Summary of Contents for KIESELMANN 91 Series

- Page 1 Operating Instructions Translation of the original Single Stage Control Valves Type 91xx P D F • a k • 0 7 / 0 8 / 2 0 2 4 ENGLISH...

- Page 2 . k i e s e l m a n n . d e • i n f o @ k i e s e l m a n n . d e Copyright: © KIESELMANN FLUID PROCESS GROUP...

-

Page 3: Table Of Contents

KIESELMANN GmbH Table of contents T a b l e o f c o n t e n t s 1 General informations .............................. 4 Informations for your safety ............................... 4 Marking of security instructions............................ 4 General designated use .............................. 4 Personnel ..................................... -

Page 4: General Informations

We will be at your disposal also after expiration of the warranty. In addition, you will also find all necessary instructions and spare part data for maintenance in this instruction manual. If you don't want to carry out the maintenance by yourself, our KIESELMANN - service team will naturally be at your disposal. -

Page 5: Modifications, Spare Parts, Accessories

KIESELMANN GmbH | Operating Instructions General informations | 1 1.5 Modifications, spare parts, accessories Unauthorized modifications, additions or conversions which affect the safety of the fitting are not permitted. Safety devices must not be bypassed, removed or made inactive. Only use original spare parts and accessories recommended by the manufacturer. -

Page 6: Safety Instructions

2 | Safety instructions Operating Instructions | KIESELMANN GmbH 2 S a f e t y i n s t r u c t i o n s 2.1 Intended use The control valve is used for the regulation of media in the food and beverage industry, in pharma- ceutical and chemical engineering, as well as in bio-engineering. - Page 7 KIESELMANN GmbH | Operating Instructions Safety instructions | 2 WARNING ATEX - Guidelines If the valve or the plant is operated in a potentially explosive atmosphere, the valid ATEX directive of the EC and the installation instructions in this operating manual must be observed.

-

Page 8: Delivery, Transport And Storage

3 | Delivery, transport and storage Operating Instructions | KIESELMANN GmbH 3 D e l i v e r y , t r a n s p o r t a n d s t o r a g e 3.1 Delivery... -

Page 9: Specification | 4

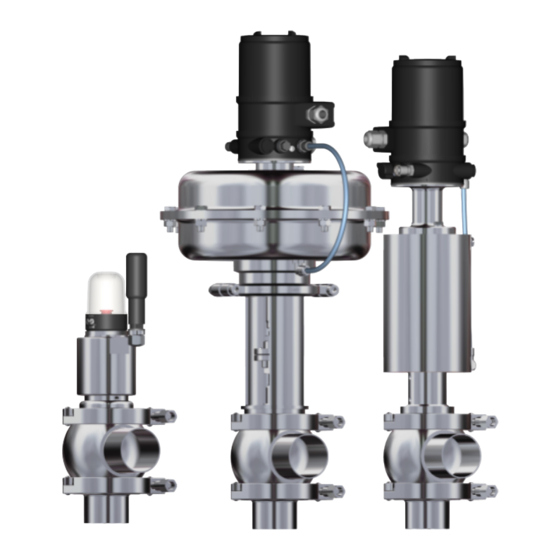

KIESELMANN GmbH | Operating Instructions Specification | 4 4 S p e c i f i c a t i o n 4.1 Modular system control systems positioner Guth DigiPos Bürkert Type 869x Bürkert Type 879x Samson Type 3730-X drive systems... -

Page 10: Function And Operation

5 F u n c t i o n a n d o p e r a t i o n 5.1 Description of function The control valve is based on the KIESELMANN AI DS technology. Media with a Kvs-values 0,1 m³/h to 160 m³/h can be regulated through the interchangeable seat concept. -

Page 11: Valve Basic Position

KIESELMANN GmbH | Operating Instructions Function and operation | 5 5.2 Valve basic position: Basic positon: Valve closed Valve open Kind of actuation: Normally closed (NC) Normally open (NO) Type: 911x Angle valve Section A - B closed Section A - B opened... -

Page 12: Commissioning, Service And Maintenance

6 | Commissioning, service and maintenance Operating Instructions | KIESELMANN GmbH 6 C o m m i s s i o n i n g , s e r v i c e a n d m a i n t e n a n c e 6.1 Commissioning... -

Page 13: Service

KIESELMANN GmbH | Operating Instructions Commissioning, service and maintenance | 6 6.2 Service RECOMMENDATION Replacement of seals To achieve optimal maintenance cycles, the following points must be observed! – When replacement of seals, all product-contacting seals should be replaced. –... -

Page 14: Technical Data

7 | Technical data Operating Instructions | KIESELMANN GmbH 7 T e c h n i c a l d a t a 7.1 control control valves Model control valve • elastomer sealing at the regulation cone (Elastomer / Elastomer) •... -

Page 15: Identification

KIESELMANN GmbH | Operating Instructions Technical data | 7 7.2 Identification Standards Manufacturer Logo 0036 EN ISO 4126-1 Date Order number Material Order No.: xxxxxxxx / x MM/JJJJ Item number Serial No.: xxxxxxxxxx-xxxx AISI xxxx Operating temperature Nominal width DN xxx Ts -xx°C/+xxx°C... -

Page 16: Kv - Value

7 | Technical data Operating Instructions | KIESELMANN GmbH 7.4 KV - value -value, Valve size & Actuator size Pneumatic actuator Piston actuator Diaphragm actuator Valve size H104 H129 H167 H190 H230 Control air pressure [bar] Seat-Ø Stroke Adm. Operating Pressure [bar]... -

Page 17: Disassembly And Assembly | 8

KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 8 D i s a s s e m b l y a n d a s s e m b l y Assembly Tools Pos. Figure Designation Article number... -

Page 18: Valve With Manual Actuator

8 | Disassembly and assembly Operating Instructions | KIESELMANN GmbH 8.1 Valve with Manual actuator Dismount the valve insert • Unscrew the clamp coupling (VK). • Dismount the valve insert (VE) out of the housing (VG). • Remove the housing bottom (Gb1) and inter- changeable seat (Ws). -

Page 19: Disassembly And Assembly

KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 Assembly piston / control cone INFORMATION Construction-conditioned, there are two variants for dismantle of the piston (1) or metallic sealing control cone (Rkm): Variant A: Dismounting via bore (B1). Variant B: Dismounting via spanner flat (SW1) –... - Page 20 8 | Disassembly and assembly Operating Instructions | KIESELMANN GmbH Assembly seal (D1) • Clamp the cone (Rk) in a soft jawed vice. Un- screw the screw (Rk1). Remove piston (1) and dismantle O-ring (D1). Figure 7 20 / 55...

-

Page 21: Valve With Pneum. Linear Actuator

KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 8.2 Valve with pneum. linear actuator Dismount the valve insert Valve insert (lö-fs) • Connect compressed air to air supply (LA). The piston (1) retracts. • Unscrew the locking clip (VK). - Page 22 8 | Disassembly and assembly Operating Instructions | KIESELMANN GmbH Assembly piston / control cone INFORMATION Construction-conditioned, there are two variants for dismantle of the piston (1) or metallic sealing control cone (Rkm): Variant A: Dismounting via bore (B1). Variant B: Dismounting via spanner flat (SW1) –...

- Page 23 KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 Assembly seals (D4) und (D5) • Unscrew the lantern (4) with a pin wrench (T10) from actuator (PHA) and push it from piston rod (6). Figure 6 • Remove the distance (8), O-rings (D4) and (D5).

- Page 24 8 | Disassembly and assembly Operating Instructions | KIESELMANN GmbH Assembly seal (D1) • Clamp the cone (Rk) in a soft jawed vice. Un- screw the screw (Rk1). Remove piston (1) and dismantle O-ring (D1). Figure 10 24 / 55...

-

Page 25: Valve With Electric Linear Actuator

KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 8.3 Valve with electric linear actuator Dismount the valve insert Valve insert (lö-fs) • Unscrew the transparent cap on the actuator (bayonet socket). • Activate the local-operation via switch (S1). - Page 26 8 | Disassembly and assembly Operating Instructions | KIESELMANN GmbH Replacement of seals • Loosen the insert (2) from the lantern (4) us- ing a hook spanner (T11). Figure 4 Assembly piston / control cone INFORMATION Construction-conditioned, there are two variants for dismantle of the piston (1) or metallic sealing control cone (Rkm): Variant A: Dismounting via bore (B1).

- Page 27 KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 • Unscrew the insert (2) and remove the shaft seal (D3). • Unscrew the screws (4-1) and remove the lantern (4). Figure 7 Assembly seals (D4) und (D5) NOTICE The bearing bushes (3) and the O-rings (D4) and (D5) do not need to be removed for a product- contacted seal change.

-

Page 28: Valve With Diaphragm Actuator Fpg

8 | Disassembly and assembly Operating Instructions | KIESELMANN GmbH 8.4 Valve with Diaphragm actuator FPG Dismount the valve insert Valve insert (lö-fs) • Connect compressed air to air supply (LA). The piston (1) retracts. • Unscrew the locking clip (VK). - Page 29 KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 Replacement of seals Assembly piston / control cone INFORMATION Construction-conditioned, there are two variants for dismantle of the piston (1) or metallic sealing control cone (Rkm): Variant A: Dismounting via bore (B1).

- Page 30 8 | Disassembly and assembly Operating Instructions | KIESELMANN GmbH • Clamp the insert (2) in a soft jawed vice. Unscrew the lantern insert (7) from the in- sert (2) with a pin type face spanner (T12). Figure 5 • Dismount seal (D3).

-

Page 31: Valve With Diaphragm Actuator - Samson

KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 8.5 Valve with Diaphragm actuator - Samson Dismount the valve insert Valve insert (lö-fs) • Connect compressed air to air supply (LA2). The piston (1) retracts. • Unscrew the locking clip (VK). - Page 32 8 | Disassembly and assembly Operating Instructions | KIESELMANN GmbH Replacement of seals Assembly piston / control cone INFORMATION Construction-conditioned, there are two variants for dismantle of the piston (1) or metallic sealing control cone (Rkm): Variant A: Dismounting via bore (B1).

- Page 33 KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 • Unscrew insert (2). Figure 5 • Clamp the insert (2) in a soft jawed vice. Unscrew the lantern insert (7) from the in- sert (2) with a pin type face spanner (T12).

- Page 34 8 | Disassembly and assembly Operating Instructions | KIESELMANN GmbH Assembly seal (D1) • Clamp the cone (Rk) in a soft jawed vice. Un- screw the screw (Rk1). Remove piston (1) and dismantle O-ring (D1). Figure 8 34 / 55...

-

Page 35: Assembly

KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 8.6 Assembly • Assemble in reverse order. • Before installation, thoroughly clean and slightly lubricate mounting areas and running sur- faces. • Check the function according to the specified performance data in the operating state. -

Page 36: Mounting Kit For Positioner

9 | Mounting kit for positioner Operating Instructions | KIESELMANN GmbH 9 M o u n t i n g k i t f o r p o s i t i o n e r 9.1 Bürkert positioner Type 8692, 8694... - Page 37 KIESELMANN GmbH | Operating Instructions Mounting kit for positioner | 9 Assembly • Assemble in reverse order. • Before installation, thoroughly clean and slightly lubricate mounting areas and running surfaces. • Check the function according to the specified performance data in the operating state.

-

Page 38: Guth Positioner Digipos

9 | Mounting kit for positioner Operating Instructions | KIESELMANN GmbH 9.2 Guth Positioner DIGIPOS Disassembly NOTICE Before reaching into the device or the equipment, please note the operating instructions and the safety instructions for the Guth DigiPos Positioner. (Operating Instructions for Guth DigiPos Type BA_DP_022012) - Page 39 KIESELMANN GmbH | Operating Instructions Mounting kit for positioner | 9 Assembly • Assemble in reverse order. • Before installation, thoroughly clean and slightly lubricate mounting areas and running surfaces. • Check the function according to the specified performance data in the operating state.

-

Page 40: Drawings And Dimensions

10 | Drawings and dimensions Operating Instructions | KIESELMANN GmbH 1 0 D r a w i n g s a n d d i m e n s i o n s 10.1 Drawings 10.1.1 Valve structure Manual electrical... -

Page 41: Valve Inserts

KIESELMANN GmbH | Operating Instructions Drawings and dimensions | 10 10.1.3 Valve inserts Design: Manual actuator • 1 = Piston DS 1 DS 2 • 2 = Insert VS 1 • 3 = Plain bearing • 4 = Lantern • 5 = Bearing bush •... - Page 42 10 | Drawings and dimensions Operating Instructions | KIESELMANN GmbH Version: electric linear actuator • 1 = Piston DS 1 DS 2 • 2 = Insert VS 2 • 3 = Plain bearing • 4 = Lantern • 4-1 = Screw •...

-

Page 43: Drawings And Dimensions

KIESELMANN GmbH | Operating Instructions Drawings and dimensions | 10 Design: Diaphragm actuator FPG • 1 = Piston DS 1 • 2 = Insert DS 2 • 3 = Bearing bush VS 3 • 4 = Lantern • 5 = -- •... - Page 44 10 | Drawings and dimensions Operating Instructions | KIESELMANN GmbH Valve with Diaphragm actuator and Positioner Samson VS 3 • 1 = Piston DS 1 • 2 = Insert DS 2 • 3 = Bearing bush • 4 = Lantern •...

-

Page 45: Dimensions

KIESELMANN GmbH | Operating Instructions Drawings and dimensions | 10 10.2 Dimensions Wrench size (SW) DN / OD = Nominal size DN 25 DN 40 DN 50 DN 65 DN 80 DN 100 DN 125 OD 1 OD 1½ OD 2 OD 2½... - Page 46 10 | Drawings and dimensions Operating Instructions | KIESELMANN GmbH Dimension DN / OD Actuator DN 20 Ø 23 x 1,5 H104 Ø 104 ~550 3277-175v2 Ø 215 3277-355v2 Ø 280 3277-750v2 Ø 394 DN 25 Ø 29 x 1,5...

- Page 47 KIESELMANN GmbH | Operating Instructions Drawings and dimensions | 10 Dimension DN / OD Actuator 3277-750v2 Ø 394 DN 80 Ø 85 x 2,0 Manual ~252 H129 Ø 129 ~620 OD 3 Ø 76,2 x 1,65 H167 Ø 167 ~620 H190 Ø...

-

Page 48: Wearing Parts

11 | Wearing parts Operating Instructions | KIESELMANN GmbH 1 1 W e a r i n g p a r t s 11.1 Overview - Seal and wearing parts kits Seal kit Material Description - - in product contact... - Page 49 KIESELMANN GmbH | Operating Instructions Wearing parts | 11 Wearing part set DS1 (elastomeric sealing) Seat-Ø Wear parts kit Wear parts kit Wear parts kit Value DS 1a EPDM DS 1b HNBR DS 1c FKM ø 5 9110 010 200-K990...

- Page 50 11 | Wearing parts Operating Instructions | KIESELMANN GmbH Wearing part set DS2 (metallic sealing) Seat-Ø Wear parts kit Wear parts kit Wear parts kit Value DS 2a EPDM DS 2b HNBR DS 2c FKM ø 6 9110 010 400-M990...

- Page 51 KIESELMANN GmbH | Operating Instructions Wearing parts | 11 Wearing part set - Actuator Kind of actuation Wear parts kit Wear parts kit Wear parts kit Actuator 1 Actuator 2 Actuator 3 manual actuator 9111 000 000-991 Linear actuator ø104 9112 000 001-991 ø129...

-

Page 52: Classification

12 | Classification Operating Instructions | KIESELMANN GmbH 1 2 C l a s s i f i c a t i o n 12.1 Structure of Order Number Feedback unit/positioner Variations of actuation Seal Separator Connection Valve outlet Connection Valve inlet... -

Page 53: Appendix | 13

KIESELMANN GmbH | Operating Instructions Appendix | 13 1 3 A p p e n d i x 13.1 Declaration of incorporation Declaration of Incorporation according to Directive 2006/42/EC of the European Parliament and the Council of 17 May 2006... - Page 54 KIESELMANN GmbH Notes 54 / 55...

- Page 55 . k i e s e l m a n n . d e • i n f o @ k i e s e l m a n n . d e Copyright: © KIESELMANN FLUID PROCESS GROUP...

Need help?

Do you have a question about the 91 Series and is the answer not in the manual?

Questions and answers