Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Stober C0

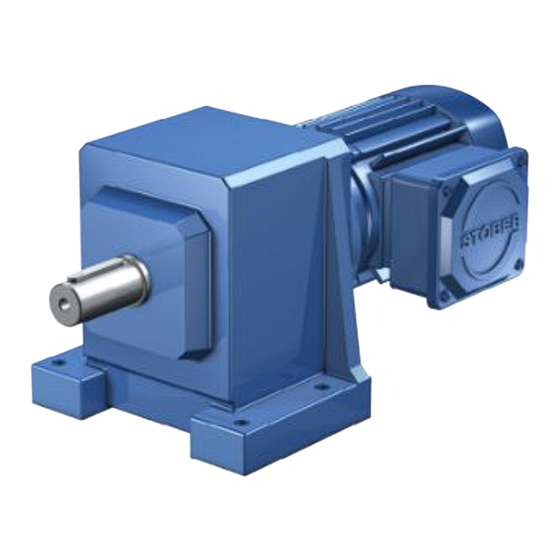

- Page 1 C0 – C9 gear units, geared motors Operating manual en-US 07/2023 ID 443365_en.00...

-

Page 2: Table Of Contents

Table of contents Table of contents User information............................... 4 Storage and transfer.............................. 4 Original language.............................. 4 Formatting conventions ............................ 4 Terms.................................. 5 Supporting documents ............................ 5 Limitation of liability.............................. 5 Product names and brands............................ 5 Copyright notice .............................. 5 General safety instructions............................ 6 Intended use................................ - Page 3 Table of contents 5.2.4 Mounting the motor on a gear unit with MQ/MR adapter with curved tooth coupling...... 21 5.2.5 Mounting the motor on a gear unit with MQ/MR adapter with plug-in coupling ....... 23 5.2.6 Mounting the motor on a gear unit with MB adapter................ 25 Mounting drive elements on a solid shaft......................

-

Page 4: User Information

User information This documentation is a part of the product. It applies to products in the standard design according to the corresponding STOBER catalog. Storage and transfer As this documentation contains important information for handling the product safely and efficiently, it must be stored in the immediate vicinity of the product until product disposal and be accessible to qualified personnel at all times. -

Page 5: Terms

Supporting documents Separate documents apply to the drive components which can be attached to STOBER gear units, depending on the design. These documents can be found by entering the serial number of the drive at https://id.stober.com... -

Page 6: General Safety Instructions

2 | General safety instructions General safety instructions There are risks associated with the product described in this documentation that can be prevented by complying with the described warning and safety instructions as well as the included technical rules and regulations. Intended use The drives described in this documentation are intended for installation in industrial machines or systems. -

Page 7: Thermal Hazards

2 | General safety instructions WARNING! Sinking or falling of gravity-loaded axes or vertical axes after switching off the motor due to gravity! Falling gravity-loaded axes or vertical axes can cause serious injuries or even death! ▪ Be aware that the holding brake of the motor does not offer sufficient safety for persons that are in the hazard area of gravity-loaded axes or vertical axes. -

Page 8: Product Description

3 | Product description Product description In this chapter, you will find product details that are relevant for assembly, commissioning and servicing. Detailed technical data on your drive can be found in the order confirmation. You will find more product information and dimensional drawings in the corresponding catalog (Additional documentation [} 13]). -

Page 9: Type Designation

3 | Product description Type designation In this chapter, you will find an explanation of the type designation with the associated options. Example code 0280 ME20 Explanation Code Designation Design Type Helical gear unit Size 2 (example) Generation Generation 0 Generation 1 Stages Two-stage... -

Page 10: Nameplate

3 | Product description Nameplate An example gear unit nameplate is explained in the figure below. Code Designation Name of manufacturer Type designation Gear ratio of the gear unit Lubricant specification Serial number of the gear unit QR code (link to product information) Dimensions of the motor adapter (pilot/bolt circle/motor shaft diameter) Date of manufacture (year/calendar week) Lubricant fill volume... -

Page 11: Direction Of Rotation

3 | Product description IMB6 IMV1, IMV5, IMV18 IMV3, IMV6, IMV19 An adhesive label is applied to the gear unit that explains the designated mounting position. The arrow on the adhesive label indicates the side with which the gear unit must be mounted facing down. Fig. 1: Adhesive label for the mounting position Direction of rotation C002 −... -

Page 12: Ambient Conditions

Paint Black RAL 9005 Lubricant Synthetic; for specification and quantity, see nameplate Ventilation C0 – C5: No ventilation C6 – C9: Air release valves installed according to the mounting position Weight See order documents Protection class: IP65 Observe the protection class of all the components. -

Page 13: Additional Documentation

443016_en Gear unit + IE3D asynchronous motor Asynchronous geared motors 443136_en Gear unit Lubricant filling quantities for gear units 441871 If you have questions about your drive that are not answered by this documentation, please contact STOBER Service (Service [} 35]). -

Page 14: Transport And Storage

4 | Transport and storage Transport and storage STOBER products are packaged carefully and delivered ready for installation. The type of packaging depends on the product size and the transport method. Observe the following information during transport and storage: §... -

Page 15: Long-Term Storage

2. Completely fill the gear unit with lubricant. The lubricant specification can be found by entering the serial number of the gear unit at https://id.stober.com or by scanning the QR code on the nameplate of the gear unit. Before commissioning the gear unit, reduce the lubricant fill volume to the fill volume that is specified on the nameplate of... -

Page 16: Installation

This chapter contains information on how to mount a motor on a STOBER gear unit with a motor adapter. The motor adapter type of your gear unit can be found on the nameplate of the gear unit. STOBER recommends using a motor with a shaft without a feather key, since the keyway negatively affects smooth operation. -

Page 17: Permitted Tilting Torques At The Gear Unit Input

Permitted tilting torques at the gear unit input If you mount a STOBER gear unit on the machine in a horizontal mounting position, check that the permitted tilting torque is not exceeded on the gear unit input before mounting the corresponding motor. Information on the permitted tilting... -

Page 18: Mounting The Motor On A Gear Unit With Me Adapter

Procedure In order to prevent unfavorable shifting or tilting of the motor shaft, STOBER recommends mounting the motor on the gear unit with the motor shaft pointing down vertically. 1. Position the gear unit (5), if necessary with the aid of lifting gear, so that the motor can be mounted in a vertical position. - Page 19 5 | Installation 9. If necessary, use two suitable attachment points to secure the motor with the lifting gear so that the motor shaft is pointing down vertically. 10. Turn the motor in an axial position to the gear unit so that the nameplates are on the same side, if possible, and can also be read after installation in the machine.

- Page 20 5 | Installation Fig. 2: Mounting a motor on a K gear unit with ME motor adapter (example) Torque wrench Hexagon insert Motor adapter Gear unit Adapter bushing (if present) Motor shaft Motor Screw Slot of the clamping hub Locking screw Grooved pin Screw plug Adhesive label...

-

Page 21: Mounting The Motor On A Gear Unit With Mq/Mr Adapter With Curved Tooth Coupling

This chapter describes the attachment of a motor with a solid shaft with feather key to a STOBER gear unit with an MQ (for a square motor flange) or MR (for a round motor flange) motor adapter with a curved tooth coupling. Since the assembly steps for the MQ or MR motor adapter are identical, only one motor adapter type is shown in the figures. - Page 22 5 | Installation 8. If necessary, use two suitable attachment points to secure the motor with the lifting gear so that the motor shaft is pointing down vertically. 9. Turn the motor in an axial position to the gear unit so that the nameplates are on the same side, if possible, and can also be read after installation in the machine.

-

Page 23: Mounting The Motor On A Gear Unit With Mq/Mr Adapter With Plug-In Coupling

This chapter describes the attachment of a motor with a solid shaft without feather key to a STOBER gear unit with an MQ (for a square motor flange) or MR (for a round motor flange) motor adapter with a plug-in coupling. Since the assembly steps for the MQ or MR motor adapter are identical, only one motor adapter type is shown in the figures. - Page 24 5 | Installation 9. Turn the motor in an axial position to the gear unit so that the nameplates are on the same side, if possible, and can also be read after installation in the machine. 10. Carefully place the motor on the motor adapter and make sure that the claws of the motor-side clampring (9) are positioned between the claws of the gear unit-side coupling hub (7) and the teeth of the gear rim (8).

-

Page 25: Mounting The Motor On A Gear Unit With Mb Adapter

5 | Installation Tightening torques for clamping screws (3) Size of clamping screw [mm] Tightening torque [Nm] 5.2.6 Mounting the motor on a gear unit with MB adapter The assembly of a motor on a gear unit with an MB motor adapter with brake is described in a separate document (see Supporting documents [} 5]). -

Page 26: Mounting The Gear Unit On The Machine

5 | Installation Fig. 3: Mounting device for a belt drive (example) Washer Set screw Axial bearing Belt drive (example) Solid shaft Mounting the gear unit on the machine Depending on the design, the C gear unit is mounted on the machine via the pitch circle diameter, output flange or foot mount. - Page 27 5 | Installation Tab. 3: Mounting the gear unit to the machine, using C613G (left) and a C613F gear unit (right) as an example Tab. 4: Mounting the gear unit on the machine using C612N as an example Threaded hole in the housing Output flange bore Feather key Solid shaft...

- Page 28 5 | Installation Gear unit type Number of screws Screw size Min. screw-in depth Strength class [mm] C9_G 10.9 C0_F – C1_F – C2_F – C3_F – C4_F – C5_F – C6_F – C7_F – C8_F – C9_F – C0_N –...

-

Page 29: Tightening Torques

6 | Tightening torques Tightening torques Note that the following tightening torques apply to screws that are used for mounting the motor on the gear unit or the gear unit on the machine. For clamp couplings, clamping screws of shrink rings and other connection elements, other tightening torques apply that are specified in the specific context. -

Page 30: Commissioning

The maximum surface temperature occurs in approx. 3 hours, depending on the utilization of the drive, and must not exceed the maximum value of 90 °C in the event of a maximum surrounding temperature. Immediately shutdown the drive if the maximum value is exceeded and contact STOBER Service. -

Page 31: Servicing

Changing the oil You can find information on changing the oil for the C6 – C9 gear units in this chapter. C0 – C5 gear units are lubricated for their entire service life and do not require an oil change. - Page 32 8 | Servicing The gear units are filled with synthetic gear oil at the factory. The oil fill volume depends on the mounting position of the gear unit. The specification and fill volume of the gear oil is specified on the nameplate of the gear unit and in the documentation (see chapter Additional documentation [} 13])

- Page 33 8 | Servicing Air release valve (filling connection) Screw plug (draining connection) Filling and draining connections for C613 – C913 gear units...

-

Page 34: Remedying Faults

8 | Servicing Air release valve (filling connection) Screw plug (draining connection) For C913 gear units in the EL5 mounting position, the filling and draining connections are arranged as they are for C912 gear units in EL5. Remedying faults WARNING! Moving machine parts can cause serious injuries or even death! Before performing work, switch off the machine with the main switch and secure the switch from being turned on again. -

Page 35: Troubleshooting Faults

Servicing Have the necessary servicing work carried out on the drive by the STOBER Service department or by STOBER service partners. Be aware that improper servicing may cause material damage and may void the manufacturer's warranty. Only use replacement parts delivered by STOBER. Specify the type designation and serial number of the drive when ordering replacement parts. - Page 36 Contact data of parent company in Germany STÖBER Antriebstechnik GmbH + Co. KG Kieselbronner Strasse 12 75177 Pforzheim Germany Service hotline: +49 7231 582-3000 mail@stoeber.de Contact data of subsidiary in US STOBER Drives Inc. 1781 Downing Drive Maysville, KY 41056 Service Hotline +1 606 563-6035 service@stober.com...

-

Page 37: Removal And Disposal

9 | Removal and disposal Removal and disposal Removal Remove the drive as follows: 1. If the drive had been in operation immediately beforehand, allow it to cool. 2. Disconnect the connection cable and the grounding conductor from the motor. 3. - Page 38 443365_en.00 07/2023 STÖBER Antriebstechnik GmbH + Co. KG Kieselbronner Str. 12 75177 Pforzheim Germany Tel. +49 7231 582-0 mail@stoeber.de www.stober.com 24 h Service Hotline +49 7231 582-3000 www.stober.com...

Need help?

Do you have a question about the C0 and is the answer not in the manual?

Questions and answers