Advertisement

Quick Links

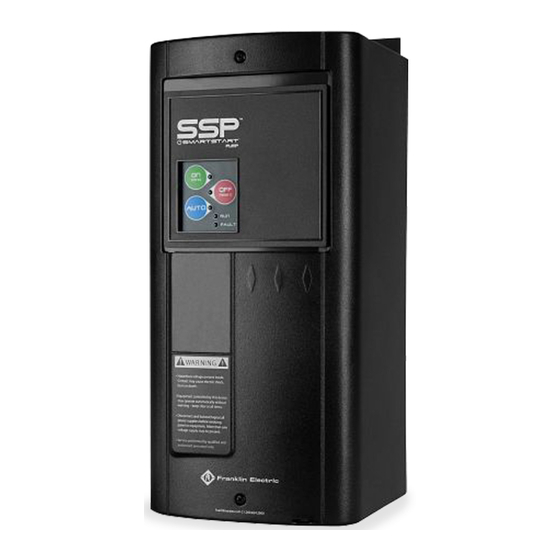

Operation

• Intended for use with 3-Phase, 50/60Hz

• Accepts 208-600VAC +10%

• Short Circuit (RMS, Symmetrical)

Stand-Alone Overload Unit - 200 KAIC, 600V Max.

Standard Starter - See UL label on panel

Combination Starter - See UL label on panel

• Ambient Operating Temperature = -20°C to 60°C

• Ambient Storage Temperature = -40°C to 85°C

DANGER

• Ensure that all connections are properly torqued and enclosure is closed

prior to applying power to the device.

• Ensure all mechanical equipment operated by the starter is clear for safe

operation in case of starter activation.

• When in AUTO mode, starter may be activated remotely by the

control system

Operation Modes

HAND

Place the switch in the HAND position to manually engage motor.

OFF (RESET)

Place the switch in the OFF position to manually disengage the

motor. Additionally, the OFF position serves as a manual reset.

Place the switch in the OFF position for 5 seconds to reset the

starter after a fault trip.

AUTO

Placing the switch in the AUTO position will allow the starter to be

controlled by a remote Start/Stop command.

Setting Adjustments

Overload

Set the overload dial to the SFA amperage value listed on the

motor nameplate. If no amperage value for SFA is provided, set the

overload dial to the FLA listed on the motor nameplate.

Underload

For submersible motor applications, it is suggested that the dial be

set to 70% to protect against dry-run condition.

I/O Descriptions

TERMINAL

DESCRIPTION

BLOCK

Dry Auto Input - When closed, the starter will run when in

D1 / D2

Auto Mode. (N.O. dry contact or transistorized input)

Fault Relay Output - Normally open relay contacts that

O1 / O2

closes in the event of a fault condition.

120VAC, 0.6A

For the above: Use 12-20AWG wire for I/O terminal blocks

TERMINAL

DESCRIPTION

Run-Timer Input - Connections for optional 1/2-12hr run

T- / TI / T+

timer.

Pilot Device Input - Connections for a 3-position (HOA)

D3 / D4 / D5

switch for motor control.

(Wired from manufacturer on N3R enclosed units)

Contactor Output - Provides a 24V output to close the

contactor when the motor starter is commanded in either

HAND or AUTO mode. Once the contactor is closed, the

C- / C+

output drops to 2-4V to maintain contactor closure while

optimizing efficiency. Only for use with Franklin Electric

contactor with 24VAC coil (24V, 0.875A Max).

For the above: Use 14-26AWG wire for I/O terminals, torque to 3.5 lb-in

WARNING

OVERLOAD/CONTROL UNIT MUST BE REPLACED IF BURNOUT OF THE

EXTERNAL CURRENT TRANSFORMERS OCCURS.

SSP I2t Trip Curve

1000

100

10

1

1

2

3

4

5

6

% of Overload Amperage Setting x100

Product improvement is a continual process. Cerus, Mira, Smartstart and

associated logos are trademarks of Franklin Electric Co., Inc.

All sales are subject to FE Terms & Conditions.

800.348.2420 | www.franklinwater.com

Installation & Operation Guide

This manual is available for download at

www.franklinwater.com

Precautions

To prevent injury and property damage, follow these instructions.

Failure to adhere to installation/operation procedures and all

applicable codes may result in hazards as indicated by warning

codes outlined below:

DANGER

indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury. This signal word is to be limited to the

most extreme situations.

WARNING

indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against

unsafe practices.

This is the safety alert symbol. Read and follow instructions carefully to

avoid a dangerous situation.

This symbol alerts the user to the presence of "dangerous voltage"

inside the product that might cause harm or electrical shock.

Safety Instructions

DANGER

Equipment can start automatically. Lockout/tagout before servicing.

7

8

9

10

CAUTION

As with all electrical products, read manual thoroughly. Only qualified,

expert personnel should perform maintenance and installation. Contact the

nearest authorized service facility for examination, repair, or adjustment.

Do not disassemble or repair unit unless described in this manual; death

or injury to electrical shock or fire hazard may result. Specifications and

manual data subject to change. Consult factory for additional information.

QSTART-SSP/S4-V1

Advertisement

Summary of Contents for Franklin Electric SmartStart SSP Series

- Page 1 Product improvement is a continual process. Cerus, Mira, Smartstart and expert personnel should perform maintenance and installation. Contact the associated logos are trademarks of Franklin Electric Co., Inc. nearest authorized service facility for examination, repair, or adjustment. All sales are subject to FE Terms & Conditions.

- Page 2 Program Switches Electronic Overload Operation Installation When an fault trip occurs, the fault LED will illuminate. The type of fault will Position be indicated by flashing a combination of the HAND/OFF/AUTO/RUN/FAULT DANGER LEDs as indicated in the table below. HAZARDOUS VOLTAGE •...

Need help?

Do you have a question about the SmartStart SSP Series and is the answer not in the manual?

Questions and answers