GREAT PLAINS BD7410-13 Operator's Manual

Min-till drill

Hide thumbs

Also See for BD7410-13:

- Predelivery manual (21 pages) ,

- Manual (44 pages) ,

- Installation manual (30 pages)

Table of Contents

Advertisement

Quick Links

Great Plains

Min-Till Drill

OPERATOR MANUAL

MODELS BD7410-13

Table of Contents

Original Instructions

!

Index

Read the operator manual entirely. When you see

this symbol, the subsequent instructions and

warnings are serious - follow without exception.

Your life and the lives of others depend on it!

Illustrations may show optional equipment not

supplied with standard unit.

TP-80371

175-600m

Advertisement

Table of Contents

Summary of Contents for GREAT PLAINS BD7410-13

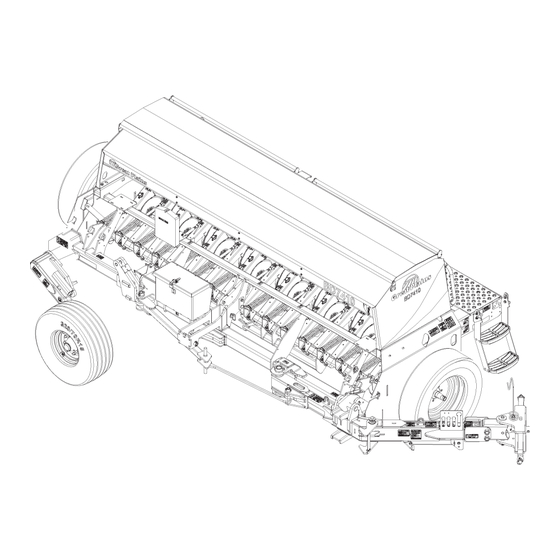

- Page 1 Table of Contents Index Great Plains Min-Till Drill OPERATOR MANUAL MODELS BD7410-13 TP-80371 175-600m Original Instructions Read the operator manual entirely. When you see this symbol, the subsequent instructions and warnings are serious - follow without exception. Your life and the lives of others depend on it! Illustrations may show optional equipment not supplied with standard unit.

-

Page 2: Machine Identification

Machine Identification Record your machine details in the log below. If you replace this manual, be sure to transfer this information to the new manual. If you or the dealer have added options not originally ordered with the machine, or removed options that were originally ordered, the weights and measurements are no longer accurate for your machine. - Page 3 Printed 10/29/2024 | English Great Plains reserves the right to revise and improve its products at any time. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future. The content of this publication may be...

- Page 4 Trademarks of Great Plains Manufacturing, Inc. include: AccuShot, DrillCommand, Max-Chisel, Row-Pro, Singulator Plus, Short Disk, Swath Command, Terra-Tine, Ultra-Chisel, and X-Press. Registered trademarks of Great Plains Manufacturing, Inc. include: Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand, Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo-Max, Turbo-Trill, Ultra-Till, Whirlfilter, and Yield-Pro.

-

Page 5: Table Of Contents

Keeton® Seed Firmer (Option)... 40 Operation ......19 Great Plains | 175-600m | 10/29/2024... - Page 6 Opener Lift ......63 Transport Lift / Fold ....64 Great Plains | 175-600m | 10/29/2024...

-

Page 7: Introduction

Table of Contents Index Introduction Introduction The BD7410-13 is a towed seeding implement. This Parts Manual QRC drill has a working width of 13 feet (3.9m) and folds The QR code to the left will take you to a width of 9.5 feet (2.9m) for transport. -

Page 8: Machine Identification

Health Your machine’s parts were specially designed and and Safety at Work. Untrained or unauthorized should only be replaced with Great Plains parts. persons are not permitted to use the machine. Always use the serial and model number when ordering parts from your dealer. -

Page 9: Safety Information

Non-Great Plains components on this machine may machine and advises on how to avoid it. contain additional safety information not found in this The notice symbol indicates a potential for manual. -

Page 10: Machine Use

Avoid contacting overhead obstructions such as low bridges, overpasses, and power lines. Do not operate near ditches, holes, steep slopes, embankments, or other surfaces which may collapse under the machine’s weight or tip the machine over. Great Plains | 175-600m | 10/29/2024... -

Page 11: Machine Maintenance

Detach the tractor. Secure the implement using Stay clear of and never step over any rotating parts. blocks. Great Plains | 175-600m | 10/29/2024... -

Page 12: Safety Decals

Read and follow decal directions. Keep all safety decals clean and legible. Replace all damaged, faded, or missing decals. Order new decals from your Great Plains dealer. One reflector near each turn signal and brake light Refer to this section for proper decal placement. -

Page 13: Excessive Speed Hazard

To prevent serious injury or death: Always be certain implement is hitched securely TP-80487 to tractor drawbar before raising. Lower implement BEFORE unhitching. 818-019C Rev. D One decal on tongue near hose holder bracket. TP-80487 Great Plains | 175-600m | 10/29/2024... -

Page 14: Do Not Ride

TP-80487 Two decals - one on either end of the drill box near the walkboard ladders. Falling Hazard 848-575C Two decals - one on either end of drill box near the walkboard ladders. TP-80487 Great Plains | 175-600m | 10/29/2024... - Page 15 Four decals - One on the tongue, one on the side of the frame near the transport lock, one on each side Two decals - one on each end of the walkboard near on or near the rock shaft. the ladder. TP-80487 TP-80488 TP-80486 TP-80486 Great Plains | 175-600m | 10/29/2024...

- Page 16 ◦ 818-518C ◦ Keep all components in good repair. 818-339C Rev. D Two decals - one on or near each chain guard. One decal on tongue near the hitch. TP-80486 TP-80487 Great Plains | 175-600m | 10/29/2024...

- Page 17 Do now allow riders. Keep others away during operation. Safely support and secure implement before repairs are made. 818-719C TP-80486 WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov One Decal on tongue near the hitch. Great Plains | 175-600m | 10/29/2024...

-

Page 18: Preparation And Setup

These connections can be made in any order, and Color Hydraulic Function must be made before moving the drill. Blue Transport Lift / Fold Opener Lift Green Marker Great Plains | 175-600m | 10/29/2024... -

Page 19: Hitch Drill To Tractor

Equipment Damage Risk to be bled or otherwise serviced by a trained Turning too far to the right while in transport professional; contact your Great Plains dealer for mode can lead to contact between tractor service. wheel and the implement tongue. -

Page 20: Set Range

Then move the handle up or down as needed until the pointer (2) is at the desired rate. You can temporarily stop seed flow to a drill section by disengaging the chain. TP-80500 71512 Great Plains | 175-600m | 10/29/2024... -

Page 21: Adjust For Dry Fertilizer Density

The drill must be hitched to a tractor for material box lid. This will keep material out of the front loading. The openers may be raised or lowered, but compartment. the drill must be in field mode for access to the walkboard. Great Plains | 175-600m | 10/29/2024... -

Page 22: Small Seeds Compartment Loading

Open the slide gates to the correct position on the feed cups you are using for calibration. 2. With the seed hoses connected, remove the feed cup funnels on the feed cups you are using for calibration. Great Plains | 175-600m | 10/29/2024... - Page 23 (hectare) is counted on the acremeter. Check that the feed cups have plenty of material coming into them. Refer to the table below for crank rotations. Crank Rotations Drill Model Per Acre Per Hectare BD7410-13 Great Plains | 175-600m | 10/29/2024...

- Page 24 If applying more or less product than desired, adjust the rate slightly to make up for field conditions. Great Plains | 175-600m | 10/29/2024...

-

Page 25: Operation

During operation always raise openers planting. before turning. To avoid plugging openers Raise the openers for turns. and possible damage to equipment, never back up or turn sharply with openers in the ground. Great Plains | 175-600m | 10/29/2024... -

Page 26: End Operating

To avoid serious injury or death, use handrails when climbing ladder and walking on walkboard. Equipment Damage Risk Make sure ladders are fully folded up before moving or folding the drill. Always use the walkboard ladder to access the walkboard. Great Plains | 175-600m | 10/29/2024... -

Page 27: Opener Frame Down-Force

Check for loose hydraulic hoses and electrical wiring before shifting between modes. These instructions are beginning with the implement in road (folded) mode. They will finish with the machine in field (unfolded) mode. TP-80573 Great Plains | 175-600m | 10/29/2024... -

Page 28: Folding

4. Set the transport lock on rock shaft hydraulic the tractor while the rock shaft lowers the other cylinder. end wheel to the ground in one smooth motion. 5. The drill is in road mode and ready for transport. Great Plains | 175-600m | 10/29/2024... -

Page 29: Drill Box

The feed cups (5) attached to the bottom of the box use seed wheels to dispense a multiple of size and variety of seeds and dry fertilizer. See the Feed Cup section for more information. 71389 Great Plains | 175-600m | 10/29/2024... - Page 30 5. Install the knobs (3) and side seals to secure the vinyl flap and divider flap. 6. Tighten all knobs (2 and 3). 71388 The illustration below shows the divider flap (1) open and secured under the vinyl flap. 71394D Great Plains | 175-600m | 10/29/2024...

-

Page 31: Box Dividers

50.5 bu (1780 liter) Standard 30.3 bu (1068 liter) 20.2 bu (712 liter) Offset to back 32.8 bu (1156 liter) 17.7 bu (624 liter) Offset to front 27.8 bu (980 liter) 22.7 bu (800 liter) Great Plains | 175-600m | 10/29/2024... -

Page 32: Rain Flap

4. Lift the spill flap assembly (12) out of the box. 5. Lift the dividers (13) out of the box. 6. Install the new dividers. 7. Reinstall the spill flap assembly to the box. 71394D 71397 Great Plains | 175-600m | 10/29/2024... -

Page 33: Feed Cups

Positions 2, 3, and 4 - medium to extra large seeds Position 5 - clean out To change the position, pull out the handle and move it to the appropriate position for your desired material rate. 71378 71355 Great Plains | 175-600m | 10/29/2024... -

Page 34: Slide Gate

Disk scraper (5) - In sticky soils, an optional disk scraper helps keep the opener disks operating freely. A slotted scraper is standard. 71356A Great Plains | 175-600m | 10/29/2024... -

Page 35: Acremeter Operation

The T-handle (8) is used for press wheel adjustments. A variety of press wheels are available, some are region specific. Ask your Great Plains dealer. Opener height adjustment (9) - The pivot point for the opener body can be adjusted for lower ground level in rows or planting in tire tracks. -

Page 36: Operating Instructions

Pressing Select while password is salted - **** - will navigate to the A1 screen. Pressing Select while the correct password value is entered will navigate to the P1 screen. If the password is incorrect, the PW screen is reset. Great Plains | 175-600m | 10/29/2024... - Page 37 CHPW screen. TP-80586 Displays either the calibration request status or the current calibration value. If displaying the request status - YES or NO - and status is YES, pressing Select begins sensor calibration. Great Plains | 175-600m | 10/29/2024...

-

Page 38: Markers (Option)

This Kit mounts a selector valve beside the sequence valves for the tractor transport / lift. The selector valve allows you to operate either the markers (right position) or the transport lift / fold (left). Great Plains | 175-600m | 10/29/2024... -

Page 39: Small Seeds Box (Option)

2. To perform this calibration, you need the 11. Record the weight of the collapsible bucket. calibration tray, the collapsible bucket, and the digital scale from the tool box. 3. Disengage the lock-out hub to permit rotation of the main jackshaft. Great Plains | 175-600m | 10/29/2024... - Page 40 = new setting measured rate Example: x 50 = 39.68 12.6 New small seeds rate: 40 on the seed rate handle. 18. Set the Small Seeds Rate Handle to the new scale setting. Great Plains | 175-600m | 10/29/2024...

-

Page 41: Small Seeds Row Shut-Off

Allow sufficient stopping distance and reduce speed before any turns or maneuvers. If the drill is transported full, allow extra stopping distance. Great Plains | 175-600m | 10/29/2024... -

Page 42: Parking

Unplug the light harness and any other electrical harnesses. Protect the connections with any plugs or caps provided. Remove the hitch pins from the tractor draw bar. Start the tractor and pull away from the drill. Great Plains | 175-600m | 10/29/2024... -

Page 43: Adjustments

Make sure all openers are pivoting in the same hole at the opener mount. Make sure opener depth is all set the same. Make sure all opener spring down pressure is the same. 71478B Great Plains | 175-600m | 10/29/2024... -

Page 44: Opener Height

(4) and the top edge of the lower/rear spring stop (5). The factory preset length is recommended for conventional till and min-till conditions. Shorten the length for no-till conditions. 26427 26452 Great Plains | 175-600m | 10/29/2024... -

Page 45: Opener Depth Adjustment

If press wheels are digging into the Sharp Object Hazard ground, reduce down pressure. Disk blades are sharp. To avoid serious injury, wear gloves when working in this area. Great Plains | 175-600m | 10/29/2024... -

Page 46: Seed Firmer Adjustments

In some wet and sticky conditions the wheels may 26435 accumulate soil. To avoid this problem, you can lock up the wheels: 1. Pull up on the Seed-Lok arm (1). 2. Raise the lever (2). 24453 Great Plains | 175-600m | 10/29/2024... -

Page 47: Marker Adjustments

With tractor idling at normal operating speed, adjust marker folding to a safe speed. Excessive folding speed could damage markers and void the warranty. After adjusting folding speed, tighten jam nuts on hex adjustment screws to hold settings. Great Plains | 175-600m | 10/29/2024... -

Page 48: Marker Disk Adjustment

The valves are located on the mainframe of the To have the marker throw out dirt, turn around the implement. disk on the spindle. Turn around the disk assembly as shown below. TP-80487 11248 Great Plains | 175-600m | 10/29/2024... -

Page 49: Maintenance Schedule

Inspect hydraulic hoses for cuts, cracks, and aging. Check fittings and cylinder for evidence of leaks. Repair or replace as needed. Keep disk scrapers properly adjusted. Replace any worn, damaged, or illegible safety decals. Order new decals from your Great Plains dealer. Great Plains | 175-600m | 10/29/2024... -

Page 50: Hydraulic Maintenance

High Pressure Fluid Hazard chemicals corrosive to metal. Do not attempt to make hydraulic system repairs. Great Plains strongly recommends that all 1. Place a tarp or bucket under the rows to be hydraulic system repairs to be completed by a cleaned out. - Page 51 4. Loosen the set screws (2) on the two locking collars at the right end of the flap shaft (3). 71393 71593 5. Remove the shaft up to the feed cup to be removed. Great Plains | 175-600m | 10/29/2024...

- Page 52 Make sure the seed wheel divider (4) goes into the slot (5) on the feed cup flap. 6. Place the new seed wheel assembly into the feed cup housing. 7. Close the windshield. 71410. Great Plains | 175-600m | 10/29/2024...

-

Page 53: Installation

6. Insert the shaft key (2) with the arrows aligned (3). Install the clip with the open end facing away from the direction of chain travel. 71412 26482 Great Plains | 175-600m | 10/29/2024... - Page 54 If the grease seal cap (1) for the marker disk hub bearings is damaged or missing, disassemble and TP-80039 clean the hub. Repack with grease and install a new seal or grease cap. 18795 Great Plains | 175-600m | 10/29/2024...

-

Page 55: Seed Flap Replacement

Otherwise, the machine may be damaged through impaired use. TP-80486A Grease fittings Lubricate with grease at the hourly interval indicated in the arrow. If you operate the machine in extremely wet and/or muddy conditions, lubricate grease fittings more frequently. Great Plains | 175-600m | 10/29/2024... - Page 56 Apply grease to grease fitting until grease emerges. Apply grease to both grease fittings on each clutch until grease emerges. There is a clutch on the seed drive and the fertilizer drive. 18082 TP-80615 Great Plains | 175-600m | 10/29/2024...

- Page 57 Apply grease until grease emerges. 2 - 3 yrs TP-80283A 36281 Transport Wheel Hubs Grease transport hubs seasonally. Repack two bearings on each hub every 2 - 3 years. Seasonal TP-80618 Great Plains | 175-600m | 10/29/2024...

-

Page 58: Shaft Monitor

Shaft Monitor Fertilizer 175-545A Work Light Kits TP-80623 Description Part Number TP-80620 Standard Seed Tube 222-017A Description Part Number Small Seeds Tube 222-305A Work Lights Main Box 175-543A Work Lights Small Seeds Box 175-546A Great Plains | 175-600m | 10/29/2024... -

Page 59: Seed Hoses

Press wheels are available as bundle options on the initial drill order. A variety of kits are available to Needham Hose with Clip 195-673A change the press wheels in the field. *Needham hose is shown on the right. Great Plains | 175-600m | 10/29/2024... - Page 60 Order one scraper kit per opener. TP-80630 Description Part Number 3x13 Press Wheel Scraper 270-139K 2x13 Press Wheel Scraper 270-140K Hole Plug TP-80632 Description Part Number Hole Plug 1 3/4” 817-688C Great Plains | 175-600m | 10/29/2024...

-

Page 61: Troubleshooting

Unclean seed Use clean seed Build-up of seed treatment in feed cups Clean out feed cups Uneven seed spacing Seed-Lok® plugging Lock up Seed-Lock® Inspect openers for damage, replace if Opener disks not turning needed. Great Plains | 175-600m | 10/29/2024... - Page 62 Rough field conditions may move seed in empty evenly Rework field. the box Check all feed cup gates and reset as Feed cup slide gates not set the same. needed. See upper slide position in Material Rate Manual rate charts. Great Plains | 175-600m | 10/29/2024...

- Page 63 Lower tractor hydraulic oil level needed. Loose or missing bolts or fasteners Check all bolts and fasteners. Marker disk does not Disk angle too straight for soil conditions Increase angle of marker disk. mark Great Plains | 175-600m | 10/29/2024...

-

Page 64: Specifications

32.8 bu (1156 liters) 17.7 bu (624 liters) front compartment rear compartment w/ offset to front divider 27.8 bu (980 liters) 22.7 bu (800 liters) Small Seeds Box 6.3 bu (222 liters) Great Plains | 175-600m | 10/29/2024... -

Page 65: Torque Chart

For assistance or Transport 320/70R15 73 psi 170 lb ft information, contact your nearest authorized farm tire retailer. 255/70R22.5 93 psi 170 lb ft Wheel Manufacturer Website Firestone www.firestoneag.com www.bkt-tires.com/en Goodyear www.titan-intl.com Great Plains | 175-600m | 10/29/2024... - Page 66 BD7410 Box Drill Table of Contents Index Specifications Electrical Harness Routing Lighting Harness TP-80271 Great Plains | 175-600m | 10/29/2024...

- Page 67 BD7410 Box Drill Table of Contents Index Specifications Work Light Harness TP-80246 Great Plains | 175-600m | 10/29/2024...

- Page 68 BD7410 Box Drill Table of Contents Index Specifications Work Light Harness for Small Seeds Box TP-80245 Great Plains | 175-600m | 10/29/2024...

-

Page 69: Hydraulic Diagrams

BD7410 Box Drill Table of Contents Index Specifications Hydraulic Diagrams Opener Lift TP-80285 Great Plains | 175-600m | 10/29/2024... - Page 70 BD7410 Box Drill Table of Contents Index Specifications Transport Lift / Fold TP-80286 Great Plains | 175-600m | 10/29/2024...

- Page 71 BD7410 Box Drill Table of Contents Index Specifications Marker Hydraulics TP-80457 Great Plains | 175-600m | 10/29/2024...

- Page 72 BD7410 Box Drill Table of Contents Index Specifications Marker Hydraulics with Selector Valve TP-80237 Great Plains | 175-600m | 10/29/2024...

-

Page 73: Warranty

Great Plains reserves the right to make changes in materials or design of the product at any time without notice. The warranty shall not be interpreted to render Great Plains liable for damages of any kind, direct or consequential or contingent to property. - Page 74 Table of Contents Index...

- Page 75 ......... 28 Operating Checklist ......19 Parts Manual QRC .......1 range ..........14 Seed-Lok ..........40 sequence valve ........41 shutdown ..........5 Small Seeds Box ........33 storage ..........5 transport hooks ........22 transport speed ........5 warranty ..........41 waste disposal ........4 Great Plains | 175-600m | 10/29/2024...

- Page 76 Cover Table of Contents...

- Page 77 Table of Contents Index...

- Page 78 Great Plains, Mfg. 1525 E. North St. P.O. 5060 Salina, KS 67402...

Need help?

Do you have a question about the BD7410-13 and is the answer not in the manual?

Questions and answers