Advertisement

Quick Links

EPS ohne Ghostscript

Connection plan

Motor EZ_AA on SDS5000 Harting special

1 Safety notes

Serious risks to life and limb can occur when connecting and operat-

ing motors! Observe the following operating manuals, the operating

manual of the motor as well as the applicable national, local and sys-

tem-specific regulations.

WARNING!

The motor is powered by high electrical voltage!

Touching live parts is extremely dangerous and potentially fatal!

▪

The electrical connection of the motor may be carried out only

by an electrician.

▪

Before performing the electrical connection, switch off the

power supply of the machine with the main switch and secure

it from being turned on again.

▪

Only connect the motor using power connection cables

recommended by STOBER

▪

Do not open the housing of the power plug connector.

ATTENTION! This connection plan applies only to the motor type

and drive controller type specified in the title! Check whether this

connection plan matches the information on the nameplate of the

motor and drive controller and whether the connection cables corre-

spond to this connection plan. In case of questions, contact STOBER.

ATTENTION! Directly connecting the motor to the power grid will

cause damage to the motor! Only connect the motor to the in-

tended drive controller in accordance with this connection plan.

ATTENTION! Connection cables not coordinated to the motor can

cause damage to the motor or result in non-compliance with the

legal requirements for EMC and thus the voiding of warranty

claims! Use connection cables coordinated to your motor from the

STOBER supply range or, when connecting to a drive controller from

a third-party manufacturer, the corresponding original cables of that

manufacturer.

ATTENTION! Motor components such as encoders or temperature

sensors can be damaged by electrostatic discharge! Do not touch

the contacts of the plug connectors with your fingers.

ATTENTION! The plug connectors can be damaged by improper

handling. Note the following information:

§

Tighten the cap nuts of screw connections by hand (not with a

tool).

§

Turn the plug connector of the motor using the connected mat-

ing connector of the connection cable (not with a tool).

§

Turn the plug connector only within the permitted turning

range.

12/2024

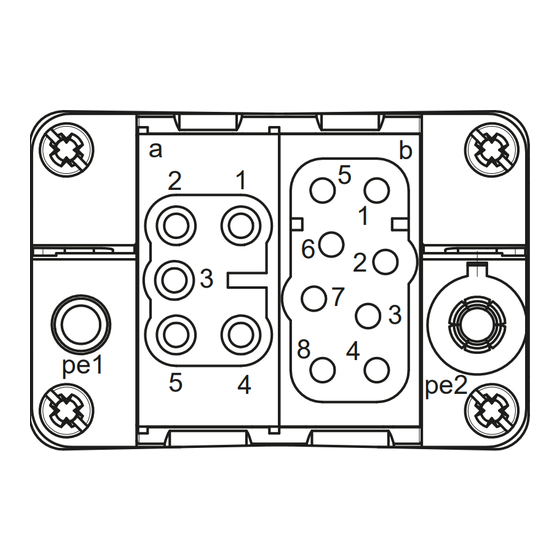

2 Terminal assignment of the power plug

connector

Connection diagram

a

b

5

2

1

1

6

2

3

7

3

8

4

pe1

5

4

pe2

KV = cable gland

3 Terminal assignment of the encoder plug

connector

Connection diagram

Pin

1

3

4

2

2

5

3

1

4

7

8

6

5

6

7

8

KV

KV = cable gland

4 Temperature sensor connection

The type of the temperature sensor is specified on the nameplate of

the motor.

§

PTC thermistor 145 °C

§

Pt1000 temperature sensor

ATTENTION! Incorrect or a lack of monitoring of the temperature

sensor can cause damage to the motor! Always monitor the tem-

perature sensor using devices that will switch the motor off if the

maximum permitted winding temperature is exceeded.

1

Pin

Connection

a1

1U1 (U phase)

a2

1V1 (V phase)

a3

1W1 (W phase)

pe1

PE (grounding

conductor)

b1

1BD1 (brake +)

b2

1BD2 (brake −)

pe2

Inner shield for

1BD1/1BD2

b3

1TP1 (temperature

sensor +)

b4

1TP2 (temperature

sensor -)

pe2

Inner shield for

1TP1/1TP2

KV

Overall shield

Connection

Data +

Data −

Clock −

Clock +

Sense

DGND

UB+

Shield

ID 443453_en.00

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Stober EZ AA Series

- Page 1 Overall shield motor and drive controller and whether the connection cables corre- spond to this connection plan. In case of questions, contact STOBER. KV = cable gland ATTENTION! Directly connecting the motor to the power grid will...

- Page 2 Motor EZ_AA on SDS5000 Harting special 5 Holding brake connection The (optional) motor holding brake is connected via the power plug connector. ATTENTION! Connection errors can cause damage to the holding brake! Observe the polarity of the connections and the nominal volt- age of the holding brake.

Need help?

Do you have a question about the EZ AA Series and is the answer not in the manual?

Questions and answers