Jasic Plasma Cut Series Operator's Manual

Hide thumbs

Also See for Plasma Cut Series:

- Operator's manual (32 pages) ,

- Operator's manual (12 pages) ,

- Operator's manual (22 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Jasic Plasma Cut Series

-

Page 2: Your New Product

Please ensure that you carry out daily and periodic maintenance checks to ensure years of reliable and trouble free operation. Please call your Jasic distributor in the unlikely event of a problem occurring. Please record below the details from your product as these will be required for warranty purposes and to ensure you get the correct information should you require assistance or spare parts. -

Page 3: Table Of Contents

Plasma Hand Torch PT60 Information Plasma Machine Torch TM125 Information Cut Charts - Machine/Mechanised Torch Maintenance Troubleshooting Plasma Cutting Problems WEEE Disposal RoHS Compliance Declaration UKCA Declaration of Conformity EC Declaration of Conformity Statement of Warranty Notes Jasic Contact Details... -

Page 4: Notes

NOTES _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________... -

Page 5: Safety Instruction

SAFETY INSTRUCTION These general safety norms cover both arc welding machines and plasma cutting machines unless otherwise noted. It is important that users of this equipment protect yourselves and others from harm or even death. The equipment must only be used for the purpose it was designed for. Using it in any other way could result in damage or injury and in breach of the safety rules. -

Page 6: Welding Processes Lens Shade Selector Guide

SAFETY INSTRUCTION Use of Personal Protective Equipment (PPE) Welding arc rays from all welding processes produce intense, visible and invisible (ultraviolet and infrared) rays that can burn eyes and skin. • Wear an approved welding helmet fitted with an appropriate shade of filter lens to protect your face and eyes when welding or watching. -

Page 7: Fume And Welding Gases

SAFETY INSTRUCTION Safety against fumes and welding gases The HSE have identified welders as being an ‘at risk’ group for occupational diseases arising from exposure to dusts, gases, vapours and welding fumes. The main identified health effects are pneumonia, asthma, chronic obstructive pulmonary disease (COPD), lung and kidney cancer, metal fume fever (MFF) and lung function changes. -

Page 8: The Working Environment

SAFETY INSTRUCTION The working environment Ensure the machine is mounted in a safe and stable position allowing for cooling air circulation. Do not operate equipment in an environment outside the laid down operating parameters. The welding power source is not suitable for use in rain or snow. Always store the machine in a clean, dry space. -

Page 9: Rf Declaration

SAFETY INSTRUCTION RF Declaration Equipment that complies with directive 2014/30/EU concerning electromagnetic compatibility (EMC) and the technical requirements of EN60974-10 is designed for use in industrial buildings and not those for domestic use where electricity is provided via the low voltage public distribution system. Difficulties may arise in assuring class A electromagnetic compatibility for systems installed in domestic locations due to conducted and radiated emissions. -

Page 10: Product Overview

Optional CNC interface available* (suitable for most cutting tables) • Optional circle cutting guide kit available The CNC interface option needs to be requested at time of machine order from Jasic UK as we install this option prior to shipping the machine from our warehouse. -

Page 11: Product Details And Application

Powerful cutting performance The Jasic 45 plasma machine provides economical cutting of metals using compressed air as the plasma gas source. The cutting speed is 1.8 times when compared with oxy acetylene cutting. These machines can cut steel, stainless steel, copper, cast iron and aluminium easily and quickly. -

Page 12: Technical Specifications

TECHNICAL SPECIFICATIONS Parameter Unit Jasic Cut 45PWV Rated input voltage 1PH 95 - 265V AC ±15% Rated input frequency 50/60 Connected supply 115V 230V Rated input power Rated input current Imax Rated input current Ieff 13.5 Cutting current range 20 ~ 30... -

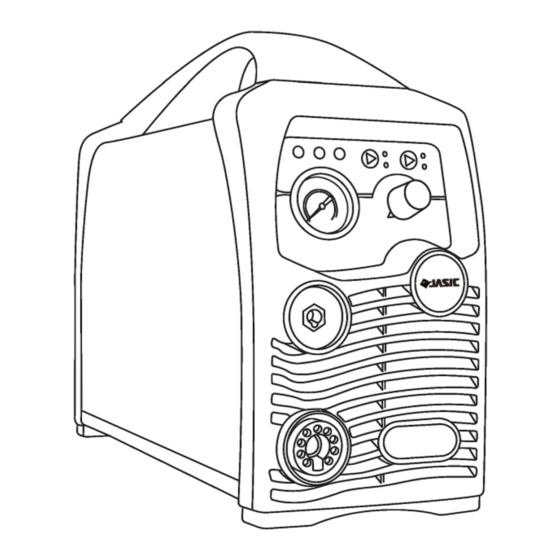

Page 13: Description Of Controls

CONTROLS Front view Jasic Cut 45 1. Pressure gauge 2. Work return connector (10/25mm Socket) 3. Torch connector, the plasma torch connection (see page 16 for fitting instructions) 4. 2T/4T torch trigger latch selection switch: A useful function when carrying out longer cuts,... - Page 14 CONTROLS Control panel view Jasic Cut 45 Number Symbol Function Power indicator. When illuminated indicates that the machine is powered on. Once a welding arc has been established this LED will flash. Overheating indicator. Normally off. If this LED is on it indicates that the temperature inside the machine is too high and the machine is under over heating protection status.

-

Page 15: Installation

Never connect the machine to the mains supply with the panels removed. Input air connection • The Jasic Plasma Cut 45 are only designed to be used with compressed air, do not use with oxygen or any other gas and the compressor or air cylinder air requirements are as follows: ... - Page 16 Fitting the PT60 plasma torch On the Jasic Cut 45 plasma machine, the below torch fitting instructions will need to be observed. Locate plasma torch plug into euro connector socket as shown in image 1 below ...

-

Page 17: What Is Plasma

WHAT IS PLASMA? • Plasma is commonly described as the fourth state of matter (i.e. solid, liquid, gas then plasma). • If you increase gas to an extremely high temperature you get the fourth state plasma, the energy begins to break apart the gas molecules and the atoms begin to split. -

Page 18: Operation

OPERATION Before starting any welding or cutting activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. Plasma cutting Check that all connections have been made as required. Check the following before starting the machine. •... - Page 19 OPERATION Before starting any welding or cutting activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. Modes of cutting Piercing is the process in which a quick hole is made in the work piece. Piercing is often just a starting hole that will be used to make a ‘circular’...

-

Page 20: Cut Quality

If you plan to keep the piece from which the circle was cut from then move in an anti-clockwise direction. Jasic Plasma Cut 45 Circle Cutting Guide Kit - Part number 51866... -

Page 21: Typical Cutting Speeds

Speeds shown below are offered as a guide only for our Jasic hand cutting systems using compressed air, cutting mild steel material with the stated output currents ensuring that the cutting tip fitted matches the stated amperages. -

Page 22: General Cutting Information

GENERAL CUTTING INFORMATION Before starting any welding or cutting activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the welding area. Notes for cutting operation 1. Do not touch the hot work piece with bare hands to avoid burning. 2. -

Page 23: Plasma Hand Torch Pt60 Information

60389 Retaining Cap 60389C Shield Cup Body 60432 Double Pointed Spacer (for items 6 & 7 only) 60485 Shield Cap, Hand 09600.63 Wrench for Electrode Please Note: Configuration above only to be used on the Jasic Cut 45 Plasma Machine... - Page 24 Extended Tip Contact (0.8) 20-30A Back Striking 60389 Retaining Cap 60432 Double Pointed Spacer (for items 6 & 7 only) 60389S Retaining Cap (long life) 09600.63 Wrench for electrode Please Note: Configuration above only to be used on the Jasic Cut 45 Plasma Machine...

- Page 25 Shielded Cutting Tip (0.9) 30-40A Back Striking 51318C.10 Shielded Cutting Tip (1.0) 40-50A Back Striking 60389C Shield Cup Body 60485 Shield Cap, Hand 09600.63 Wrench for electrode Please Note: Configuration above only to be used on the Jasic Cut 45 Plasma Machine...

-

Page 26: Plasma Machine Torch Tm125 Information

Shield Cup Body (45-85A) 51929 Shield Cap (45A) Precision Cut 220817 Machine Shield (45-85A) 07219 Positioning Tube With Rack 60309THA Shield Cup Body (45-85A) C/W Ohmic Clip Please Note: Configuration above only to be used on the Jasic Cut 45 Plasma Machine... -

Page 27: Cut Charts - Machine/Mechanised Torch

MACHINE TORCH CUTTING CHARTS AND CHART INFORMATION The following pages offer cutting charts settings for each set of machine/mechanized plasma torch consumable set-up. These charts are for reference and should be considered a good starting point for data such as cutting speeds although differences between installations and material composition may cause actual results to vary from the data shown in the tables. - Page 28 TM125 MACHINE TORCH RECOMMENDED CUTTING SPEED CHART 45Amp ‘Shielded’ Standard Set Up Material Plate Thickness Cutting Height Pierce Height Pierce Delay Cutting Speed Cutting Voltage seconds mm/min Mild Steel 7440 Mild Steel 3960 Mild Steel 1430 Mild Steel 1020 Mild Steel Mild Steel Stainless Steel 7480...

- Page 29 TM125 MACHINE TORCH RECOMMENDED CUTTING SPEED CHART 45Amp ‘Shielded’ Precision Cut Set Up Precision Cut - High Speed Material Plate Thickness Cutting Height Pierce Height Pierce Delay Cutting Speed Cutting Voltage seconds mm/min Mild Steel 8250 Mild Steel 8250 Mild Steel 5250 Mild Steel 2750...

-

Page 30: Maintenance

MAINTENANCE The following operation requires sufficient professional knowledge on electric aspects and comprehensive safety knowledge. Make sure the input cable of the machine is disconnected from the electricity supply and wait for 5 minutes before removing the machine covers. In order to guarantee that your cutting and welding machine works efficiently and in safety, it must be maintained regularly. -

Page 31: Air Pressure Setting

MAINTENANCE The following operation requires sufficient professional knowledge on electric aspects and comprehensive safety knowledge. Make sure the input cable of the machine is disconnected from the electricity supply and wait for 5 minutes before removing the machine covers. Please note: The following should only be carried out by an authorised electrical technician. Air pressure setting The internal air pressure regulator is preset prior to leaving the factory and the users should not need to set it. -

Page 32: Troubleshooting

TROUBLESHOOTING The following operation requires sufficient professional knowledge on electric aspects and comprehensive safety knowledge. Make sure the input cable of the machine is disconnected from the electricity supply and wait for 5 minutes before removing the machine covers. Before any welding and cutting machines are dispatched from the factory, they have already been checked thoroughly. - Page 33 Plasma Cutting Problems Problem Possible cause Suggested action Check for low air pressure to the plasma machine (low flow be caused by a long air hose with a small internal diameter Low air pressure or low air Ensure your compressor is set to deliver the correct CFM flow (or too detailed in the plasma owner’s manual and can keep this...

-

Page 34: Weee Disposal

Jasic has a relevant recycling system which is compliant and registered in the UK with the environment agency. Our registration reference is WEEMM3813AA. -

Page 35: Ec Declaration Of Conformity

EC Declaration of Conformity... -

Page 36: Statement Of Warranty

This should be carried out by a suitably qualified competent person. In the unlikely event of a problem, this should be reported to Jasic technical support team to review the claim. -

Page 37: Notes

NOTES _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________ _____________________________________... -

Page 38: Jasic Contact Details

January 2022 - Issue 11...

Need help?

Do you have a question about the Plasma Cut Series and is the answer not in the manual?

Questions and answers