mL/min ■ Standard concentration: 23 mmol/L ■ Source current: 18.5 mA ■ ■■■■■■■■ 948 Continuous IC Module (2.948.00x0) -

Page 27: Overview

) opening. EPC plug Exhaust opening with stopper Oxygen escapes from the bottle through the riser (8- ) and the Exhaust opening (see Handling stopper at the exhaust opening). EPC OUT outlet EPC IN inlet 948 Continuous IC Module (2.948.00x0) ■■■■■■■■... -

Page 28: Continuous Trap (Ct)

A stopper closes the Exhaust opening of the Eluent Producer cartridge. Concentrate may leak out if the exhaust opening is open while the bottle is being handled. Make sure that the 948 Continuous IC Module is switched off to ■ change the concentrate bottle. -

Page 29: Figure 9 Continuous Trap - Function

→ 2OH O + 2e Exchange resin + Exchange resin + Anionic exchanger O → 2H + ½O + 2e Waste → H + 2H O, O Anode Figure 10 Continuous trap – Functional diagram 948 Continuous IC Module (2.948.00x0) ■■■■■■■■... -

Page 30: Overview

3.3 Continuous Trap (CT) ■■■■■■■■■■■■■■■■■■■■■■ 3.3.2 Overview Figure 11 Continuous trap – Overview Rinse OUT outlet Eluent OUT outlet Type label Eluent IN inlet (see chapter 1.2, page 1) Rinse IN inlet CT plug ■■■■■■■■ 948 Continuous IC Module (2.948.00x0) -

Page 31: High-Pressure Degasser (H-Deg)

High-pressure degasser – Function *) The optional port can be used, for example, to remove condensate from the outer tubing or for active external rinsing. Metrohm recommends a passive setup for applications with an MSM (see chapter 4.5.1, page 33). -

Page 32: Figure 13 Degasser Tubing At The Rear Of The High-Pressure Degasser

Do not remove or loosen the degasser tubing at the rear of the high- pressure degasser. Doing so would mean that the perfect functioning of the high-pressure degasser is no longer ensured. Figure 13 Degasser tubing at the rear of the high-pressure degasser ■■■■■■■■ 948 Continuous IC Module (2.948.00x0) -

Page 33: Overview

Overview Figure 14 High-pressure degasser – Overview Eluent IN inlet Rinse OUT outlet Rinse IN inlet Eluent OUT outlet Degasser tubings Type label Rinsing tubing and gas-permeable eluent (see chapter 1.2, page 1) tubing 948 Continuous IC Module (2.948.00x0) ■■■■■■■■... -

Page 34: Installation

Material damage caused by explosive gases Oxygen from the exhaust opening and hydrogen from the high-pres- sure degasser can form an explosive gas mixture. Place the 948 Continuous IC Module and the waste canister in a ■ place protected against electrostatic discharge. -

Page 35: Setup Configurations

The 948 Continuous IC Module is placed on the bottle holder of the ion chromatograph. In addition, two 1-liter bottles (6.1608.020) or one 2-liter bottle (6.1608.070) can be placed in front of the 948 Continuous IC Mod-... -

Page 36: Figure 15 Bottle Holder With 948 Continuous Ic Module And Bottles

4.2 Setup configurations ■■■■■■■■■■■■■■■■■■■■■■ Figure 15 Bottle holder with 948 Continuous IC Module and bottles The following columns can be used for applications with the 948 Continu- ous IC Module: Metrosep A Supp 10 ■ Metrosep A Supp 17 ■... -

Page 37: Preparing The Eluent Producer Cartridge

A stopper closes the Exhaust opening of the Eluent Producer cartridge. Concentrate may leak out if the exhaust opening is open while the bottle is being handled. Make sure that the 948 Continuous IC Module is switched off to ■ change the concentrate bottle. - Page 38 GL 45 (6.1608.040). Metrohm cannot guarantee leak-tightness with other bottles. 1 Rinsing the Eluent Producer cartridge NOTE The 948 Continuous IC Module is free of metal. The screw visible inside the Eluent Producer cartridge is made of titanium. Unscrew the Eluent Producer cartridge from the bottle. ■...

-

Page 39: Preparing Fep Tubing

■ NOTE Screw the bottle tightly shut by hand. 3 Removing the back panel of the 948 Continuous IC Module Loosen the two knurled screws on the back panel of the housing. ■ Remove the back panel of the housing and set it aside. -

Page 40: Establishing Capillary Connections And Tubing Connec- Tions

The tubing is prepared. The tubing connection can be established. 3 Screw the end of the tubing labeled 948 WASTE to the UNF 10/32 external / M6 internal (6.2744.200) adapter. Establishing capillary connections and tubing con-... -

Page 41: Structure With Conductivity Detection And Sequential Suppression (Ses)

4 Installation 4.5.1 Structure with conductivity detection and sequential suppression (SeS) The 948 Continuous IC Module can be rinsed either with STREAM (Sup- pressor Treatment with Reused Eluent After Measuring) or with external rinsing. STREAM (see figure 17, page 34): ■... -

Page 42: Figure 17 948 Continuous Ic Module With Conductivity Detection And Ses - Flow

4.5 Establishing capillary connections and tubing connections ■■■■■■■■■■■■■■■■■■■■■■ Figure 17 948 Continuous IC Module with conductivity detection and SeS – Flow path with STREAM PEEK capillary, 0.25 mm, HPP OUT PEEK capillary, 0.25 mm, EPC OUT (6.01831.010) (6.01831.020) PEEK capillary, 0.25 mm, CT OUT PEEK capillary, 0.25 mm, H-DEG Eluent... -

Page 43: Figure 18 948 Continuous Ic Module With Conductivity Detection And Ses - Flow Path With External Rinsing

■■■■■■■■■■■■■■■■■■■■■■ 4 Installation Figure 18 948 Continuous IC Module with conductivity detection and SeS – Flow path with external rinsing PEEK capillary, 0.25 mm, HPP OUT PEEK capillary, 0.25 mm, EPC OUT (6.01831.010) (6.01831.020) PEEK capillary, 0.25 mm, CT OUT PEEK capillary, 0.25 mm, H-DEG Eluent... - Page 44 – FEP tubing M6, 1/8" x 1.59 mm, CT OUT (6.01805.470) equipped with flangeless fittings (see chapter 4.4, page 31) – 2 x M6 / UNF 10/32 thread adapter (6.2744.080) – 2 x pressure screw, short, (6.2744.070), 5 pieces ■■■■■■■■ 948 Continuous IC Module (2.948.00x0)

- Page 45 Otherwise, the connections are no longer accessible. 3 Connecting the continuous trap and the high-pressure degasser Use the PEEK capillary, 0.25 mm, CT OUT (17-3) and 2 pressure screws to connect the continuous trap and the high-pressure degas- ser. 948 Continuous IC Module (2.948.00x0) ■■■■■■■■...

- Page 46 Screw the end of the tubing labeled CT OUT onto the Rinse ■ OUT outlet of the continuous trap with a pressure screw. Screw the end of the tubing labeled 948 WASTE onto the waste ■ collector. ■■■■■■■■...

-

Page 47: Structure For Equilibrating

Rinse OUT outlet of the high-pressure degasser using a pres- sure screw and an M6 / UNF 10/32 thread adapter (6.2744.080). Screw the end of the capillary labeled 948 WASTE onto the ■ waste collector. Use one of the PVDF pressure screws already on the waste collector. -

Page 48: Figure 19 Equilibrating The Continuous Trap - Flow Path

PEEK capillary, 0.25 mm, CT OUT PEEK capillary, 0.25 mm, H-DEG Eluent (6.01831.030) (6.01831.040) MSM connection capillary waste rinse FEP tubing M6, 1/8" x 1.59 mm, CT OUT (6.01805.470) PEEK capillary, 0.25 mm, H-DEG Rinse (6.01831.050) ■■■■■■■■ 948 Continuous IC Module (2.948.00x0) - Page 49 Eluent OUT outlet of the high-pressure degasser. Loosen the PEEK capillary, 0.25 mm, H-DEG Rinse (19-7) from the ■ RINSE OUT outlet of the high-pressure degasser. Loosen the PEEK capillary, 0.25 mm, H-DEG Rinse (19-7) from the ■ waste collector. 948 Continuous IC Module (2.948.00x0) ■■■■■■■■...

-

Page 50: Establishing The Cable Connections

To do this, use the M6 / UNF 10/32 thread adapter (6.2744.080) that is already located on the Rinse IN inlet. Screw the end of the capillary labeled 948 WASTE onto the Elu- ■ ent OUT outlet of the high-pressure degasser using a pressure screw. - Page 51 Outside of operation, the Exhaust opening must always be closed with the stopper so that no concentrate leaks out when the 948 Continuous IC Module is moved. Remove the stopper from the Exhaust opening.

-

Page 52: Closing The Housing

1 Insert guide clips into both slots for guide clips on the housing. Figure 20 Mounting the guide clips 2 Place all cables, capillaries and tubings leading out of the 948 Contin- uous IC Module in the guide clips. 3 Insert the back panel of the housing. Tighten the knurled screws by hand to fasten the back panel in place. -

Page 53: Connecting The Instrument To The Power Grid

Unplug the power plug immediately if you suspect that moisture has ■ gotten inside the instrument. Only personnel who have been issued Metrohm qualifications may ■ perform service and repair work on electrical and electronic parts. Connecting the power cord... -

Page 54: Start-Up

Metrohm service representative. Equilibration The continuous trap must be equilibrated at the time of initial start-up, after each restart of the 948 Continuous IC Module and after the continu- ous trap has been replaced. NOTE During operation, condensate may form in the outer tubing of the high-pressure degasser. - Page 55 ■■■■■■■■■■■■■■■■■■■■■■ 5 Start-up 2 Switching on the devices Switch on the 948 Continuous IC Module. ■ Switch on the ion chromatograph. ■ MagIC Net detects all of the instruments and asks if they are to be saved to the device table.

- Page 56 The separation column is now on ultrapure water and ready to be connected to the suppressor. NOTE Do not store the separation column on the ultrapure water for lon- ger than 1 day. Parameter 948_930_Preparation_1 ■■■■■■■■ 948 Continuous IC Module (2.948.00x0)

-

Page 57: Equilibrating The System

Monitor temp- erature stability 948 Continuous IC Module Continuous Eluent Producer (CEP) ▶ Pump Pump of IC used Equilibrating the system The system is equilibrated with the 948_ProfIC Vario_15_930 method and initial measurements are made. 948 Continuous IC Module (2.948.00x0) ■■■■■■■■... - Page 58 Parameter 948_ProfIC Vario_15_930 Analysis Hardware assign- ment ▶ Cond detector ▶ Conductivity Data source Injection valve of the IC used Injection valve Pump Pump of IC used Column Columns used (see chapter 4.2, page 27) ■■■■■■■■ 948 Continuous IC Module (2.948.00x0)

- Page 59 Compact IC/Eco IC", page 49) Oven/Thermostat Analogous to parameter 948_930_Preparation_1 (see menu "Professional IC/ Compact IC/Eco IC", page 49) 948 Continuous IC Module Analogous to parameter 948_930_Preparation_1 (see menu "948 Continuous IC Module", page 49) 948 Continuous IC Module (2.948.00x0) ■■■■■■■■...

-

Page 60: Operation

■■■■■■■■■■■■■■■■■■■■■■ 6 Operation The 948 Continuous IC Module is operated using the MagIC Net software. You can find information on operating the software in the tutorial for MagIC Net or in the online help. ■■■■■■■■ 948 Continuous IC Module (2.948.00x0) -

Page 61: Operation And Maintenance

However, unplug the power plug immediately if you suspect that corrosive media have gotten inside the instrument. This is the only way to prevent extreme damage to the instrument electronics. Contact Metrohm Service immediately. 948 Continuous IC Module (2.948.00x0) -

Page 62: Maintenance By Metrohm Service

Maintenance by Metrohm Service Maintenance of the instrument is best carried out as part of annual service, which is performed by specialist personnel from Metrohm. A shorter maintenance interval is recommended if you frequently work with caustic and corrosive chemicals. Regional Metrohm service representatives offer every form of technical advice for maintenance and service of all Metrohm devices. -

Page 63: Replacing The Eluent Producer Cartridge Or Concen- Trate

■ Required accessories: New Eluent Producer cartridge (6.02850.2x0) and/or bottle with high- ■ purity 4 mol/L potassium hydroxide (not available from Metrohm AG) Wrench for pressure screws (6.2739.000) ■ NOTE Tighten the connections in the high-pressure section with the wrench for pressure screws. - Page 64 Use only high purity 4 mol/L potassium hydroxide as concen- ■ trate. 1 Removing the back panel of the 948 Continuous IC Module Loosen the two knurled screws on the back panel of the housing. ■ Remove the back panel of the housing and set it aside.

- Page 65 A stopper closes the Exhaust opening of the Eluent Producer car- tridge. Concentrate may leak out if the exhaust opening is open while the bottle is being handled. Make sure that the 948 Continuous IC Module is switched off ■ to change the concentrate bottle.

- Page 66 Screw the end of the PEEK capillary, 0.25 mm, EPC OUT ■ (6.01831.020) labeled EPC OUT onto the Eluent OUT outlet of the Eluent Producer cartridge. Tighten both connections with the wrench for pressure screws. ■ ■■■■■■■■ 948 Continuous IC Module (2.948.00x0)

- Page 67 Outside of operation, the Exhaust opening must always be closed with the stopper so that no concentrate leaks out when the 948 Continuous IC Module is moved. Remove the stopper from the Exhaust opening.

-

Page 68: Replacing The Continuous Trap

NOTE Tighten the connections in the high-pressure section with the wrench for pressure screws. 1 Removing the back panel of the 948 Continuous IC Module Loosen the two knurled screws on the back panel of the housing. ■ Remove the back panel of the housing and set it aside. - Page 69 Insert guide clips into both slots for guide clips on the housing. ■ Place all cables, capillaries and tubings leading out of the 948 ■ Continuous IC Module in the guide clips. Insert the back panel of the housing. Tighten the knurled screws ■...

-

Page 70: Replacing The High-Pressure Degasser

NOTE Tighten the connections in the high-pressure section with the wrench for pressure screws. 1 Removing the back panel of the 948 Continuous IC Module Loosen the two knurled screws on the back panel of the housing. ■ Remove the back panel of the housing and set it aside. -

Page 71: Shutting Down The 948 Continuous Ic Module

Always keep the concentrate bottle screwed onto the Eluent Pro- ■ ducer cartridge. Even if the device is shut down. If the 948 Continuous IC Module is shut down for 1 week or more, rinse the system. This prevents eluent salts from crystallizing and clogging the high-pressure degasser. -

Page 72: Rinsing The System

Shutting down the 948 Continuous IC Module Required accessories: Coupling 2 x UNF 10/32 (6.2744.040) ■ 1 Stopping the ion chromatograph In the software, stop the ion chromatograph to which the 948 ■ Continuous IC Module is connected. Wait until the pressure has been released. ■... - Page 73 Continuous IC Module is moved. Close the Exhaust opening with the stopper. ■ To put the 948 Continuous IC Module back into operation, proceed in the same way as for installation (see chapter 4, page 26). 948 Continuous IC Module (2.948.00x0)

-

Page 74: Troubleshooting

Replace the concentrate (see chapter 7.5, current is low, the the concentrate is too low. page 55). voltage is very high. The Eluent Producer car- Replace the Eluent Producer cartridge (see tridge is defective. chapter 7.5, page 55). ■■■■■■■■ 948 Continuous IC Module (2.948.00x0) -

Page 75: Technical Specifications

50–60 Hz range Current max. 1.5 A Output Nominal volt- 24 V DC Current max. 2.7 A Power output 65.0 W Instrument Inlet Nominal volt- 24 V DC Power con- max. 36.0 W sumption 948 Continuous IC Module (2.948.00x0) ■■■■■■■■... -

Page 76: Dimensions

2.2 kg (device without power supply unit and accessories) 2.948.0010 approx. 3.6 kg (device with power supply unit and accessories) Housing Materials Cover, back panel 1.4301 stainless steel, powder-coated Base PP, polypropylene IP degree of pro- IP 22 tection ■■■■■■■■ 948 Continuous IC Module (2.948.00x0) -

Page 77: Connectors Specifications

21 MPa Concentration 0.1 – 100 mmol/L, depending on flow (see "Source current", page 18). Solvents max. 25% methanol Eluent Producer refillable (see "Replacing the Eluent Producer cartridge and/or the con- cartridge centrate", page 55) 948 Continuous IC Module (2.948.00x0) ■■■■■■■■... - Page 78 Preparing Cable connection ..... 42 Functional description FEP tubing ......31 Capillary connection ....32 948 Continuous IC Module . 10 Product versions ......1 Care ......... 53 Continuous trap ....20 Cleaning ........54 Eluent Producer cartridge ... 16 Replace Closing the housing ....

Need help?

Do you have a question about the 948 and is the answer not in the manual?

Questions and answers