Subscribe to Our Youtube Channel

Summary of Contents for Stober PK Series

- Page 1 PK/PKX/PHK/PHKX/PHQK/KS/KL gear units, geared motors Operating manual en-US 10/2019 ID 443150_en.00...

-

Page 2: Table Of Contents

Table of contents Table of contents User information ............................... 4 Storage and transfer .............................. 4 Original language .............................. 4 Formatting conventions............................ 4 Terms .................................. 5 Supporting documents............................. 5 Limitation of liability .............................. 5 Product names and brands ............................ 5 Copyright notice............................... 5 General safety instructions............................ - Page 3 Table of contents Transport and storage ............................. 21 Transport ................................ 21 Storage................................... 21 4.2.1 Long-term storage .......................... 21 Installation ................................ 22 Cleaning agent and solvent............................ 22 Mounting the motor on a gear unit ........................ 22 5.2.1 Permitted tilting torques at the gear unit input ................... 23 5.2.2 Tolerances for the add-on motor ......................

-

Page 4: User Information

User information This documentation is a part of the product. It applies to products in the standard design according to the corresponding STOBER catalog. Storage and transfer As this documentation contains important information for handling the product safely and efficiently, it must be stored in the immediate vicinity of the product until product disposal and be accessible to qualified personnel at all times. -

Page 5: Terms

Supporting documents Separate documents apply to the drive components which can be attached to STOBER gear units, depending on the design. These documents can be found by entering the serial number of the gear unit at https://id.stober.com... -

Page 6: General Safety Instructions

2 | General safety instructions General safety instructions There are risks associated with the product described in this documentation that can be prevented by complying with the described warning and safety instructions as well as the included technical rules and regulations. Intended use The drives described in this documentation are intended for installation in industrial machines or systems. -

Page 7: Thermal Hazards

2 | General safety instructions WARNING! Sinking or falling of gravity-loaded axes or vertical axes after switching off the motor due to gravity! Falling gravity-loaded axes or vertical axes can cause serious injuries or even death! ▪ Be aware that the holding brake of the motor does not offer sufficient safety for persons that are in the hazard area of gravity-loaded axes or vertical axes. -

Page 8: Product Description

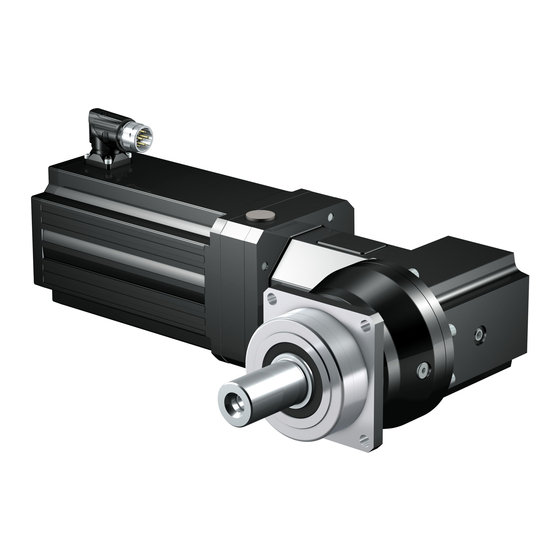

3 | Product description Product description In this chapter, you can find product details that are relevant for assembly, commissioning and maintenance. Detailed technical data on your gear unit/geared motor can be found in the order confirmation. You will find more product information and dimensional drawings in the corresponding catalog (Additional documentation [} 20]). -

Page 9: Basic Structure Of Phk, Phkx, Phqk

3 | Product description 3.1.2 Basic structure of PHK, PHKX, PHQK Tab. 2: Basic structure of a PHQ831_K402 gear unit (left) and PH731_KX7 gear unit (right) Flange shaft Output flange Gear unit housing Nameplate ME motor adapter 3.1.3 Basic structure of KS Tab. -

Page 10: Basic Structure Of Kl

3 | Product description 3.1.4 Basic structure of KL Tab. 4: Basic structure of a KL102ANG gear unit (left) and KL102PF gear unit (right) Hollow shaft Solid shaft with feather key Foot plates (option) Output flange (option) Nameplate Gear unit housing MQ motor adapter Type designation 3.2.1... -

Page 11: Ph9K - Ph10K, Phq9K - Phq12K Type Designation

3 | Product description Code Designation Design Bearing Standard bearing Axially reinforced bearing (P gear unit) Radially reinforced bearing (P gear unit) Reinforced bearing (PH/PHQ gear unit) Backlash Standard Reduced 0050 Transmission ratio of output i = 5 (example) (i x 10) K102VF Input K1 right-angle gear unit (example) -

Page 12: Ks Type Designation

3 | Product description 3.2.3 KS type designation In this chapter, you can find an explanation of the type designation for the gear unit types mentioned in the title. Sample code 0200 Explanation Code Designation Design Type Right-angle servo gear unit Size 5 (example) Generation... -

Page 13: Pk, Phk, Kl Nameplate

3 | Product description Code Designation Design Housing Pitch circle diameter Flange Foot + pitch circle diameter 0080 Transmission ratio (i x 10) i = 8 (example) Motor adapter Square motor adapter with backlash-free plug-in coupling Motor EZ synchronous servo motor LM Lean motor PK, PHK, KL nameplate An example nameplate for the gear unit types listed above is explained in the figure below. -

Page 14: Pkx, Phkx, Ks Nameplate

PK, PHK, PHQK mounting positions STOBER coordinates the lubricant fill volume and structure of the gear unit types listed above to the mounting position of the gear unit in the machine. The mounting position of a gear unit is determined upon ordering and specified in the order documents. - Page 15 3 | Product description An adhesive label is applied to the gear unit that explains the designated mounting position. The arrow on the adhesive label indicates the side with which the gear unit must be mounted facing down. Fig. 1: Adhesive label for the mounting position...

-

Page 16: Pkx, Phkx, Ks Mounting Positions

PKX, PHKX, KS mounting positions STOBER coordinates the lubricant fill volume and structure of the gear unit types listed above to the mounting position of the gear unit in the machine. The mounting position of a gear unit is determined upon ordering and specified in the order documents. -

Page 17: Kl Mounting Positions

3 | Product description 3.5.3 KL mounting positions The KL gear unit can be installed in any mounting position. The figure below illustrates the gear sides referenced by the shaft and housing designs. Direction of rotation The following figures illustrate the direction of rotation of the output in relation to the direction of rotation at the input of the respective gear unit. - Page 18 3 | Product description Output on side 4 of K gear unit Output on side 3 of K gear unit Tab. 7: Direction of rotation of the PHK, PHQK gear unit PH3KX − PH5KX PH7KX − PH8KX Tab. 8: Direction of rotation of the PHKX gear unit Tab.

-

Page 19: Ambient Conditions

3 | Product description Output on side 4 Output on side 3 Tab. 10: Direction of rotation of the KL gear unit The specified direction of rotation also applies to other designs of the KL gear unit: § Design with hollow shaft (A), for which the entry side of the machine shaft corresponds to the side of the solid shaft that is shown §... -

Page 20: Other Product Features

Gear unit + EZ synchronous servo motor EZ synchronous servo geared motors 442437_en Gear unit + LM Lean motor Lean motors 443016_en If you have questions about your drive that are not answered by this documentation, please contact STOBER Service (Service [} 45]). -

Page 21: Transport And Storage

4 | Transport and storage Transport and storage STOBER products are packaged carefully and delivered ready for installation. The type of packaging depends on the product size and the transport method. Observe the following information during transport and storage: §... -

Page 22: Installation

This chapter contains information on how to mount a motor on a STOBER gear unit with a motor adapter. The motor adapter type of your gear unit can be found on the nameplate of the gear unit. STOBER recommends using a motor with a shaft without a feather key, since the keyway negatively affects smooth operation. -

Page 23: Permitted Tilting Torques At The Gear Unit Input

Permitted tilting torques at the gear unit input If you mount a STOBER gear unit on the machine in a horizontal mounting position, check that the permitted tilting torque is not exceeded on the gear unit input before mounting the corresponding motor. Information on the permitted tilting... -

Page 24: Mounting The Motor On A Gear Unit With Me/Mel/Mf/Mfl Adapter

Procedure In order to prevent unfavorable shifting or tilting of the motor shaft, STOBER recommends mounting the motor on the gear unit with the motor shaft pointing down vertically. 1. Position the gear unit (5), if necessary with the aid of lifting gear, on a suitable support (1) so that the motor can be mounted in a vertical position. - Page 25 5 | Installation 9. If necessary, use two suitable attachment points to secure the motor with the lifting gear so that the motor shaft is pointing down vertically. 10. Turn the motor in an axial position to the gear unit so that the nameplates are on the same side, if possible, and can also be read after installation in the machine.

- Page 26 5 | Installation Fig. 3: Mounting a motor on a P planetary gear unit with ME motor adapter (example) Support Torque wrench Hexagon insert Motor adapter Planetary gear unit Clamping sleeve (if present) Motor shaft Motor Screw Slot of the clamping hub Locking screw Cross pin Threaded sealing plug...

- Page 27 5 | Installation Type [mm] [mm] [Nm] _ME10 d2≤14 _ME10 14<d2≤19 _ME20 d2≤19 _ME20 19<d2≤24 _ME20 24<d2≤32 _ME30 d2≤24 _ME30 24<d2≤38 _ME40 d2≤38 _ME40 38<d2≤48 _ME50 55<d2≤60 Tightening torques for the locking screw (11) for KS gear units Type [mm] [Nm] [mm] [Nm]...

-

Page 28: Mounting The Motor On A Gear Unit With Mb Adapter

[} 5]). 5.2.5 Mounting the motor on a gear unit with MQ adapter This chapter describes the attachment of a motor to a STOBER KL gear unit with an MQ motor adapter. Prerequisites § Dimensional tolerances of the motor correspond to the requirements in the chapter Tolerances for the add-on motor [} 23]... - Page 29 5 | Installation 15. If the motor shaft cannot be inserted into the clamping hub, do not use force and instead turn the locking screw (11) counterclockwise one quarter rotation with the hexagon insert (3). The size of the hexagon insert can be found on the adhesive label (14) as well as in the following tables.

- Page 30 5 | Installation Fig. 4: Mounting a motor to a KL helical bevel gear unit with MQ motor adapter (example) – Torque wrench Hexagon insert Motor adapter Gear unit Clamping sleeve (if present) Motor shaft Motor Screw Slot of the clamping hub Locking screw Threaded sealing plug Adhesive label...

-

Page 31: Mounting The Output Shaft

5 | Installation Tightening torques for the locking screw (11) Type [mm] [Nm] KL102 KL202 Abbreviations used: § KS = Nominal diameter of the locking screw (11) § = Tightening torque for the locking screw (11) § s = Size of the hexagon insert (3) Mounting the output shaft This chapter contains information on how to correctly connect the different designs of the gear unit output shaft with the machine so that the torque can be transmitted properly. -

Page 32: Mounting Drive Elements On A Flange Shaft

5 | Installation Fig. 5: Mounting device for a belt drive (example) Washer Threaded pin Axial bearing Belt drive (example) Solid shaft 5.3.2 Mounting drive elements on a flange shaft This chapter describes the assembly of drive elements, such as belt drives or pinions, on a flange shaft. ATTENTION! Damage to encoders, bearings and shafts due to improper assembly! Never use force when mounting drive elements with fittings, e.g. -

Page 33: Mounting A Hollow Shaft With Keyway

5 | Installation Gear unit type Number of screws Screw size Min. screw-in depth [mm] PH5_KX PH7_KX PH8_KX PH5_K PH7_K PH8_K PH9_K PH10_K PHQ5_K PHQ7_K PHQ8_K PHQ9_K PHQ10_K PHQ11_K 35.5 PHQ12_K Tab. 11: Information on screws for mounting drive elements on the flange shaft 5.3.3 Mounting a hollow shaft with keyway This chapter describes how to mount gear units with a hollow shaft and keyway on a machine shaft. -

Page 34: Mounting A Hollow Shaft With Shrink Ring

5 | Installation 4. Insert the gear unit with the hollow shaft onto the machine shaft. 5. Pull the gear unit onto the machine shaft with the help of the cheese-head screw and washer up to the stop, which is determined by the collar of the machine shaft, the keeper plate or the output flange. - Page 35 5 | Installation Socket Machine shaft Hollow shaft Shrink ring Clamping screw Surface, greased Surface, free of grease Inner and outer surface, free of grease Information on mounting the shrink ring Gear unit type ds [mm] [Nm] Width across flats [mm] –...

-

Page 36: Mounting The Gear Unit On The Machine

5 | Installation Mounting the gear unit on the machine This chapter contains information on how to mount the gear unit on the machine. 5.4.1 Mounting PK, PKX, PHK, PHKX, PHQK gear units on the machine Prerequisites § The connecting structure for the drive in the machine is designed according to the weight and torque and takes into account forces that act on the drive. - Page 37 5 | Installation Tab. 13: Mounting the gear unit to the machine, using PHQ831_K402 (left) and PH731_KX7 (right) as an example Threaded hole of the flange shaft Outer pilot of the flange shaft Pilot/pilots of the housing Output flange bore Inner pilot of the flange shaft Threaded hole for disassembly (if present) Gear unit type...

-

Page 38: Mounting The Ks Gear Unit To The Machine

5 | Installation Gear unit type Number of screws Screw size Strength class PHQ8_K 12.9 PHQ9_K 12.9 PHQ10_K 12.9 PHQ11_K 12.9 PHQ12_K 12.9 Tab. 14: Information on screws for mounting the gear unit housing on the machine 5.4.2 Mounting the KS gear unit to the machine Prerequisites §... -

Page 39: Mounting The Kl Gear Unit On The Machine

5 | Installation Tab. 15: Mounting the gear unit to the machine, using KS502F (left) and a KS502S gear unit (right) as an example Output flange bore Threaded hole of the flange shaft Inner pilot of the flange shaft Hollow shaft bush Outer pilot of the flange shaft Housing pilot Shrink ring... - Page 40 5 | Installation Procedure 1. Remove the corrosion protection from the contact surfaces of the pitch circle diameter/output flange/foot plates and from the connecting structure. 2. For a gear unit with a hollow shaft and keyway, mount the hollow shaft on the machine shaft (see Mounting a hollow shaft with keyway [} 33]).

-

Page 41: Tightening Torques

5 | Installation Gear unit type Number of screws Screw size Min. screw-in depth Strength class [mm] KL102_G 10.9 KL202_G 10.9 KL102_F – 10.9 KL202_F – 10.9 KL102_NG – 10.9 KL202_NG – 10.9 Tab. 18: Information on screws for mounting the gear unit housing on the machine Tightening torques Note that the following tightening torques apply to screws that are used for mounting the motor on the gear unit or the gear unit on the machine. -

Page 42: Commissioning

The maximum surface temperature occurs in approx. 3 hours, depending on the utilization of the drive, and must not exceed the maximum value of 90 °C in the event of a maximum surrounding temperature. Immediately shutdown the drive if the maximum value is exceeded and contact STOBER Service. -

Page 43: Servicing

7 | Servicing Servicing Cleaning If the surface of the gear unit/geared motor is dirty, sufficient heat dissipation through the ambient air is no longer possible. As a result, impermissibly high operating temperatures could occur, which reduce the lubricating effect of the lubricant and accelerate its aging. -

Page 44: Remedying Faults

Servicing Have the necessary servicing work carried out on the drive by the STOBER Service department or by STOBER service partners. Be aware that improper servicing may cause material damage and may void the manufacturer's warranty. Only use replacement parts delivered by STOBER. Specify the type designation and serial number of the drive when... -

Page 45: Service

7 | Servicing Service If you contact STOBER Service, have the following information ready: § Serial number and type designation of the drive according to the nameplate § Type of fault and surrounding circumstances § Presumed cause § If possible, digital photo of the drive or a video recording of the drive in the context of the fault Contact data of parent company in Germany STÖBER Antriebstechnik GmbH + Co. -

Page 46: Removal And Disposal

8 | Removal and disposal Removal and disposal Removal This chapter contains information on removing the gear unit. WARNING! Moving machine parts can cause serious injuries or even death! Before performing work, switch off the machine with the main switch and secure the switch from being turned on again. WARNING! Falling gravity-loaded axes or vertical axes can cause serious injuries or even death! Move gravity-loaded axes or vertical axes to their lowest position and lock or brace them mechanically before entering the danger area. -

Page 47: Disposal

8 | Removal and disposal 4. Unscrew the screws used to mount the drive to the machine. 5. For gear units with a hollow shaft and shrink ring: Unscrew the clamping screws of the shrink ring in multiple cycles by one quarter rotation each in turn, but do not completely remove the clamping screws from the thread. - Page 48 443150_en.00 10/2019 STÖBER Antriebstechnik GmbH + Co. KG Kieselbronner Str. 12 75177 Pforzheim Germany Tel. +49 7231 582-0 mail@stoeber.de www.stober.com 24 h-Service-Hotline +49 7231 582-3000 www.stober.com...

Need help?

Do you have a question about the PK Series and is the answer not in the manual?

Questions and answers