Subscribe to Our Youtube Channel

Summary of Contents for Sumake ST-6410

- Page 1 INSTRUCTION MANUAL ST-6410 ITEM NO.: AIR HYDRAULIC LOCKBOLT TOOL ONLY (W/O NOSE) ST-6410H ITEM NO.: AIR HYDRAULIC LOCKBOLT TOOL (W/ NOSE) ST-6410 ST-6410H ST-6410(H)-I-1905B-C1...

- Page 2 Contents TOOL SPECIFICATION .................2 GENERAL DESCRIPTION................3 SAFETY INSTRUCTIONS................4 PREPARATION FOR USE................5 OPERATION.......................5 MAINTENANCE………………………………………………………………5 DISASSEMBLY AND ASSEMBLY……………………………………...……6 TROUBLESHOOTING ...................6 ADD OIL…………………………..……………………………………………7 OUTLINE DIMENSIONS……………………………………………………..8 PRINCIPLE OF OPERATION………………………………………..………8...

- Page 3 TOOL SPECIFICATIONS Technical Data Model Of Tool…………………………..……… ST-6410(H) Dimensions……………………………………... 8.85” X 12.63” X 4.46” (Length X Height X Width) (224.8mm X 321mm X113.5mm) Weight…………………………..………..3.83 lbs [1.74 Kgs] Air Inlet………………………………………… 1/4” NPT Recommended Operating Pressure………...… 70 to 95 psi [4.9 to 6.67 kg/cm2] Air Consumption………………...….

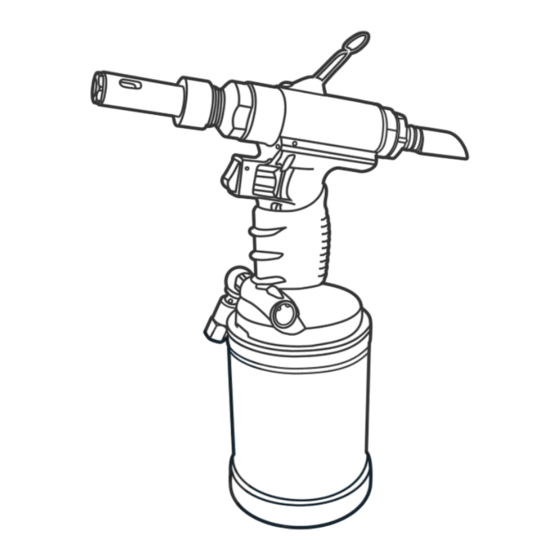

- Page 4 GENERAL DESCRIPTION The ST-6410(H) Installation Tool illustrated in Fig. 1 with its pneumatic hydraulic system provides an efficient, lightweight, powerful, and quiet tool for rivet nut installation. It is designed to provide long life and trouble free services. SAFETY CAP...

- Page 5 SAFETY INSTRUCTIONS DANGER Read this manual and understand all safety instructions before operating the tool. If you have any questions, please contact our authorized representatives. Any other use is prohibited ` Be sure all hoses and fittings are the cor rect size and are tightly secured.

- Page 6 PREPARATION FOR USE An air supply of 85- 90 psi must be available (6, 3kp/cm2). Every attempt should be made to furnish 90 psi of clean dry air to the tool. Connect the tool to an air supply equipped with a filter, regulator and lubricator. If no lubricato r is available, pour a small quantity of clean light machine oil into air inlet (57 ).

- Page 7 DISASSEMBLY AND ASSEMBLY 1. Disconnect air hose and remove nose assembly. 2. Unscrew cylinder cap (1) with φ 6.1 pin(60). 3. Pull out air piston (7) in a straight line with suitable pliers. 4. Remove Adapter (40) 5. Unscrew front gland (46), remove spring (56) and push out pull piston (42). 6.

- Page 8 ADD OIL The maintenance required when the tool of ST-6410(H) pulling strength diminish, it is only necessary to add ISO VG46 oil or DEXRON III., the operation steps as below: 1. Turn the tool upside down and well fixed, then use spanner remove No.1 parts.

- Page 9 OUTLINE DIMENSIONS 224.8 30.0 37.0 113.5 Fig.4 OUTLINE DIMENSIONS PRINCIPLE OF OPERATION When the tool is connected to a proper air supply and the trigger is depressed, air pressure acts upon the air piston and moves it upwards. The piston rod serves as a hydraulic piston and acts on a volume of hydraulic fluid in the handle.

- Page 10 Air Hose (I.D.) 3/8” (10 mm) to risk of Air Pressure 90 psi (6.3 bar) impaired Uncertainty Uncertainty hearing! K= 1.5 m/s ² K= 3dB Net Weight 3.84 lbs (1.74 kg) SUMAKE INDUSTRIAL CO., LTD 4F,NO.351,Yangguang St.,Neihu District TAIPEI, TAIWAN, ZIP:114-91 ST-6410-S-1905B-C1F...

- Page 11 DECLARATION OF CONFORMITY SUMAKE INDUSTRIAL CO., LTD. 4F, No. 351, Yangguang St., Neihu District, Taipei City, Taiwan declare in sole responsibility that the equipment Equipment: AIR HYDRAULIC LOCKBOLT TOOL ONLY (W/O NOSE) Model/ Serial No.:ST-6410 to which this declaration applies, complies with these normative documents: ...

- Page 12 Air Hose (I.D.) 3/8” (10 mm) to risk of Air Pressure 90 psi (6.3 bar) impaired Uncertainty Uncertainty hearing! ² K= 1.5 m/s K= 3dB Net Weight 3.84 lbs (1.74 kg) SUMAKE INDUSTRIAL CO., LTD 4F,NO.351,Yangguang St.,Neihu District TAIPEI, TAIWAN, ZIP:114-91 ST-6410H-S-1905B-C1F...

- Page 13 DECLARATION OF CONFORMITY SUMAKE INDUSTRIAL CO., LTD. 4F, No. 351, Yangguang St., Neihu District, Taipei City, Taiwan declare in sole responsibility that the equipment Equipment: AIR HYDRAULIC LOCKBOLT TOOL (W/ NOSE) Model/ Serial No.:ST-6410H to which this declaration applies, complies with these normative documents: ...

- Page 14 ST-6410 AIR HYDRAULIC LOCKBOLT TOOL ONLY (W/O NOSE) ST-6410H AIR HYDRAULIC LOCKBOLT TOOL (W/ NOSE) ST-6410(H)-P-2109E-C1...

- Page 15 ST-6410 AIR HYDRAULIC LOCKBOLT TOOL ONLY (W/O NOSE) ST-6410H AIR HYDRAULIC LOCKBOLT TOOL (W/ NOSE) PARTS LIST Parts No. Description Q'ty Parts No. Description Q'ty 6410-01 Cylinder Cap 6410-35 O-Ring 6410-02 Rubber Bottom 6410-36 O-Ring 6410-03 Air Cylinder Body 6410-37...

- Page 16 3/16"(4.8mm) Huck C6L Nose Ass'y 3/16"(4.8mm) Huck Magna-Grip Nose Ass'y Parts No. Description Q'ty Parts No. Description Q'ty 6410H-02-01 Anvil Assembly 6410H-04-01 Anvil Assembly 6410H-02-02 Collet 6410H-04-02 Collet 6410H-02-03 Unitized Jaws 6410H-04-03 Unitized Jaws 6410H-02-04 Locator 6410H-04-04 Extension 6410H-02-05 Extension ST-6410(H)-P-2109E-C1...

- Page 17 RIVETER Original instructions SUMAKE Industrial Co. Ltd.

- Page 18 The tool has been manufactured in conformity with the instruction of EU machine directive. The EU mark will be considered void in the event of inexpert repairs, the use of non-original parts and in case of non-observance of the safety instructions in the user’s manual. Possible direct or indirect consequential damages are not the responsibility of SUMAKE Industrial co., Ltd. General safety rules: Watch the tool at all times when in use.

- Page 19 Safety precautions for repetitive motions hazards 1. When using a power tool, the operator may experience discomfort in the hands, arms, shoulders, neck, or other parts of the body. 2. While using a power tool, the operator should adopt a comfortable posture. Maintain secure footing and avoid awkward or off-balanced postures.

- Page 20 General preparation and connection: Before connecting the air hose, apply 4 to 5 drops of SAE 10W-20 (ISO Viscosity Grade 46/32) Hydraulic Oil at the air inlet. Also, every 3 to 4 hours of operation, oiling is necessary. Twist Teflon thread tape to ensure a proper seal air inlet. Then tighten the air coupler into air tool.

Need help?

Do you have a question about the ST-6410 and is the answer not in the manual?

Questions and answers