Summary of Contents for Franklin Electric GUARDIAN Series

- Page 1 FUELING SYSTEMS GUARDIAN SERIES™ GRID SOLUTIONS THREE-PHASE CONTROLLER 220 VOLT EV SYSTEMS I N S T A L L G U I D E 223987102 r4 MODEL TPGC-220...

- Page 2 Copyright © 2023 Franklin Electric Co., Inc., Madison, WI 53718. All world rights reserved. No part of this publication may be stored in a retrieval system, transmitted, or reproduced in any way, including, but not limited to, photocopy, photograph, magnetic, or other record, without the prior written permission of Franklin Electric.

-

Page 3: Table Of Contents

Contents 1 Introduction ........................1 1.1 Documentation ......................1 1.1.1 Symbol Legend ....................1 2 Safety/Security ........................2 2.1 General Safety Information..................2 2.2 Documentation Availability ..................2 2.2.1 Station Owner or Operator ................2 2.2.2 Miscellaneous ....................2 2.3 Hazard Assessment ....................3 2.4 Required Personal Protective Equipment (PPEs) ............3 2.5 Cyber Security ......................3 3 Pre-Installation Overview ....................4 3.1 Upon Receipt of Item(s) .....................4... - Page 4 5.4.2 Incoming Voltage Alarm ................17 5.4.3 Overload Alarm .....................18 5.4.4 Open Circuit Alarm..................19 5.4.5 Uncalibrated Alarm ..................20 5.4.6 Extended Run Alarm ..................20 5.4.7 Relay Fault Alarm ..................21 6 Appendix .........................22 6.1 Wiring Diagrams ......................22 6.1.1 Standalone ....................22 6.1.2 Primary-Secondary ..................23 6.1.3 Alternating Circuit ..................24 6.1.4 Primary-Secondary / Alternating Circuit ............25 6.1.5 DEF-PMA 150D 3-Phase 60 Hz ..............26...

-

Page 5: Introduction

Introduction The Three Phase Guardian Series™ Controller (model TPGC-220) is a submersible turbine pump controller designed for use with 3-Phase, 208-240 Volt, 60 Hertz rated FE PETRO® or similar competitive pump motor assemblies and 3 or 4-Wire Delta or WYE input supplies. The TPGC-220 provides the running and fault status of the attached pump motor assemblies when properly installed and calibrated according to the instructions contained in this guide. -

Page 6: Safety/Security

Safety/Security General Safety Information • Procedures in this document are only to be performed by people qualified and certified to perform them. • Personnel working on or with energized equipment must be authorized by relevant regulatory bodies to carry out such work and must have the appropriate training. -

Page 7: Hazard Assessment

The manufacturer, Franklin Electric, and its affiliates are not liable for damages and / or losses related to such security breaches, unauthorized access, interference, intrusion,... -

Page 8: Pre-Installation Overview

• Check all items for damage. • If any item shows damage or is not in accordance with the order, inform Franklin Electric immediately. • Remove the packaging material. • Follow all local laws, rules and regulations regarding disposal of discarded parts, packaging material or items and any subsequent components. -

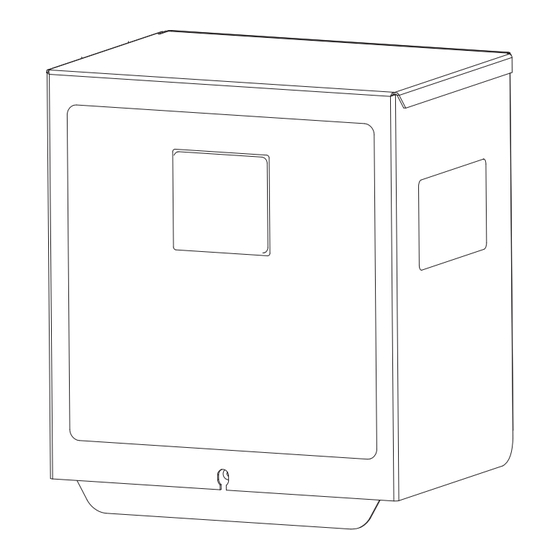

Page 9: Component Identification

3.2.2 Component Identification ISOMETRIC VIEW – COVER REMOVED Detail View Switches located on User Interface Panel Earth Grounding Terminals FRONT VIEW – COVER REMOVED Incoming Hook Terminals (120-240 VAC, 50/60 Hz, Single Phase ) User Interface Display Torque spec: 4.4-5.3 in-lbs (0.5-0.6 Nm) SW5 Rotary Select Switch (future) SW3 Option Select Switch (future) Alarm Silence / Calibrate Button... -

Page 10: Installation

Installation WARNING: Before installing any equipment: • Discharge static electricity from the equipment to ground. • Verify the equipment is properly grounded while in service. • Verify both power supplies (120–240 VAC hook and 208–240 VAC input) are disconnected before installing or servicing the equipment. NOTE: •... - Page 11 5. Remove the cover, and install the base on a wall or other flat (vertical) surface. • Installation holes are located in mounting tabs on the back of the controller. • The controller must be installed level on a vertical surface at a height of 2–6' (0.6–1.9 m) where it is easy to view and access.

-

Page 12: Configuration Instructions

Configuration Instructions 4.2.1 Primary-Secondary / Alternating Circuit NOTE: See section 6.1 for wiring diagrams fitting your application needs. • The PRIMARY-SECONDARY feature allows additional STPs to be turned on when there is an abnormal condition or an STP needs help due to loading (flow rate). •... - Page 13 • There can be only one Primary in a system but up to 31 Secondaries. If using Turbine Pump Interface (TPI) with a Franklin Electric fuel management console, the TPGC-220 cannot be configured to control address 31 (SW1 with poles 1-5 ON).

-

Page 14: Factory Default Switch Settings

4.2.2 Factory Default Switch Settings NOTE: See § 3.2.2 for switch locations. The STANDALONE configuration is the Factory Default setting (all selectable features off). • Fault Readout Switches located on User Interface Panel • Bypass N 1 2 3 4 5 N 1 2 3 4 5 6 7 8 6 7 8... -

Page 15: Selectable Features

4.2.3 Selectable Features 4.2.3.1 Auto Restart Mode (SW1, Pole 8) When this mode is selected, with (SW1, Pole 8) in the ON position, if the controller detects an empty tank/under load condition, it shuts down the pump and it attempts to start the pump when a hook signal is removed and reintroduced to the controller. -

Page 16: Calibration

4.2.4 Calibration NOTE: • During calibration, the display will alternate “CAL” and the kilowatts reading of the attached pump motor. • The TPGC-220 calibrates only when the STP has no abnormalities and a dispenser handle is turned on within 10 minutes of calibration starting. •... -

Page 17: Troubleshooting

Troubleshooting NOTE: Reference Section 3.2.2 for Alarm Silence and Controller Reset button locations. The TPGC-220 has a microprocessor that allows the unit to diagnose abnormal conditions and communicate them through an audible alarm and LEDs on the front panel. The following describes these indications: •... -

Page 18: Selectable Features To Aid Troubleshooting

Selectable Features To Aid Troubleshooting 5.3.1 Fault Read Out Mode (SW1, Pole 6) To enable this mode, 1. Turn off power to the TPGC-220. 2. Remove the console cover. 3. Turn ON SW1 pole 6. 4. Reinstall the cover. 5. Turn on power to the TPGC-220 (to see the fault readout). In Fault Read Out Mode, the controller displays the last five abnormal conditions, starting with the most recent one. -

Page 19: Troubleshooting Warnings & Error Alarms

Troubleshooting Warnings & Error Alarms NOTE: Some ATGs include a Turbine Pump Interface (TPI) that can provide additional troubleshooting information. See TPI Application Guide, p/n AG-016, for more information. Identify the issue with site personnel. Does the site Print the system alarm history reports. have an ATG with TPI? Use the alarm history reports to help... -

Page 20: Underload Error Alarm

5.4.1 Underload Error Alarm • Error code flashes: UL The UNDERLOAD ERROR alarm indicates that the TPGC-220 has detected that the motor power consumption (in watts) is below the acceptable range compared to the stored calibration value. This alarm is typically caused by dry running (due to a clogged intake) or improper calibration. -

Page 21: Incoming Voltage Alarm

5.4.2 Incoming Voltage Alarm • Error code flashes: LI or HI The LOW INCOMING (under-voltage) and HIGH INCOMING (over-voltage) alarms activate when the incoming voltage to the TPGC-220 (L1, L2, L3) is outside the acceptable range (LI activates below 185 V, HI activates above 260 V). The TPGC-220 automatically resets this alarm when the incoming voltage returns to the acceptable range (LI resets above 200 V, HI resets below 245 V). -

Page 22: Overload Alarm

5.4.3 Overload Alarm • Error code flashes: Lr or OL The OVERLOAD (while running) and LOCKED ROTOR (at startup) alarms indicate that the TPGC-220 has detected that the motor power consumption (in watts) is above the acceptable range compared to the calibration value. The OVERLOAD and LOCKED ROTOR alarms are usually caused by a locked PMA rotor (due to debris or damage) or improper calibration. -

Page 23: Open Circuit Alarm

5.4.4 Open Circuit Alarm • Error code flashes: OC The OPEN CIRCUIT alarm activates when there is a hook signal and the TPGC-220 does not detect power consumption by the PMA (hook signal present without motor load). This alarm is typically caused by a broken output connection (wiring and/or relay) or a PMA thermal overload due to a locked rotor event. -

Page 24: Uncalibrated Alarm

5.4.5 Uncalibrated Alarm • Error code flashes: unc TPGC-220s must be calibrated before they can be used. See § 4.2.4 of this document for the calibration procedure. Was the calibration Go to the troubleshooting topic successful? for the code that is displayed. Observe for proper operation. -

Page 25: Relay Fault Alarm

5.4.7 Relay Fault Alarm • Error code flashes: rEL The RELAY FAULT alarm indicates the TPGC-220 is running the PMA without a proper hook signal. This alarm is typically caused by a smart controller relay contact failure. Press and hold the Reset button until the error code lights dim. -

Page 26: Appendix

Appendix Wiring Diagrams • Wiring must conform to all applicable federal, state, and local codes. • TPGC-220 controllers are for non-hazardous, indoor use only. See § 4.1, Step 4. • Route RS485 wiring (where applicable) a minimum of 1/4" (6 mm) away from power wiring. -

Page 27: Primary-Secondary

6.1.2 Primary-Secondary IMPORTANT: Reference § 6.1 for additional wiring information. PRIMARY DISPENSER SUBMERSIBLE TURBINE PUMP (STP) 120 –240 VAC Supply. RETURN/NEUTRAL ORANGE Dispenser BLACK PLUG Handle DISPENSER CONNECTOR Switch HOOK SIGNAL From Dispnser (HOOK) If BLUE Thermal Overload leads are present, DO NOT INCOMING connect to TPGC... -

Page 28: Alternating Circuit

6.1.3 Alternating Circuit IMPORTANT: Reference § 6.1 for additional wiring information. PRIMARY DISPENSER SUBMERSIBLE TURBINE PUMP (STP) 120 –240 VAC Supply. RETURN/NEUTRAL ORANGE Dispenser BLACK PLUG Handle DISPENSER CONNECTOR Switch HOOK SIGNAL From Dispnser (HOOK) If BLUE Thermal Overload leads are present, DO NOT INCOMING connect to TPGC... -

Page 29: Primary-Secondary / Alternating Circuit

6.1.4 Primary-Secondary / Alternating Circuit IMPORTANT: Reference § 6.1 for additional wiring information. PRIMARY DISPENSER SUBMERSIBLE TURBINE PUMP (STP) 120 –240 VAC Supply. RETURN/NEUTRAL ORANGE Dispenser BLACK PLUG Handle DISPENSER CONNECTOR Switch HOOK SIGNAL From Dispnser (HOOK) If BLUE Thermal Overload leads are present, DO NOT INCOMING... -

Page 30: Def-Pma 150D 3-Phase 60 Hz

6.1.5 DEF-PMA 150D 3-Phase 60 Hz IMPORTANT: Reference § 6.1 for additional wiring information. • NOTE: Set SW2, Pole 6 to ON for DEF Mode (see § 4.2.3.4). PRIMARY DISPENSER 120 –240 VAC Supply. RETURN/NEUTRAL Dispenser Handle DISPENSER Switch HOOK SIGNAL From Dispnser (HOOK) BRN (RED) INCOMING... -

Page 31: Related Documents

Related Documents Documentation can be found at www.franklinfueling.com. TABLE 6.1 – Related Documents Part Number Description 223844101 STP-DHI Installation and Owner’s Manual AG-016 TPI Application Guide Glossary DEF .........Diesel Exhaust Fluid ELLD ........Electronic Line Leak Detection FMS .........Fuel Management System IS ........Intrinsically Safe LCD .........Liquid Crystal Display MLD ........Mechanical Leak Detection... - Page 32 FUELING SYSTEMS GRID SOLUTIONS EV SYSTEMS 223987102 r4...

Need help?

Do you have a question about the GUARDIAN Series and is the answer not in the manual?

Questions and answers