Table of Contents

Advertisement

Quick Links

Operating instructions

- Translation of the original -

5093 xxx 000-xxx

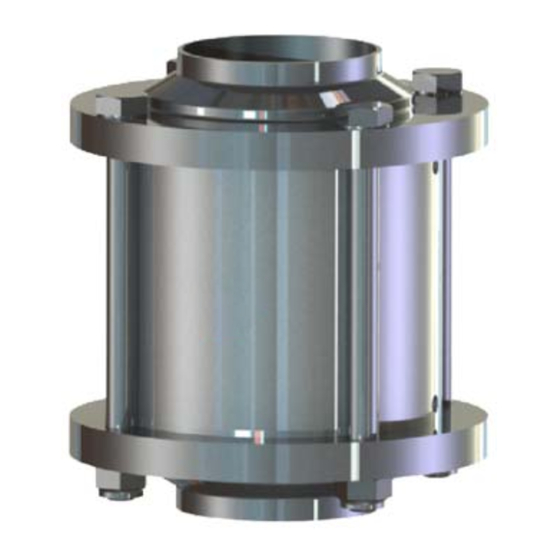

Check valve

DN 25 - DN 100

OD 1inch - OD 4inch

EPDM O-Ring-design

Intermediate flanged with welding ends

GBR

English

KIESELMANN GmbH

Paul-Kieselmann-Str.4-10

D - 75438 Knittlingen

+49 (0) 7043 371-0Fax: +49 (0) 7043 371-125

www.kieselmann.desales@kieselmann.de

1

Advertisement

Table of Contents

Summary of Contents for KIESELMANN 5093 xxx 000 series

- Page 1 5093 xxx 000-xxx Check valve DN 25 - DN 100 OD 1inch - OD 4inch EPDM O-Ring-design Intermediate flanged with welding ends English KIESELMANN GmbH Paul-Kieselmann-Str.4-10 D - 75438 Knittlingen +49 (0) 7043 371-0Fax: +49 (0) 7043 371-125 www.kieselmann.desales@kieselmann.de...

-

Page 2: Table Of Contents

1. List of contents List of contents ..........................1 General Information........................2 Information for your safety ....................2 Marking of security instructions in the operating manual ...........2 Designated use ........................2 Personnel ...........................2 Modifications, spare parts, accessories ................2 General instructions ......................2 Safety instructions .........................3 Field of application ......................3 General safety instructions ....................3 General notes ........................3... -

Page 3: General Information

2. General Information 2.1 Information for your safety We are pleased that you have decided for a high-class KIESELMANN product. With correct application and adequate maintenance, our products provide long time and reliable operation. Before installation and initiation, please carefully read this instruction manual and the security advices contained in it. -

Page 4: Safety Instructions

3. Safety instructions 3.1 Field of application The check valve is suitable for use as a reflux - check valve for gas and fluid in plants in the food and beverage, in pharmaceutical, biotechnological and chemical industries. ATTENTION • To avoid danger and damage, the fitting must be used in accordance with the safety instructions and technical data contained in the operating instructions. -

Page 5: Maintenance

6. Maintenance 6.1 Maintenance The maintenance intervals depend on the operating conditions "temperature, temperature-intervals, medium, cleaning medium, pressure and opening frequency". We recommend replacing the seals every 1 years. The user, however should establish appropriate maintenance intervals according to the condition of the seals. -

Page 6: Disassembly And Assembly

8. Disassembly and assembly 8.1 Disassembly • Unscrew the nuts (8). see Fig. 1 /page 5 • Remove axially the screws / threat bolts (9). • Dismantle housing (11) and cramp it axially in a vise. • Unscrew the headless pin (10). ... -

Page 7: Dimensions

10. Dimensions DN / OD 29x1,5 35x1,5 41x1,5 53x1,5 70x2 85x2 104x2 INCH 25,4x1,65 1½ INCH 38,1x1,65 INCH 50,8x1,65 2½ INCH 63,5x1,65 Fig. 2 INCH 76,1x2,00 INCH 101,6x2,00 11. Wearing parts Seal kit - EPDM O-Ring - type: 5095 DN 029-054 (incl. Pos. 2, 4, 6, 7) Gasket seal - type: 5095 DN 000-054 (incl.

Need help?

Do you have a question about the 5093 xxx 000 series and is the answer not in the manual?

Questions and answers