Summary of Contents for KIESELMANN 5629 Series

- Page 1 Operating Instructions Translation of the original Double seat tank outlet valve Type 5629 Seal material: EPDM, HNBR, FKM P D F • a k • 2 1 / 0 6 / 2 0 2 3 ENGLISH...

- Page 2 . k i e s e l m a n n . d e • i n f o @ k i e s e l m a n n . d e Copyright: © KIESELMANN FLUID PROCESS GROUP...

-

Page 3: Table Of Contents

KIESELMANN GmbH Table of Contents T a b l e o f C o n t e n t s 1 General informations .............................. 4 Informations for your safety ............................... 4 Marking of security instructions............................ 4 General designated use .............................. 4 Personnel ..................................... -

Page 4: General Informations

We will be at your disposal also after expiration of the warranty. In addition, you will also find all necessary instructions and spare part data for maintenance in this instruction manual. If you don't want to carry out the maintenance by yourself, our KIESELMANN - service team will naturally be at your disposal. -

Page 5: Modifications, Spare Parts, Accessories

KIESELMANN GmbH | Operating Instructions General informations | 1 1.5 Modifications, spare parts, accessories Unauthorized modifications, additions or conversions which affect the safety of the fitting are not permitted. Safety devices must not be bypassed, removed or made inactive. Only use original spare parts and accessories recommended by the manufacturer. -

Page 6: Safety Instructions

2 | Safety instructions Operating Instructions | KIESELMANN GmbH 2 S a f e t y i n s t r u c t i o n s 2.1 General notes NOTICE - observe the operating instructions To avoid danger and damage, the fitting must be used in accordance with the safety instructions and technical data contained in the operating instructions. - Page 7 KIESELMANN GmbH | Operating Instructions Safety instructions | 2 CAUTION Before starting the system, the entire pipeline system must be thoroughly cleaned. CAUTION Steps should be taken to ensure that no external forces are exerted on the fitting. 5629_Doppelsitz-Tankauslaufventile_EN 7 / 33...

-

Page 8: Delivery, Transport And Storage

3 | Delivery, transport and storage Operating Instructions | KIESELMANN GmbH 3 D e l i v e r y , t r a n s p o r t a n d s t o r a g e 3.1 Delivery... -

Page 9: Specification | 4

KIESELMANN GmbH | Operating Instructions Specification | 4 4 S p e c i f i c a t i o n 4.1 Modular system KI-Top control head feedback unit Stainless steel hood Transparent hood Feedback unit with finger guard... -

Page 10: Function And Operation

5 | Function and operation Operating Instructions | KIESELMANN GmbH 5 F u n c t i o n a n d o p e r a t i o n 5.1 Description of function The valve is opened in direction ’X’ by means of control air, and is closed from top to bottom by means of spring power without any leakage. -

Page 11: Pneumatic Valve Activation

KIESELMANN GmbH | Operating Instructions Function and operation | 5 5.3 Pneumatic valve activation Valve functions Pneum. activation Pneum. activation via control head via external with solenoid valves (MV) Solenoid valves (MV external) main lift Control supply air Control supply air valve “OPEN“... -

Page 12: Commissioning, Service And Maintenance

6 | Commissioning, service and maintenance Operating Instructions | KIESELMANN GmbH 6 C o m m i s s i o n i n g , s e r v i c e a n d m a i n t e n a n c e 6.1 Commissioning... -

Page 13: Service

KIESELMANN GmbH | Operating Instructions Commissioning, service and maintenance | 6 6.2 Service RECOMMENDATION Replacement of seals To achieve optimal maintenance cycles, the following points must be observed! – When replacement of seals, all product-contacting seals should be replaced. –... -

Page 14: Technical Data

7 | Technical data Operating Instructions | KIESELMANN GmbH 7 T e c h n i c a l d a t a 7.1 Double seat valve Type 5629 Model Double seat valve Size DIN: DN25 - DN150 Inch: OD1 - OD4... -

Page 15: Kv - Value

KIESELMANN GmbH | Operating Instructions Technical data | 7 7.3 KV - value Inch 1½ 2½ flow direction: [m³/h] transition-flow at top ↔ from tank to pipe system 7.4 Cleaning flow rate Cleaning parameters for the leakage chamber Cleaning step... -

Page 16: Disassembly And Assembly

8 | Disassembly and assembly Operating Instructions | KIESELMANN GmbH 8 D i s a s s e m b l y a n d a s s e m b l y 8.1 Disassembly NOTICE All threaded joint have right-hand thread. -

Page 17: Dismount The Valve Insert (Ve)

KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 8.1.1 Dismount the valve insert (VE). CAUTION Risk of injury by falling parts First secure the valve insert (VE) against falling down. For example, with lugs (L) and a safety chain. -

Page 18: Replacement Wear Parts

8 | Disassembly and assembly Operating Instructions | KIESELMANN GmbH 8.1.2 Replacement wear parts • Unscrew the lower piston (6) SW17 from the upper piston (7) with the assembly tool ST16. Hold against the spanner flat SW17. • Remove piston plate (9), O-ring (D3), (D5) and seal (D4). - Page 19 KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 • Unscrew the upper piston (7) with the mounting plate ST15 from piston rod (3). Hold against the hole (B) with a pin spanner T10. NOTICE! Valve ≥ DN 40 / 1½“...

-

Page 20: Assembly

8 | Disassembly and assembly Operating Instructions | KIESELMANN GmbH 8.2 Assembly Mounting seal (D4), pair of piston (7)/(8) Pair of piston upper = Piston (7) and piston plate (8) • Screw together the piston plate (7) / (8) without the seal (D4) to the metal limit stop by hand. - Page 21 KIESELMANN GmbH | Operating Instructions Disassembly and assembly | 8 Mounting seal (D4), pair of piston (6)/(9) Pair of piston upper = Piston (6) and piston plate (9) • Screw together the piston plate (6) / (9) without the seal (D4)

-

Page 22: Drawings And Dimensions

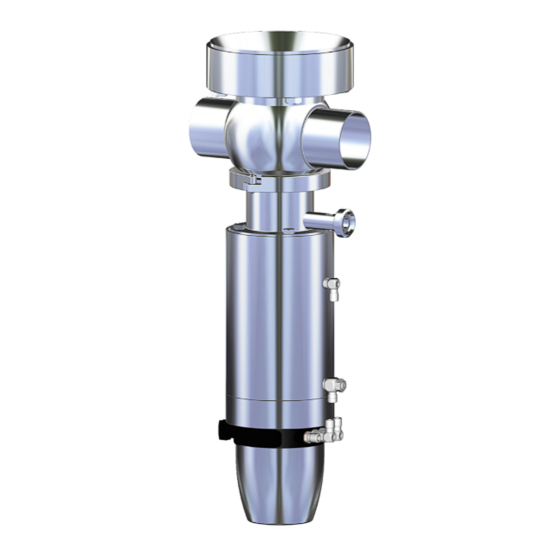

9 | Drawings and dimensions Operating Instructions | KIESELMANN GmbH 9 D r a w i n g s a n d d i m e n s i o n s 9.1 Drawings Double seat tank outlet valve Type 5629... - Page 23 KIESELMANN GmbH | Operating Instructions Drawings and dimensions | 9 Valve insert VE 1 = - 2 = Spindle 3 = Piston rod 4 = Bearing bush 5 = Insert 6 = Piston 7 = Piston 8 = Piston plate...

-

Page 24: Dimensions

9 | Drawings and dimensions Operating Instructions | KIESELMANN GmbH 9.2 Dimensions Inch 1½ 2½ Ø29x1,5 Ø41x1,5 Ø53x1,5 Ø70x2 Ø85x2 Ø104x2 Ø129x2 Ø 154x2 Inch Ø25.4x1.65 Ø38,1x1,65 Ø50,8x1,65 Ø63,5x1,65 Ø76.2x1.6 Ø101,6x2 (DN50 red.) (DN50 red.) Ø 128 Ø 128 Ø 128 Ø... -

Page 25: Control Units

KIESELMANN GmbH | Operating Instructions Drawings and dimensions | 9 9.3 Control units Control head KI-TOP with plastic hood - transparent with stainless steel hood Ø 105 Ø 105 Feedback unit with finger guard (E) • E1 = Cap 59,5 •... -

Page 26: Wearing Parts

10 | Wearing parts Operating Instructions | KIESELMANN GmbH 1 0 W e a r i n g p a r t s 10.1 Spare parts list Housing Seal Item number Valve insert VE Wear parts kit EPDM 5629 DN 730-xxx... - Page 27 KIESELMANN GmbH | Operating Instructions Wearing parts | 10 Spare-parts list - Valve insert No. Designation Material DN50 red DN25 DN50 red DN40 DN50 DN65 Valve insert EPDM EPDM 5629 050 735-041 5629 050 735-041 5629 050 735-041 5629 065 735-041...

- Page 28 10 | Wearing parts Operating Instructions | KIESELMANN GmbH Seal kit EPDM No. Designation Material DN50 red DN25 DN50 red DN40 DN50 DN65 Seal kit a) EPDM 5629 050 739-020 5629 050 739-020 5629 050 739-020 5629 065 739-020 Seal kit b)

- Page 29 KIESELMANN GmbH | Operating Instructions Wearing parts | 10 Seal kit HNBR No. Designation Material DN25 DN40 DN50 DN65 Seal kit a) HNBR 5629 025 729-020 5629 040 729-020 5629 050 729-020 5629 065 729-020 Seal kit b) HNBR 5629 025 729-000...

- Page 30 10 | Wearing parts Operating Instructions | KIESELMANN GmbH Seal kit FKM No. Designation Material DN25 DN40 DN50 DN65 Seal kit 5629 025 749-000 5629 040 749-000 5629 050 749-000 5629 065 749-000 Shaft seal O-ring (2x) O-ring Seal (2x)

-

Page 31: Classification | 11

KIESELMANN GmbH | Operating Instructions Classification | 11 1 1 C l a s s i f i c a t i o n 11.1 Structure of Order Number 10 11 12 13 14 - Control system - Feedback unit... - Page 32 11 | Classification Operating Instructions | KIESELMANN GmbH Separator xxxx xxx xxx - xxxx Pos. 10 - Standard Control system, position indicator, surfaces xxxx xxx xxx- XXXX Pos.11 Pos.12 Pos.13 Pos.14 Valve without control system, External surface AISI304 E-pol- ished...

-

Page 33: Appendix | 12

KIESELMANN GmbH | Operating Instructions Appendix | 12 1 2 A p p e n d i x 12.1 Declaration of incorporation Declaration of incorporation Translation of the original Manufacturer / authorised representative: KIESELMANN GmbH Paul-Kieselmann-Str. 4-10 75438 Knittlingen Germany...

Need help?

Do you have a question about the 5629 Series and is the answer not in the manual?

Questions and answers